Crude biodiesel refining method

A refining method and biodiesel technology, which are applied in the petroleum industry, fractionation, fuel and other directions, can solve the problems of high control precision and control difficulty of vacuum distillation column, biodiesel wastewater discharge, increase difficulty and cost, etc. Control, prolong service life, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

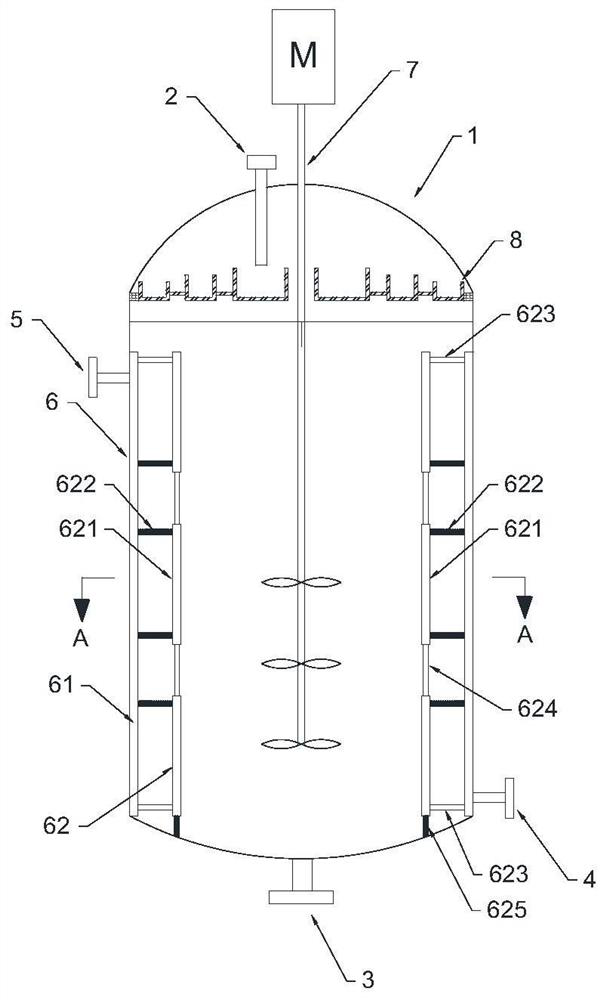

[0040] The invention provides a crystallizer for the cooling crystallization process for refining the crude biodiesel. according to image 3 As shown, the crystallizer includes a crystallizer shell 1, the top of the crystallizer shell 1 is provided with a material inlet 2, and the bottom is provided with a material outlet 3; the lower end of the side wall of the crystallizer shell 1 is provided with a cooling The medium inlet 4, the upper end of the side wall is provided with a cooling medium outlet 5; the inside of the crystallizer shell 1 is provided with a cooling structure 6 that communicates with the cooling medium inlet 4 and the cooling medium outlet 5, and has a sufficient heat exchange area; A mechanical stirring paddle 7 driven by an external motor is installed at the axis of the crystallizer shell 1 for mixing the materials in the crystallizer; the inside of the crystallizer shell 1 is provided with a material distributor 8 below the material inlet 2, It is used to...

Embodiment 2

[0054] Get described crude product biodiesel 1L in the crystallizer described in embodiment 1, add non-polar solvent respectively: normal pentane, cyclopentane, n-butanol, normal hexane and cyclohexane as regulator, the regulation The addition amount of additive is 1.5% of crude product biodiesel quality.

[0055] Set the crystallization temperature of the crystallizer to 10°C, drop the temperature from room temperature 20°C to the crystallization temperature at a cooling rate of 1°C / min, and maintain the crystallization temperature for 30 minutes at a stirring rate of 300rpm. Phase precipitation is attached to the wall of the cooling structure of the crystallizer, and the biodiesel in the liquid phase is separated into solid and liquid and then enters the rectification tower. ℃, the bio-asphalt is extracted from the bottom of the tower as a by-product, and the refined biodiesel is obtained from the top of the rectification tower.

[0056] The content of components in biodies...

Embodiment 3

[0060] Get described crude product biodiesel 1L in the crystallizer described in embodiment 1, and add cyclopentane as regulator, the addition of described cyclopentane is 0.5%-3.0% of crude product biodiesel quality, is respectively 0.5 %, 1%, 1.5%, 2%, and 3%.

[0061] Set the crystallization temperature of the crystallizer to 10°C, drop the temperature from room temperature 20°C to the crystallization temperature at a cooling rate of 1°C / min, and maintain the crystallization temperature for 30 minutes at a stirring rate of 300rpm. Phase precipitation is attached to the wall of the cooling structure of the crystallizer, and the biodiesel in the liquid phase is separated into solid and liquid and then enters the rectification tower. ℃, the bio-asphalt is extracted from the bottom of the tower as a by-product, and the refined biodiesel is obtained from the top of the rectification tower.

[0062] Analysis and determination of impurity content and fatty acid methyl ester conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com