Device and method for preparing rice hull forming and briquetting fuel

A preparation device and rice husk technology, which is applied in the direction of material molding presses, fuels, solid fuels, etc., can solve the problems of easy blockage of ring die holes, low production efficiency, and temperature rise of ring dies, so as to reduce slagging, The effect of improving production efficiency and improving molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

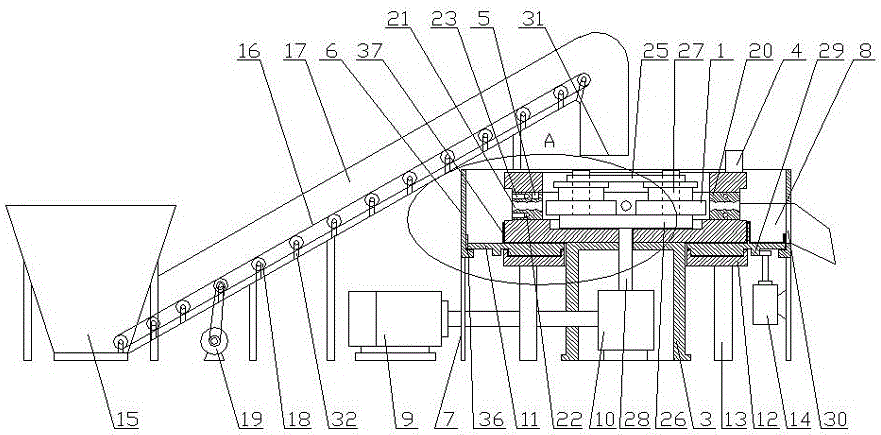

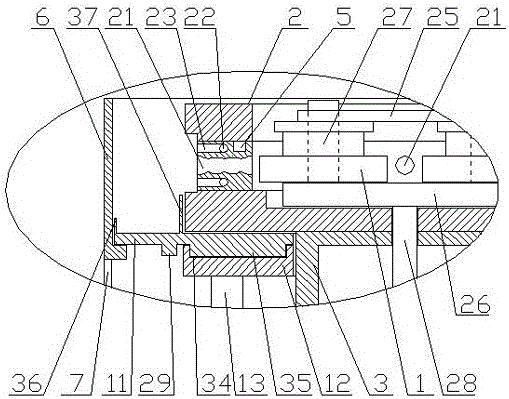

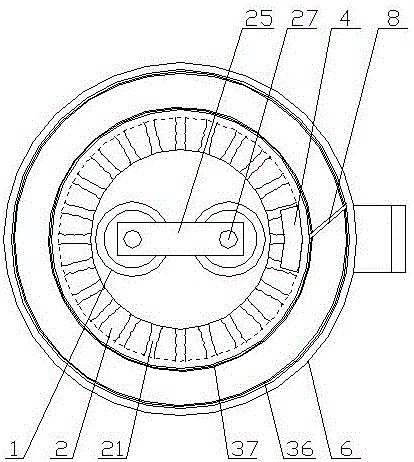

[0022] Example 1: Preparation method of rice husk briquette fuel. The preparation method is as follows:

[0023] a. Raw material processing: detect the moisture content in the rice husk raw materials through the humidity sensor, dry or humidify the raw materials, control the moisture content of the rice husk raw materials to 10%, by adding coal powder to the rice husk raw materials, and mixing and stirring Evenly, the weight ratio of coal powder to rice husk raw material is 3:100, and then the rice husk raw material is sent into the feeding bin;

[0024] b. Feeding: the temperature of the extrusion bin 2 is preheated to 100 degrees by the heater 4, and the rice husk in the feeding bin 15 is transported to the extrusion bin 2 through the conveyor belt 16, and the rice husk is adjusted during the transportation process. The rotation speed of the roller motor 19 controls the conveying speed of the conveyor belt 16 so that the height of the rice husk in the extrusion bin 2 does not exc...

Embodiment 2

[0028] Embodiment 2: The preparation method of rice husk briquette fuel, the preparation method is as follows:

[0029] a. Raw material processing: detect the moisture content in the rice husk raw materials through the humidity sensor, dry or humidify the raw materials, control the moisture content of the rice husk raw materials to 15%, by adding coal powder to the rice husk raw materials and mixing and stirring Evenly, the weight ratio of coal powder to rice husk raw material is 3:100, and then the rice husk raw material is sent into the feeding bin;

[0030] b. Feeding: the temperature of the extrusion bin 2 is pre-heated to 110 degrees by the heater 4, and the rice husk in the feeding bin 15 is transported to the extrusion bin 2 through the conveyor belt 16, and the rice husk is adjusted during the transportation process. The rotation speed of the roller motor 19 controls the conveying speed of the conveyor belt 16 so that the height of the rice husk in the extrusion bin 2 does ...

Embodiment 3

[0034] Embodiment 3: The preparation method of rice husk briquette fuel, the preparation method is as follows:

[0035] a. Raw material processing: detect the moisture content in the rice husk raw materials through the humidity sensor, dry or humidify the raw materials, control the moisture content of the rice husk raw materials to 30%, by adding coal powder to the rice husk raw materials, and mixing and stirring Evenly, the weight ratio of coal powder to rice husk raw material is 3:100, and then the rice husk raw material is sent into the feeding bin;

[0036] b. Feeding: the temperature of the extrusion bin 2 is preheated to 120 degrees by the heater 4, and the rice husk in the feeding bin 15 is transported to the extrusion bin 2 through the conveyor belt 16. The rice husk is adjusted during the transportation process. The rotation speed of the roller motor 19 controls the conveying speed of the conveyor belt 16 so that the height of the rice husk in the extrusion bin 2 does not ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com