Production technology of silk down feather

A production process, down technology, applied in the field of clothing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

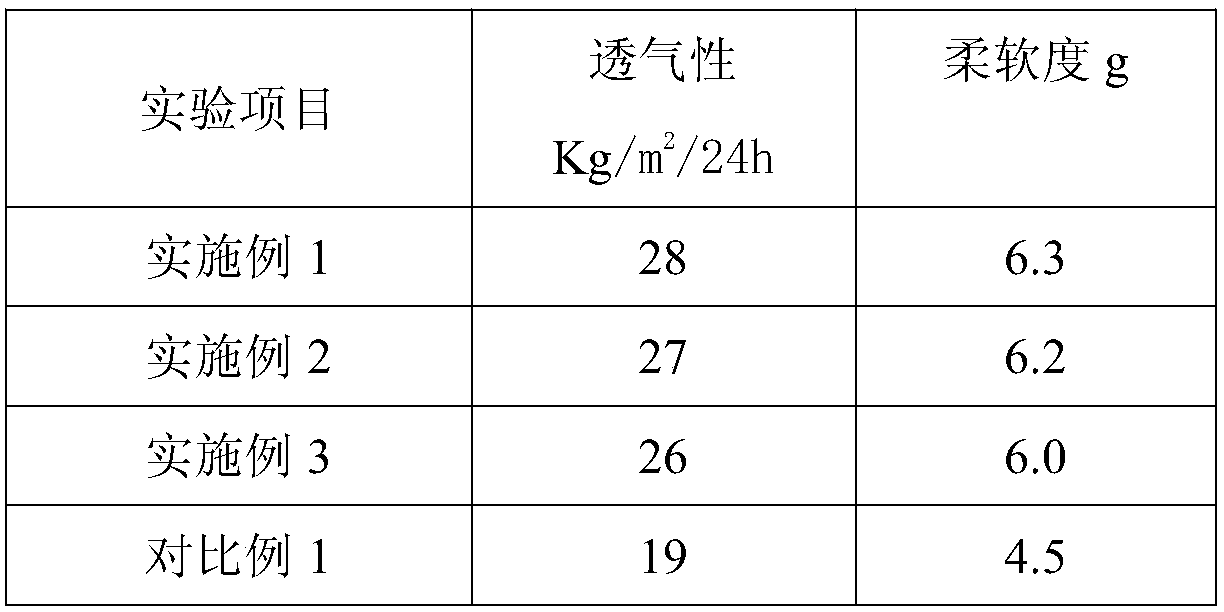

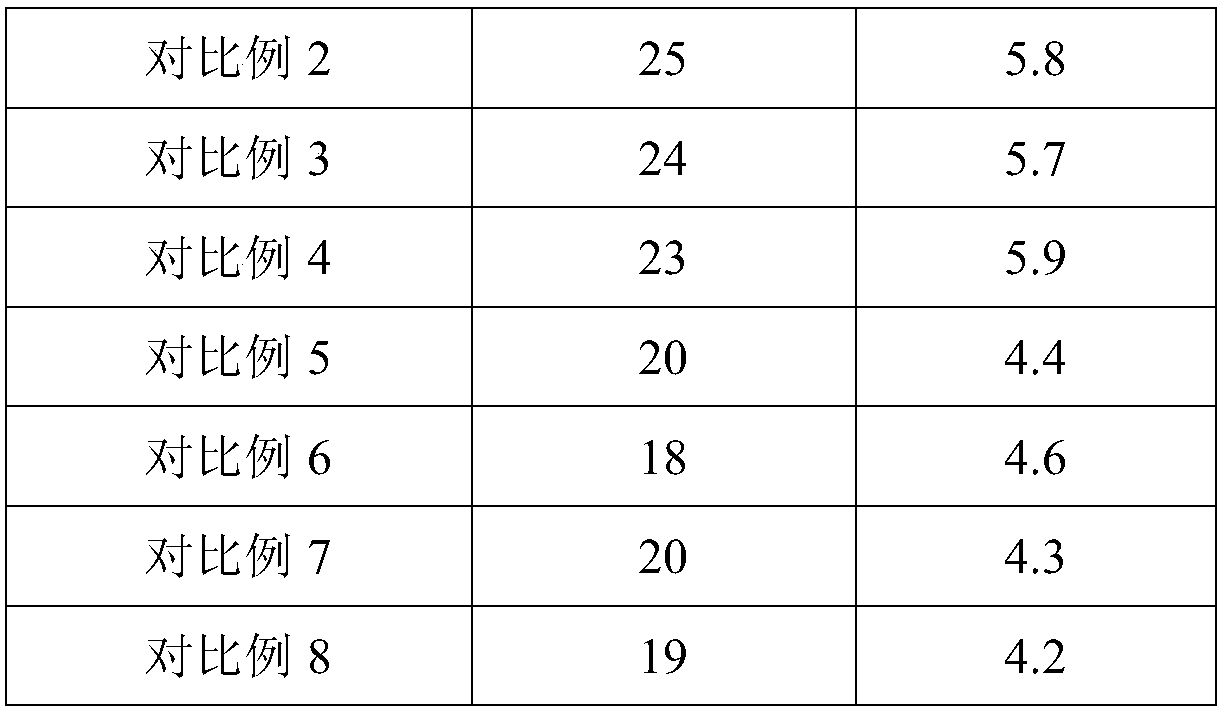

Embodiment 1

[0024] A production process for silk down, comprising the following steps: (1) firstly wash the down with water, degrease, remove impurities, and then dry the down, then mix and stir the down and pretreatment liquid for 13 hours according to the volume ratio of 1:4.5, and the treatment is completed After taking out and washing for 4 times, it is standby; (2) 100 mass parts of eiderdown that step (1) obtains is put into concentration and is in the glutaraldehyde aqueous solution of 3.5%, pH value 8.5, and the volume ratio of eiderdown, glutaraldehyde aqueous solution is 1 : 4.5, react 1.2h under 57 ℃ of conditions, drop into the silk micropowder of 35 mass parts, 5 mass parts casein, the bacterial cellulose of 3 mass parts, the polylactic acid fiber of 2 mass parts after the reaction finishes, after stirring and mixing Ultrasonic reaction at 63°C for 2.5h, filter after the reaction, and heat-treat the filtrate at 75°C for 1.5h before use; (3) Put the product of step (2) into the...

Embodiment 2

[0027]A production process for silk down, comprising the following steps: (1) firstly wash the down with water, degrease, remove impurities, and then dry, then mix and stir the down and pretreatment liquid for 15 hours according to the volume ratio of 1:5, and finish the treatment After taking out and washing for 3 times, it is standby; (2) 100 mass parts of eiderdown that step (1) obtains