Antimony-less environment-friendly novel flame-retardant polyvinyl chloride cable material and preparation method thereof

A technology for flame-retardant polyvinyl chloride and cable materials, which is applied in the direction of plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems of physical and mechanical performance degradation, and achieve good physical and mechanical properties, stable performance, and good performance. The effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

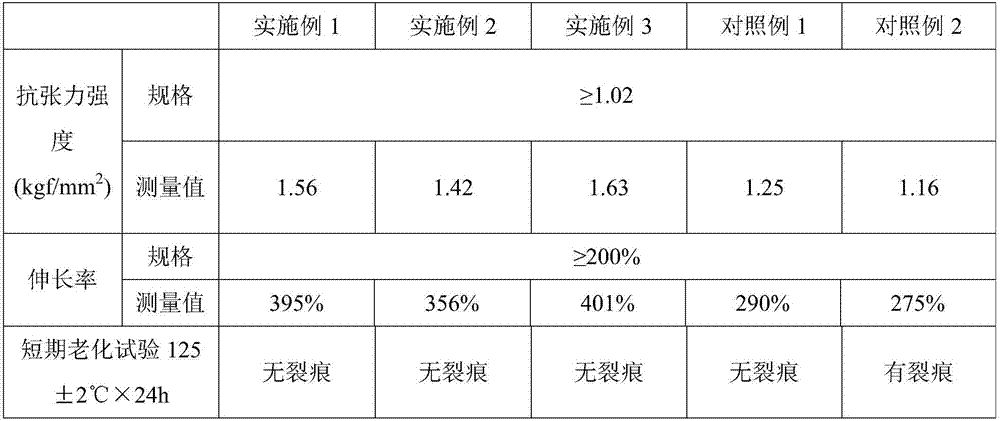

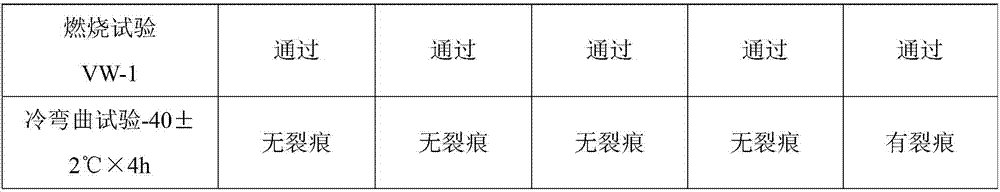

Examples

Embodiment 1

[0019] The cable material of this embodiment 1 is made of the following raw materials by weight: 100 parts of three-type PVC resin powder, 40 parts of polyadipate-1,2-propylene glycol ester, 4 parts of composite calcium zinc stabilizer, calcium stearate 0.5 parts, 25 parts of calcium carbonate, 3 parts of formula A component; said formula A consists of the following raw materials in parts by weight: 1 part of zinc stannate, 2 parts of aluminum hydroxide, 1.2 parts of aluminum diethylphosphinate, melamine 1.5 parts, 1.5 parts of ammonium polyphosphate, 2 parts of magnesium hydroxide, 0.3 parts of pentaerythritol, 0.3 parts of calcium stearate, wherein the aluminum hydroxide and magnesium hydroxide are 10000 mesh, and the particle size of the calcium carbonate is 0.01-0.08 μm .

[0020] The cable material preparation method of present embodiment 1 comprises the steps:

[0021] Step 1. Take zinc stannate, aluminum hydroxide, aluminum diethylphosphinate, melamine, ammonium polyph...

Embodiment 2

[0024] The cable material of the present embodiment 2 is made of the following raw materials in parts by weight: 100 parts of three-type PVC resin, 50 parts of polyadipate-1,2-propylene glycol ester, 8 parts of composite calcium-zinc stabilizer, and 1 part of polyethylene wax , 40 parts of filler, 5 parts of formula A component; Said formula A is made up of the raw material of following parts by weight: 1 part of zinc stannate, 2 parts of aluminum hydroxide, 1.2 parts of diethyl ethyl phosphonate, sodium melamine phosphate 1.5 parts, 1.5 parts of ammonium polyphosphate, 2 parts of magnesium hydroxide, 0.3 parts of pentaerythritol, 0.3 parts of polyethylene wax, wherein aluminum hydroxide and magnesium hydroxide are 10000 mesh, and the particle size of the calcium carbonate is 0.01-0.08 μm.

[0025] The cable material preparation method of present embodiment 2 comprises the steps:

[0026] Step 1. Take zinc stannate, aluminum hydroxide, diethyl ethyl phosphonate, sodium melamin...

Embodiment 3

[0029] The cable material of the present embodiment 3 is made of the following raw materials in parts by weight: 150 parts of three-type PVC resin, 40 parts of polyadipate-1,2-propylene glycol ester, 4 parts of composite calcium zinc stabilizer, glyceryl stearate 0.5 parts, 25 parts of calcium carbonate, and 3 parts of formula A component; said formula A is composed of the following raw materials in parts by weight: 0.6 part of zinc stannate, 1 part of aluminum hydroxide, 0.8 part of aluminum diethylphosphinate, melamine 0.8 part of cyanurate, 1 part of ammonium polyphosphate, 1 part of magnesium hydroxide, 0.1 part of pentaerythritol, 0.1 part of glyceryl stearate, wherein the aluminum hydroxide and magnesium hydroxide are 10000 mesh, and the particle size of calcium carbonate is 0.1 ~0.2 μm.

[0030] The cable material preparation method of present embodiment 3 comprises the steps:

[0031] Step 1. Take zinc stannate, aluminum hydroxide, aluminum diethylphosphinate, melamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com