A kind of sawdust biomass fuel and preparation method thereof

A technology for biomass fuel and wood chips, which is applied in the fields of biomass fuel, waste fuel, fuel, etc., can solve the problems of wood chip biomass fuel combustion efficiency, low calorific value, low calorific value of biomass fuel, limitation of biomass fuel, etc. , to achieve the effect of expanding the effective combustion temperature range, reducing the ignition temperature, and improving stability and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

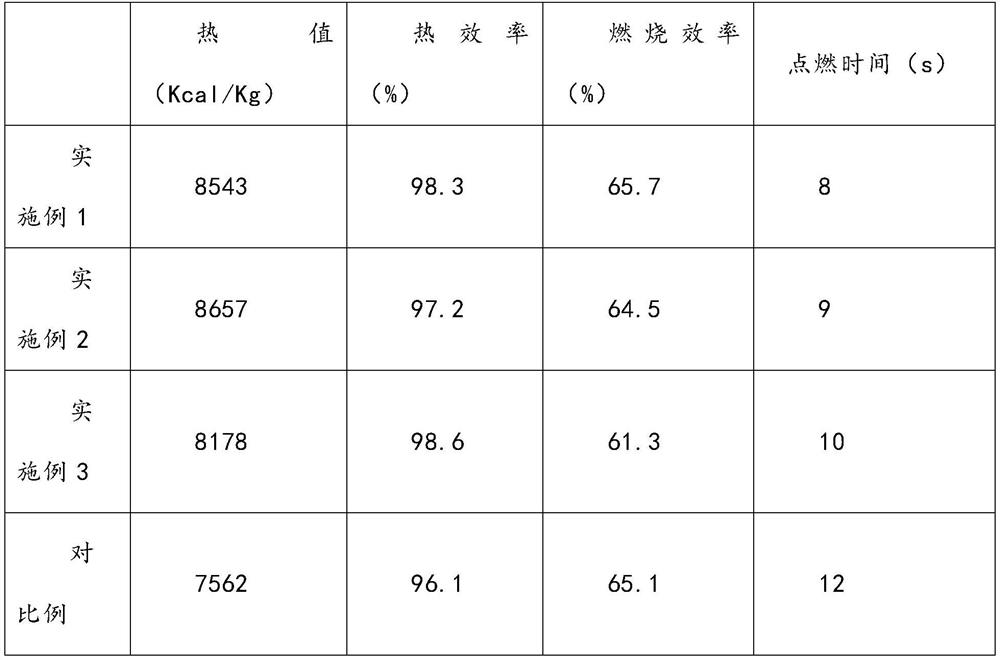

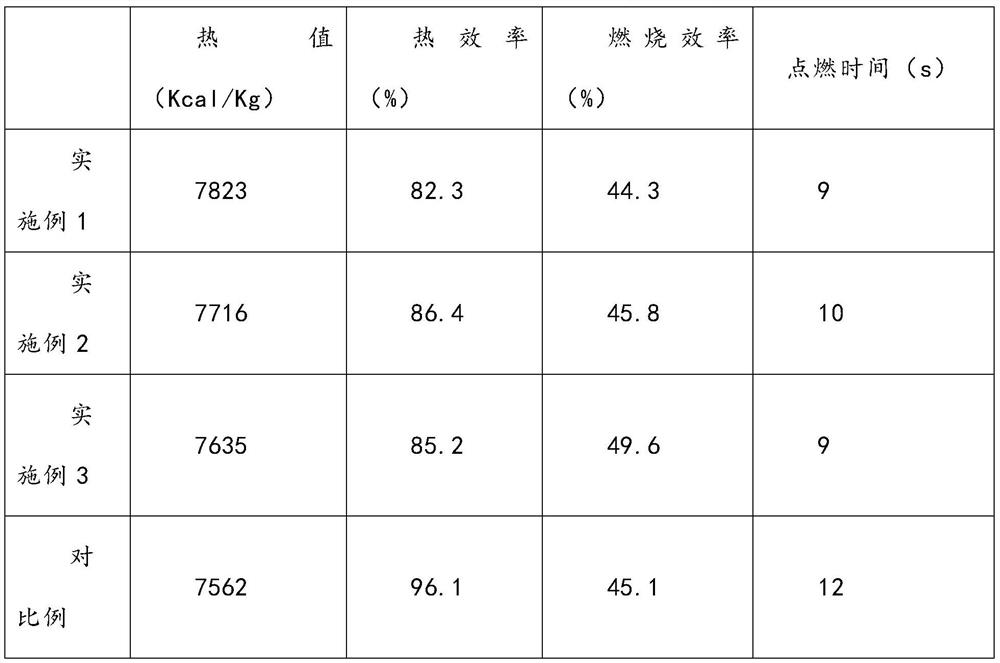

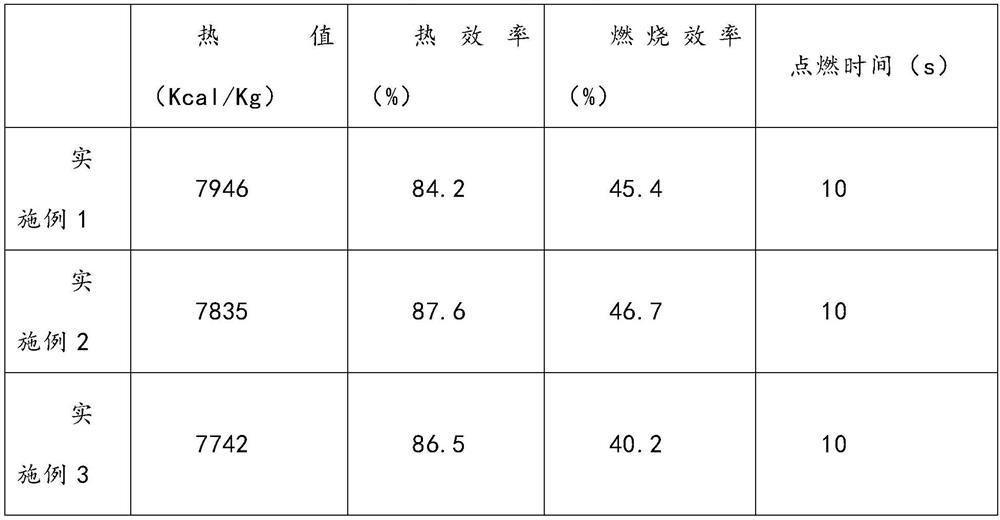

Embodiment 1

[0022] A wood chip biomass fuel, characterized in that the plastic shivel fuel comprises a weight of the following weight:

[0023] 60 wood chips, 14 parts of the aid, 6 pieces of concave polishing powder, 2 rare earth minerals, 2 oxygenation drugs, 0.3 oxygenhard, 8 bio-asphalt, 3.5 parts of cyanobena, 1.5 ammonium sulphate, ammonium sulphate, The auxiliary is polyanionic cellulose (PAC-LV), the rare earth mineral is a fluorocarbon ore; the wood chip is pine shavings; the oxygenating agent is potassium permanganate; the preparation of oxygenation The method is obtained from 1-bromo-3,5-dimethyl metane 11.3 g and magnesium hydroxide 2.3 g from 100 ml of THF to obtain a solution, 4-bromo-1-methoxy-2-2- Methylcylase 3.2 g and 1.6 g of maleic anhydride were reacted at 80 ° C for 1 h, and the resulting system was dried to increase the oxygenhane.

[0024] step:

[0025] (1) Place the wood chip, biological asphalt, and cyanae mud in a microwave vacuum drying apparatus, the vacuum is 0....

Embodiment 2

[0031] A wood chip biomass fuel, characterized in that the plastic shivel fuel comprises a weight of the following weight:

