Method for preparing Si-Al alloy using spray deposition forming process

A spray deposition and alloy technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as increased cost and complex procedures, and achieve the effects of high machining accuracy, low conductivity, and good welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

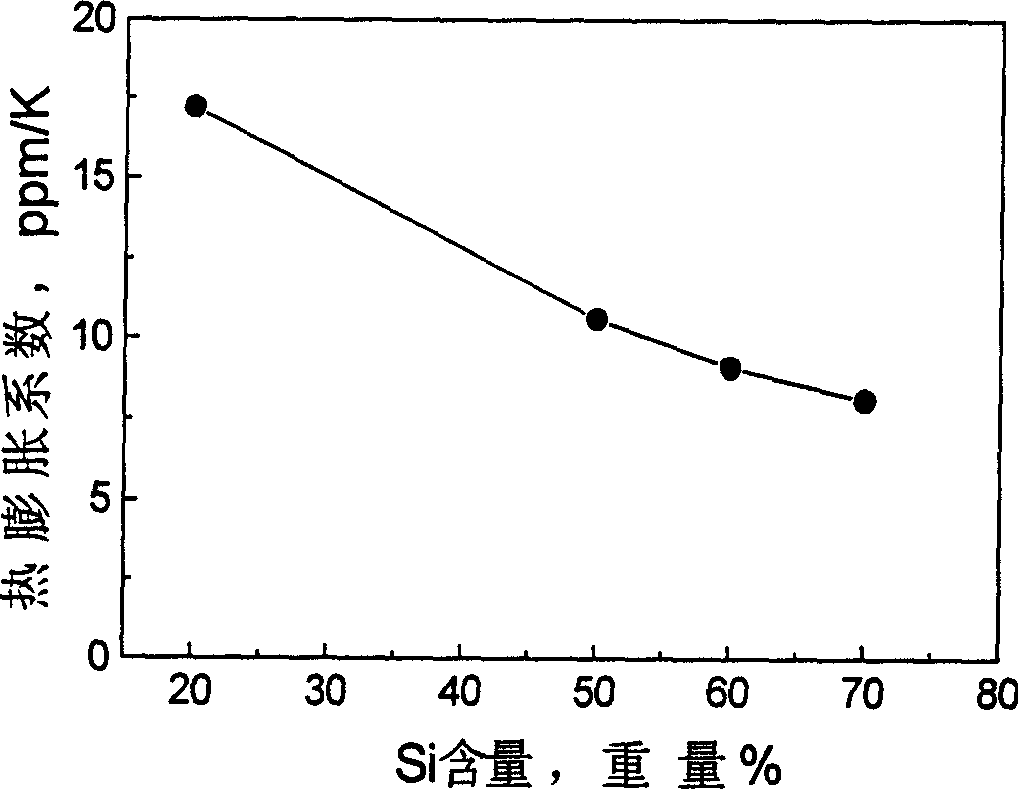

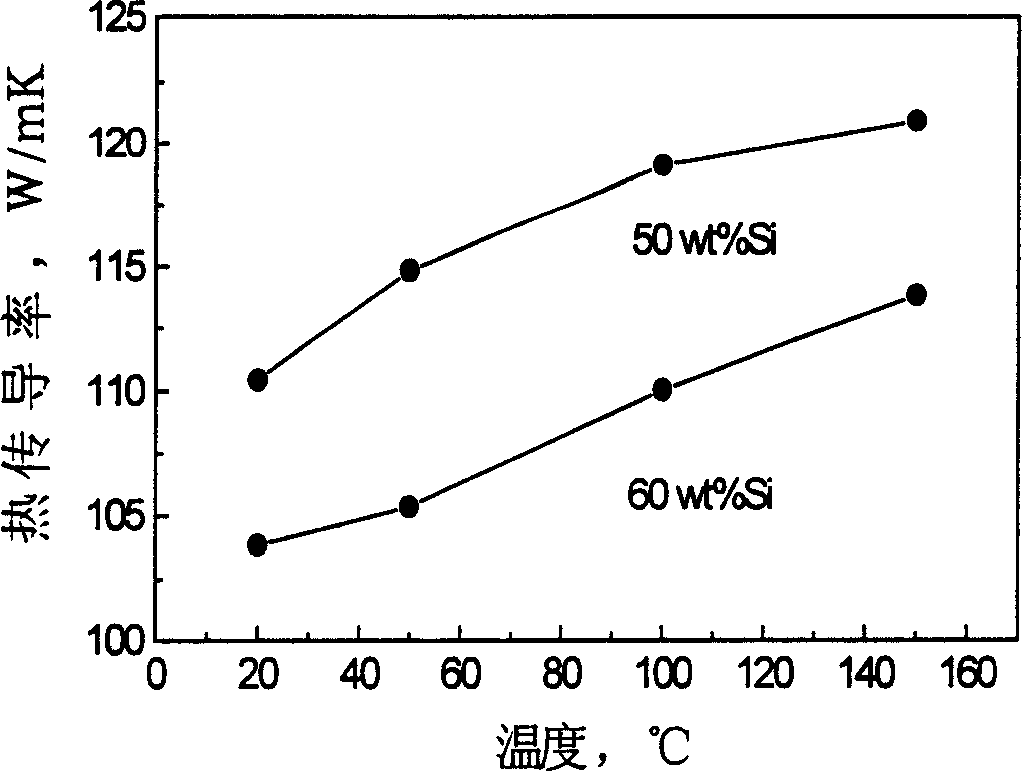

[0023]A 50% by weight Si-Al alloy was prepared. A 50% by weight Si-Al master alloy ingot was melted in a 150 kg medium frequency induction furnace. Put pure Si with a block size of 4-6 mm and a weight of 15 kg and industrial pure Al with a weight of 15 kg into an intermediate frequency induction furnace crucible, heat up to melt, and cast into an intermediate alloy ingot for later use. The above-mentioned master alloy ingot was remelted, and a 50% by weight Si-Al alloy was prepared by a spray deposition forming method. The process parameters are selected as follows: atomization gas: nitrogen; atomization pressure: 0.7MPa; deposition distance: 550mm; diameter of draft tube: 3.6mm. The coefficient of thermal expansion of the material is 10.6×10 -6 / K. The thermal conductivity is 121W / mK (150°C). The resistivity is 0.4×10 -6 Ωm.

