Patents

Literature

34 results about "Bioasphalt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bioasphalt is an asphalt alternative made from non-petroleum based renewable resources. These sources include sugar, molasses and rice, corn and potato starches, natural tree and gum resins, natural latex rubber and vegetable oils, lignin, cellulose, palm oil waste, coconut waste, peanut oil waste, canola oil waste, dried sewerage effluent and so on. Bitumen can also be made from waste vacuum tower bottoms produced in the process of cleaning used motor oils, which are normally burned or dumped into land fills.

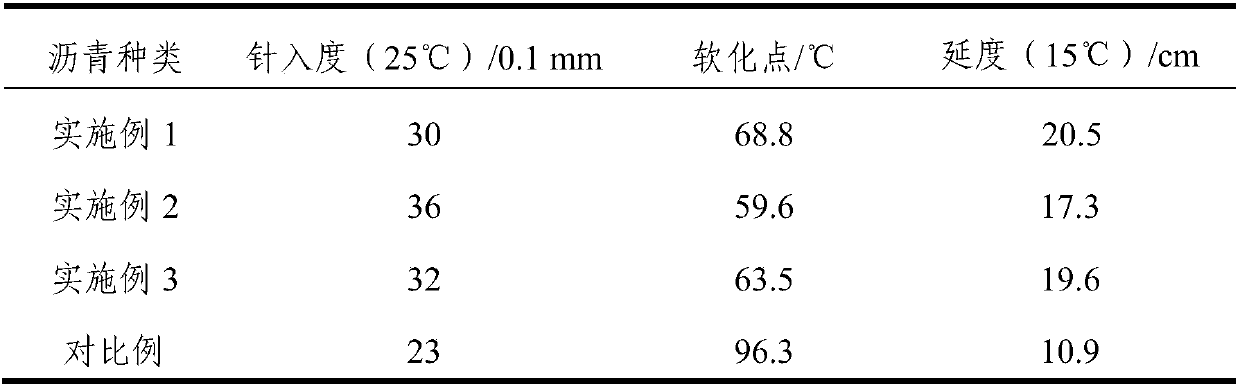

Esterified biological asphalt and preparation method thereof

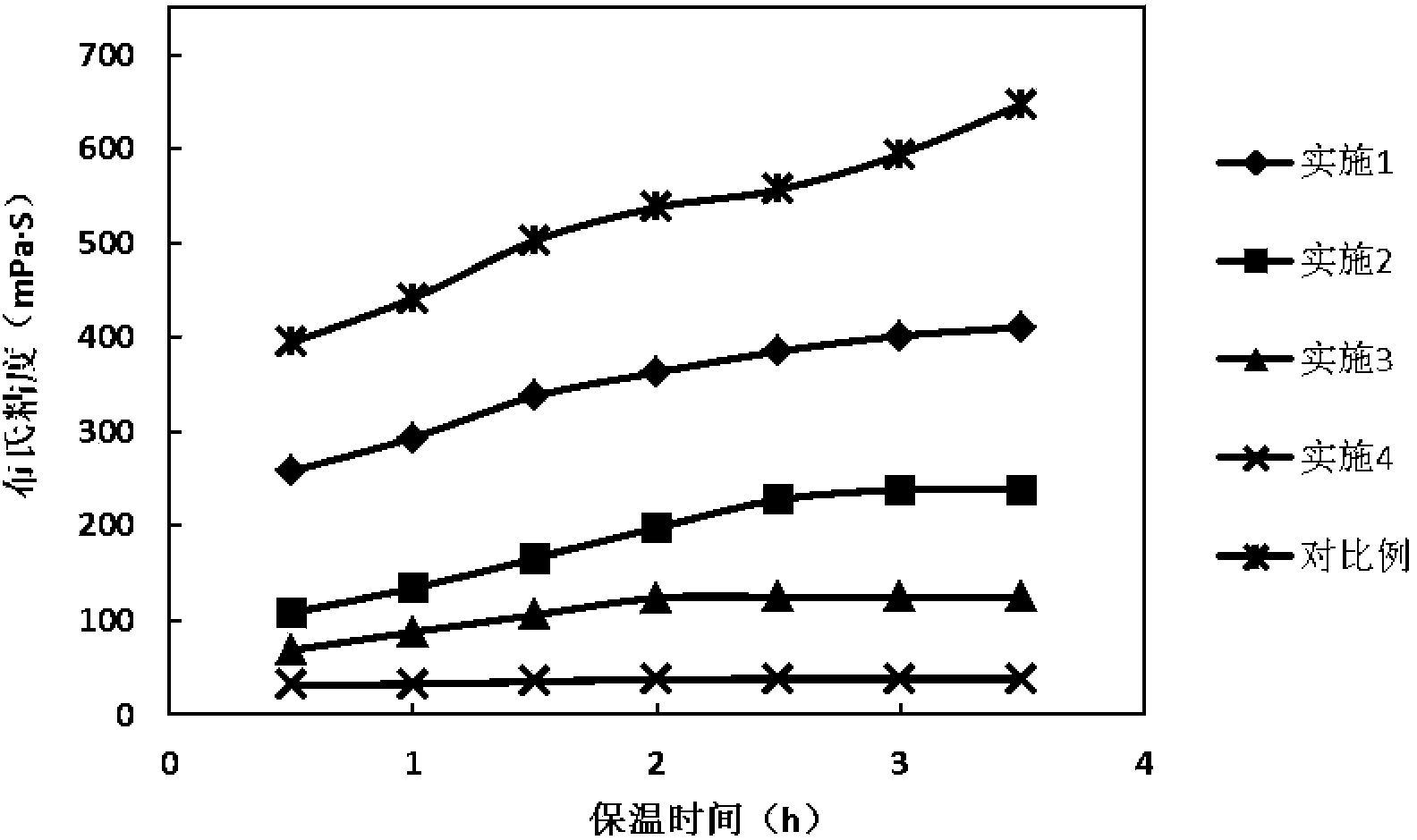

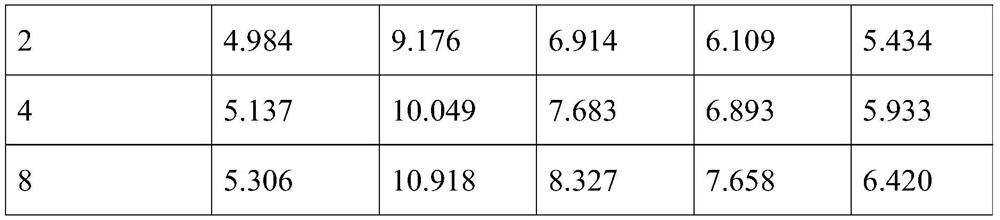

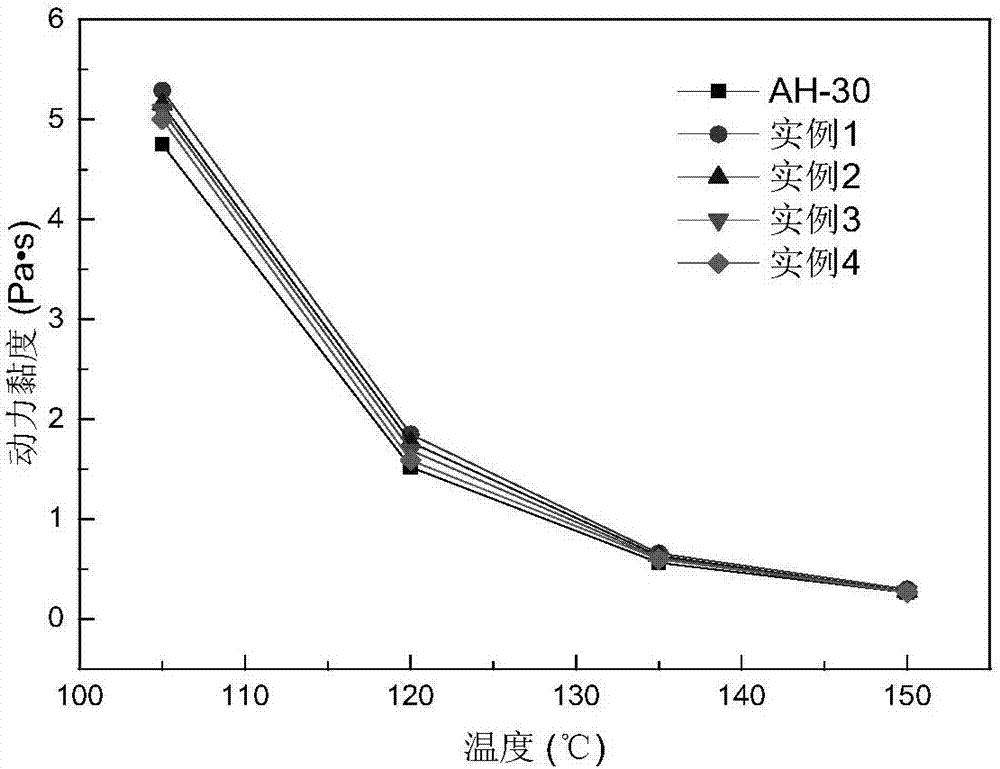

ActiveCN104388107AEfficient use ofAdequate responseWorking-up pitch/asphalt/bitumen by selective extractionFatty acid esterificationAlcoholAging resistance

