High-strength sealing thermoplastic elastomer and preparation method thereof

A technology for thermoplastic elastomer and sealing, which is applied in the field of high-strength sealing thermoplastic elastomer and its preparation, which can solve the problems of high welding strength, poor effect, and short thermal welding time of refrigerator sealing strips, and achieve good melting and mixing effects , more uniform mixing and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

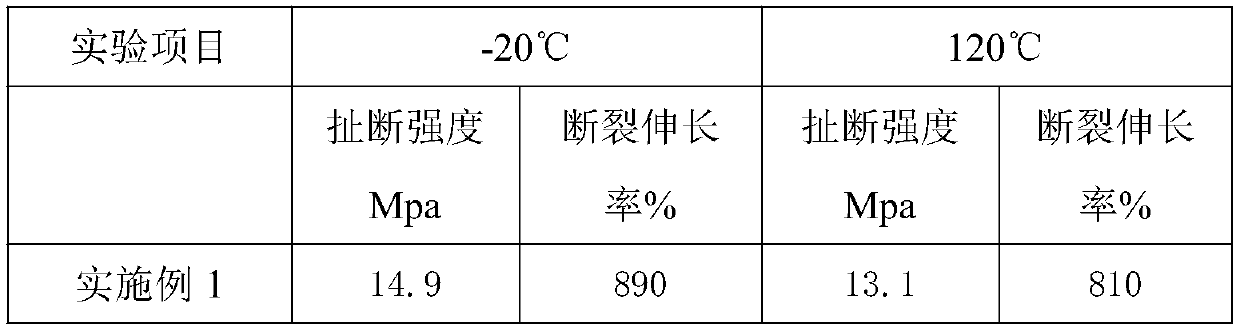

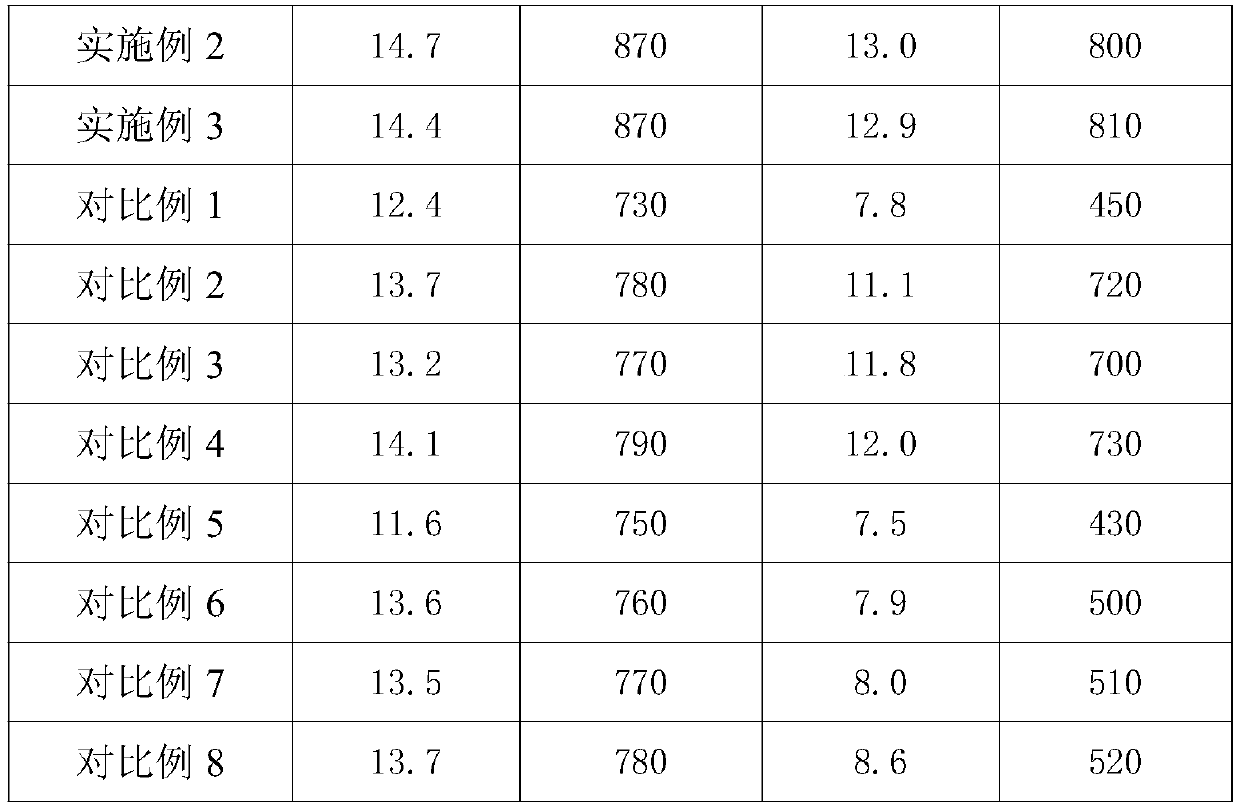

Examples

Embodiment 1

[0026] The thermoplastic elastomer for high-strength sealing is in parts by weight, including the following raw materials: 15 parts of hydrogenated styrene elastomer, 20 parts of white oil, 2.5 parts of polypropylene, 4 parts of olefinic elastomer POE, 3.5 parts of metallocene polyethylene, poly 3.5 parts of modified propylene alloy, 5.5 parts of mineral powder, 0.8 parts of stabilizer, 5 parts of natural rubber latex, 7.5 parts of hydroxyl silicone oil, and 2 parts of lignosulfonic acid.

[0027] The polypropylene is a homopolypropylene with a melt index of 6.5 g / 10 min. The white oil has a viscosity of 90mm at 40°C 2 · s paraffin oil. The metallocene polyethylene is a low melt index metallocene polyethylene with a melt index of 1 g / 10min. The olefinic elastomer POE is ethylene-octene copolymer, and the polypropylene alloy modified product is the modified product of Shandong Tairuifeng New Material Co., Ltd., the model is TF45D. This product is a high-flow material, and the...

Embodiment 2

