Preparation method of modified biological asphalt, modified biological asphalt and use thereof

A bio-asphalt and modification technology, applied in building structures, building components, building insulation materials, etc., can solve the problems of non-homogeneous, complex composition of bio-asphalt, easy to hard and brittle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-R

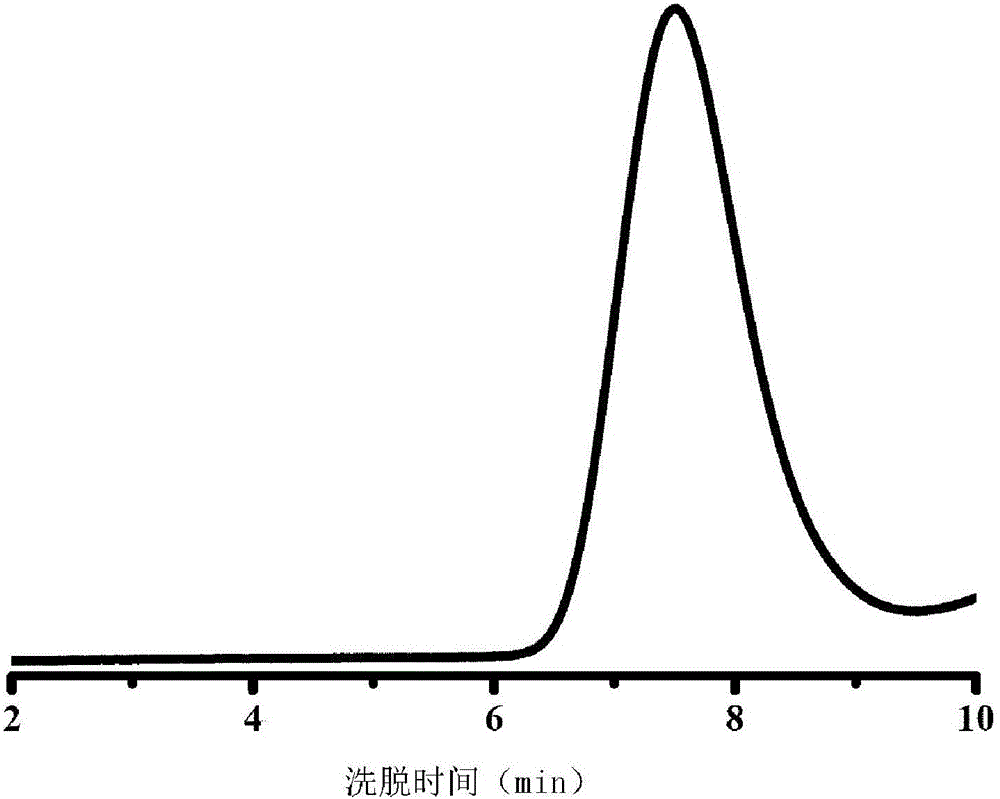

[0035] Embodiment 1-RAFT homogeneous polymerization

Embodiment 1a

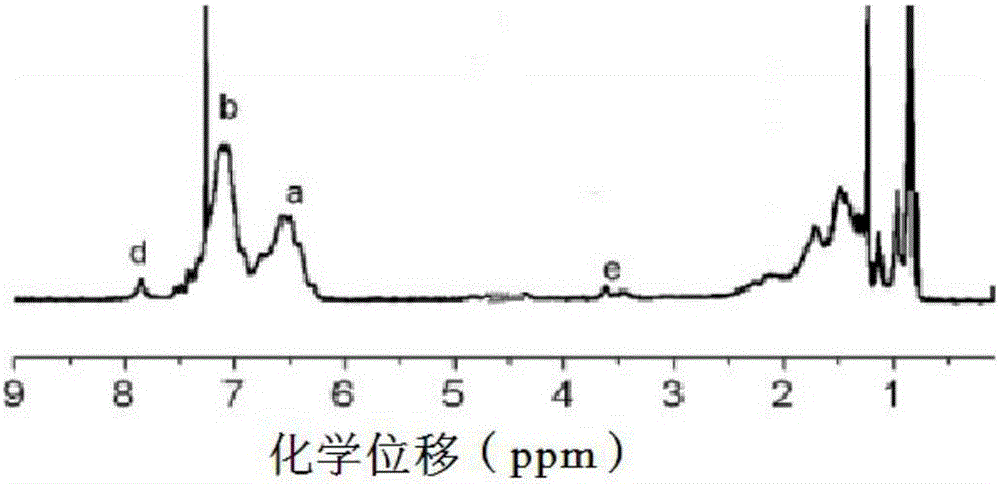

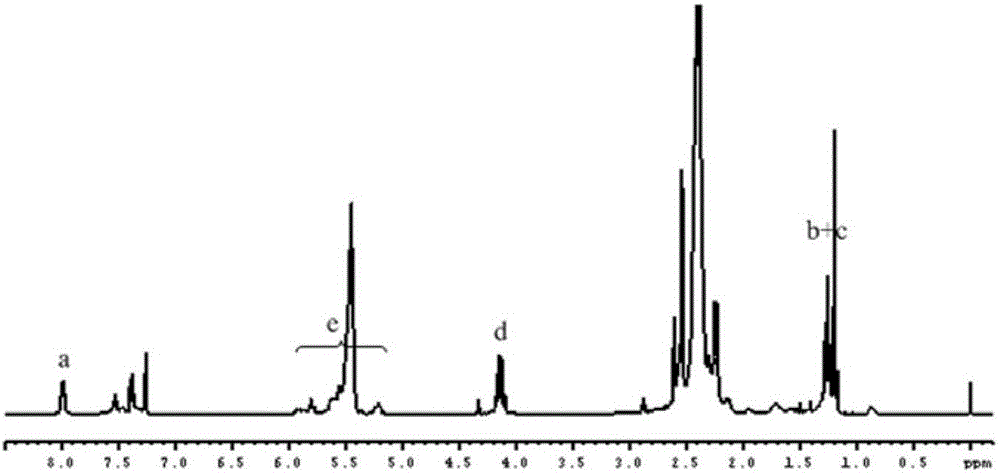

[0036] Example 1a - RAFT Homogeneous Polymerization of Monomer Styrene (St)

[0037] According to the ratio ([St]: [RAFT]: [initiator] = 450 ~ 5000: 3 ~ 5: 1), add styrene monomer into the single-branched round bottom reaction flask, as the 2-ethoxylate of RAFT reagent Carbonylpropane-2-dithiobenzoate (EPDTB), azo initiators (azobisisobutyrocyanide [AIBN] / azobisisoheptylcyanide [ABVN]), benzene solvents (benzene / toluene / xylene), magnetic stirring to dissolve. In the polymerization, the ratio of molar concentration of styrene monomer to RAFT reagent is (150-1000:3-5), and the ratio of molar concentration of RAFT reagent to initiator is (3-5:1). Place in frozen ice brine and bubble with argon for 10 minutes to remove oxygen