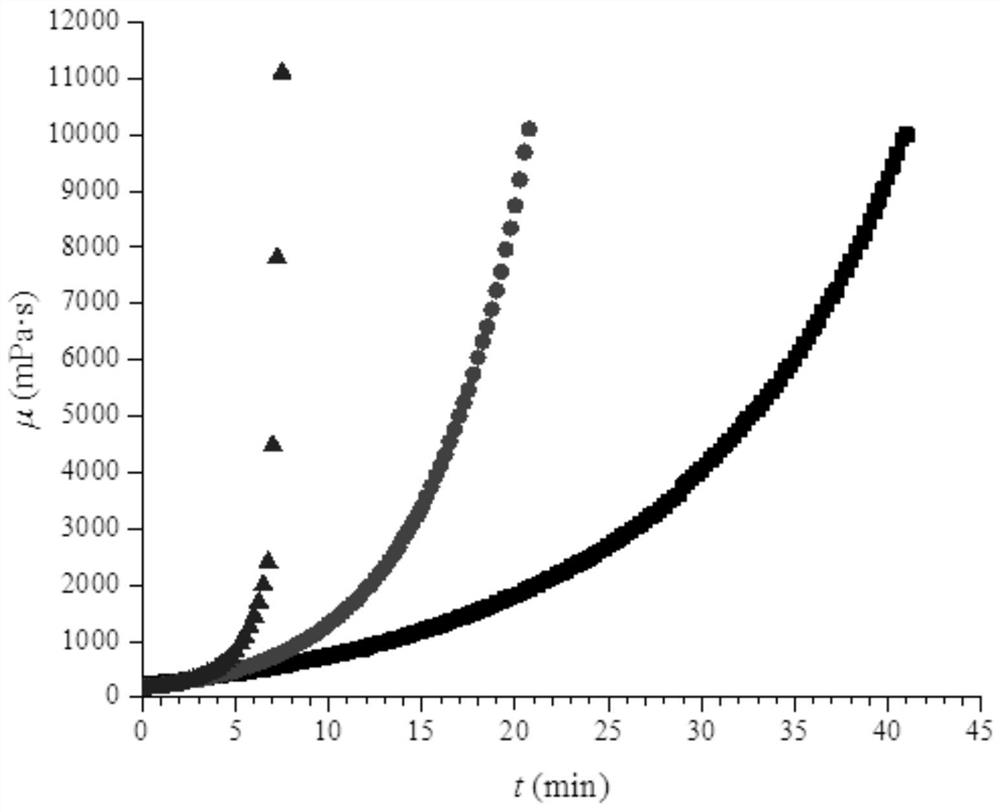

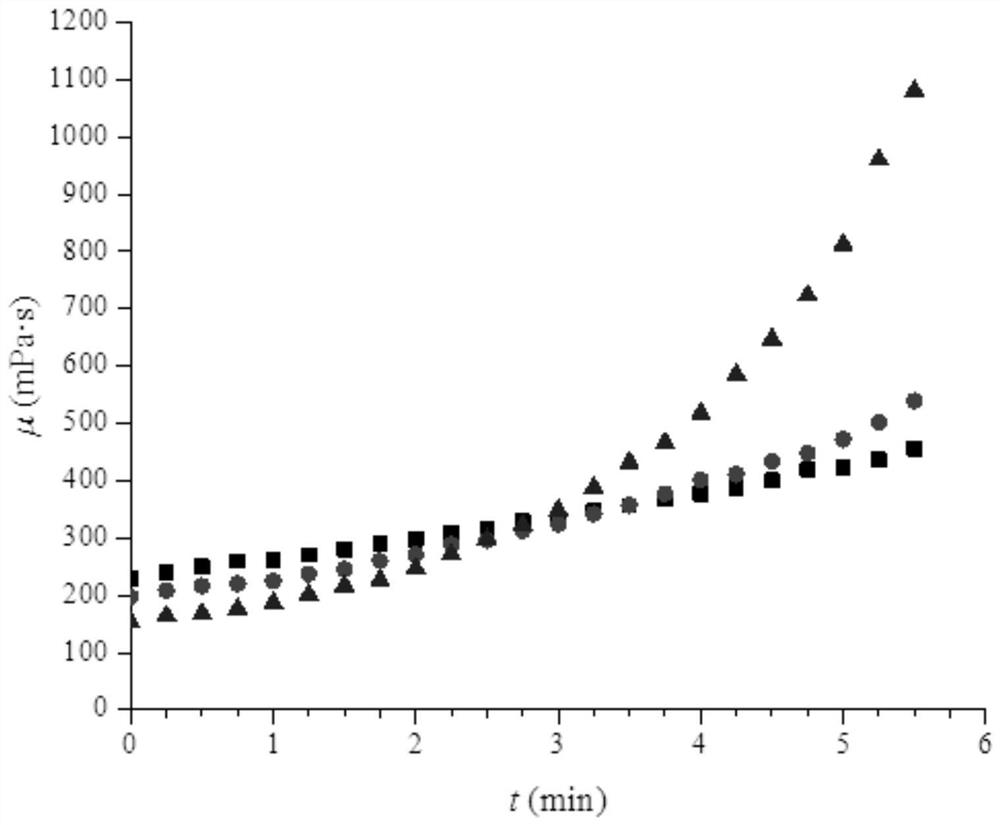

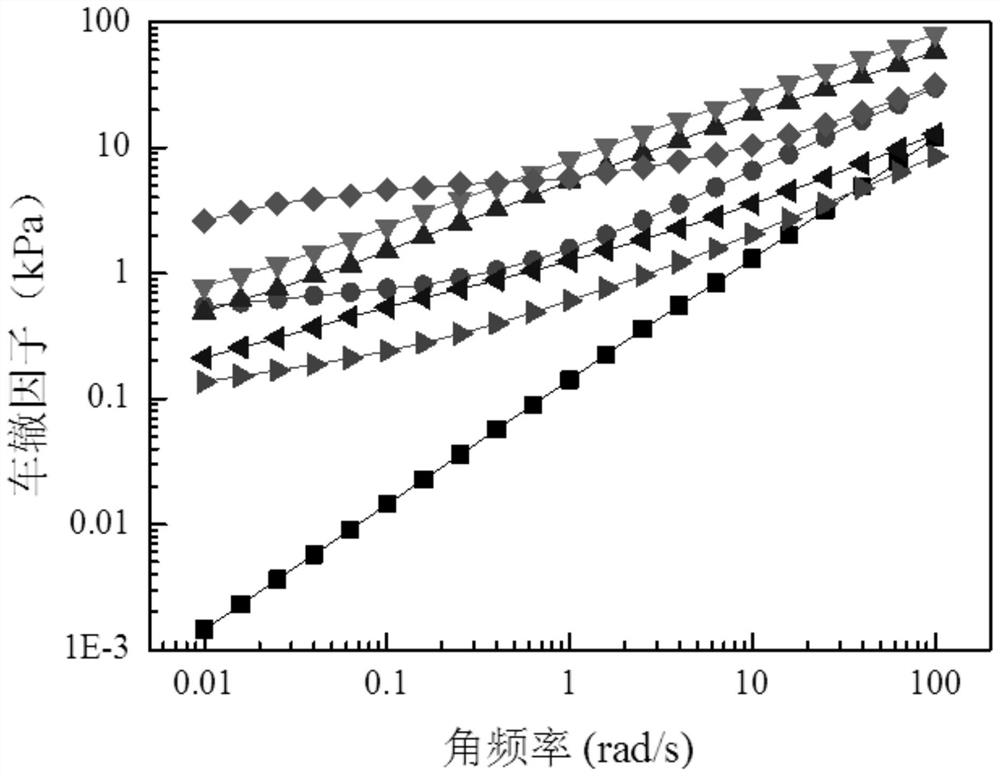

The invention relates to a preparation method of esterified biological asphalt. The preparation method comprises the following steps: 1) mixing bio-oil with alcohol, and adding a catalyst to perform esterification reaction; 2) extracting the esterified bio-oil obtained in the step 1) with water to obtain an insoluble matter; and 3) performing oxidation treatment on the insoluble matter obtained in the step 2) to obtain the esterified biological asphalt. By adopting the preparation method provided by the invention, heavy components of biomass oil can be effectively utilized and turned from wastes into treasure; and furthermore, by improving the process, the fuller reaction of alcohol and bio-oil can be promoted, and the esterification efficiency of the biological asphalt is improved. The prepared biological asphalt has the characteristics of low viscosity increasing speed, good aging resistance and the like.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

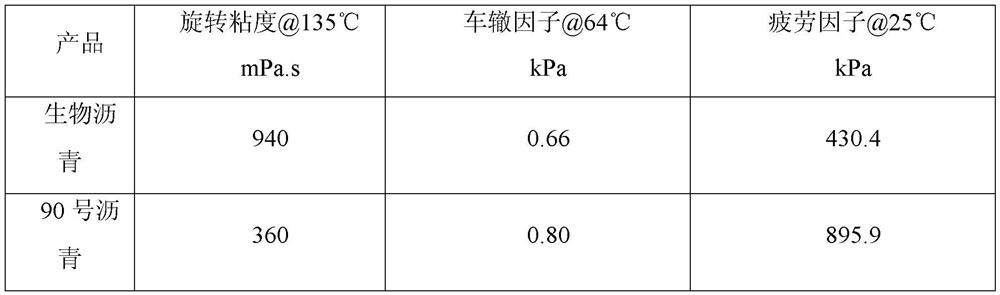

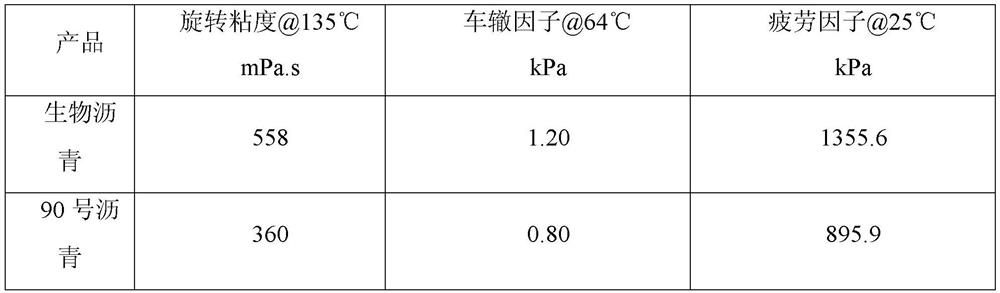

Bio-asphalt, bio-asphalt composition and method for preparing them

ActiveUS20160194580A1Low production costLow costOrganic oxidationIn situ pavingsBituminous materialsAromatic hydrocarbon

The disclosure provides bio-asphalt, bio-asphalt compositions and a method for preparing them. It belongs to the technical field of asphalt material. The method of the disclosure uses bio-oil as the raw material, adopts a combination of extraction process and oxidation process to prepare bio-asphalt, and modifies the product obtained from bio-oil by extraction process or bio-asphalt with ordinary petroleum asphalt and / or aromatic hydrocarbon oil and a macromolecular material to obtain a bio-asphalt composition.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

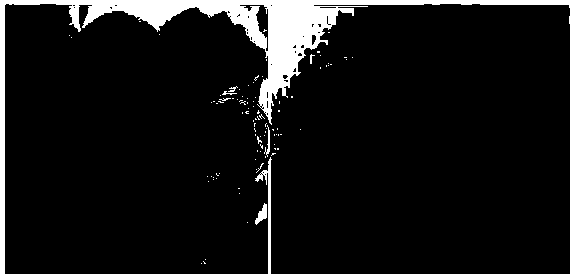

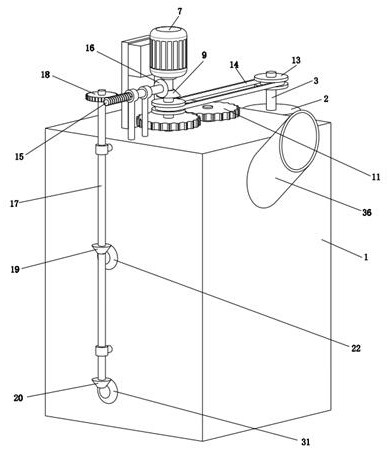

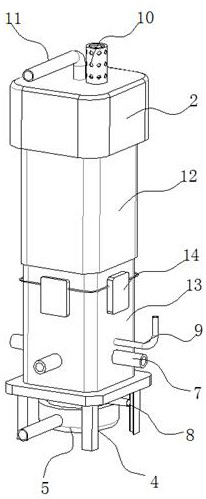

Waste asphalt mixture oil stone separation device with bio-oil as solvent oil and using method thereof

The invention discloses a waste asphalt mixture oil stone separation device with bio-oil as solvent oil and a using method thereof. The old asphalt mixture oil stone separation device comprises a bio-oil supply mechanism, a waste asphalt mixture conveying belt, an oil stone separation generator, an oil stone filtering mechanism, an oil stone separated aggregate conveying belt and an aggregate grading screening mechanism. The upper surface of a bearing net in the oil stone filtering mechanism is high in left and low in right, and the slope gradient is 3%; a plurality of round holes are evenly formed in the surface of multiple layers of vibrating screens in the aggregate grading screening mechanism, the hole diameter of the vibrating screens is gradually decreased from top to bottom, and each vibrating screen is of a conical surface structure with the slope gradient of 3%. Waste asphalt in a waste asphalt mixture is dissolved by adopting bio-oil, oil stone separation of the waste asphaltmixture is economically and efficiently achieved, aggregate obtained after oil stone separation can be directly used as a recycled aggregate for complete utilization, asphalt does not need to be extracted from bio-oil obtained through filtration, the bio-oil is recycled and stored through a bio-oil recycling tank, 100% of the bio-oil is used as a bio-asphalt preparation raw material, re-extraction is not needed, and the process is simple.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

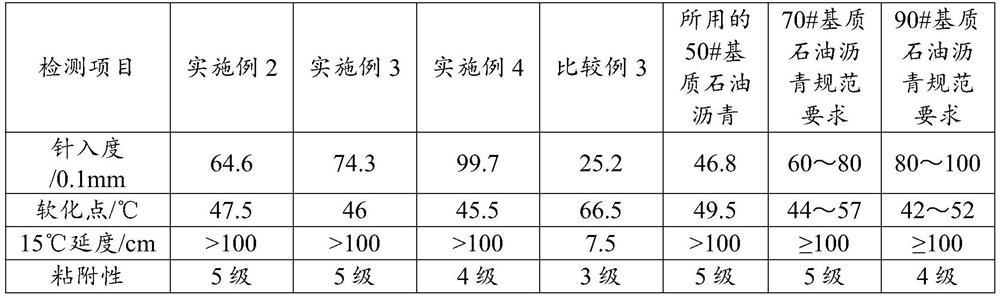

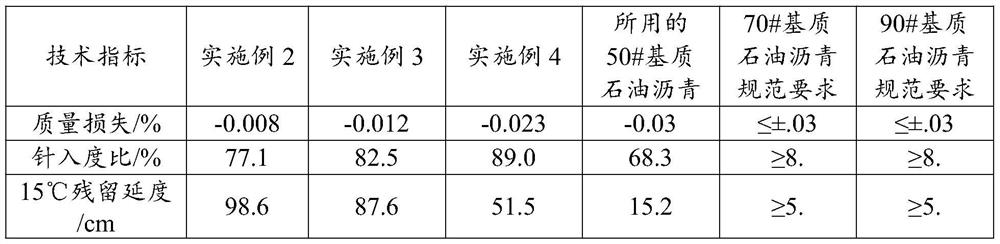

Preparation method of modified biological asphalt, modified biological asphalt and use thereof

Owner:CHINA ACAD OF TRANSPORTATION SCI +1

Preparation method of RAP large-proportion mixing amount asphalt regenerant

InactiveCN112280323ALarge-scale regeneration performance is stableReduce viscosityBuilding insulationsFiberRoad engineering

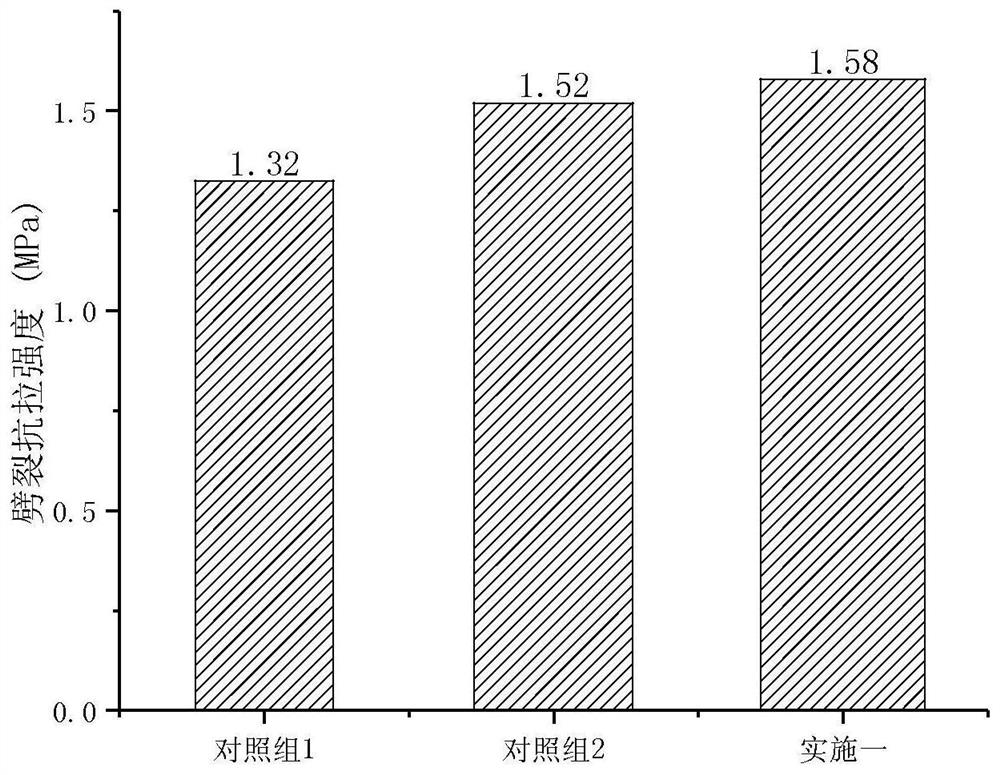

The invention discloses a preparation method of an RAP large-proportion mixing amount asphalt regenerant, belongs to the field of road engineering, and aims to solve the problem that the regenerationefficiency of a waste asphalt mixture is relatively low. The preparation method comprises the following steps: 1, weighing biological asphalt, rubber oil, styrene, SBS and corn straw fibers as raw materials; 2, stirring and mixing biological asphalt, styrene, a part of rubber oil and corn straw fibers to obtain a component A; 3, adding SBS particles into the rubber oil, and heating and stirring toobtain a component B; and 4, mixing the component A and the component B to obtain the asphalt regenerant. After the biological asphalt reacts with styrene, the bonding effect between the recycled asphalt and stone can be improved. SBS and a rubber oil solution can be used as interface enhancing components, so that the interface performance of the mixture is further enhanced, and the durability isimproved, and the stability of RAP large-proportion regeneration performance is ensured. The asphalt regenerant prepared by the invention can realize large-proportion regeneration application with RAP exceeding 50%.

