Modified biological asphalt and preparation method thereof

A bio-asphalt and modification technology, which is applied in the direction of chemical processing of tar asphalt/petroleum asphalt/natural asphalt, etc., can solve the unfavorable large-scale use of bio-asphalt, poor high-temperature stability and road performance, and increase the production of bio-asphalt Cost and other issues, to achieve sustainable development, improve high temperature stability and low temperature crack resistance, improve high temperature stability and road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

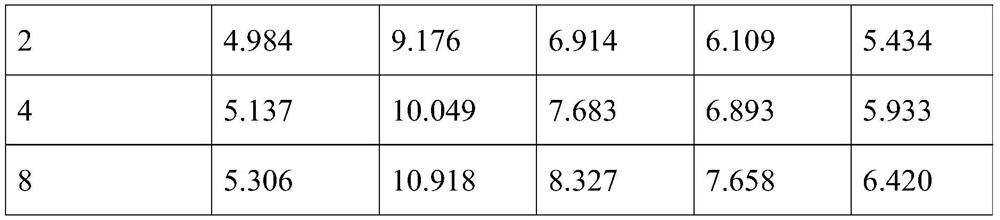

Image

Examples

Embodiment 1

[0025] This embodiment provides a modified bio-asphalt, its raw material is composed of: 100g of bio-asphalt, 5g of bio-char, 2g of rubber powder; 3g of a mixture of 25wt% hydrogen peroxide and propanol, wherein: bio-char is corn stalk charcoal, The rubber powder is waste tire powder with a particle size of 100 mesh, and the volume ratio of hydrogen peroxide and propanol is 1:7.

[0026] The method for preparing the modified bio-asphalt by using the above-mentioned raw materials comprises the following steps:

[0027] (1) The corn stalks were subjected to thermal cracking reaction at 450° C. under oxygen-limited conditions for 2 h, separated to obtain biochar and gas fraction, and the gas was cooled to obtain bio-oil. Distill the bio-oil under reduced pressure, collect heavy oil with a boiling point greater than 100°C, mix the heavy oil with water, stir in a circulating water bath at 5°C for 30 minutes, then place the mixed solution at room temperature for 1 hour, Filtration,...

Embodiment 2

[0031] This embodiment provides a modified bio-asphalt, the raw material composition of which is: 100g of bio-asphalt, 10g of bio-char, 5g of rubber powder; 7g of a mixture of 25wt% hydrogen peroxide and butanol, wherein: bio-char is corn stalk charcoal, The rubber powder is waste tire powder with a particle size of 50 mesh, and the volume ratio of hydrogen peroxide and butanol is 1:10.

[0032] The method for preparing the modified bio-asphalt by using the above-mentioned raw materials comprises the following steps:

[0033] (1) The oak was pyrolyzed for 2 hours under oxygen-limited conditions at 450°C, separated to obtain biochar and gas, and the gas was cooled to obtain bio-oil. Distill the bio-oil under reduced pressure, collect heavy oil with a boiling point greater than 100°C, mix the heavy oil with water, stir in a circulating water bath at 5°C for 30 minutes, then place the mixed solution at room temperature for 1 hour, Filtration, separation to obtain insoluble compo...

Embodiment 3

[0037] This embodiment provides a modified bio-asphalt, its raw material composition is: 100g of bio-asphalt, 8g of bio-char, 3.5g of rubber powder; 5g of a mixture of 25wt% hydrogen peroxide and ethanol, wherein: bio-char is corn stalk charcoal, The rubber powder is waste tire powder with a particle size of 80 mesh, and the volume ratio of hydrogen peroxide and ethanol is 1:8.

[0038] The method for preparing the modified bio-asphalt by using the above-mentioned raw materials comprises the following steps:

[0039] (1) The rice husk was pyrolyzed for 2 hours under oxygen-limited conditions at 450° C., separated to obtain biochar and gas, and the gas was cooled to obtain bio-oil. Distill the bio-oil under reduced pressure, collect heavy oil with a boiling point greater than 100°C, mix the heavy oil with water, stir in a circulating water bath at 5°C for 30 minutes, then place the mixed solution at room temperature for 1 hour, Filtration, separation to obtain insoluble compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com