Method for preparing biological asphalt from lignocellulose biomass hydrothermal carbon

A technology of lignocellulose and bio-asphalt, which is applied in the field of environmental protection and comprehensive utilization of resources, can solve the problems of high price of asphalt modifiers, obstacles to resource conservation, and aggravated oil resource dependence on pollution and emissions, so as to improve high-temperature performance, combine The effect of stability and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

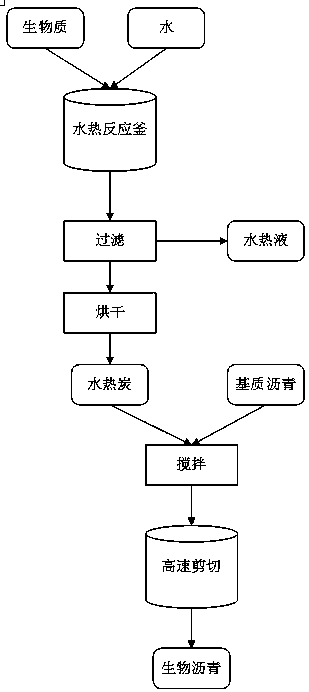

Embodiment 1

[0025] After the corn stalks were dried and crushed into powder, 150g and 2250g of water were placed in a 3L Hastelloy hydrothermal reaction kettle, and heated to 300°C, stirring continuously during the heating process. When the temperature of the mixture reaches the preset value of 300° C., keep the reaction for 1 hour and keep stirring. After the reaction was completed, the temperature was cooled down to room temperature, and the obtained product was separated by filtration. The obtained solid was filtered, dried at 80° C. for 12 hours to remove moisture, and hydrothermal charcoal was obtained. Combine the hydrothermal charcoal obtained above with Shell 70#PEN60 / 70 asphalt to prepare bio-asphalt. The specific steps are as follows: heat the base asphalt to 135°C and slowly pour in hydrothermal charcoal with a mass of 2% and 6% base asphalt respectively , and stirred rapidly for 15 minutes; continue to heat the mixture to 165 ° C, and under the action of a high-speed shear, s...

Embodiment 2

[0030] After the wheat straw was dried, crushed into powder, 100g and 2000g of water were taken and placed in a 3L Hastelloy hydrothermal reaction kettle, and heated to 330°C, stirring continuously during the heating process. When the temperature of the mixture reached the preset value of 330° C., the reaction was kept for 1 hour with constant stirring. After the reaction was completed, the temperature was cooled down to room temperature, and the obtained product was separated by filtration. The obtained solid was filtered, dried at 120° C. for 2 hours to remove moisture, and hydrothermal charcoal was obtained. Combine the hydrothermal charcoal obtained above with Shell 70#PEN60 / 70 asphalt to prepare bio-asphalt. The specific steps are as follows: heat the base asphalt to 130°C, slowly pour in hydrothermal charcoal with a mass of 10% base asphalt, and quickly Stir for 20 minutes; continue to heat the mixture to 170° C., and shear for 40 minutes under the action of a high-spee...

Embodiment 3

[0032] After drying Salix twigs, pulverize them into powder, take 200g and 2000g of water and place them in a 3L Hastelloy hydrothermal reaction kettle, and heat them to 250°C, stirring continuously during the heating process. When the temperature of the mixture reached the preset value of 250° C., the reaction was kept for 5 hours with constant stirring. After the reaction was completed, the temperature was cooled down to room temperature, and the obtained product was separated by filtration. The obtained solid was filtered, dried at 105° C. for 5 hours to remove moisture, and hydrothermal charcoal was obtained. Combine the hydrothermal charcoal obtained above with Shell 70#PEN60 / 70 asphalt to prepare bio-asphalt. The specific steps are as follows: heat the base asphalt to 140°C, slowly pour in hydrothermal charcoal with a mass of 4% base asphalt, and quickly Stir for 10 minutes; continue to heat the mixture to 160°C, and shear for 90 minutes under the action of a high-speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com