Owner:哈工元科技(辽宁)有限公司

Environment-friendly warm mix asphalt regenerant and preparation method thereof

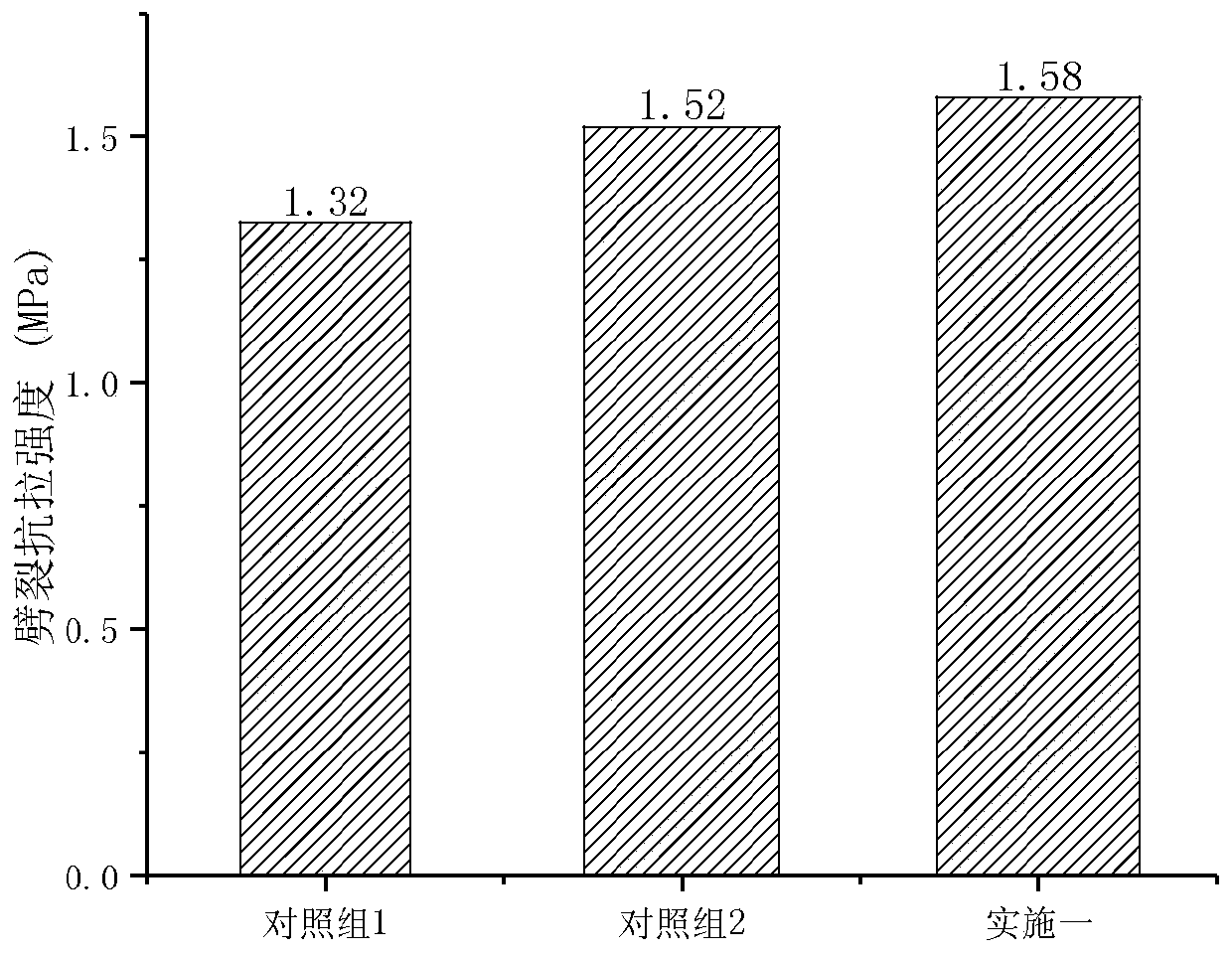

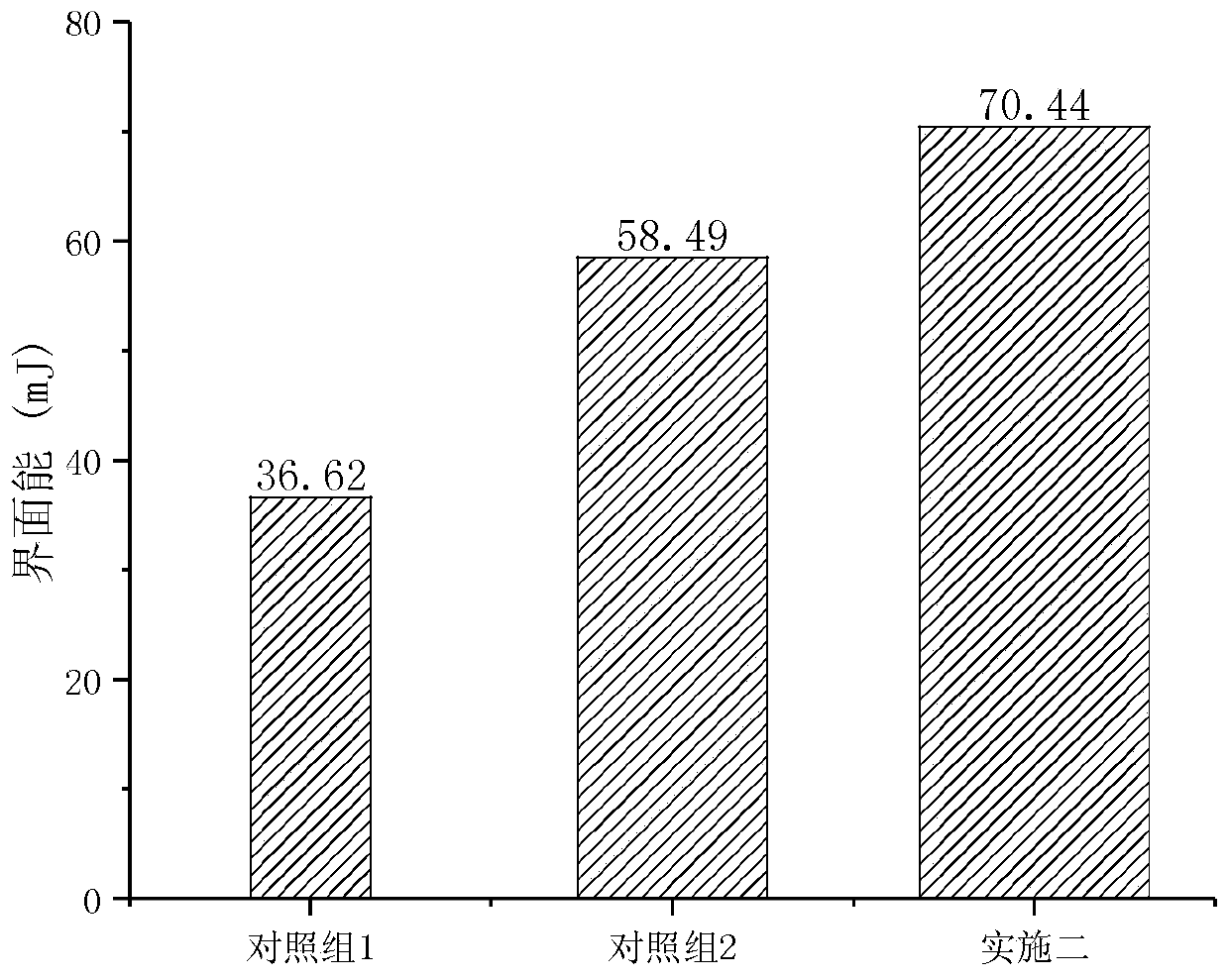

ActiveCN111518404AGood application effectImprove crack resistanceClimate change adaptationChemical industryFiberRoad engineering

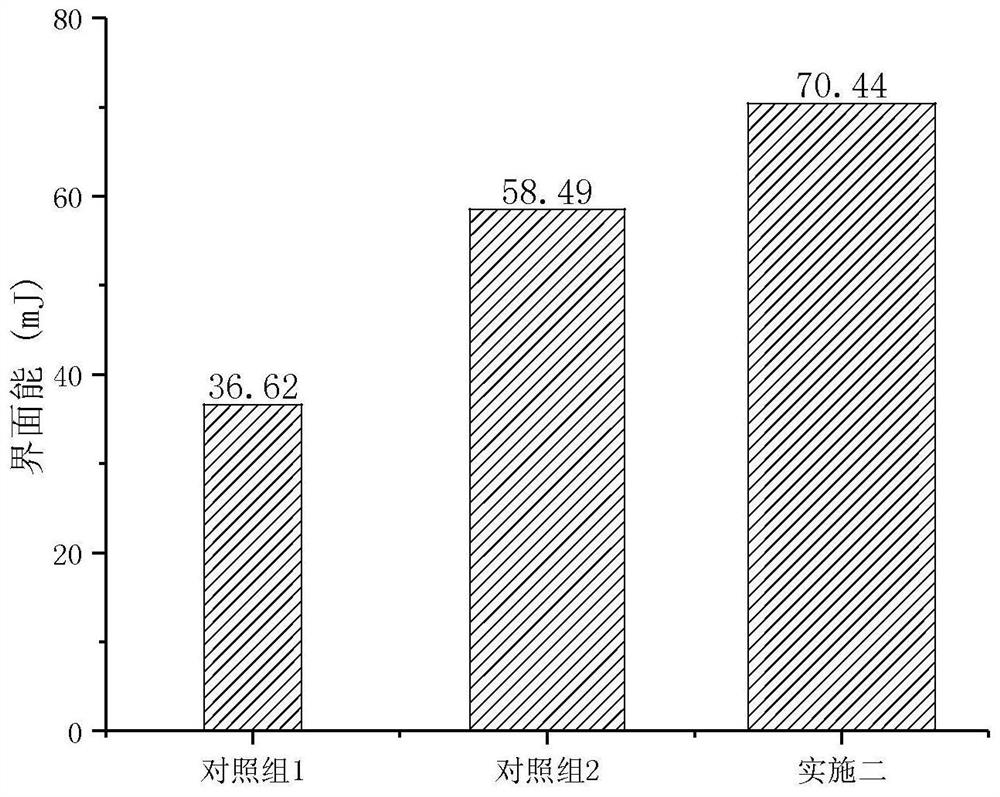

The invention discloses an environment-friendly warm mix asphalt regenerant and a preparation method thereof, belongs to the field of road engineering, and aims to solve the problems of poor diffusioneffect and higher mixing temperature of the conventional asphalt regenerant material. The preparation method comprises the following steps: 1, weighing biological asphalt, epoxidized soybean oil, a curing agent, straw fibers and an epoxy resin as raw materials; 2, putting the biological asphalt in the raw materials into a reactor, adding the curing agent, uniformly stirring at the temperature of50-60 DEG C to obtain a mixture, adding the epoxidized soybean oil in the raw materials, stirring at the temperature of 50-60 DEG C, adding the straw fibers, and continuously stirring at the temperature of 50-60 DEG C to obtain a regenerant effective component; and 3, mixing the regenerant effective component with the epoxy resin in the raw materials. The performance of the aged asphalt is recovered by adopting effective components such as the biological asphalt, the diffusion effect is enhanced through the epoxidized soybean oil, the warm-mixing production of the recycled asphalt mixture is realized, and the production process is simple and energy-saving.

Owner:HARBIN INST OF TECH

Preparation method of pig manure bio-oil, bio-asphalt prepared from pig manure and application

PendingCN112063442ASolve the shortage of resourcesGood road performanceLiquid carbonaceous fuelsFatty substance recoveryRoad engineeringProcess engineering

The invention belongs to the technical field of road engineering asphalt materials, and relates to a preparation method of pig manure bio-oil. The preparation method comprises the steps of 1) pretreating pig manure to obtain pig manure particles; 2) pyrolyzing and liquefying the pig manure particles obtained in the step 1) by adopting a rapid thermal cracking and liquefying process to obtain bio-oil prepared from pig manure, so that the pollution problem caused by pig manure solid wastes is solved, the high-added-value utilization of the pig manure is realized, and the method has important environmental protection and economic values; and the biological asphalt prepared from pig manure is obtained by replacing matrix asphalt with pig manure bio-oil and is used for road pavement, so that asphalt can be replaced by a sustainable road building material, and the problem of asphalt resource shortage caused by petroleum resource exhaustion is solved. The preparation method has the advantagesof simple preparation, easy operation, high efficiency, convenience, low raw material cost, better pavement performance, resource saving, environmental protection, cyclic utilization of wastes, and good application and popularization prospects.

