Biological asphalt and preparation method thereof

A bio-asphalt, bio-oil technology, applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, processing tar asphalt/petroleum asphalt/natural asphalt by heating, and processing tar asphalt/petroleum asphalt/natural asphalt by distillation, etc. Solve the problems of poor low temperature performance and anti-aging performance, harsh process conditions, and high economic cost, and achieve the effects of improving performance and anti-aging performance, improving anti-aging performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

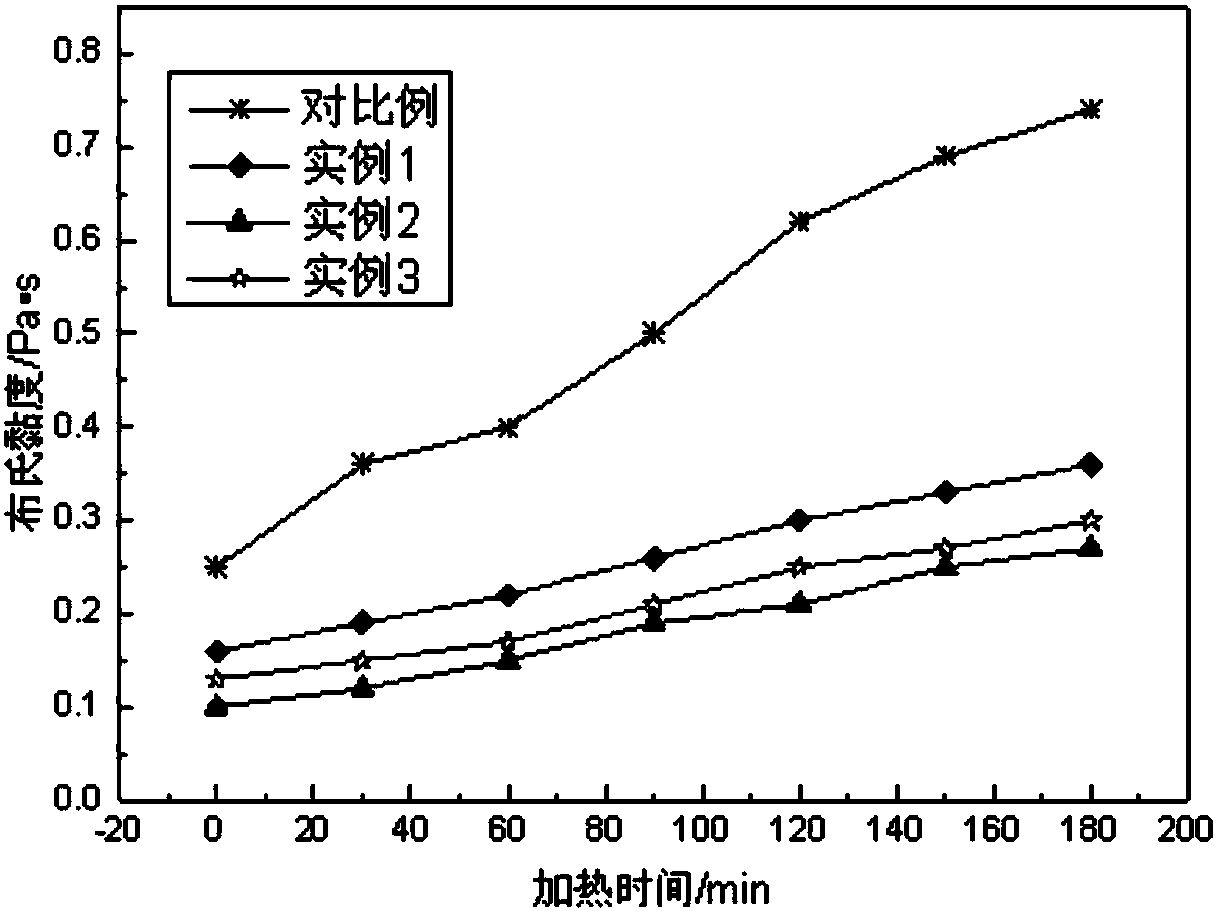

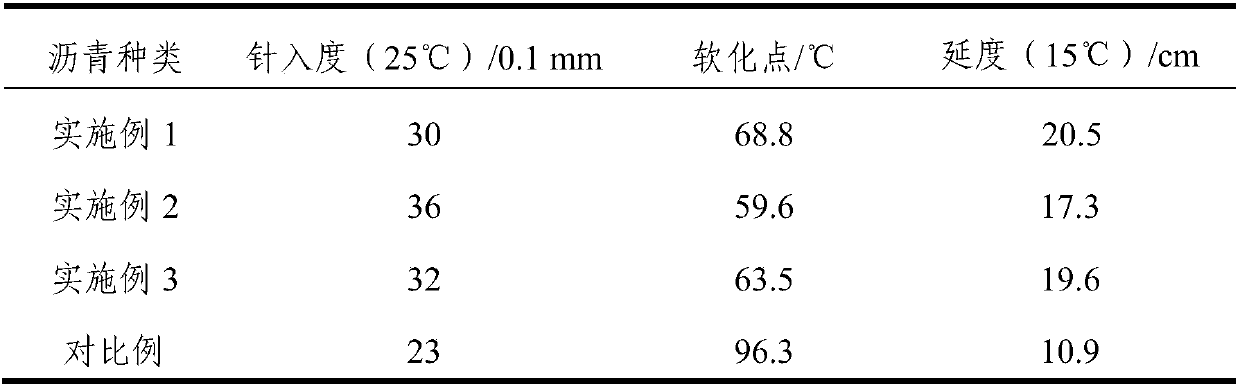

[0031] Embodiment 1 A kind of preparation method of biological asphalt

[0032] The present embodiment provides a kind of preparation method of bio-asphalt, comprises the following steps:

[0033] 1) Add 30g Cacl 2 Mix into 1000g pine wood pyrolysis oil, stir at 600r / min for 20min;

[0034] 2) the obtained step 1) mixed with Cacl 2 The pine wood pyrolysis oil of inorganic salt is mixed with 2060g biodiesel by-product (crude glycerol), and stirred at 1000r / min for 30min;

[0035] 3) Atmospheric distillation of the mixed system of pine wood pyrolysis oil, inorganic salt and glycerin until the gas phase temperature is 225°C-250°C;

[0036] 4) Collect and separate the 2396g crude glycerol-lignin pyrolysis product mixed phase at the bottom of the retort, add 11980g water to it, and let stand for 120min; filter to obtain the crude lignin pyrolysis product and crude lignin pyrolysis product with a small amount of impurities remaining. Mixed filtrate of glycerin and water;

[003...

Embodiment 2

[0038] Embodiment 2 A kind of preparation method of biological asphalt

[0039] This example provides a method for preparing bio-asphalt, the difference from Example 1 is that the pine wood pyrolysis oil in Example 1 is replaced with poplar wood pyrolysis oil.

Embodiment 3

[0040] Embodiment 3 A kind of preparation method of biological asphalt

[0041] This example provides a method for preparing bio-asphalt, the difference from Example 1 is that the pine wood pyrolysis oil in Example 1 is replaced with willow wood pyrolysis oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com