in the system, seal, vacuumize, and replace with argon for 5 times. Under the condition of avoiding light, react at a constant temperature in an oil bath at 50-100°C. React until the molecular weight of polystyrene reaches 15,000-100,000, then add frozen ...

Embodiment 1

[0038] Example 1b - RAFT Homogeneous Polymerization of Monomer Chloroprene (CP)

[0039] Add chloroprene monomer according to the ratio ([CP]:[RAFT]:[initiator]=450~5000:3~5:1) in the single-branch round bottom reaction flask, as the 2- Ethoxycarbonylpropane-2-dithiobenzoate (EPDTB), azo initiators (azobisisobutyrocyanide [AIBN] / azobisisoheptylcyanide [ABVN]), benzene solvents (benzene / toluene / xylene), magnetic stirring to dissolve. In the polymerization, the ratio of molar concentration of chloroprene monomer to RAFT reagent is (150-1000:3-5), and the ratio of molar concentration of RAFT reagent to initiator is (3-5:1). Place in frozen ice brine and bubble with argon for 10 minutes to remove oxygen in the system, seal, vacuumize, and replace with argon for 5 times. Under the condition of avoiding light, react at a constant temperature in an oil bath at 50-100°C. React until the molecular weight of polychloroprene reaches 15,000-100,000, then add frozen petroleum ether to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com