Owner:CHANGAN UNIV

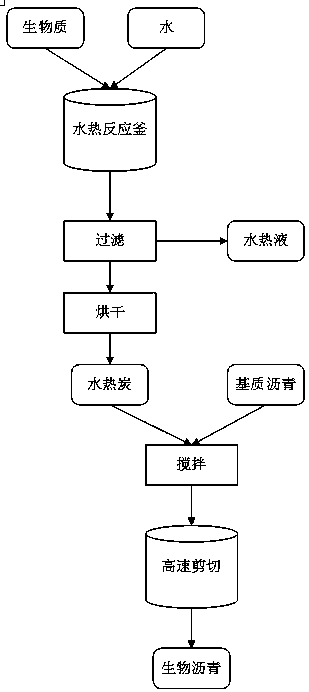

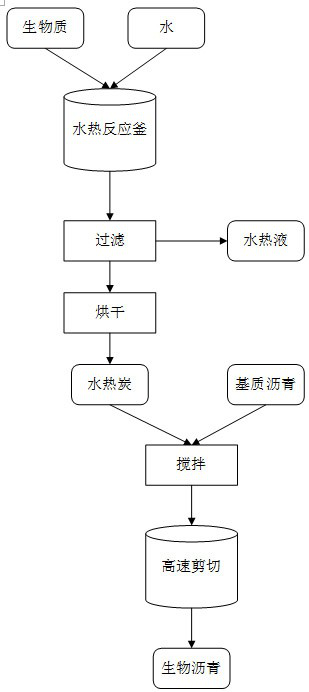

Method for preparing biological asphalt from lignocellulose biomass hydrothermal carbon

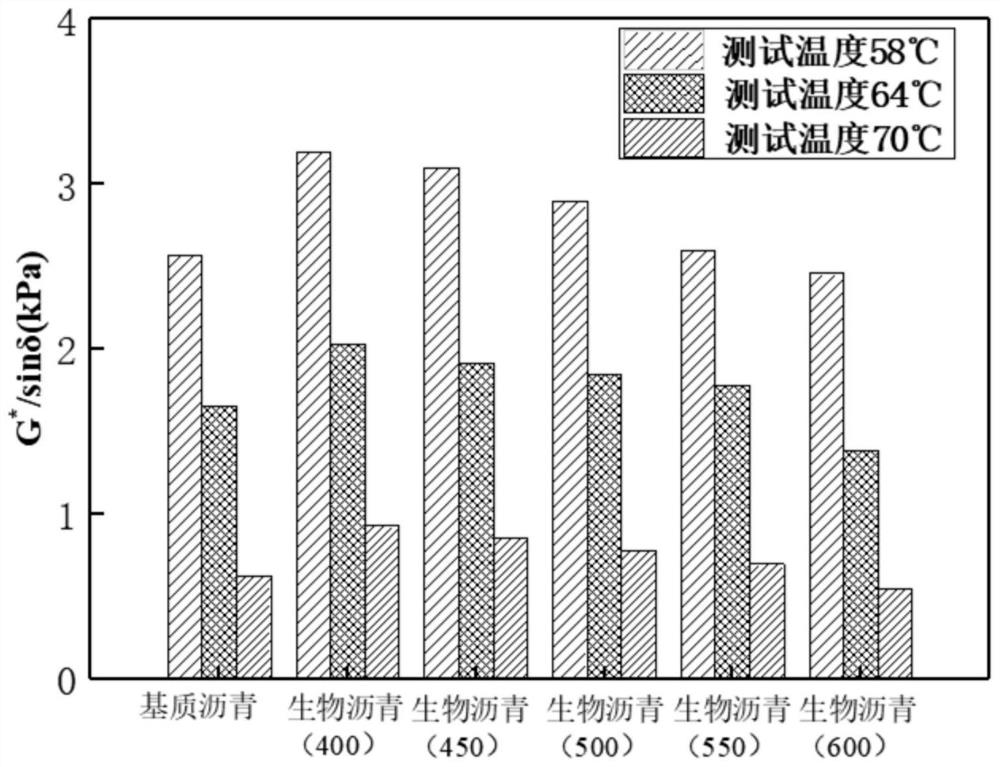

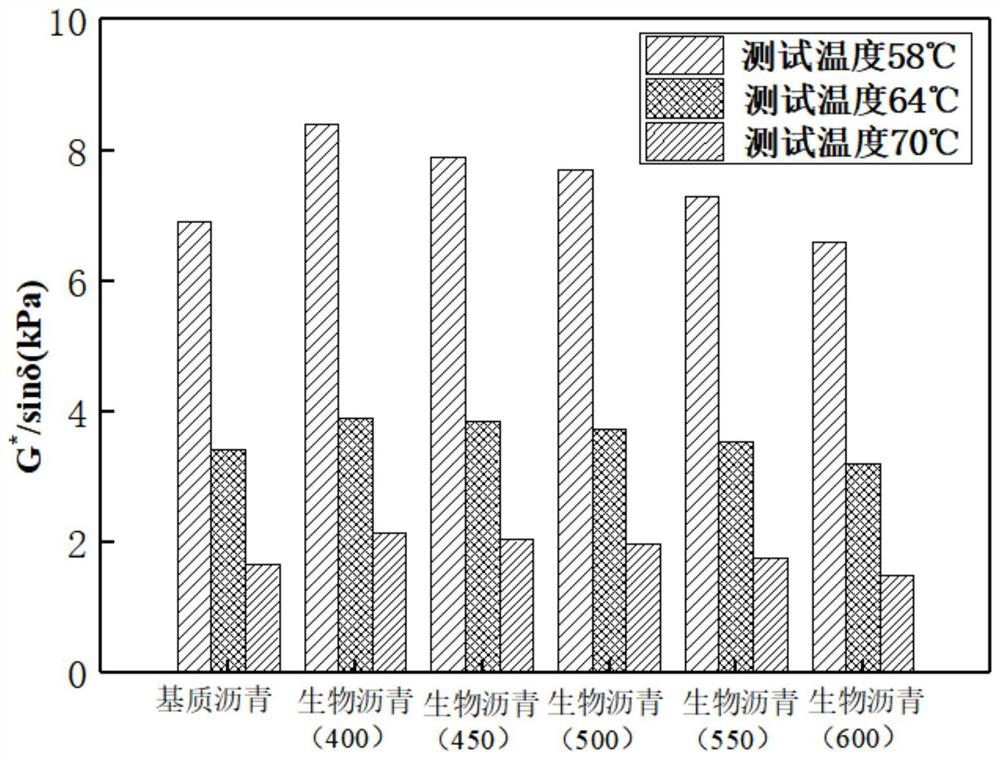

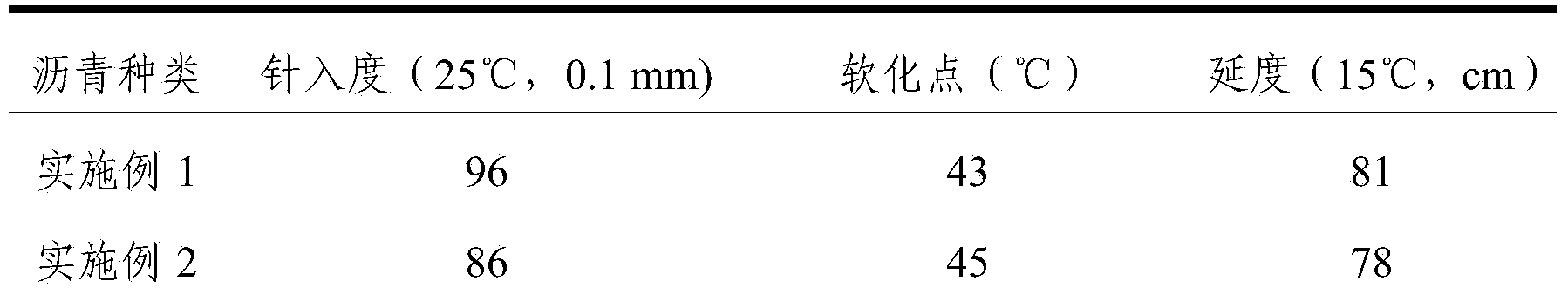

ActiveCN111019365AImprove high temperature performanceSimple processCarbon preparation/purificationBuilding insulationsBioasphaltCorn stover

The invention provides a method for preparing biological asphalt from lignocellulose biomass hydrothermal carbon. Hydrothermal carbon is prepared from lignocellulose biomass by utilizing a hydrothermal carbonization technology, and then the hydrothermal carbon is combined with matrix asphalt to prepare the biological asphalt. The biomass comprises corn straw, rice straw or wheat straw and the like. In the reaction process, a mixture of biomass and water is subjected to hydrothermal carbonization at a certain temperature and under a certain pressure to form the hydrothermal carbon, and the hydrothermal carbon is combined with asphalt through high-speed shearing to prepare the biological asphalt. The method is simple in process, a hydrothermal carbon modifier is well combined with the asphalt, the high-temperature performances of the asphalt are improved, and the novel and sustainable method is provided for improvement of an asphalt material and utilization of biomass resources.

Owner:FUDAN UNIV

Method for preparing catalytically hydrogenated biological asphalt

ActiveCN104388108AEfficient use ofImprove performanceWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansPtru catalystHydrogenation reaction

The invention relates to a method for preparing catalytically hydrogenated biological asphalt. The method comprises the following steps: (1) carrying out a hydrogenation reaction on biomass pyrolytic oil in the presence of a catalyst; (2) standing the product prepared in the step (1), separating, and extracting an upper oil phase to obtain an extract; (3) dehydrating and oxidizing the extract to obtain the biological asphalt. By adopting the preparation method, heavy components of biomass oil can be effectively utilized, waste is changed into valuable; after the biological asphalt is catalytically hydrogenated, the performance of the biological asphalt can be more stable and the quality of the biological asphalt can be improved. According to the biological asphalt prepared by the preparation method, the requirement of an asphalt pavement on petroleum asphalt can be reduced, stress caused by resource shortage can be relieved, and sustainable development of asphalt and roads can be realized since the biological asphalt belongs to renewable resources.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

High-viscosity improved asphalt and preparation process

InactiveCN108299836AImprove performanceReduce generationBuilding insulationsBituminous materialsFuel oil

The invention belongs to the technical field of asphalt materials and in particular relates to high-viscosity improved asphalt and a preparation process. The high-viscosity improved asphalt comprisesthe following components: 100-200 parts of natural asphalt, 150-200 parts of biological asphalt, 30-60 parts of a tackifying resin, 30-50 parts of rubber powder, 60-100 parts of packing, 40-70 parts of a stabilizer, 20-50 parts of a defoaming agent and 10-30 parts of a curing agent. The asphalt is prepared from the components through procedures such as mixing, stirring and defoaming. Compared withthe prior art, the high-viscosity improved asphalt has the beneficial effects that with the combination of rock asphalt with biomass heavy oil, the viscosity of the product provided by the inventioncan be improved through the tackifying resin and the rubber powder, and the asphalt is greatly improved when being compared with common asphalt; due to addition of the defoaming agent and the curing agent, bubbles inside the product can be reduced, and properties of the product can be improved; through steps of the invention, mixtures are firstly mixed at a high temperature, melting debubbling treatment is further carried out, the product provided by the invention has very large viscosity, and different properties of the asphalt can be all improved.

Owner:SHANDONG LIANXING ENERGY GRP CO LTD

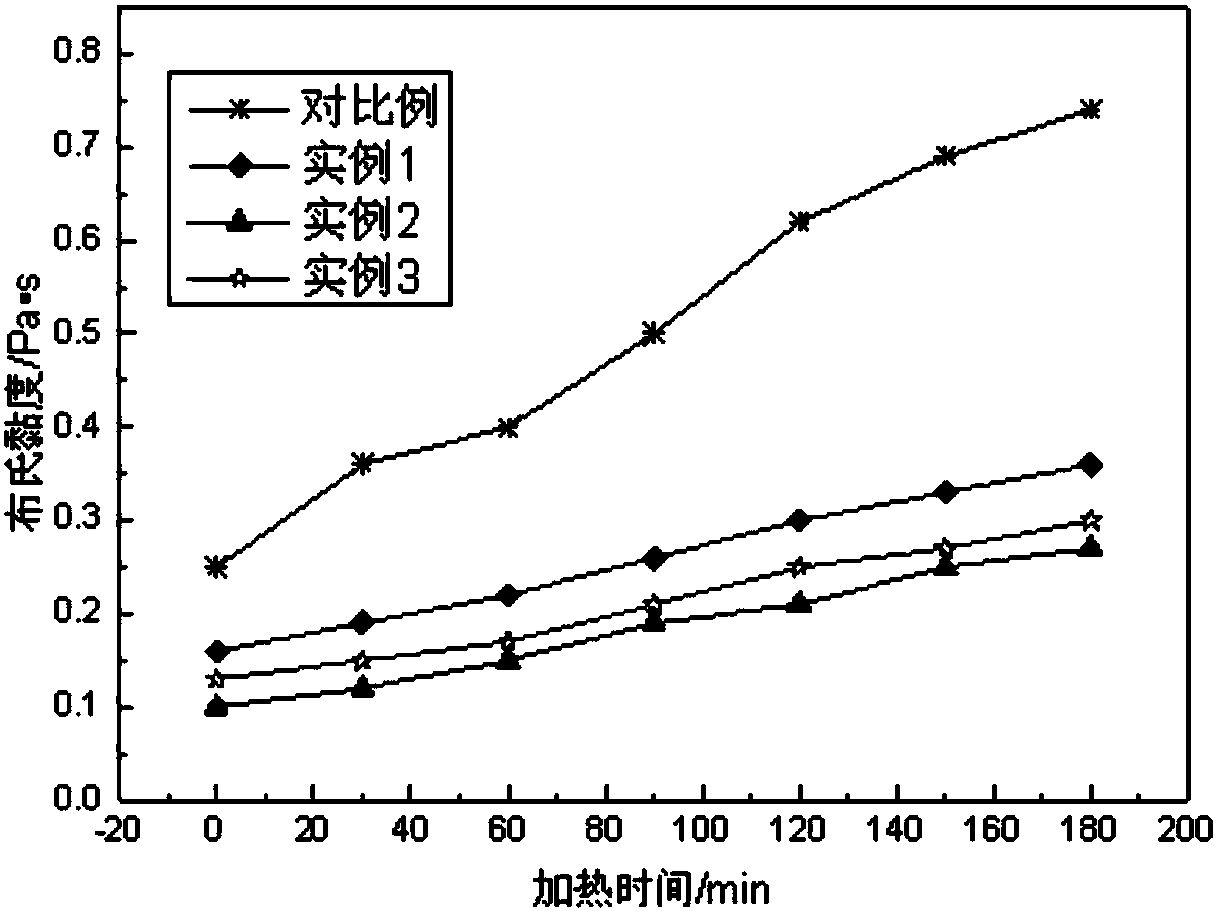

Modified biological asphalt and preparation method thereof

ActiveCN112080314AImprove performance and stabilityAvoid excessive oxidationWorking-up pitch/asphalt/bitumen by chemical meansProcess engineeringRenewable resource

The invention relates to the technical field of preparation of road paving materials, and particularly discloses a modified biological asphalt and a preparation method thereof. The modified biologicalasphalt is prepared from biological asphalt, biochar, rubber powder and a mixed solution of hydrogen peroxide and alcohol, the viscosity of the biological asphalt is reduced through synergistic cooperation of the raw materials in a specific proportion; the high-temperature stability and pavement performance of the biological asphalt are improved, the comprehensive quality of the biological asphalt is improved, the biological asphalt can partially or completely replace pavement petroleum asphalt, the dependence on petroleum resources is reduced, the pressure caused by shortage of petroleum resources is relieved, meanwhile, the biological asphalt belongs to renewable resources, and sustainable development of highway traffic infrastructure construction can be realized.

