A feed mechanism for a biomass fuel furnace

A technology of biomass fuel and feeding mechanism, which is applied in the directions of fuel supply, combustion of solid fuel, combustion method, etc., can solve the problem of inconvenient feeding of biomass fuel furnace, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

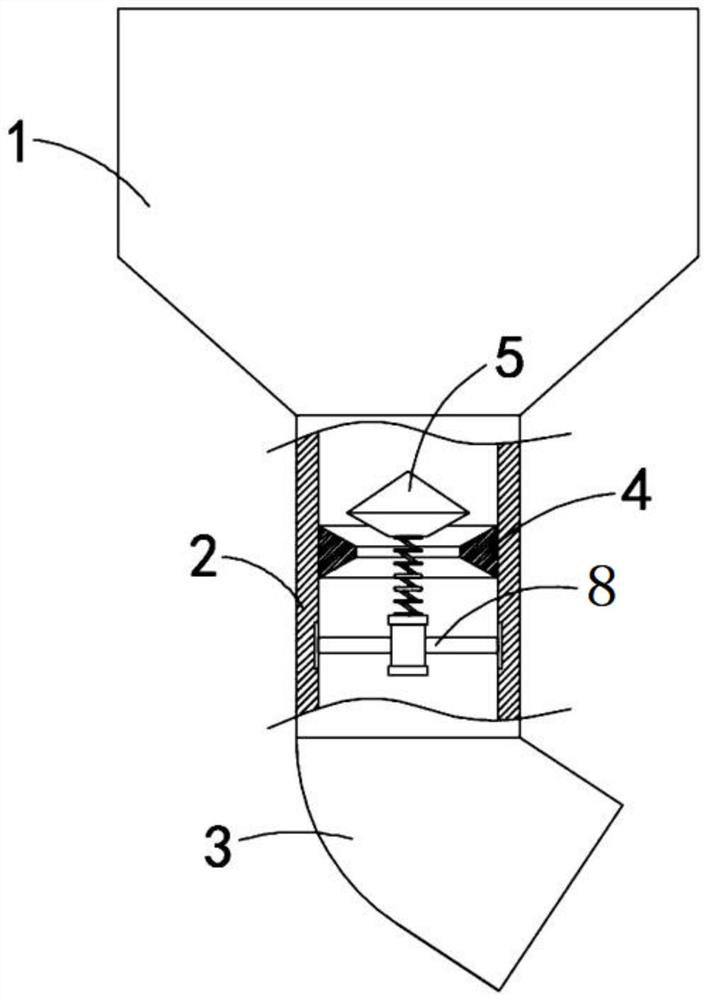

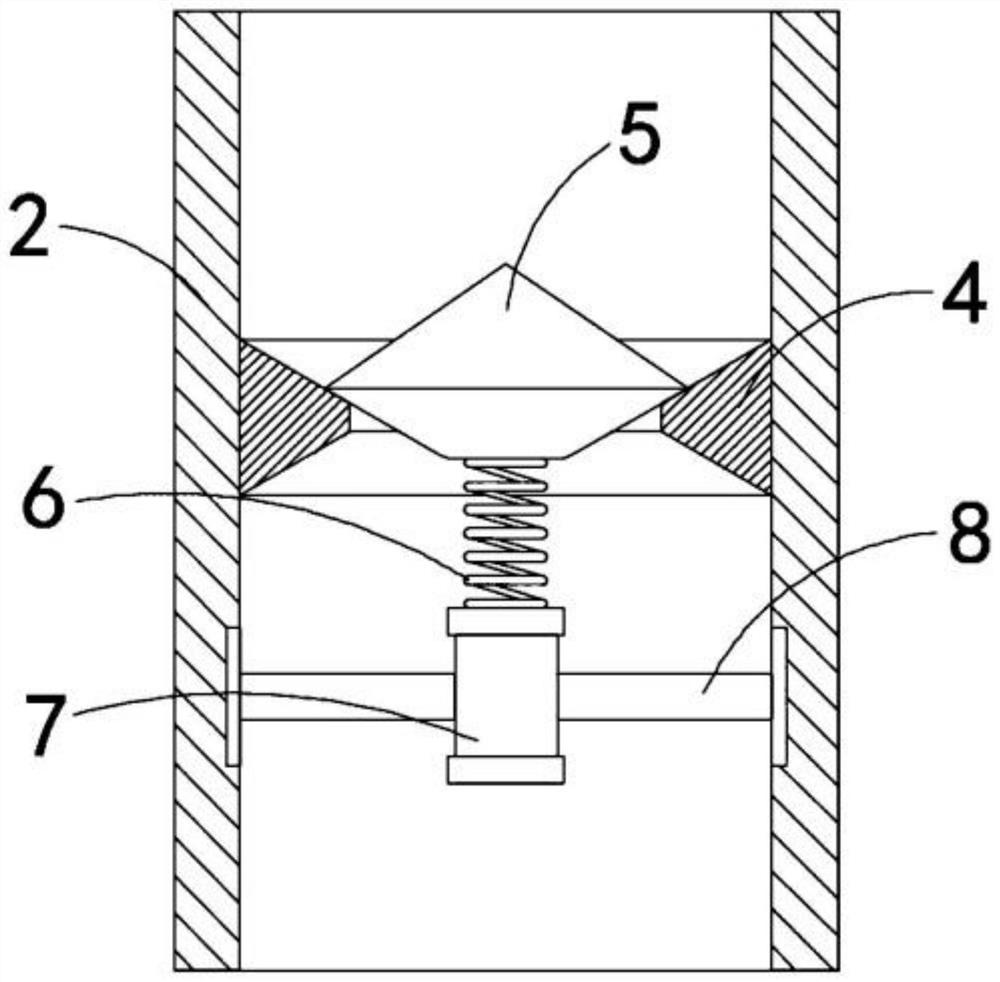

[0025] Such as Figure 1-4 As shown, a biomass fuel furnace feeding mechanism includes a feed hopper 1, the lower end of the feed hopper 1 is fixedly connected with a vertical pipe 2, the lower end of the vertical pipe 2 is fixedly connected with an inclined pipe 3, and the vertical pipe 2 is fixedly connected with There is a sealing ring 4, the upper end of the sealing ring 4 is recessed downwards and is set in a bowl shape, which can play a gathering effect and make it easier for fuel to enter the sealing ring 4. It is worth mentioning that the lower end of the sealing ring 4 is recessed upwards to form a bowl The seal ring 4 is provided with a matching seal block 5 directly above the seal ring 4, and the lower end of the seal block 5 is set in a downwardly protruding conical shape. When the seal block 5 When the lower end of the sealing block 5 is attached to the upper end of the sealing ring 4, the fuel in the feed hopper 1 can be blocked from the outside of the vertical p...

Embodiment 2

[0031] Such as Figure 5-6 As shown, the difference between this embodiment and Embodiment 1 is that the memory spring 6 is covered with a bellows 9 that expands and contracts along its axis, and the bellows 9 is made of heat-resistant rubber. Better materials such as metal, etc., the upper and lower ends of the bellows 9 are respectively fixed and sealed with the lower end surface of the sealing block 5 and the upper end surface of the connecting seat 7, and the end of the connecting rod 8 away from the connecting seat 7 is set through the vertical pipe 2. The rod 8 is hollow, and the connecting seat 7 is provided with an air delivery hole that penetrates up and down. The upper end of the air delivery hole communicates with the bellows 9, and the connecting rod 8 communicates with the air delivery hole. One-way valve 10, the lower end of connecting seat 7 is fixedly connected with second one-way valve 11, specifically, first one-way valve 10 allows gas to enter the air delive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com