Isocyanate adhesive and method for preparing multilayer polyurethane structural composite by using same

A technology of isocyanate and composite materials, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of uncontrollable sizing amount, complicated application of preparation process, and bonding rubber rollers, etc., to achieve The amount of sizing can be accurately controlled and the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

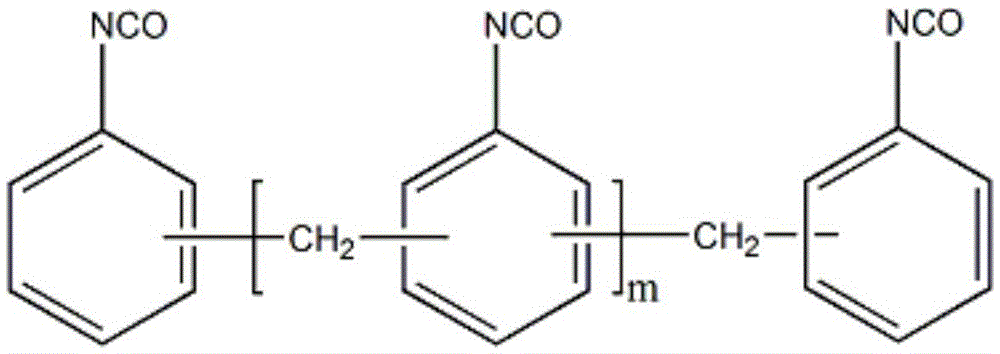

[0068] Isocyanate component A1: PM200, viscosity 200 mPaS (25°C), NCO content 31%.

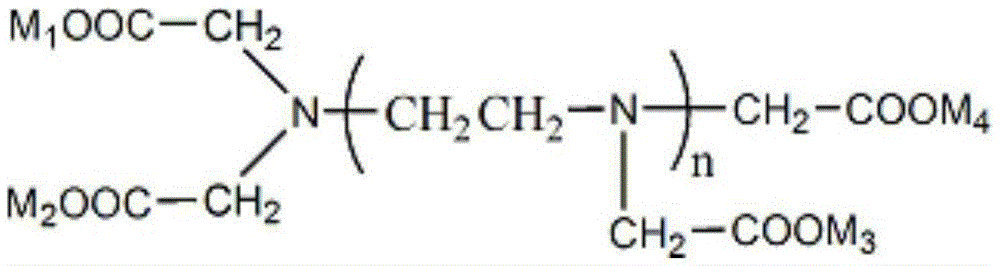

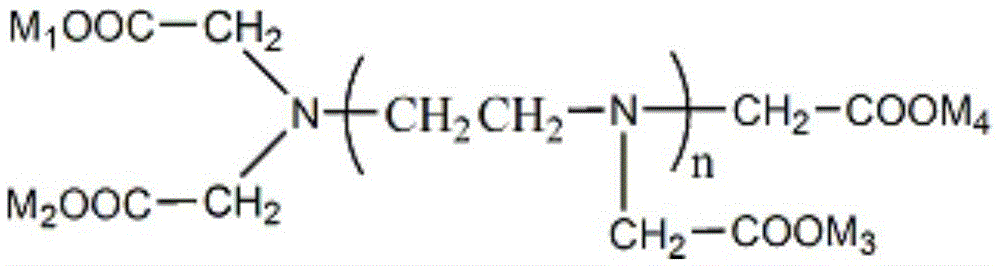

[0069] Composite catalyst aqueous solution B1: the concentration is 3wt%, and the composite catalyst is composed of dimethylaminoethyl ether and trisodium aminotriacetate in a weight ratio of 100:2.

[0070] Coat the two sides of the glass fiber mat with isocyanate component A1, and cover the two sides of the polyurethane foam respectively to form a three-layer structure. Spray the composite catalyst aqueous solution B1 on both sides of the three-layer structure, and cover the non-woven fabric. Press in the mold for 28 seconds to form, and obtain the polyurethane five-layer structure composite material.

[0071] Among them, the amount of isocyanate component A1 is 60g / m 2 , the dosage of composite catalyst aqueous solution B1 is 50g / m 2 .

[0072] In the embodiment, no precipitation occurs during the spraying of the composite catalyst aqueous solution B1, the isocyanate component A1 is even...

Embodiment 2

[0074] Isocyanate component A2: PM200, viscosity 200 mPaS (25°C), NCO content 31%.

[0075] Composite catalyst aqueous solution B2: the concentration is 8wt%, and the composite catalyst is composed of dimethylaminoethyl ether and trisodium aminotriacetate in a weight ratio of 100:0.5.

[0076] The isocyanate component A2 is coated on both sides of the glass fiber mat, respectively covering both sides of the polyurethane foam to form a three-layer structure, and the composite catalyst aqueous solution B2 is sprayed on both sides of the three-layer structure, and covered with non-woven fabric. Press in the mold for 40 seconds to form, and obtain the polyurethane five-layer structure composite material.

[0077] Among them, the amount of isocyanate component A2 is 90g / m 2 , the dosage of composite catalyst aqueous solution B2 is 10g / m 2 .

[0078] In the embodiment, no precipitation occurs during the spraying process of the composite catalyst aqueous solution B2, the isocyanat...

Embodiment 3

[0080] Isocyanate component A3: formed by reacting 95 parts by weight of PM200 and 5 parts of polyether polyol 1, with a viscosity of 220 mPaS (25° C.) and an NCO content of 30.2%.

[0081] Composite catalyst aqueous solution B3: the concentration is 5wt%, and the composite catalyst is composed of triethylenediamine and tetrasodium ethylenediaminetetraacetic acid in a weight ratio of 100:1.

[0082] The isocyanate component A3 is coated on both sides of the glass fiber felt, respectively covered on both sides of the polyurethane foam to form a three-layer structure, and the composite catalyst aqueous solution B3 is sprayed on both sides of the three-layer structure, and covered with non-woven fabrics. Press in the mold for 20 seconds to form, and obtain the polyurethane five-layer structure composite material.

[0083] Among them, the amount of isocyanate component A3 is 70g / m 2 , the dosage of composite catalyst aqueous solution B3 is 20g / m 2 .

[0084] In the embodiment, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com