Owner:BEIJING SANJU GREEN ENERGY TECH CO LTD +1

Hard-asphalt extender and preparation method thereof

The invention relates to a hard-asphalt extender and a preparation method thereof. the method comprises the following steps: 1, smashing biological substances; 2, performing pyrolysis on the obtained biological substances to obtain biological oil; 3, mixing the obtained biological oil and an inorganic-salt solution, performing stirring in cold water bath, and performing vacuum filtration to obtain a non-water-soluble component; and 4, performing heat treatment on the obtained non-water-soluble component in a nitrogen atmosphere to obtain the hard-asphalt extender. According to the invention, the ordinary biological substances such as waste wood residues and waste rice hulls are converted into the biological oil, a physical separation method used for asphalt material components in the biological oil is improved, and therefore usage performance of the biological asphalt extender is improved and an optimal usage range of biological asphalt which is used as the extender is decided.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

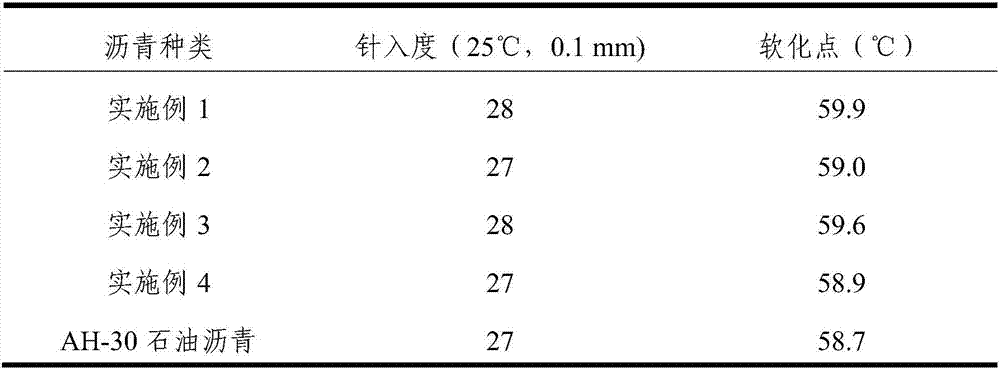

Biological asphalt and preparation method thereof

InactiveCN107916122AWide variety of sourcesLow costWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by thermal meansInorganic saltsDistillation

The invention relates to biological asphalt and a preparation method thereof. The preparation method comprises steps as follows: 1) inorganic salt is blended in biological oil and mixed uniformly; crude glycerin is added, and the mixture is mixed uniformly; 2) a product obtained in the step 1) is distilled under the normal pressure, and light components and mixed components comprising glycerin andlignin pyrolysis products are separated; 3) water is added to the mixed components, the mixture is mixed uniformly, left to stand and filtered, a water-glycerin mixed phase is removed, and a crude lignin pyrolysis product is obtained; 4) the crude lignin pyrolysis product is heated to the constant weight state, and the biological asphalt is obtained; the water-glycerin mixed phase is distilled under the normal pressure, and separated glycerin is recycled. The lignin pyrolysis product can be effectively separated through pretreatment of biomass pyrolysis oil, and meanwhile, the separation process of conventional distillation is improved, so that the asphalt components in the biomass pyrolysis oil can be sufficiently separated and have excellent usability and ageing resistance.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

Chemical synthesis method of biological asphalt for roads

InactiveCN111635637AEasy to useThe synthesis process is simpleBuilding insulationsChemical synthesisOrganic solvent

The invention discloses a chemical synthesis method of biological asphalt for roads, relates to a preparation method of biological asphalt for roads, and aims to solve the problem of poor use performance of existing biological asphalt. The chemical synthesis method comprises the following steps: 1, mixing bio-oil and an organic solvent according to a mass ratio of 1:1-3, and stirring the substances uniformly to completely dissolve the bio-oil in the organic solvent to obtain a bio-oil solution; 2, adding an initiator into the bio-oil solution to obtain a mixed solution; 3, adding an accelerantsolution into the mixed solution, and stirring the substances uniformly to obtain a reaction solution; and 4, carrying out reaction for 2-8h at a temperature of 85-130DEG C to obtain the biological asphalt for roads. According to the invention, the initiator and the accelerant are added to realize free radical polymerization of the bio-oil with a small molecular weight into long-chain molecules,so that the viscosity of the bio-oil and the adhesiveness between the bio-oil and mineral aggregates are increased, the synthesis process is simple, and the prepared bio-asphalt meets the use performance of asphalt for roads.

Owner:HARBIN INST OF TECH

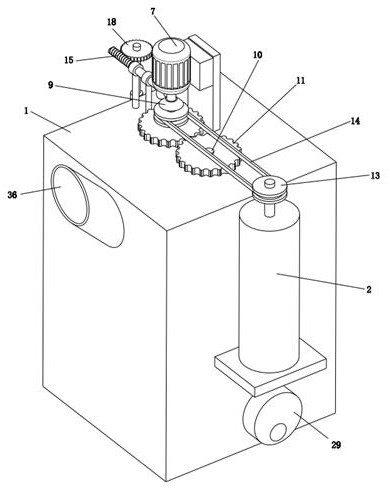

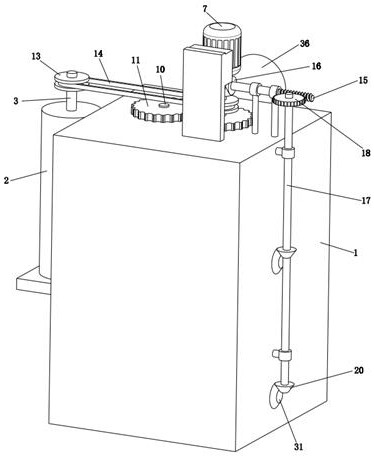

Agricultural biomass material recovery equipment based on environment-friendly biological asphalt

InactiveCN113973591AAchieve the effect of crushing and grinding materialsReasonable structural designGas current separationRenewable energy machinesAgricultural engineeringBiology

The invention discloses agricultural biomass material recovery equipment based on environment-friendly biological asphalt, relates to the technical field of renewable energy equipment, and aims to solve the problems that existing biomass material recycling equipment cannot finely grind materials, cannot screen the materials and cannot secondarily grind large-particle materials, the subsequent process is influenced, ground materials cannot be automatically conveyed, the using effect is poor, and the working efficiency is low. According to the scheme, the equipment comprises a box body, the front side of the box body is fixedly communicated with a feeding pipe, and one side of the box body is fixedly communicated with a first conveying barrel. The equipment is reasonable in structural design and easy to operate, materials can be finely ground, the materials can be screened, large material particles can be secondarily ground, the ground materials can be automatically conveyed, the using effect is good, and the working efficiency is high.

Owner:江苏融道复合材料产业技术研究院有限公司

A self-adhesive modified asphalt coating material and its preparation method and modified asphalt waterproof membrane

ActiveCN109971192BGood adhesionImprove initial tackBuilding insulationsBituminous waterproofingAdhesive

The invention discloses a self-adhesive modified asphalt coating material, a preparation method thereof and a modified asphalt waterproof coiled material. The self-adhesive modified asphalt coating material includes: 20-70 parts by weight of high-grade petroleum asphalt, 5-30 parts by weight of polymer modifier, 5-30 parts by weight of rubber powder, 5-40 parts by weight of filler, 5 parts by weight of bio-asphalt ‑50 parts by weight; the high-grade petroleum asphalt is selected from at least one of the 110‑200# petroleum asphalt; the source of the biological asphalt is a plant resource. The invention can significantly improve the initial tack at low temperature and normal temperature; can significantly improve the bonding performance of self-adhesive bitumen waterproof membrane; can improve heat resistance; after thermal aging, the bonding performance can be kept significantly improved, and the Due to its good adhesion to the base layer, the failure mode is cohesive failure.

Owner:广东东方雨虹建筑材料有限公司

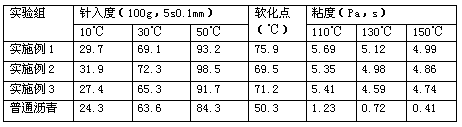

Sludge biological asphalt and preparation method thereof

ActiveCN113214668ARealize resource utilizationReduce dependenceBuilding insulationsSludgeReaction temperature

The invention discloses a sludge biological asphalt and a preparation method thereof. The preparation method comprises the following steps: (1) adding dried sludge and alcohol in a weight ratio of 1: (10-20) into a reaction kettle, stirring and heating, reacting for 30-120 minutes under the conditions that the reaction temperature is 265-300 DEG C and the reaction pressure is 5-11 MPa, and cooling to obtain a reaction mixture; (2) carrying out solid-liquid separation on the reaction mixture to obtain a solid and a mother solution; (3) concentrating the mother solution to obtain sludge heavy oil; (4) mixing the sludge heavy oil with petroleum asphalt to obtain sludge biological asphalt; wherein the weight ratio of the sludge heavy oil to the petroleum asphalt is (5-30): (70-95). The sludge biological asphalt prepared by the preparation method disclosed by the invention is relatively good in performance.

Owner:CHONGQING JIAOTONG UNIVERSITY

A kind of waste oil-based modified bio-asphalt, bio-asphalt mixture and preparation method thereof

ActiveCN106519715BSatisfy the use effectReduce manufacturing costBuilding insulationsLow-density polyethyleneBiodiesel