[0030] The thermoplastic elastomer for high-strength sealing is in parts by weight, including the following raw materials: 10 parts of hydrogenated styrene elastomer, 30 parts of white oil, 1 part of polypropylene, 6 parts of olefinic elastomer POE, 1 part of metallocene polyethylene, poly 5 parts of modified propylene alloy, 3 parts of mineral powder, 1.2 parts of stabilizer, 4 parts of natural rubber latex, 10 parts of hydroxyl silicone oil, and 1 part of lignosulfonic acid.

[0031] The polypropylene is a homopolypropylene with a melt index of 8 g / 10 min. The white oil has a viscosity of 60mm at 40°C 2 · s naphthenic oil. The metallocene polyethylene is a low melt index metallocene polyethylene with a melt index of 1.5 g / 10min. The olefinic elastomer POE is ethylene-octene copolymer, and the polypropylene alloy modified product is the modified product of Shandong Tairuifeng New Material Co., Ltd., the model is TF45D. This product is a high-flow material, and the melt inde...

Embodiment 3

[0034] The thermoplastic elastomer for high-strength sealing is in parts by weight, including the following raw materials: 20 parts of hydrogenated styrene elastomer, 10 parts of white oil, 4 parts of polypropylene, 2 parts of olefinic elastomer POE, 6 parts of metallocene polyethylene, poly 2 parts of modified propylene alloy, 8 parts of mineral powder, 0.4 part of stabilizer, 6 parts of natural rubber latex, 5 parts of hydroxyl silicone oil, and 3 parts of lignosulfonic acid.

[0035] The polypropylene is homopolypropylene or copolymerized polypropylene with a melt index of 5 g / 10min. The white oil has a viscosity of 120mm at 40°C 2 · s paraffin oil. The metallocene polyethylene is a low melt index metallocene polyethylene with a melt index of 1.5 g / 10min. The olefinic elastomer POE is ethylene-octene copolymer, and the polypropylene alloy modified product is the modified product of Shandong Tairuifeng New Material Co., Ltd., the model is TF45D. This product is a high-flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com