Digital control tooth crest chamfering machine for curved tooth and angle gear

A technology of spiral bevel gears and chamfering machines, which is applied to gear teeth manufacturing devices, gear teeth, gear cutting machines, etc., can solve the problems of low production efficiency of manual grinding, difficult grinding, difficulty in ensuring grinding consistency and Uniformity and other issues, to achieve the effect of reasonable design structure, good effect and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Next, the CNC spiral bevel gear addendum chamfering machine of the present invention will be described in detail in conjunction with the accompanying drawings and specific embodiments.

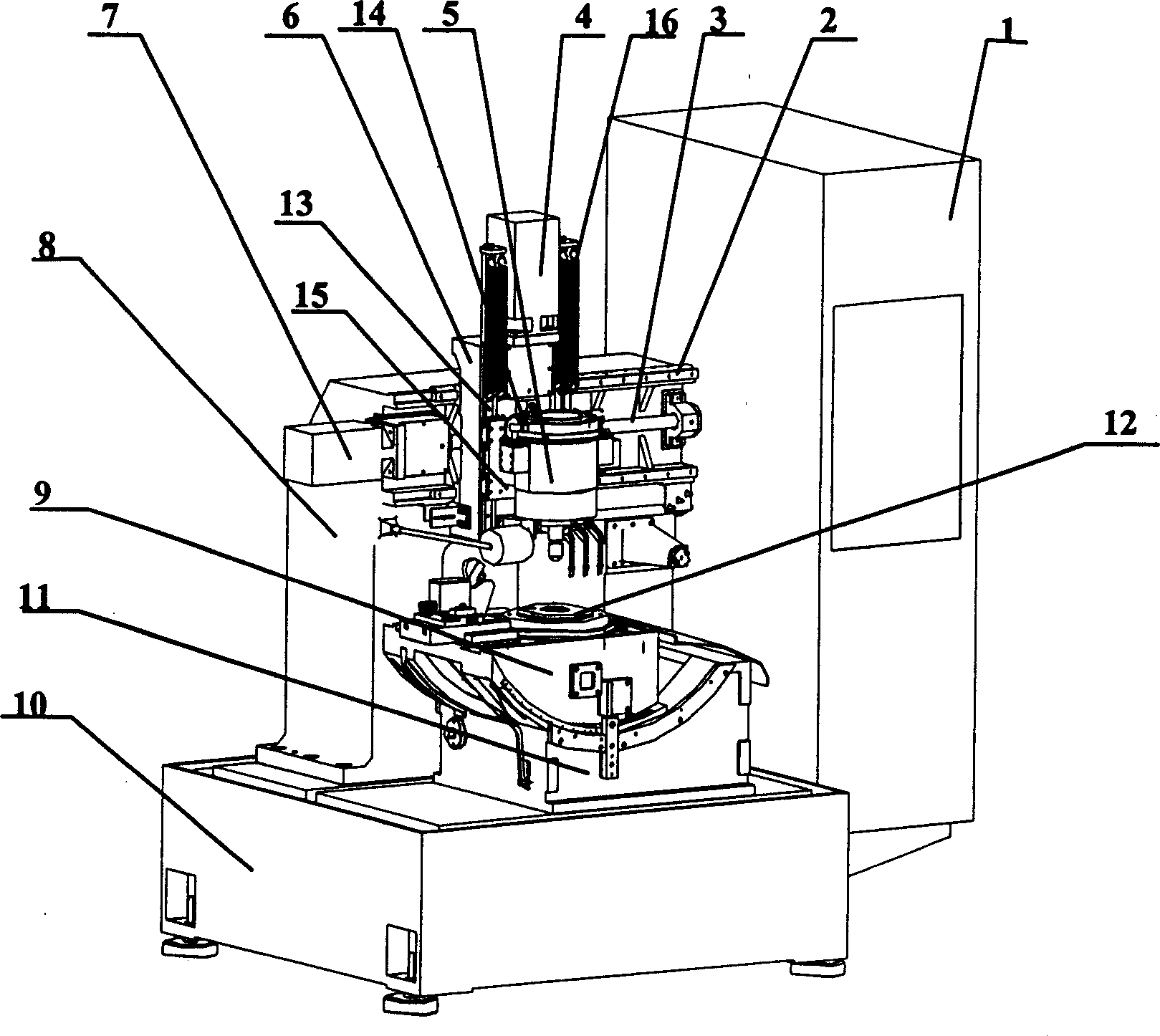

[0049] Such as figure 2 As shown, the CNC spiral bevel gear addendum chamfering machine of the present invention includes: a fuselage 10 and an electric control cabinet 1, a column 8 arranged on the fuselage 10, and a column 8 arranged on the fuselage 10 and located at the column 8 The turning table base 11 on the front side and the turning table 9 installed on the turning table base 11 are provided with a horizontal movement mechanism and a vertical movement mechanism on the column 8, and the vertical movement mechanism is arranged on the column 8 through the horizontal movement mechanism. Above, the vertical movement mechanism is provided with a grinding head mechanism 5 for chamfering the spiral bevel gear, and a spindle for installing the processed gear is provided at the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com