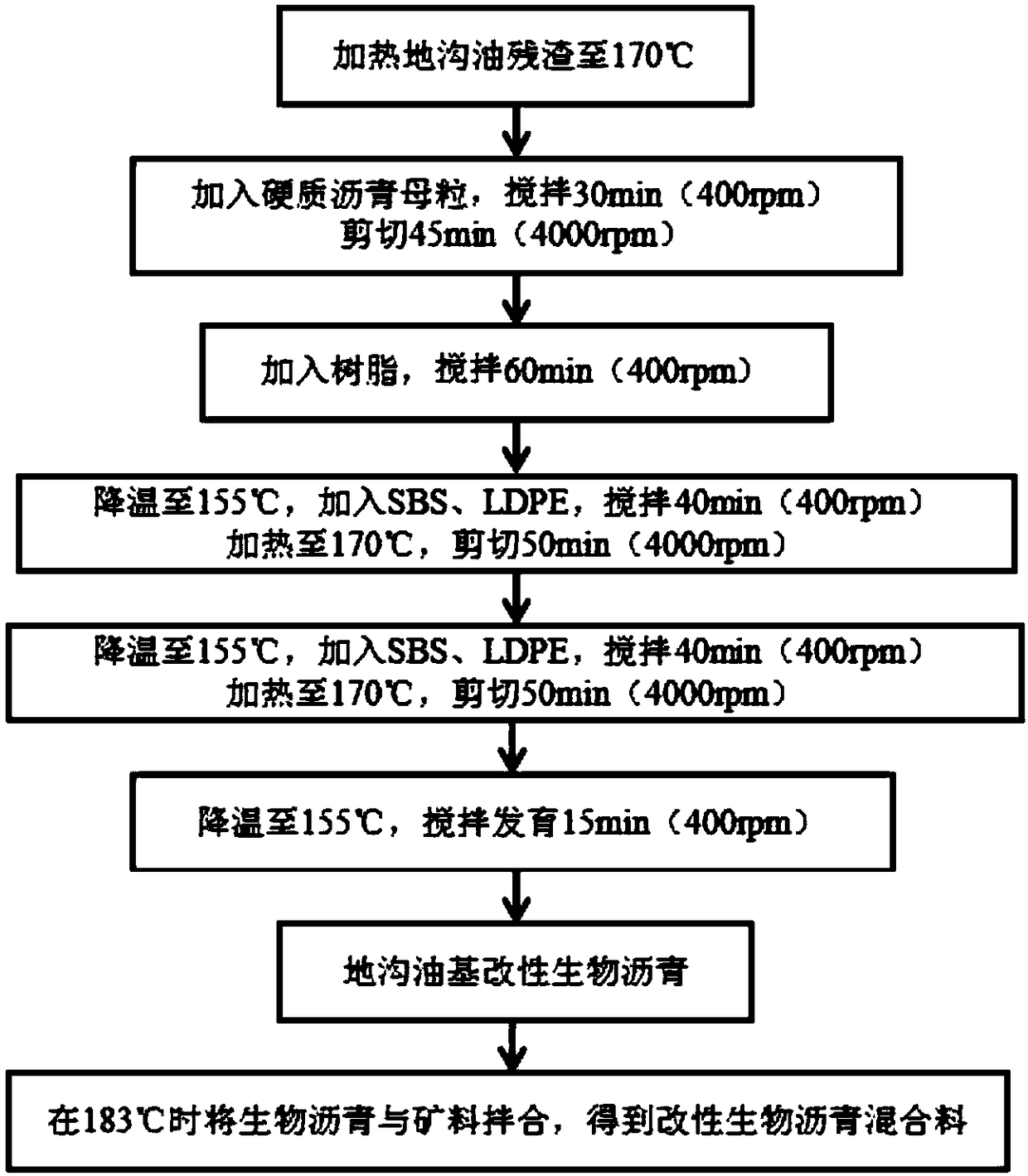

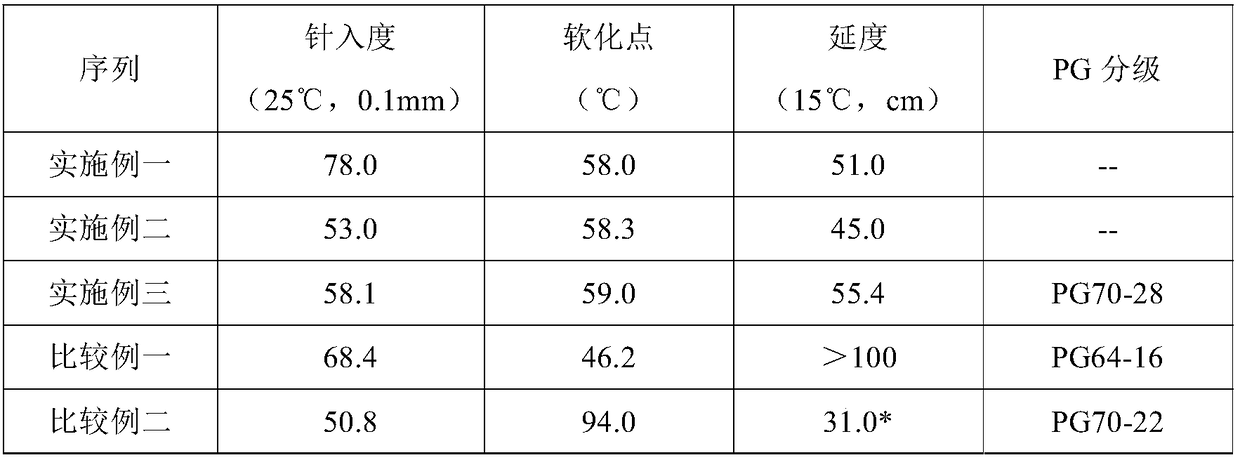

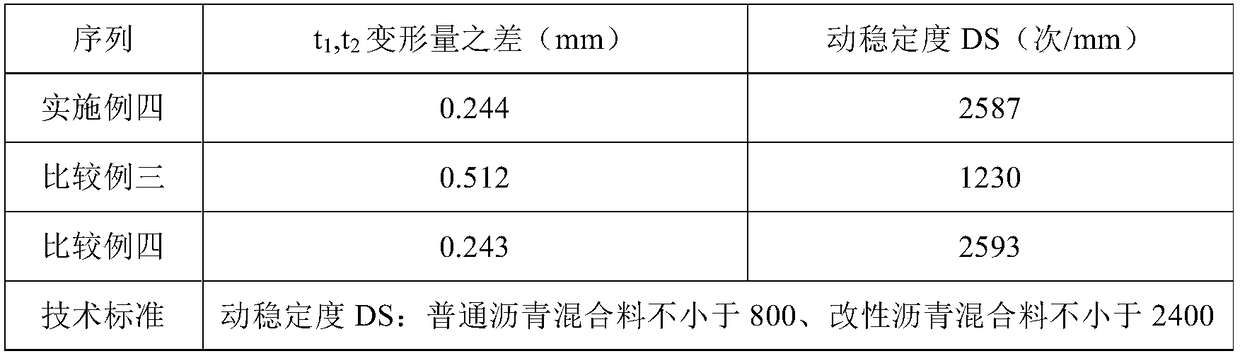

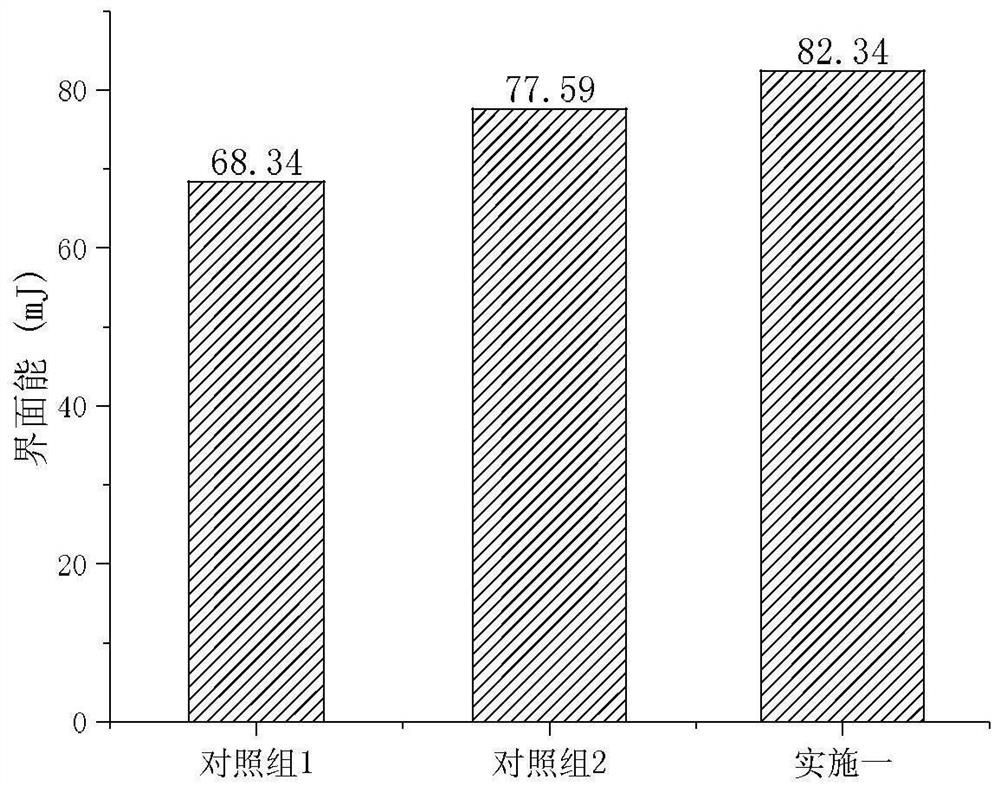

The invention relates to highway pavement materials, and discloses to swill-cooked dirty oil based modified biological asphalt, a biological asphalt mixture and a preparation method thereof. The modified biological asphalt material comprises the following components in percentage by mass: 33.3-38% of swill-cooked dirty oil residues, 28.6-33.8% of hard asphalt particles, 26.5-34% of resin, 1.2-4.6% of low-density polyethylene (LDPE) reprocessed plastics, and 3-5% of linear SBS (Styrene Butadiene Styrene). The preparation method comprises the following steps: heating the swill-cooked dirty oil residues to be 170 DEG C; uniformly adding the hard asphalt particles; stirring for 30 minutes; shearing for 45 minutes (4000r / min) until the swill-cooked dirty oil residues and the hard asphalt particles are uniformly compatible; uniformly adding the resin; stirring for 60 minutes until the mixture is uniform; cooling until the temperature reaches 155 DEG C; adding SBS and LDPE; continuously stirring and swelling for 40 minutes; shearing for 50 minutes (increasing the temperature to be 170 DEG C, shearing at the speed of 4000r / min); and then stirring to develop for 15 minutes (decreasing the temperature to be 155 DEG C). According to the method, a novel method for directly utilizing the residues obtained after extracting biodiesel from waste grease and reprocessed plastics is provided, and thus a new way is developed for energy conservation and waste recycling.

Owner:TONGJI UNIV

Environment-friendly warm mix asphalt regenerant and preparation method thereof

The invention relates to an environment-friendly warm-mix asphalt rejuvenator and a preparation method thereof. The invention belongs to the field of road engineering and aims to solve the problems of poor diffusion effect of existing asphalt rejuvenator materials and high mixing temperature. Preparation method: 1. Weigh bio-asphalt, epoxidized soybean oil, curing agent, straw fiber and epoxy resin as raw materials; 2. Put bio-asphalt in the raw material in a reactor, add curing agent, Stir evenly at high temperature to obtain a mixture, add epoxidized soybean oil in the raw material, stir at a temperature of 50-60°C, add straw fiber, and continue stirring at a temperature of 50-60°C to obtain an effective component of the regenerant; The effective components of the agent are mixed with the epoxy resin in the raw material. The invention adopts bio-asphalt and other effective components to restore the performance of aged asphalt, enhances the diffusion effect through epoxy soybean oil, and realizes the warm-mix production of recycled asphalt mixture, and the production process is simple and energy-saving.

Owner:HARBIN INST OF TECH

Environment-friendly epoxy bio-asphalt material for road and preparation method thereof

ActiveCN108440981BImprove high temperature performanceGood compatibilityBuilding insulationsEnvironmental resource managementFirming agent

The invention relates to a highway environment-friendly epoxy biological asphalt material and a preparation method thereof, in particular to an epoxy biological asphalt material to repair a pavement and a preparation method thereof in order to solve the problem that existing biological asphalt materials have difficulty in balancing high- and low-temperature properties. The highway environment-friendly epoxy biological asphalt material is made from, by weight, 100 parts of biological asphalt, 35-60 parts of a curing agent, 1-2 parts of a strong base, 0.5-1 part of a defoaming agent, and 20-34 parts of epoxy resin. The preparation method includes: I, mixing the biological asphalt, the curing agent, the strong base and the defoaming agent to obtain biological asphalt mixture; II, mixing the epoxy resin with the biological asphalt mixture. The combination of the biological asphalt with the epoxy resin herein can balance the high- and low-temperature properties; the cured cross-linked epoxyresin is used to improve the high-temperature performance; the biological asphalt is used to fill the epoxy resin to provide toughening and to improve low-temperature performance; the curing time ofthe combination is well controlled, so that quick pavement repairing is achieved.

Owner:HARBIN INST OF TECH

A kind of sawdust biomass fuel and preparation method thereof

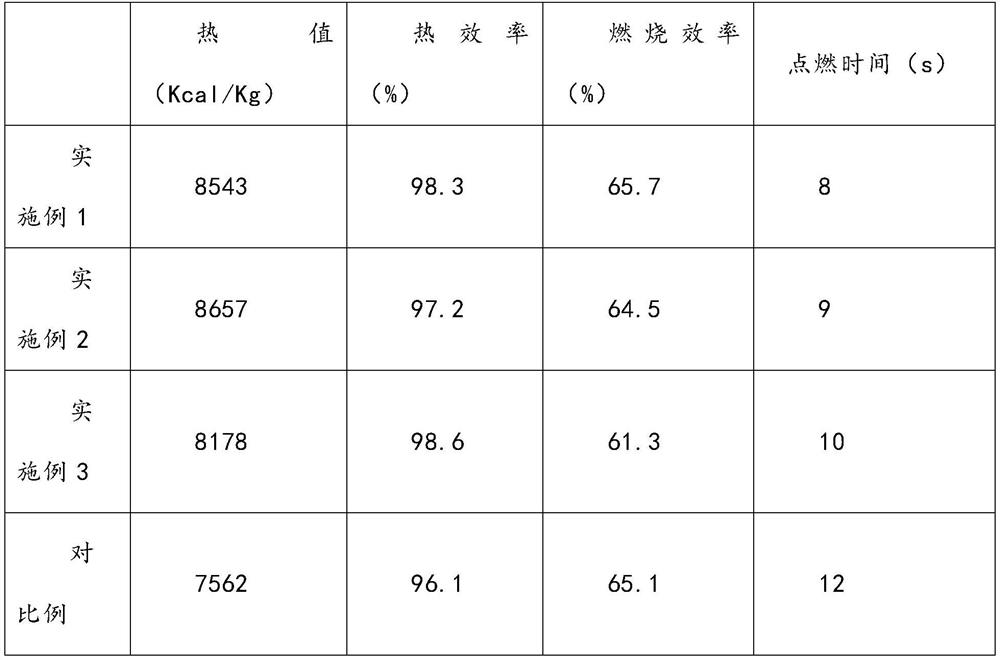

ActiveCN108517235BLow ignition temperatureImprove stabilityBiofuelsSolid fuelsCellulosePulp and paper industry

The invention discloses a sawdust biomass fuel, which comprises the following raw materials in parts by weight: 60 parts of wood chips, 14 parts of additives, 6 parts of attapulgite powder, 4 parts of rare earth minerals, 2 parts of oxygen enhancer, and 0.3 parts of oxygen increase synergist , 8 parts of biological asphalt, 3.5 parts of blue-green algae mud, 1.5 parts of ammonium sulfate, and the auxiliary agent is polyanionic cellulose. The wood chip biomass fuel prepared by the present invention has high combustion efficiency, good stability, is not easy to be oxidized, can be fully burned, and can reduce the generation of harmful gases. The optimal ratio is obtained, and then the wood chip biomass fuel has the best performance, high use value and good application prospect.

Owner:深圳市泓丰科技有限公司

Sludge biological asphalt and preparation method thereof

The preparation method comprises the following steps: (1) adding dried sludge and alcohol in a weight ratio of 1:(10-20) into a reaction kettle, stirring and heating the components, reacting for 30-120 minutes at the temperature of 265-300 DEG C and the pressure of 5-11 MPa, and cooling the reaction product to obtain a reaction mixture; (2) carrying out solid-liquid separation on the reaction mixture to obtain a solid and a mother solution; (3) concentrating the mother liquor to obtain sludge heavy oil; (4) mixing the sludge heavy oil with petroleum asphalt to obtain sludge biological asphalt, wherein the weight ratio of the sludge heavy oil to the petroleum asphalt is (5-30) : (70-95). The sludge biological asphalt prepared by the preparation method disclosed by the invention is relatively good in performance.