Embodiment 2

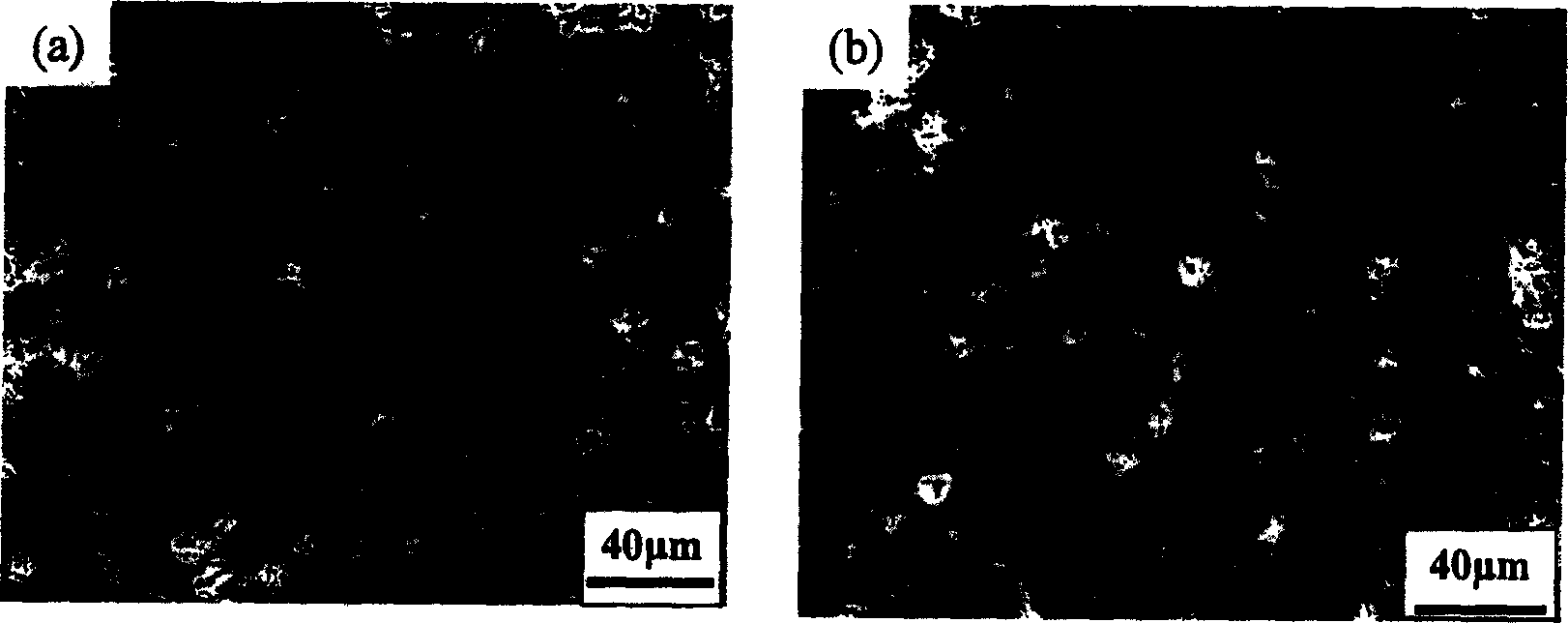

[0025] A 60% by weight Si-Al alloy was prepared. A 30% by weight Si-Al master alloy ingot was melted in a 150 kg medium frequency induction furnace. Put pure Si with a block size of 4-6 mm and a weight of 3 kg and industrial pure Al with a weight of 7 kg into an intermediate frequency induction furnace crucible, heat up to melt, and cast into an intermediate alloy ingot for later use. The above-mentioned master alloy ingot was remelted, 4.3 kg of pure Si was added, and a 60% by weight Si-Al alloy was prepared by spray deposition forming method. The process parameters are selected as follows: atomization gas: nitrogen; atomization pressure: 0.8MPa; deposition distance: 600mm; diameter of draft tube: 3.8mm. The coefficient of thermal expansion of the material is 9.1×10 -6 / K. The thermal conductivity is 113W / mK (150°C). The resistivity is 0.9×10 -6 Ωm. The density of the as-deposited 60% by weight Si-Al alloy is 2.3164g / cm 3 , the density after hot isostatic pressing is 2...

Embodiment 3

[0027] A 70% by weight Si-Al alloy was prepared. A 30% by weight Si-Al master alloy ingot was melted in a 150 kg medium frequency induction furnace. Put pure Si with a block size of 4-6 mm and a weight of 6 kg and industrial pure Al with a weight of 14 kg into an intermediate frequency induction furnace crucible, heat up to melt, and cast into an intermediate alloy ingot for later use. The above-mentioned master alloy ingot was remelted, 13.3 kg of pure Si was added, and a 70% by weight Si-Al alloy was prepared by spray deposition forming method. The process parameters are selected as follows: atomization gas: nitrogen; atomization pressure: 0.75MPa; deposition distance: 590mm; diameter of draft tube: 4.0mm. The coefficient of thermal expansion of the material is 8.1×10 -6 / K. The resistivity is 1.6×10 -6 Ωm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com