[0032] 60 wood chips, 14 parts of the aid, 6 pieces of concave polishing powder, 2 rare earth minerals, 2 oxygenation drugs, 0.3 oxygenhard, 8 bio-asphalt, 3.5 parts of cyanobena, 1.5 ammonium sulphate, ammonium sulphate, The auxiliary agent is polyanionic cellulose, the rare earth mineral is a fluorocarbon ore; the wood chip is a pine chopper; the preparation method of the oxygen-3,5-dimethyl methane is 1-bromo-3,5-dimethyl methane 11.3g and magnesium hydroxide 2.3 g dissolved in 100 ml of THF to obtain a solution, 4-bromo-1-methoxy-2-methylcylase 3.2 g and maleic anhydride at 1.6 g, 80 ° C were added to the solution. 1H, the resulting system was dried to increase oxygenation.

[0033] step:

[0034](1) Place the wood chips, biological asphalt, and cyanae mud in the microwave vacuum drying apparatus, the vacuum is 0.06 MPa, the power is 1600W, first at a te...

Embodiment 3

[0040] A wood chip biomass fuel, characterized in that the plastic shivel fuel comprises a weight of the following weight:

[0041] 60 wood chips, 14 parts of the aid, 6 pieces of concave polishing powder, 2 rare earth minerals, 2 oxygenation drugs, 0.3 oxygenhard, 8 bio-asphalt, 3.5 parts of cyanobena, 1.5 ammonium sulphate, ammonium sulphate, The auxiliary is a polyanionic cellulose, the rare earth mineral is a fluorocarbon ore; the wood brown is porcasca; the oxygenant is potassium permanganate; the preparation method of the oxygen-oxygenating agent is from 1- The bromine-3,5-dimethyl metane 11.3 g and the magnesium hydroxide 2.3 g is dissolved in 100 ml of THF to obtain a solution, and 4-bromo-1-methoxy-2-methylcylane is added to the solution. 3.2 g. And the maleic anhydride was 1.6 g, at 80 ° C for 1 h, and the resulting system was dried to increase the oxygenation.

[0042] step:

[0043] (1) Place the wood chips, biological asphalt, and cyanae mud in microwave vacuum drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com