Owner:CHONGQING JIAOTONG UNIVERSITY

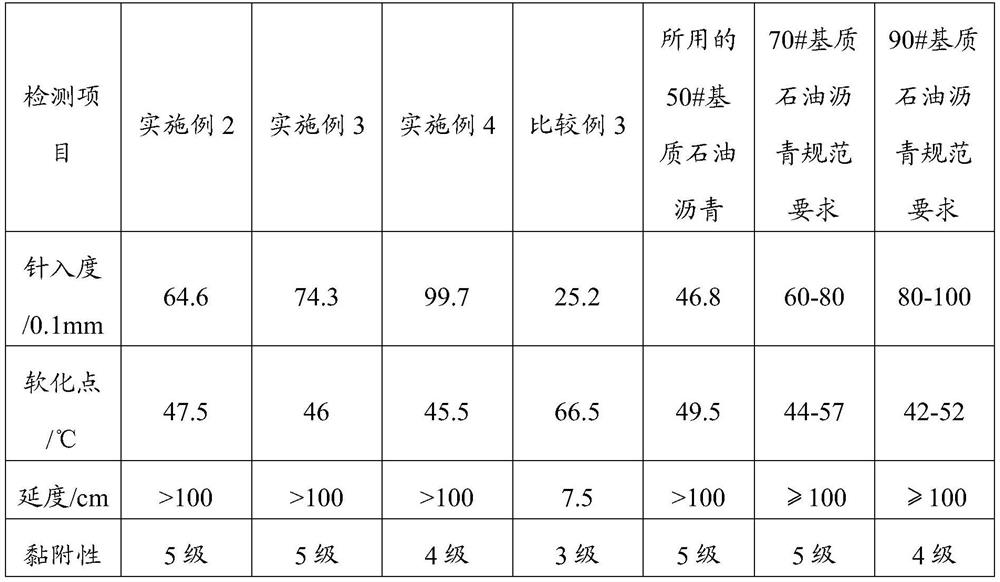

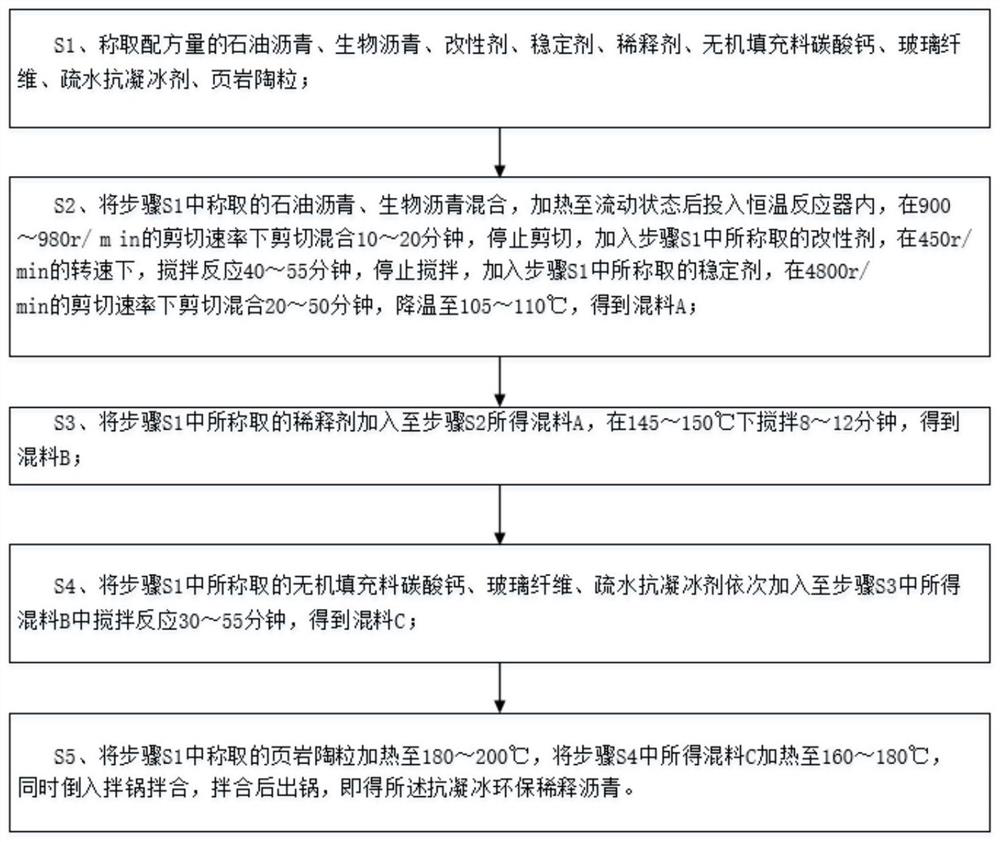

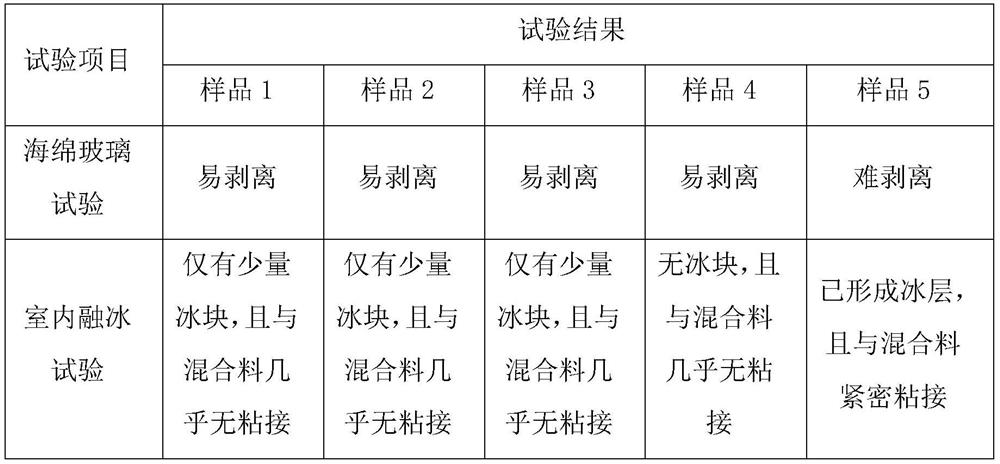

Anti-freezing environment-friendly diluted asphalt and preparation method thereof

InactiveCN112521760AImprove ductilityAvoid driving safetyBuilding insulationsGlass fiberEnvironmental engineering

The invention discloses anti-freezing environment-friendly diluted asphalt and a preparation method thereof. The anti-freezing environment-friendly diluted asphalt is prepared from the following raw materials in parts by weight: 50 to 80 parts of petroleum asphalt, 12 to 35 parts of biological asphalt, 10 to 26 parts of a modifier, 3 to 12 parts of a stabilizer, 25 to 58 parts of a diluent, 14 to25 parts of an inorganic filler calcium carbonate, 14 to 25 parts of glass fibers, 6 to 20 parts of a hydrophobic anti-freezing agent and 8 to 21 parts of shale ceramsite. The anti-freezing environment-friendly diluted asphalt of the invention solves the problems of weak high-temperature performance and strong temperature sensitivity of existing biological asphalt, high price of traditional road asphalt and the like in the prior art, has excellent high / low temperature resistance, skid resistance, wear resistance and aging resistance, does not flow at high temperature, has improved flexibilityat low temperature and favorable ductility, and can effectively overcome the problem that traditional diluted asphalt is easily limited by seasons, weather and temperature in the construction process.

Owner:上海雁岛实业有限公司

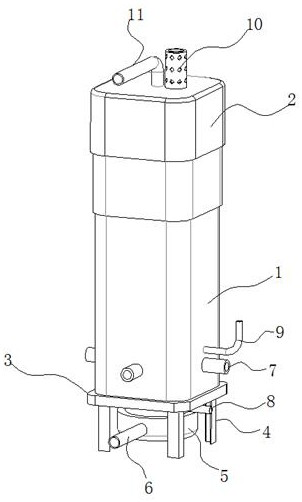

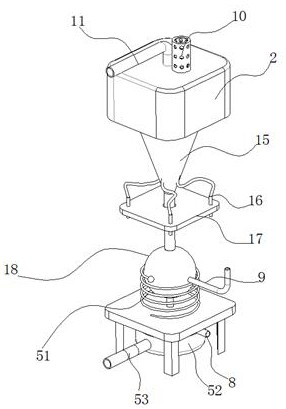

High-temperature cracking equipment for biological asphalt material

InactiveCN113684050AReduce energy consumptionEvenly heatedLiquid hydrocarbon mixture productionInsulation layerHigh energy

The invention belongs to the technical field of biological asphalt, and particularly relates to high-temperature cracking equipment for a biological asphalt material. Aiming at the problems of low heat efficiency and high energy consumption, the high-temperature cracking equipment comprises a lower tray, a furnace body main body structure is arranged on the outer wall of the top of the lower tray, and brackets are arranged at four corners of the bottom end of the lower tray; and the furnace body structure comprises an upper furnace body, a lower furnace body, a shell and a furnace cover, a heat insulation plate is arranged between the upper furnace body and the lower furnace body, the shell is connected to the outer wall of the upper furnace body and the outer wall of the lower furnace body in a sleeving mode, and heat insulation layers are arranged between the shell and the upper furnace body and between the shell and the lower furnace body. The vertical structure is adopted, the funnel-shaped heavy material liquid separation hopper enables heavy materials to be layered through the temperature difference from bottom to top, the lower sphere is evenly heated through the burners on the four sides, heat conduction is fast, heating is even, the waste heat recovery structure is used for maintaining layering of the heavy materials, heavy material separation is clearer, and it is guaranteed that heat efficiency is improved, and energy consumption is reduced.

Owner:江苏融道复合材料产业技术研究院有限公司

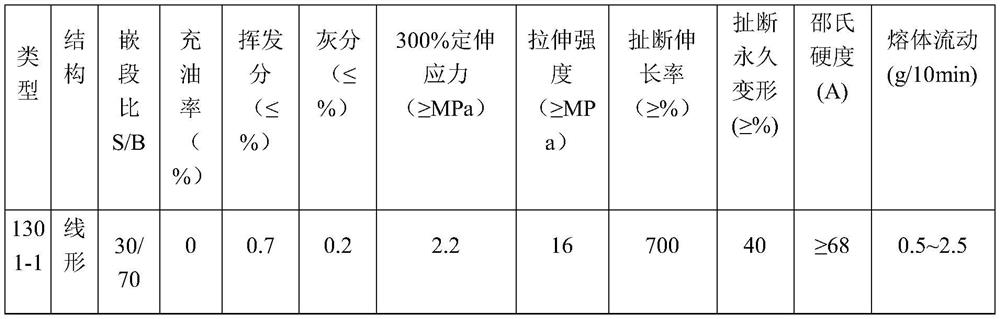

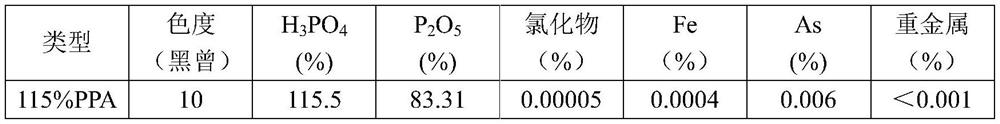

Biological asphalt, SBS and PPA composite modified asphalt and preparation method thereof

PendingCN114773868AGood compatibilityReduce dosageBuilding insulationsPolymer scienceButadiene Dioxide

The invention discloses biological asphalt, SBS (styrene-butadiene-styrene) and PPA (phenyl-propanolamine) composite modified asphalt. The composite modified asphalt is prepared from the following components in parts by mass: 50 to 99 parts of petroleum asphalt, 1 to 50 parts of biological asphalt, 1 to 6 parts of styrene-butadiene-styrene block copolymer, 0.01 to 0.02 part of stabilizer and 0.1 to 3 parts of polyphosphoric acid. The invention also discloses a preparation method of the biological asphalt, SBS and PPA composite modified asphalt. The preparation method is specifically implemented according to the following steps: step 1, heating, mixing and shearing the petroleum asphalt and the biological asphalt; step 2, adding a styrene-butadiene-styrene block copolymer into a product obtained in the step 1, and shearing and stirring; step 3, adding a stabilizer into a product obtained in the step 2, and shearing and stirring; and step 4, adding polyphosphoric acid into the product obtained in the step 3, and shearing and stirring.

Owner:GUANGXI UNIV

Lignin-based bio-asphalt

InactiveUS20200277496A1Low usageIncrease independenceBuilding insulationsPolymer scienceVegetable oil

A composition includes bitumen; optionally vegetable oil or derivative thereof; and a lignin preparation, where the lignin preparation has a lignin purity of 60-100 wt. % with respect to the weight of the lignin preparation; and a lignin average molecular weight of 1000-5000 g / mol. The composition may be an asphalt binder composition or asphalt composition. A method of paving or roofing includes use of this composition. Further, a method of preparing an asphalt composition, includes mixing bitumen with filler material, adding lignin preparation and vegetable oil to the mixture obtained. The lignin preparation and the vegetable oil may be added simultaneously.

Owner:STICHTING WAGENINGEN RES +1

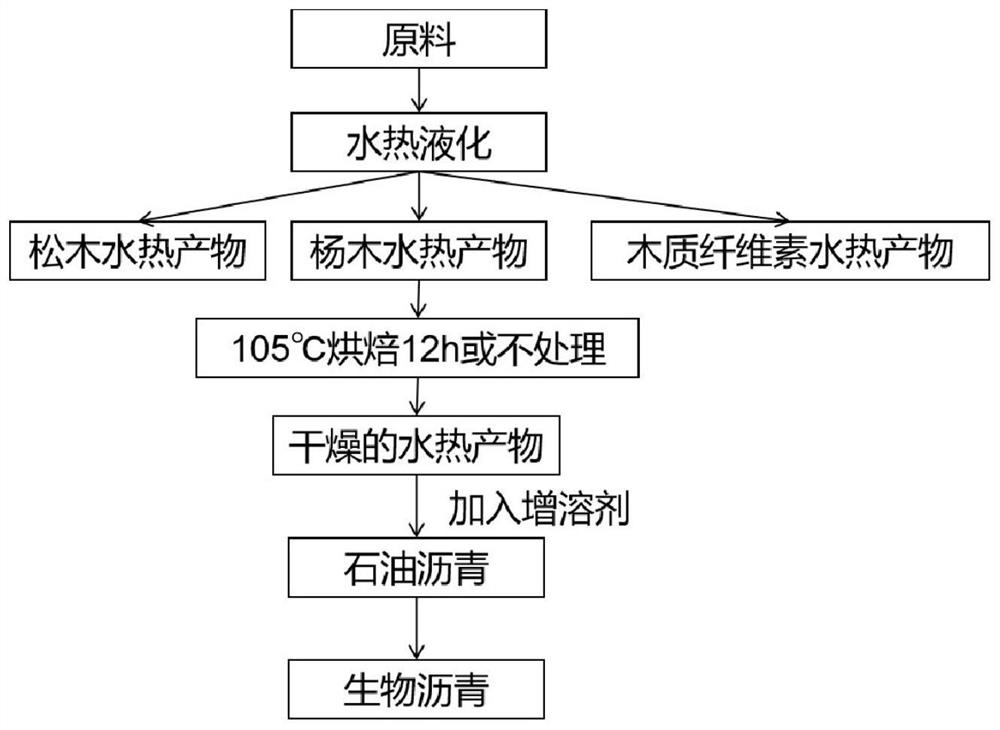

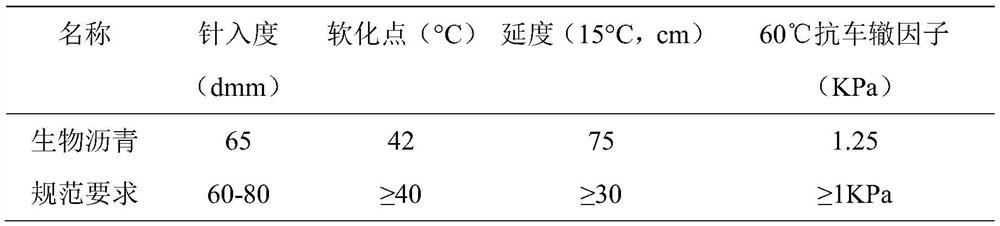

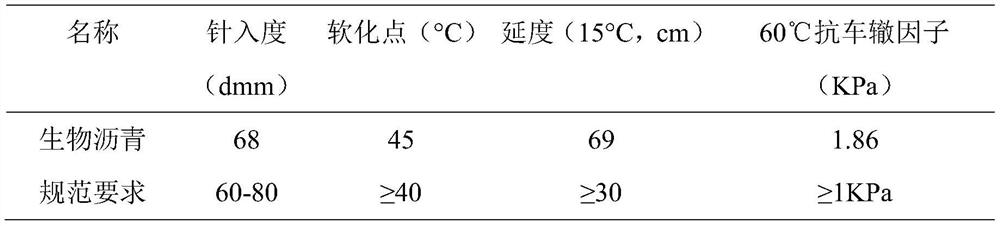

High-value utilization of wood-based biomass and application of wood-based biomass in preparation of biological asphalt

PendingCN114015463AImprove the utilization rate of solid waste resourcesEasy to applyBiofuelsSpecial form destructive distillationEnvironmental engineeringHydrothermal liquefaction

The invention discloses high-value utilization of wood-based biomass and application of the wood-based biomass in preparation of biological asphalt. According to the method, the wood-based biomass is subjected to hydrothermal liquefaction to prepare bio-oil and biochar, and then the bio-oil and the biochar are used for partially replacing petroleum asphalt to prepare the bio-asphalt. The high-value utilization of the wood-based biomass has the characteristics that the bio-oil yield is high, the ratio of the bio-oil to the biochar can be controlled by hydrothermal conditions, the bio-oil and the biochar can be utilized in a gradient manner, and the wood-based biomass is green, environment-friendly, renewable and the like. The wood-based biological asphalt prepared by the method has the advantages of high solid waste resource utilization rate, capability of partially replacing petroleum asphalt and capability of reducing environmental pollution and energy consumption. The biological asphalt can meet the use requirements of road pavement, negative carbon emission of a biomass hydrothermal product in the whole life cycle is realized, the use pressure of petroleum asphalt is greatly relieved, forestry waste is fully utilized, emission of volatile organic compounds of the asphalt is reduced, and remarkable economic and social benefits are generated.

