Biological asphalt, SBS and PPA composite modified asphalt and preparation method thereof

A technology of composite modified asphalt and bio-asphalt, applied in the preparation of PPA composite modified asphalt, SBS, PPA composite modified asphalt, bio-asphalt field, can solve the problems of poor compatibility between SBS and asphalt, high modification cost, and achieve Improved compatibility, good economy, and low SBS content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

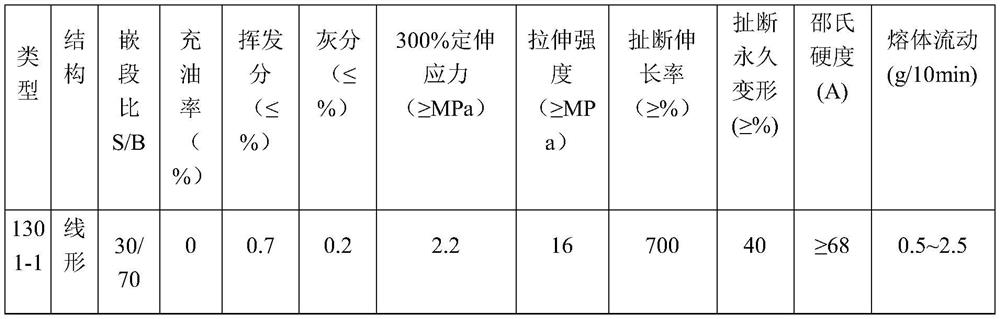

Embodiment 1

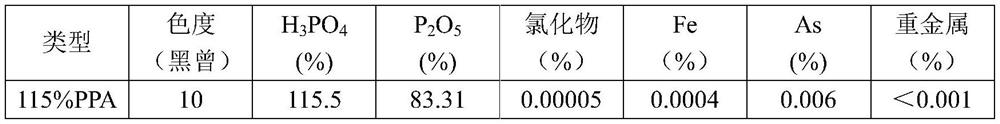

[0029] The bio-asphalt, SBS and PPA composite modified asphalt of the present invention has the following components according to mass fraction: 90 parts of petroleum asphalt, 10 parts of bio-asphalt, 3.5 parts of styrene-butadiene-styrene block copolymer, 0.02 part of stabilizer, 0.5 part of polyphosphoric acid.

[0030] The preparation method of the above-mentioned bio-asphalt, SBS, PPA composite modified asphalt is specifically implemented according to the following steps:

[0031] Step 1, heating, mixing and shearing the petroleum asphalt and bio-asphalt; the heating temperature for heating, mixing and shearing is 140°C, the shearing speed is 1000rpm, and the stirring time is 20min;

[0032] Step 2, add styrene-butadiene-styrene block copolymer to the product obtained in step 1, and carry out shearing and stirring; the heating temperature for shearing and stirring is 175°C, the shearing time is 30min, and the shearing The speed is 5000rpm;

[0033] In step 3, a stabilize...

Embodiment 2

[0036] The bio-asphalt, SBS, PPA composite modified asphalt of the present invention has the following components by mass fraction: 90 parts of petroleum asphalt, 10 parts of bio-asphalt, 3 parts of styrene-butadiene-styrene block copolymer, 0.02 part of stabilizer, 1 part of polyphosphoric acid.

[0037] The preparation method of the above-mentioned bio-asphalt, SBS, PPA composite modified asphalt is specifically implemented according to the following steps:

[0038] Step 1, heating, mixing and shearing the petroleum asphalt and bio-asphalt; the heating temperature for heating, mixing and shearing is 140°C, the shearing speed is 1000rpm, and the stirring time is 20min;

[0039] Step 2, add styrene-butadiene-styrene block copolymer to the product obtained in step 1, and carry out shearing and stirring; the heating temperature for shearing and stirring is 175°C, the shearing time is 30min, and the shearing The speed is 5000rpm;

[0040] In step 3, a stabilizer is added to the...

Embodiment 3

[0043] The bio-asphalt, SBS and PPA composite modified asphalt of the present invention has the following components according to mass fraction: 90 parts of petroleum asphalt, 15 parts of bio-asphalt, 2.5 parts of styrene-butadiene-styrene block copolymer, 0.02 parts of stabilizer, 1.5 parts of polyphosphoric acid.

[0044]The preparation method of the above-mentioned bio-asphalt, SBS, PPA composite modified asphalt is specifically implemented according to the following steps:

[0045] Step 1, heating, mixing and shearing the petroleum asphalt and bio-asphalt; the heating temperature for heating, mixing and shearing is 140°C, the shearing speed is 1000rpm, and the stirring time is 20min;

[0046] Step 2, add styrene-butadiene-styrene block copolymer to the product obtained in step 1, and carry out shearing and stirring; the heating temperature for shearing and stirring is 175°C, the shearing time is 30min, and the shearing The speed is 5000rpm;

[0047] In step 3, a stabiliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com