High-temperature cracking equipment for biological asphalt material

A high-temperature pyrolysis and bio-asphalt technology, applied in the field of bio-asphalt, can solve the problems of low thermal efficiency and high energy consumption, and achieve the effects of fast heat conduction, uniform heating and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

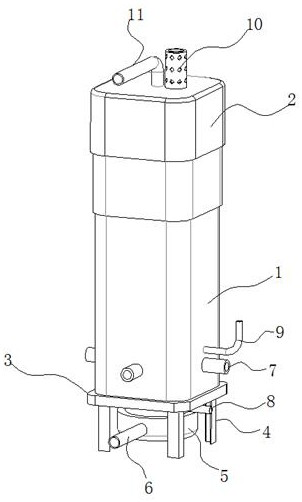

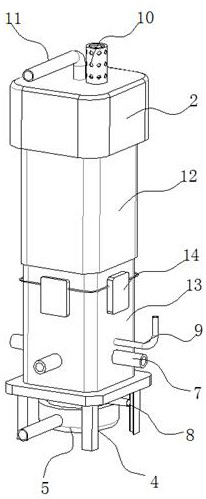

[0034] refer to Figure 1-7 A high-temperature pyrolysis device for bio-asphalt materials, comprising a lower tray 3, the top outer wall of the lower tray 3 is provided with a furnace main body structure, the bottom four corners of the lower tray 3 are provided with brackets 4; the bottom side of the lower tray 3 is provided with The fan draws the heat accumulated in the lower furnace body from the lower side to the outer wall of the bucket, and simultaneously heats the temperature of the furnace body, and the waste heat recovery pipe 16 is located above the end of the fan. The main structure of the furnace body includes an upper furnace body 12, The lower furnace body 13, the outer shell 1 and the furnace cover 2, the upper furnace body 12 and the lower furnace body 13 are provided with a heat insulating plate 17, and the outer shell 1 is sleeved on the outer walls of the upper furnace body 12 and the lower furnace body 13, and the outer shell 1, the upper furnace body 12, an...

Embodiment 2

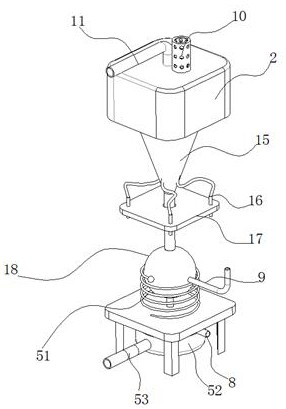

[0047] refer to Figure 8-9 : A kind of pyrolysis equipment for bio-asphalt materials, in this embodiment, with respect to embodiment 1, the main difference is that in this embodiment, it also includes a pear-shaped heating part 18-1, and the pear-shaped heating part 18-1 replaces the heating structure 18 positions, input the raw material to be cracked through the feed pipe 9, the raw material is distributed on the inner wall of a hemispherical cover, and also includes a spherical burning ball head 7-1 heated inside, wherein the burning ball head 7-1 The end is connected with a fuel feed pipe 19, which can evenly distribute the heat generated by the fuel combustion on the hemispherical cover to accelerate the heating of the raw material. At the same time, the concave heating structure reduces the heat dissipation of the heating surface and improves the heating efficiency. Further improve fuel utilization and thermal efficiency.

[0048] In the present invention, the pear-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com