Fully-automatic areca nut processing equipment

A kind of processing equipment, fully automatic technology, applied in the direction of metal processing, image data processing, image data processing, etc., can solve the problem of unsatisfactory degree of automation, practicability and equipment performance, difficult to achieve betel nut processing methods, and inability to choose betel nut cutting Face and other problems to achieve the effect of preventing the betel nut from falling out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

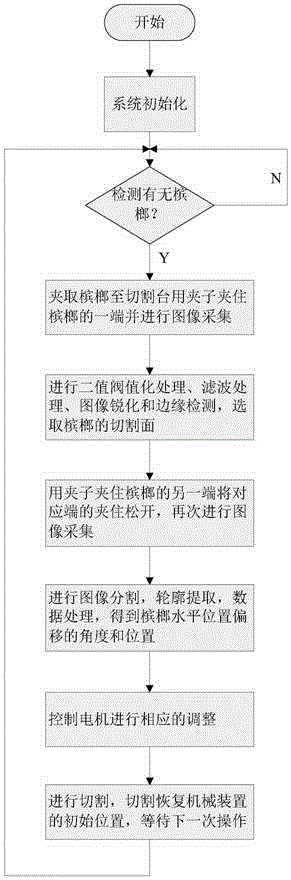

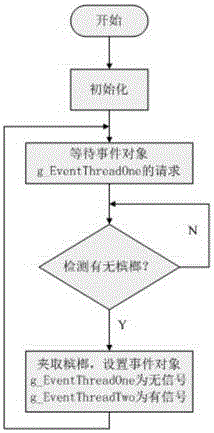

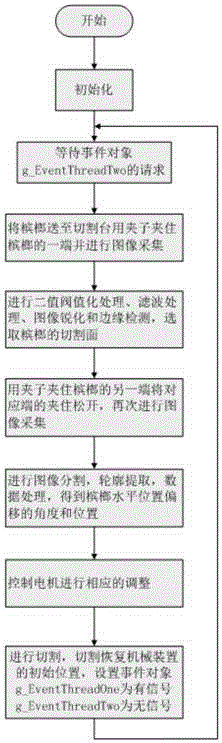

[0177] like figure 1 and figure 2 As shown, a fully automatic betel nut processing equipment includes a first frame A1 and a second frame A2 that are connected. The first frame A1 is provided with a feeding mechanism 1, a reclaiming mechanism 2, a first transmission mechanism 3 and a The first clamping mechanism 4, wherein the reclaiming mechanism 2 is connected with the feeding mechanism 1, the first transmission mechanism 3 is located at the downstream position of the reclaiming mechanism 2, the first clamping mechanism 4 is arranged on the first transmission mechanism 3, the second The frame A2 is provided with a second transmission mechanism 5, a second clamping mechanism 6, a third clamping mechanism 7, a cutting platform 8, an image capturing mechanism 9 and a cutting mechanism 10, wherein the second clamping mechanism 6, the third clamping mechanism The picking mechanism 7 and the cutting platform 8 are both arranged on the second transmission mechanism 5, the second...

Embodiment 2

[0179] Repeating Embodiment 1, the apparatus further includes a baffle 11 connecting the first chain 203 of the reclaiming mechanism 2 and the second chain 303 of the first conveying mechanism 3 .

Embodiment 3

[0181] Repeating Embodiment 2, the apparatus further includes a first detection mechanism 12 provided on the first chain 203 of the reclaiming mechanism 2 , and a second detection mechanism 13 provided on the second chain 303 of the first transmission mechanism 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com