High-combustion-rate coal briquette with coal cinder not easy to break

A combustion rate, coal block technology, applied in the direction of fuel, solid fuel, petroleum industry, etc., to achieve the effect of reducing waste, ensuring integrity, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

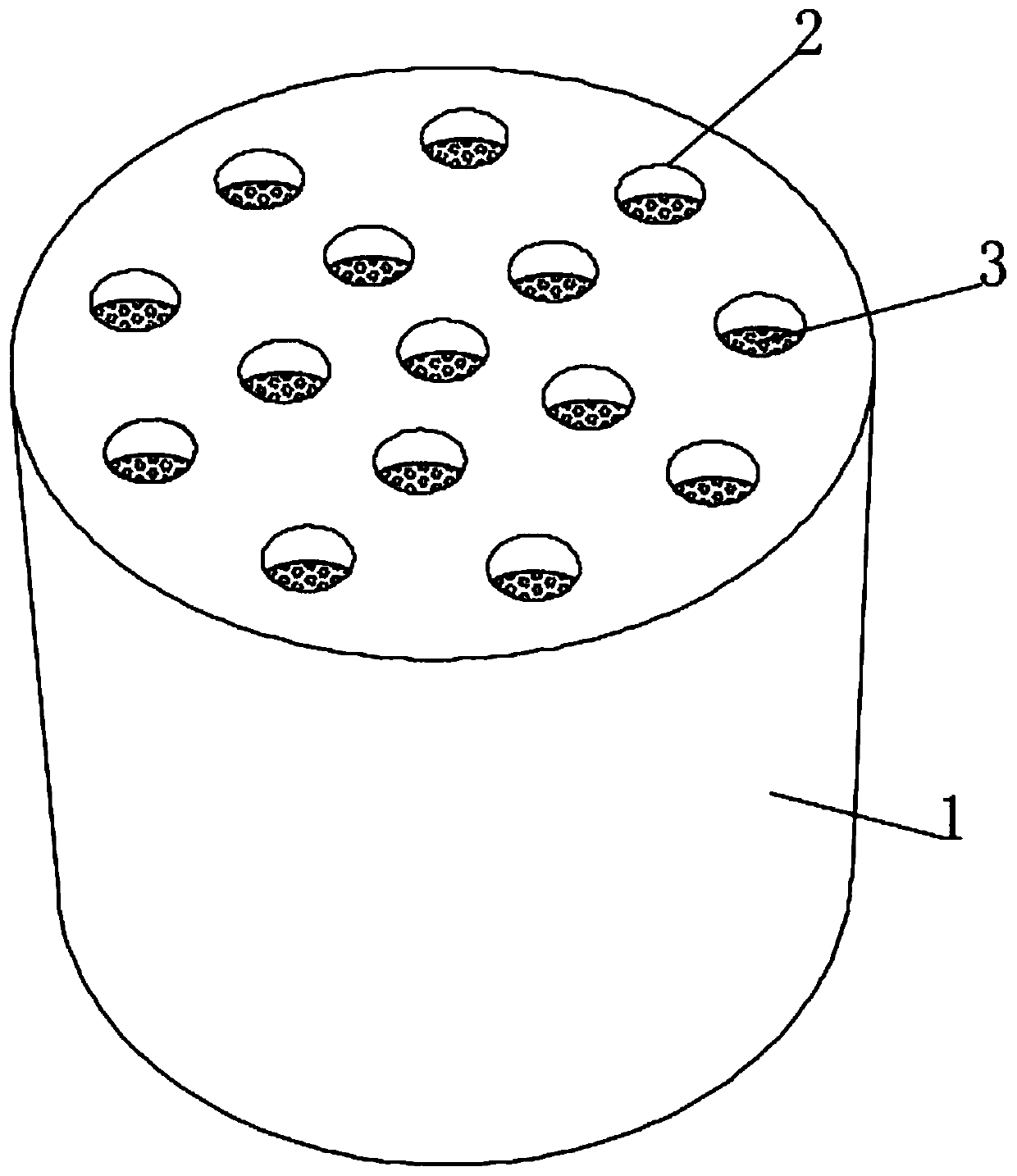

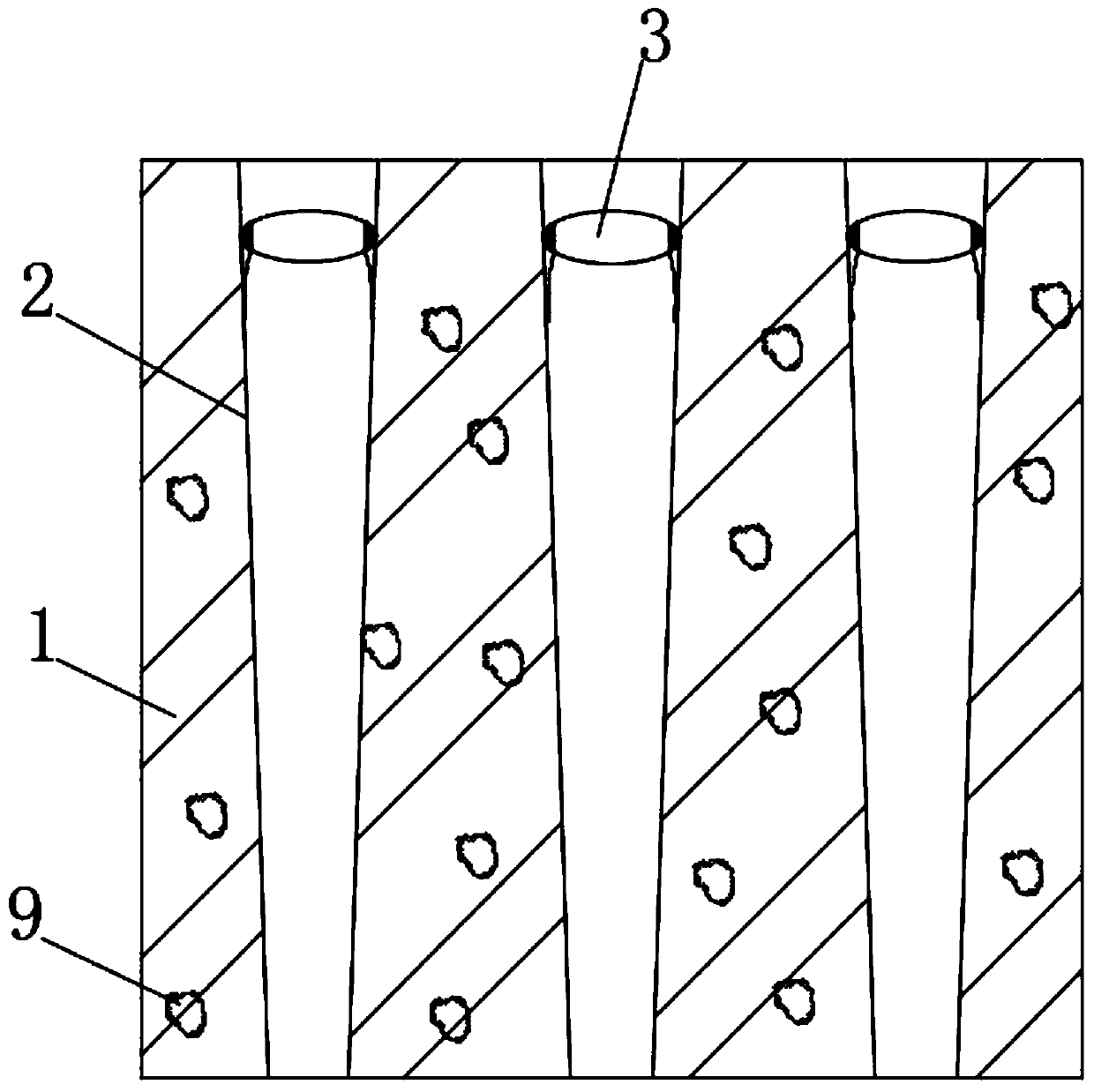

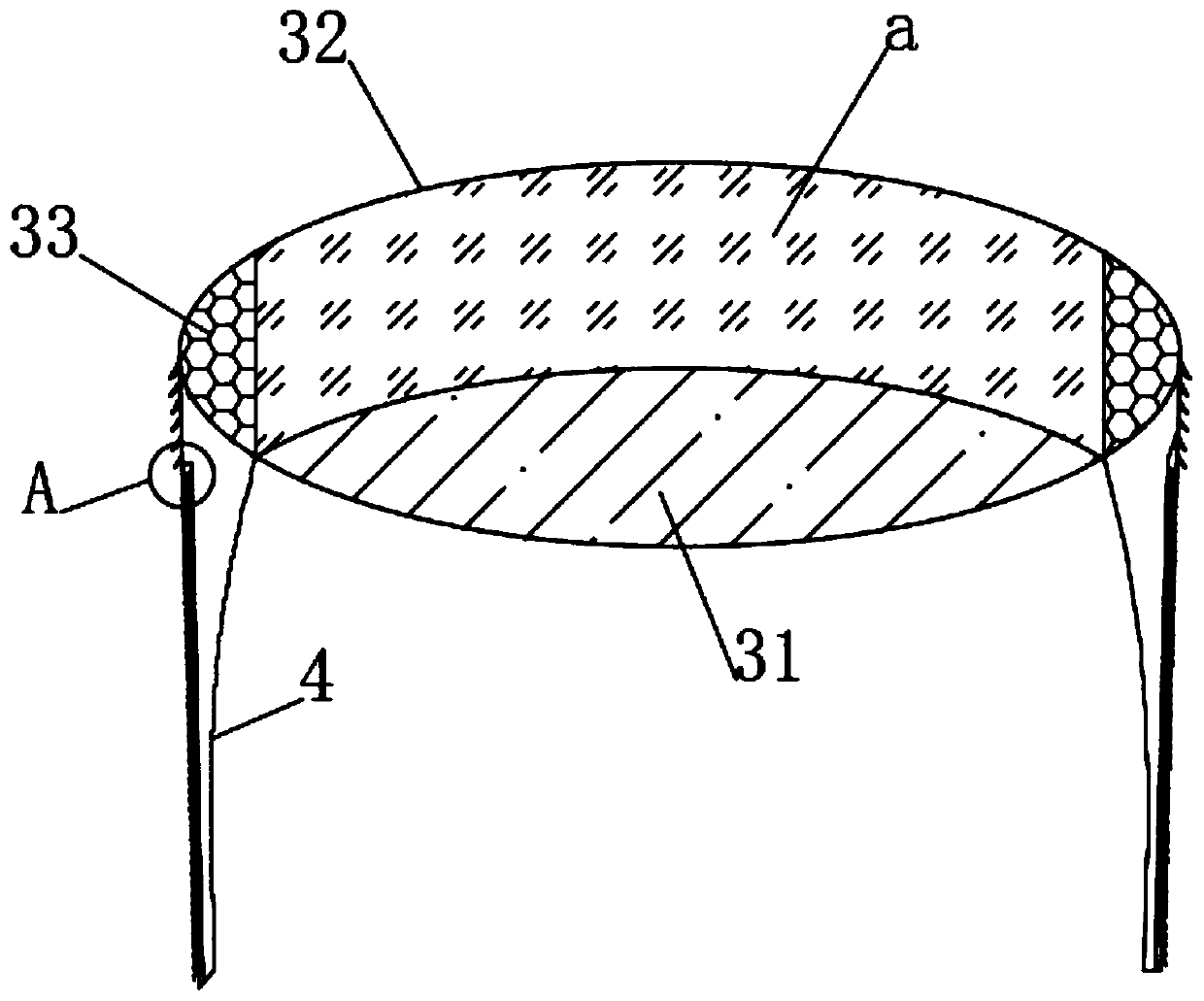

[0043] see Figure 1-2 , a coal block with a high combustion rate that cinders are not easy to break, comprising a coal block body 1, a plurality of vertically penetrating air holes 2 are dug inside the coal block body 1, and a plurality of internal combustion-supporting particles 9 are embedded in the coal block body 1, There is a broken rubber ring 3 placed inside the vent hole 2. The inner diameters of the upper and lower openings of the vent hole 2 are different, and the inner diameter of the vent hole 2 is larger than the bottom, so that the cross section of the vent hole 2 presents a parallel trapezoidal structure. The existence of can effectively ensure that the crushing rubber ring 3 can be stuck in the vent hole 2 when it is put into the vent hole 2, and the number of 9 internal combustion-supporting particles inside each coal block body 1 is 15-20. The particle size of the internal combustion-supporting particles 9 is 0.5-0.8 cm. If the number of internal combustion-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com