Method for preparing catalytically hydrogenated biological asphalt

A bio-asphalt and catalytic hydrogenation technology, which is applied to the processing of tar asphalt/petroleum asphalt/natural asphalt by chemical methods, and the processing of tar asphalt/petroleum asphalt/natural asphalt by selective extraction, which can solve the development problems of the road industry and the supply and demand of asphalt Increased contradictions, rising asphalt prices and other issues, to achieve sustainable development, alleviate resource shortages, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

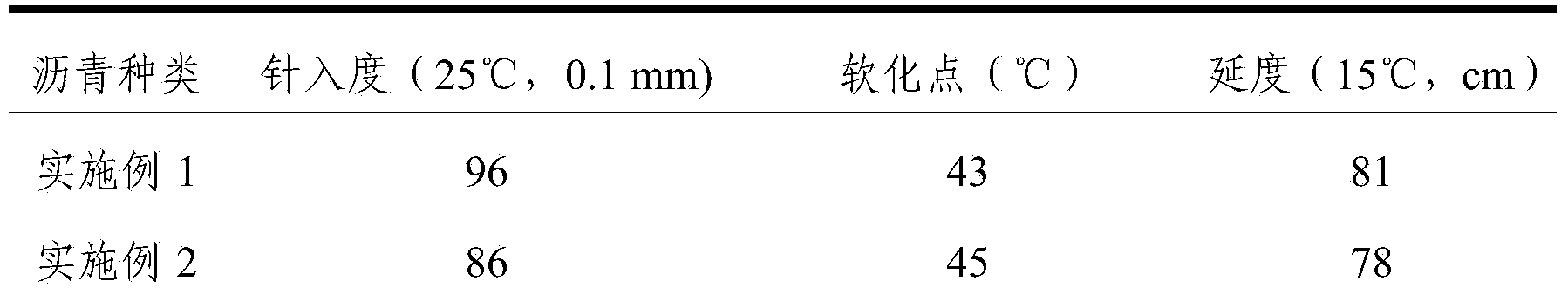

Embodiment 1

[0026] Example 1 A preparation method of catalytic hydrogenation bio-asphalt

[0027] A method for preparing catalytically hydrogenated bio-asphalt, comprising the steps of:

[0028] 1) In the Parr high-pressure reactor in the United States, the pressure in the reactor is controlled by passing hydrogen to 10MPa, and under the condition of 150°C, the biomass pyrolysis oil is heated by the catalyst Pt / γ-Al 2 o 3 A hydrogenation reaction occurs under the action, and the reaction time is 90 minutes;

[0029] Among them, biomass pyrolysis oil is an oily product obtained after pyrolysis of corn stalks, which was purchased from a bioenergy company.

[0030] Catalyst selects commercially available product for use.

[0031] Wherein, the addition amount of the catalyst is 10% of the mass of the biomass pyrolysis oil.

[0032] 2) Leave the product obtained in step 1) to stand, the upper layer is the oil phase, and the lower layer is the water phase. After separation, take the upper l...

Embodiment 2

[0034] Example 2 A preparation method of catalytic hydrogenation bio-asphalt

[0035] 1) In the Parr high-pressure reactor in the United States, the pressure in the reactor is controlled by passing hydrogen to 4MPa, and under the condition of 300°C, the biomass pyrolysis oil is heated by the catalyst Pt / γ-Al 2 o 3 A hydrogenation reaction occurs under the action, and the reaction time is 30 minutes;

[0036] Among them, biomass pyrolysis oil is an oily product obtained after pyrolysis of wood chips, which was purchased from a bioenergy company.

[0037] Catalyst selects commercially available product for use.

[0038] Wherein, the addition amount of the catalyst is 0.5% of the mass of the biomass pyrolysis oil.

[0039] 2) Let the product obtained in step 1) stand still, the upper layer is the oil phase, and the lower layer is the water phase. After separation, take the upper layer oil phase and water at a volume ratio of 1:3, mix and stir at 30°C, and separate by filtratio...

Embodiment 3

[0041] Example 3 A preparation method of catalytic hydrogenation bio-asphalt

[0042] 1) In the Parr high-pressure reactor in the United States, the pressure in the reactor is controlled by passing hydrogen to 6MPa, and under the condition of 200°C, the biomass pyrolysis oil is heated by the catalyst Pt / γ-Al 2 o 3 A hydrogenation reaction occurs under the action, and the reaction time is 60 minutes;

[0043] Among them, biomass pyrolysis oil is an oily product obtained after pyrolysis of bamboo chips, which was purchased from a bioenergy company.

[0044] Catalyst selects commercially available product for use.

[0045] Wherein, the amount of catalyst added is 5% of the mass of biomass pyrolysis oil.

[0046] 2) Leave the product obtained in step 1) to stand, the upper layer is the oil phase, and the lower layer is the water phase. After separation, take the upper layer oil phase and water at a volume ratio of 1:10, mix and stir at 5°C, and filter and separate to obtain wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com