Sludge biological asphalt and preparation method thereof

A bio-asphalt and sludge technology, applied in the direction of building structure, construction, building components, etc., can solve the problem of how to use by-products that are not mentioned, and achieve the effect of realizing resource utilization and alleviating dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

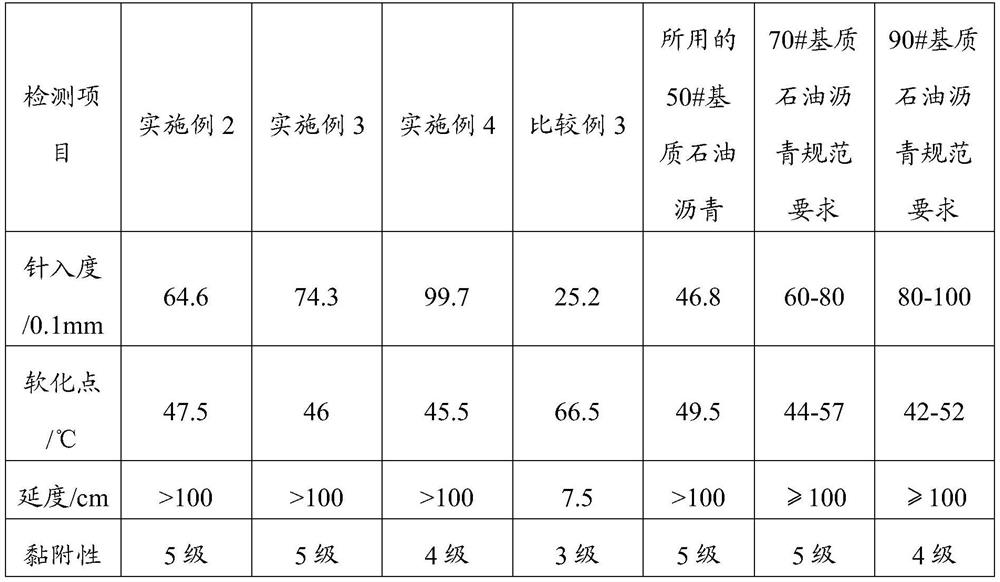

Examples

preparation example Construction

[0028] The preparation method of the sludge bio-asphalt of the present invention comprises the following steps: a sludge drying step; a sludge reaction step; a solid-liquid separation step; a step of obtaining sludge heavy oil; and a mixing step of sludge heavy oil and petroleum asphalt.

[0029]

[0030] The sludge is dried at 100-110°C, preferably, the sludge is dried at 105-110°C. This is beneficial to the reaction of the sludge under alcohol in the next step, and improves the yield of the obtained sludge heavy oil. The prior art usually adopts this kind of sludge mixed with asphalt. In the present invention, it is further processed to improve the performance of sludge bio-asphalt.

[0031]

[0032] Add the dried sludge and alcohol with a weight ratio of 1:10-20 into the reactor, stir and heat, react at a temperature of 265-300°C and a pressure of 5-11MPa for 30-120min, cool down, A reaction mixture is obtained. According to one embodiment of the present invention, 1...

Embodiment 1

[0064] Dry the sludge at 105°C to constant weight;

[0065] Add 40 parts by weight of dried sludge and 600 parts by weight of absolute ethanol into the reactor, seal the device and check the airtightness, then feed nitrogen to replace the air in the reactor, stir and heat, at temperature The temperature was 275°C, the pressure was 9MPa, and the reaction was carried out for 60 minutes, and the temperature was lowered to obtain a reaction mixture;

[0066] The reaction mixture was suction filtered to obtain solid and mother liquor;

[0067] The mother liquor was distilled under reduced pressure with a rotary evaporator, the distillation temperature was 200°C, and the vacuum degree was 0.1MPa. When it was concentrated until almost no distillate was separated, sludge heavy oil (black viscous liquid) was obtained.

Embodiment 2

[0069] The 50# base petroleum asphalt of 95 parts by weight is heated to a flow state at 135° C.;

[0070] Add 5 parts by weight of the sludge heavy oil prepared according to Example 1 to the fluid petroleum asphalt, and shear at a high speed at 135° C., with a shear rate of 2000 rpm and a shear time of 30 minutes, to obtain sludge bioasphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com