Control method and gas pretreatment system for integrated gas analysis

A treatment system and gas pretreatment technology, which is applied in the preparation of test samples, analysis materials, sampling, etc., can solve the problems of heavy system maintenance workload, affecting system work, system complexity, etc., to simplify the pretreatment process and streamline the system , Simplify the effect of the pretreatment device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

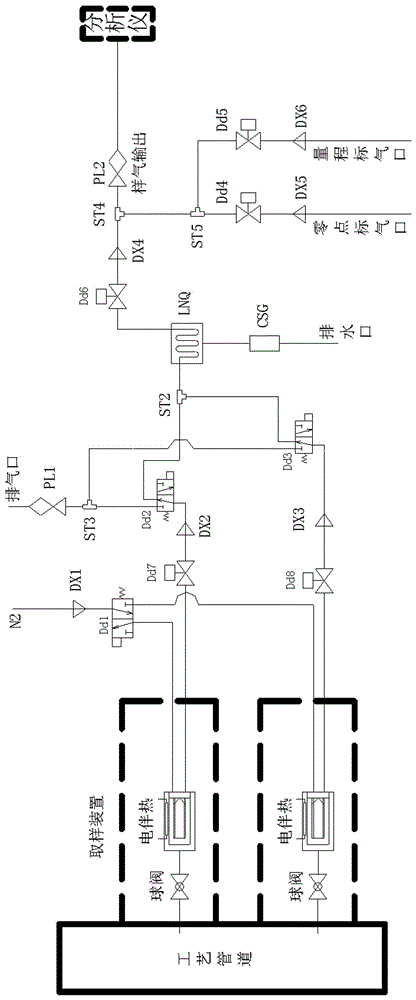

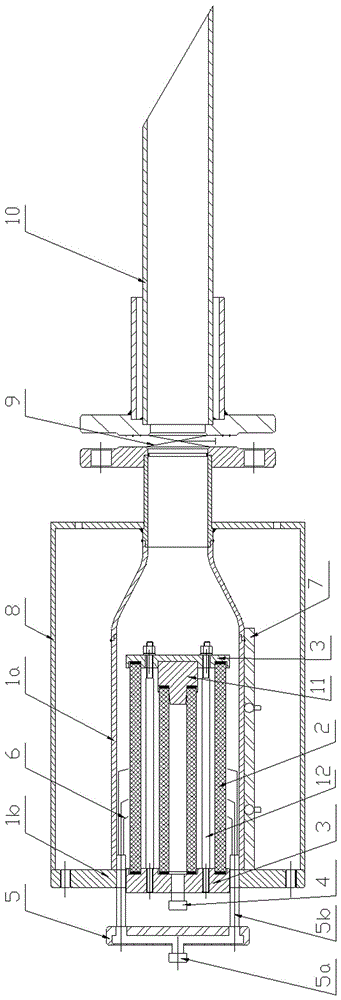

[0036] see figure 1 and figure 2 , a gas pretreatment system for comprehensive gas analysis, including two sampling devices, the sampling device includes a sampling housing 1, the sampling housing 1 is provided with a gas inlet and a gas outlet 4, the sampling housing 1 A filter element 2 is arranged inside, and the gas inlet and the gas outlet 4 communicate through the filter holes provided by the filter element 2 . The filter element 2 can adopt various structures, so that the gas inlet and the gas outlet 4 can only be communicated through the filter hole that the filter element 2 is provided with. A filter element 2 is arranged in the sampling device for filtering impurities in the gas. Preferably, the sampling housing 1 has an inner cavity, and the filter element 2 has an inner cavity. The inner cavity of the sampling housing 1 communicates with the gas inlet provided on the sampling housing 1, and the inner cavity of the sampling housing 1 is provided with a filter el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com