is put into concentration and is in the glutaraldehyde aqueous solution that 5%, pH value are 8, and the volume ratio of eiderdown, glutaraldehyde aqueous solution is 1 : 5, react 1.5h under 55 ℃ of conditions, drop into the silk micropowder of 30 mass parts, 6 mass parts casein, the bacterial cellulose of 2 mass parts, the polylactic acid fiber of 3 mass parts after the reaction finishes, after stirring and mixing Ultrasonic reaction at 60°C for 3 hours, filter after the reaction, and heat-treat the filtrate at 70°C for 2 hours before use; (3) Put the product of step (2) into the post-treatm...

Embodiment 3

[0030] A production process for silk down, comprising the following steps: (1) firstly wash the down with water, degrease, remove impurities, and then dry, then mix and stir the down and pretreatment liquid for 10 hours according to the volume ratio of 1:4, and the treatment is completed After taking out and washing for 5 times, it is standby; (2) 100 mass parts of eiderdown that step (1) obtains is put into concentration and is 2%, in the glutaraldehyde aqueous solution that pH value is 9, and the volume ratio of eiderdown, glutaraldehyde aqueous solution is 1 : 4, react 1h under 60 ℃ of conditions, drop into the silk micropowder of 40 mass parts, 4 mass parts casein, the bacterial cellulose of 4 mass parts, the polylactic acid fiber of 1 mass part after the reaction finishes, stir and mix after 65 Ultrasonic reaction at ℃ for 2 hours, filter after the reaction, and heat-treat the filtrate at 80℃ for 1 hour before use; (3) put the product of step (2) into the post-treatment so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com