A kind of waste oil-based modified bio-asphalt, bio-asphalt mixture and preparation method thereof

A technology of bio-asphalt and mixture, which is applied in the direction of building structure, building insulation materials, building components, etc., can solve the problems that cannot meet the technical requirements of road engineering, poor adhesion, low softening point, etc., and achieve good environmental and economic benefits , strong adhesion, and the effect of meeting road performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] In the preparation method of the modified bio-asphalt mixture in this embodiment, the waste oil-based modified bio-asphalt is heated to 183°C, the mineral material is heated to 183°C, and the waste-oil-based modified bio-asphalt is mixed with the ore The modified bio-asphalt mixture is obtained after the materials are evenly stirred.

[0023] The raw materials used in this embodiment are all commercially available products.

[0024] The waste oil residue used in this embodiment is the residue left after refining biodiesel from waste oil.

[0025] In the preparation method of waste oil-based modified bio-asphalt in this embodiment, the modifier is hard asphalt particles, resin, LDPE recycled plastic and linear SBS.

Embodiment 1

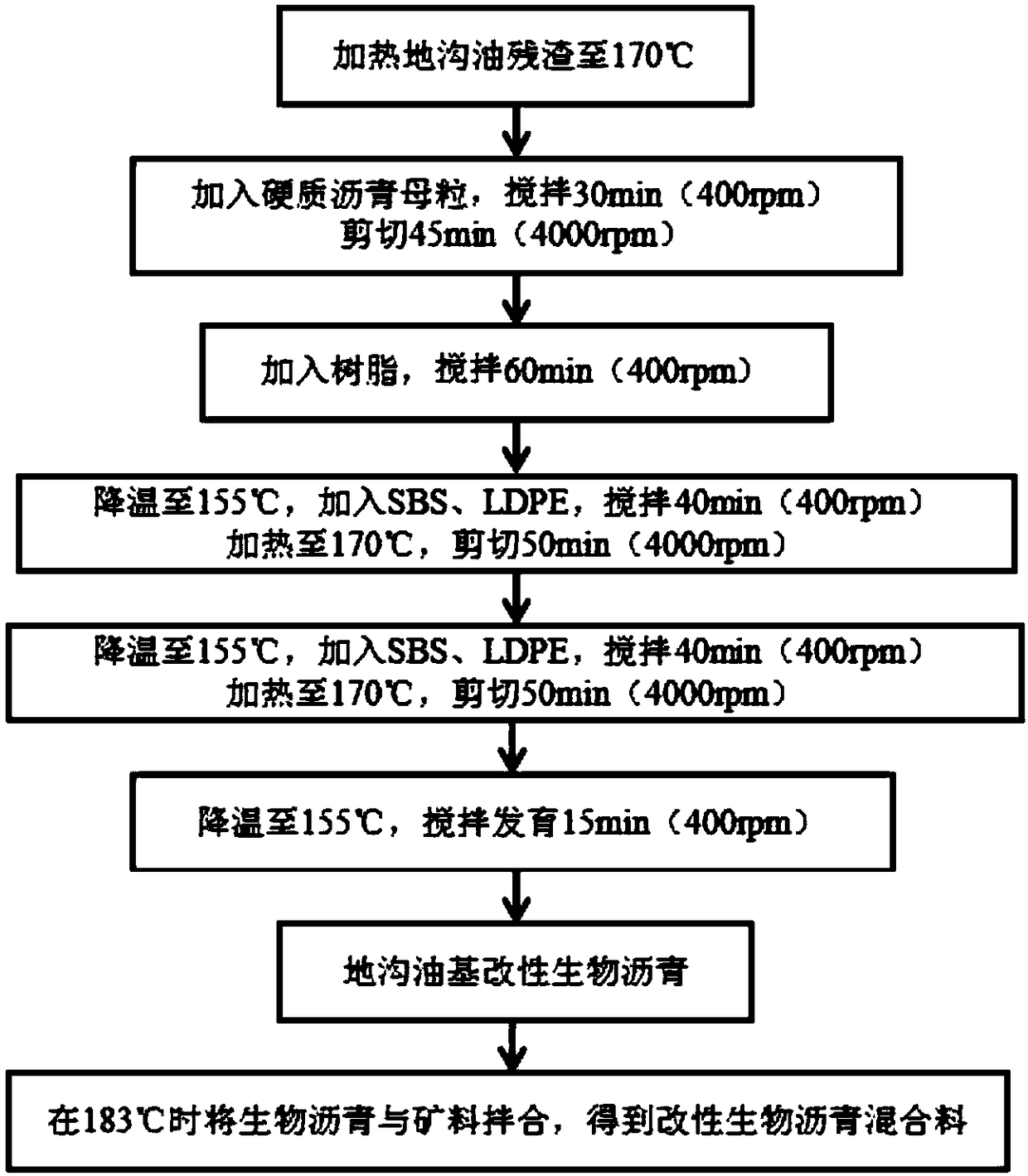

[0028] A preparation method of waste oil-based modified bio-asphalt in this embodiment is carried out according to the following steps:

[0029] 1. Weigh 190g of waste oil residue, 169g of hard asphalt granules, 132.5g of resin, 8g of LDPE recycled plastic and 20g of linear SBS;

[0030] 2. Heat the waste oil residue weighed in step 1 to 170°C, add the hard asphalt particles weighed in step 1, stir for 30min at a temperature of 170°C and a stirring rate of 400rpm, and then Shear at 4000rpm for 45min; then add the resin weighed in step 1, and stir for 60min at a temperature of 170°C and a stirring rate of 400rpm; then add the LDPE recycled plastic and linear SBS weighed in step 1, Stir at a temperature of 155°C and a stirring rate of 400rpm for 40min, then shear at a temperature of 170°C and a shear rate of 4000rpm for 50min; finally stir and develop at a temperature of 155°C and a stirring rate of 400rpm for 15min, Waste oil-based modified bio-asphalt is obtained.

Embodiment 2

[0032] A preparation method of waste oil-based modified bio-asphalt in this embodiment is carried out according to the following steps:

[0033] 1. Weigh 181.5g of waste oil residue, 143g of hard asphalt granules, 170g of resin, 6g of LDPE recycled plastic and 20g of linear SBS;

[0034] Two, preparation steps are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com