External pressing hollow fibre membrane separator and use method thereof

An external pressure hollow fiber and membrane separation technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve problems such as unscientific water system design, unreasonable water flow design route, and a large amount of raw liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

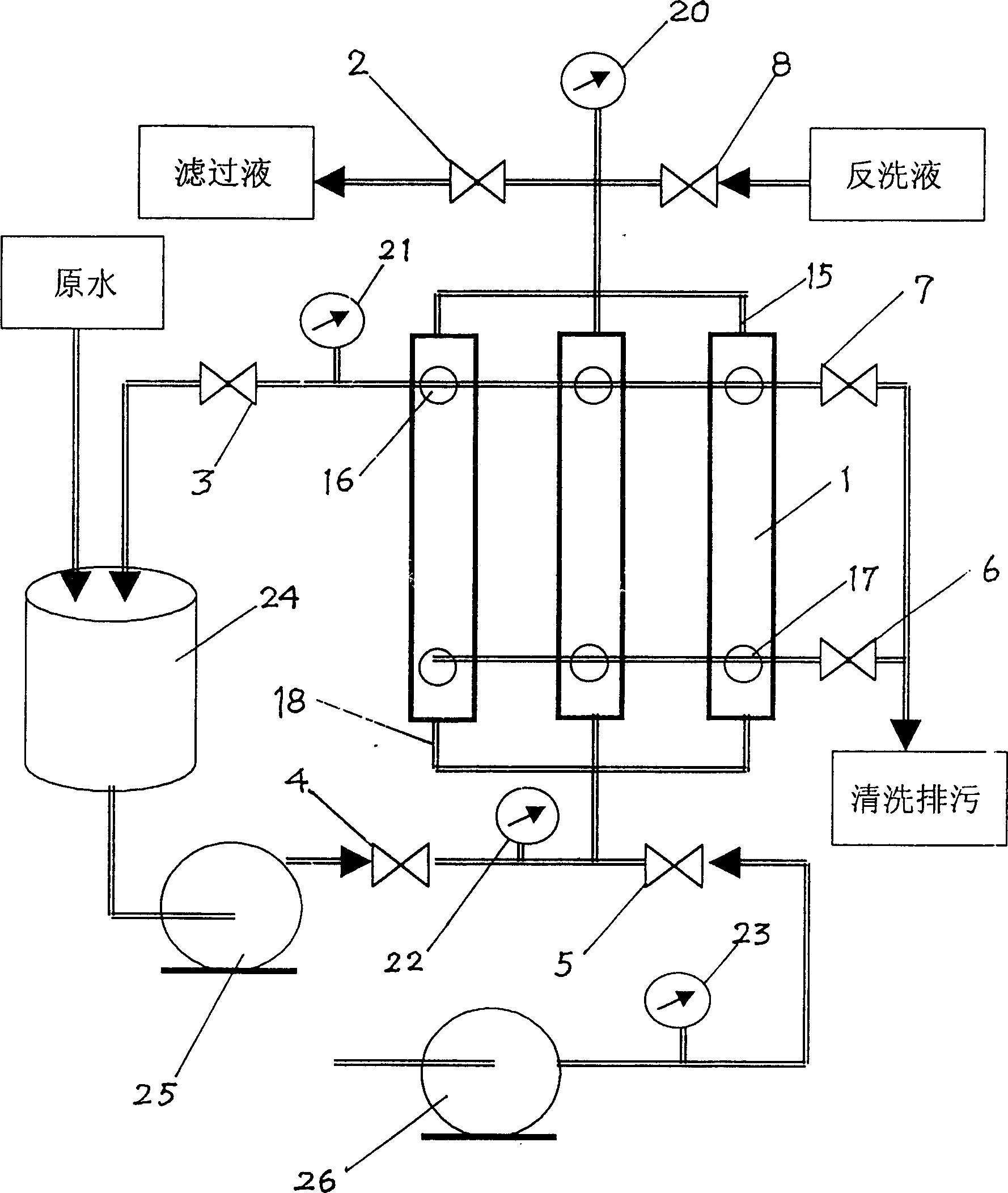

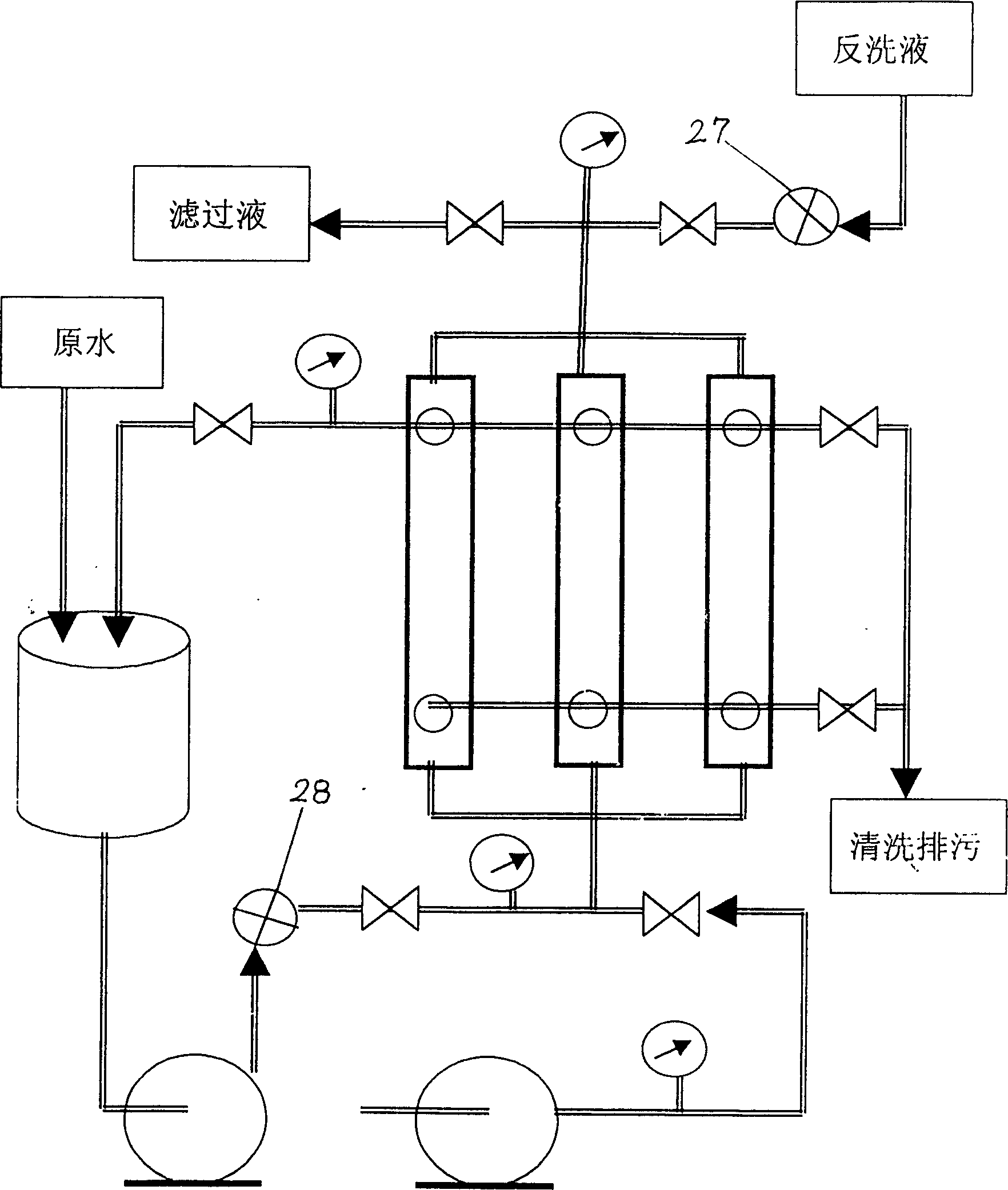

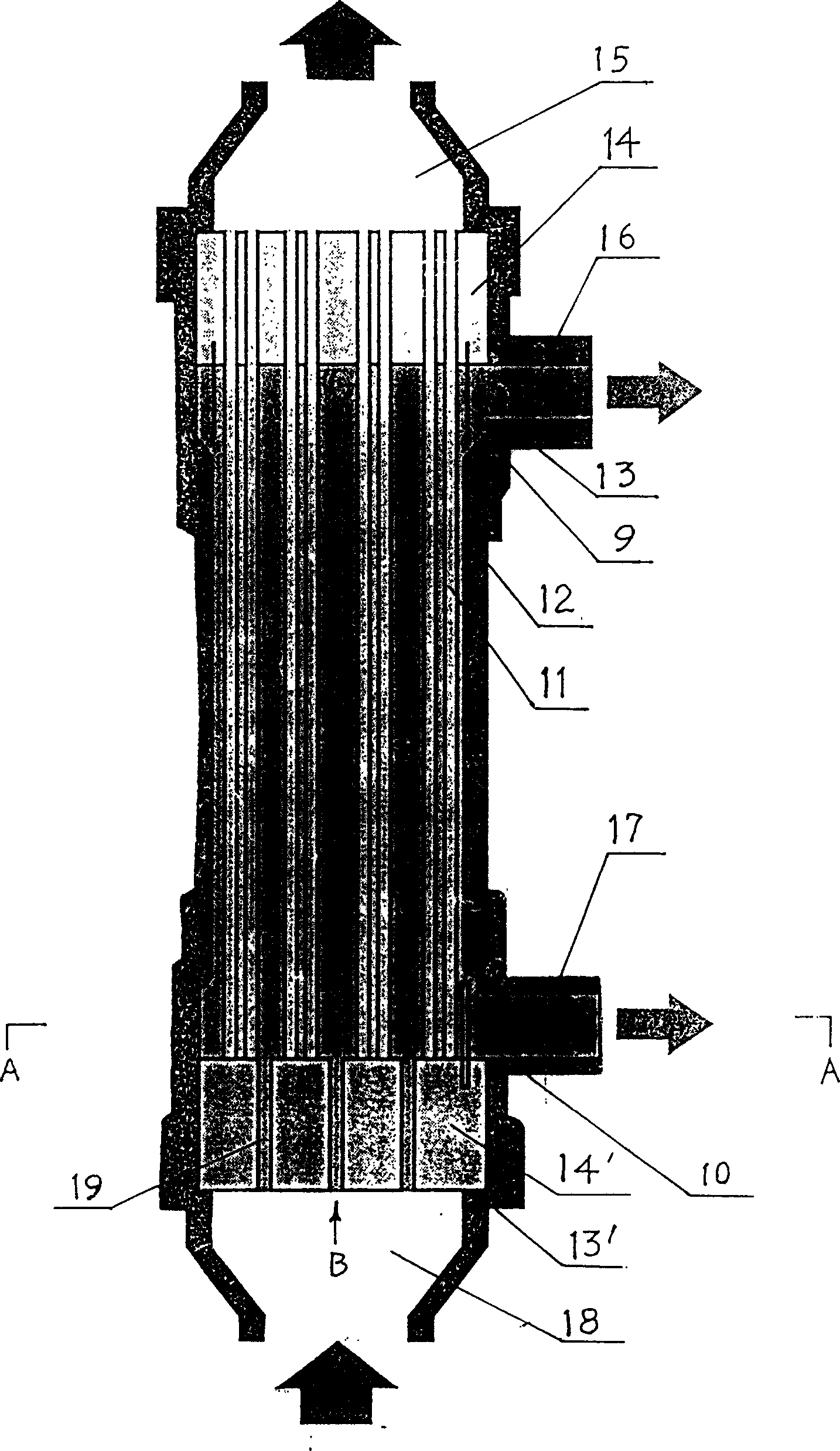

[0015] The device of the present invention is an improved design on the basis of the existing external pressure hollow fiber membrane separation device (hereinafter referred to as the membrane device) (see figure 1 , 3 ), the original membrane device design includes a membrane module 1, a control valve, a pressure gauge, a pump, an air compressor, a feed liquid tank, and connecting pipelines, etc., and the external pressure hollow fiber membrane 11 filled in the membrane module 1 is There are holes at the upper casting end 14, and closed holes at the lower casting end 14', and there are a plurality of diversion holes 19 on the lower casting end 14'. The lower port 18 of the membrane module 1 is passed through the pressure gauge After 22, one path is connected to the pump 25 through the control valve 4, and the other path is connected to the air compressor 26 through the control valve 5, the pressure gauge 23. The characteristic design is that the upper port 15 of the membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com