High-viscosity improved asphalt and preparation process

A high-viscosity, asphalt technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of reducing the durability of the road surface against deformation, high road surface hardness, and weak flexibility, and achieve various performance improvements. The effect of viscosity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

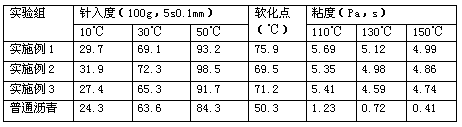

Examples

Embodiment 1

[0028] Each portion of raw material in this embodiment is 50g.

[0029] A high-viscosity modified asphalt, in parts by weight, comprising the following components: 150 parts of natural asphalt, 180 parts of biological asphalt, 40 parts of tackifying resin, 40 parts of rubber powder, 80 parts of filler, 50 parts of stabilizer, defoaming 40 parts of agent, 20 parts of curing agent.

[0030] The natural asphalt in this embodiment is rock asphalt with a particle size of 0.20 mm. The bio-asphalt is made from biomass heavy oil, the stabilizer is polyvinyl alcohol, the defoamer is butyl phosphate defoamer, and the rubber powder The particle size is 40 mesh, the mesh particle size of the filler is 120 mesh, the softening point of the tackifying resin is 100°C-110°C, and the curing agent is m-xylylenediamine.

[0031] The specific preparation method of this embodiment is as follows:

[0032] (1) In parts by weight, 150 parts of natural asphalt, 180 parts of bio-asphalt, and 40 parts ...

Embodiment 2

[0037] Each portion of raw material in this embodiment is 100g.

[0038] A high-viscosity modified asphalt, including the following components: 100 parts of natural asphalt, 200 parts of biological asphalt, 30 parts of tackifying resin, 50 parts of rubber powder, 60 parts of filler, 70 parts of stabilizer, 20 parts of defoamer, curing 30 doses.

[0039] The natural asphalt in this example is rock asphalt with a particle size of 0.090 mm, and the bio-asphalt is made from biomass heavy oil.

[0040] The stabilizer in this embodiment is polyvinyl alcohol, the defoamer is butyl phosphate defoamer, the particle size of the rubber powder is 40 mesh, the particle size of the filler is 90 mesh, and the softening point of the tackifying resin is 100°C-110°C. °C, the curing agent is m-xylylenediamine.

[0041] The specific preparation method of this embodiment is as follows:

[0042] (1) In parts by weight, 100 parts of natural asphalt, 200 parts of bio-asphalt, and 30 parts of tacki...

Embodiment 3

[0047] Every part of raw material of this embodiment is 200g

[0048] A high-viscosity modified asphalt, including the following components: 200 parts of natural asphalt, 150 parts of biological asphalt, 60 parts of tackifying resin, 30 parts of rubber powder, 100 parts of filler, 40 parts of stabilizer, 20 parts of defoamer, curing 10 doses.

[0049] The natural asphalt in this example is rock asphalt with a particle size of 0.45mm, and the bio-asphalt is made from biomass heavy oil.

[0050] The stabilizer in this example is polyvinyl alcohol, the defoamer is butyl phosphate defoamer, the particle size of the rubber powder is 40 mesh, the particle size of the filler is 50 mesh, and the softening point of the tackifying resin is 100°C-110°C. °C, the curing agent is m-xylylenediamine.

[0051] The specific preparation method of this embodiment is as follows:

[0052](1) In parts by weight, 200 parts of natural asphalt, 150 parts of bio-asphalt, and 60 parts of tackifying re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com