Owner:山西省交通科技研发有限公司

A method for preparing bio-asphalt from lignocellulosic biomass hydrothermal charcoal

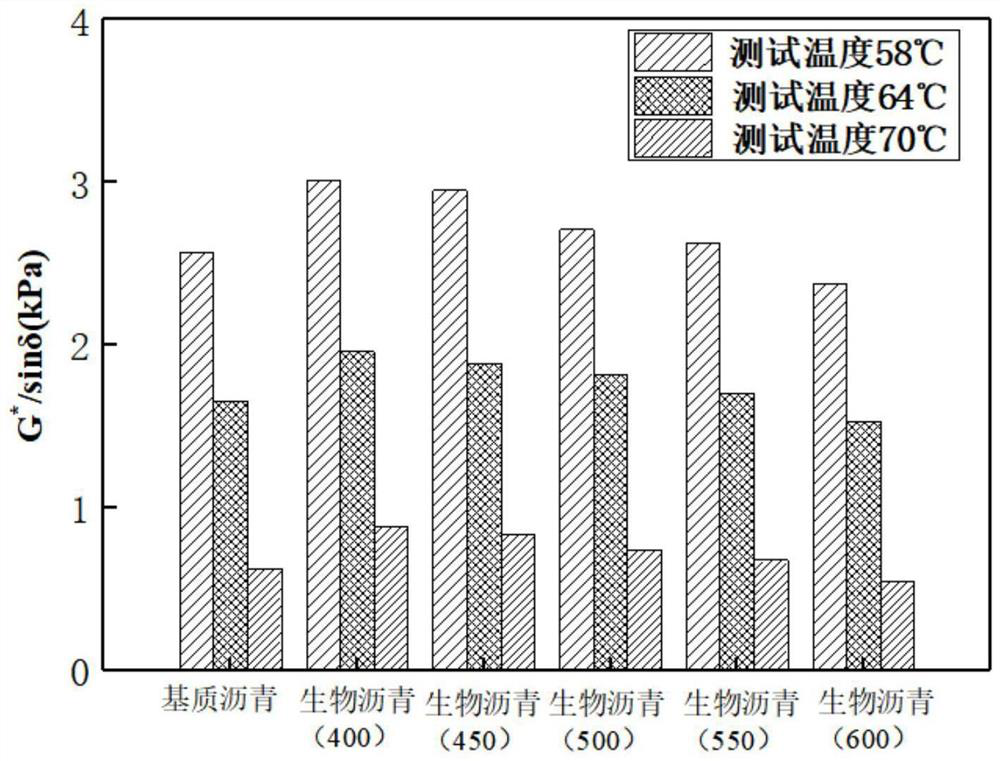

ActiveCN111019365BImprove high temperature performanceSimple processCarbon preparation/purificationBuilding insulationsEnvironmental engineeringLignocellulosic biomass

The invention provides a method for preparing bio-asphalt from lignocellulosic biomass hydrothermal charcoal. The invention uses lignocellulosic biomass as raw material, utilizes hydrothermal carbonization technology to prepare hydrothermal charcoal, and then combines it with matrix asphalt to prepare bio-asphalt. Asphalt technology. Biomass includes corn stover, rice straw or wheat straw etc. During the reaction process, the mixture of biomass and water is hydrothermally carbonized at a certain temperature and pressure to form hydrothermal charcoal, which is then combined with asphalt through high-speed shearing to prepare bio-asphalt. The process of the invention is simple, the hydrothermal carbon modifier is well combined with the asphalt, the high temperature performance of the asphalt is improved, and a novel and sustainable method is provided for the improvement of asphalt materials and the utilization of biomass resources.

Owner:FUDAN UNIV

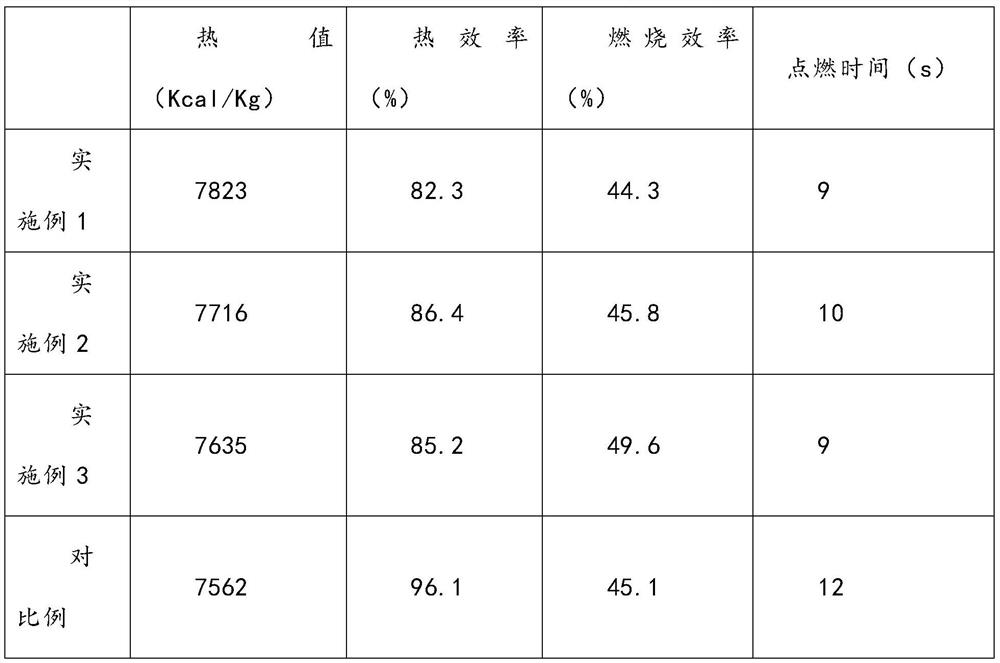

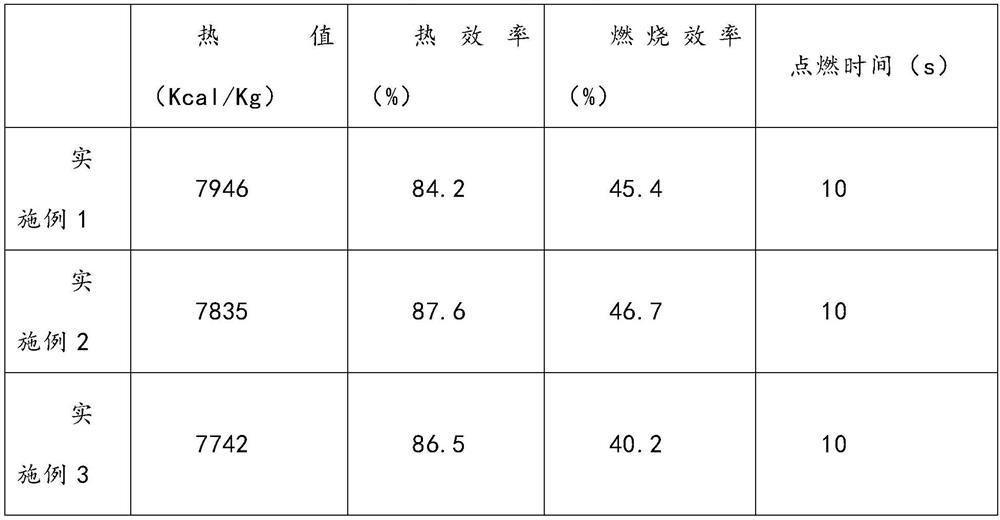

Using tanning waste to synergize wood chip biomass fuel and its preparation method

ActiveCN108485744BTo achieve the purpose of useLarge heat releaseSolid fuelsWaste based fuelCellulosePulp and paper industry

The invention discloses a synergistic sawdust biomass fuel utilizing tanning waste, comprising the following parts by weight: 58-64 parts of raw wood chips, 10-15 parts of chrome-containing leather chips, 12-16 parts of polyanionic cellulose, and 4-4 parts of attapulgite powder 8 parts, 3-5 parts of bastnaesite, 1-3 parts of oxygen enhancer, 0.2-0.5 parts of oxygen-enhancing synergist, 6-10 parts of bio-asphalt, 2-5 parts of cyanobacteria algae mud, 1-2 parts of ammonium sulfate Parts and 3~5 parts of substance A. The chromium-containing leather shavings of the present invention release a large amount of heat during the combustion process, and the wood chips and chromium-containing leather shavings are used to coordinate and match. With the combination of oxygen-increasing synergist and substance A, it releases a large amount of heat, and the hexavalent chromium Ions are not detected, and the purpose of waste utilization is achieved without secondary pollution.

Owner:山东仁合新材料科技有限公司

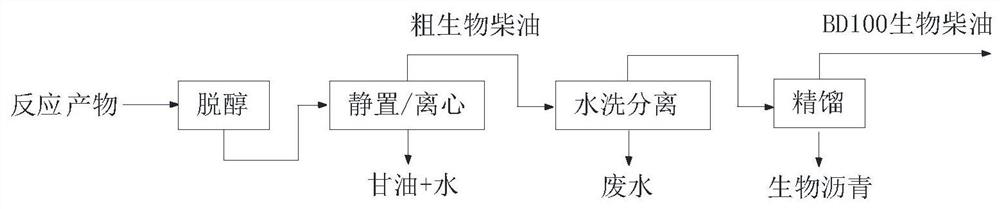

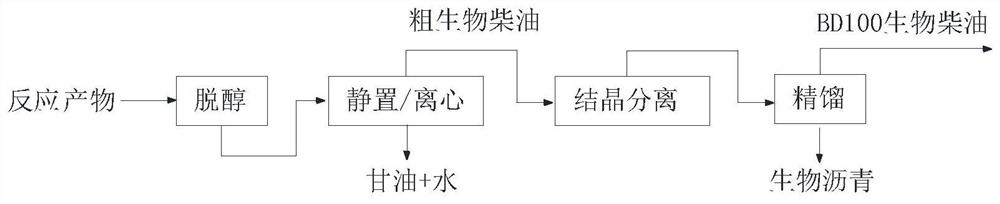

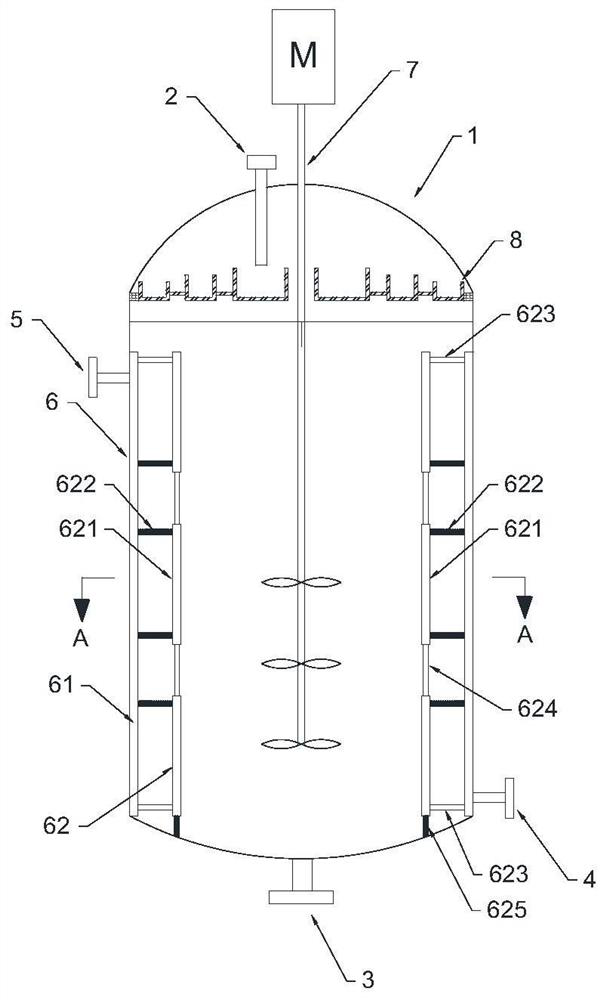

Crude biodiesel refining method

ActiveCN113828002AReduce contentSimple processBiofuelsLiquid carbonaceous fuelsBiodieselPtru catalyst

The present invention provides a novel crude biodiesel refining method, which comprises: placing crude biodiesel in a crystallizer, adding a conditioning agent, and uniformly conducting mixing; conducting cooling to a cooling crystallization temperature from room temperature at a certain cooling rate, and maintaining a certain crystallization time; allowing glycerin, a catalyst, residual soap and other impurities to be separated out in a solid phase mode and attached to the wall face of the cooling structure of a crystallizer; and introducing biodiesel existing in a liquid phase form into a rectifying tower, and obtaining refined biodiesel at the top of the tower. According to the refining method, a non-polar solvent is added, the content of residual impurities such as glycerin, a catalyst and residual soap in the crude biodiesel is greatly reduced through cooling crystallization, and standard requirements are met through further rectification; a washing process is not needed, and wastewater discharge is avoided; control of a high-vacuum rectification process is facilitated, the separation load of the rectification process is reduced, and the service life of filler in a rectification tower is prolonged; and meanwhile, the quality of the biological asphalt as a byproduct is improved.

Owner:上海中器环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com