Hot-blast stove secondary air inlet system

A technology of secondary air intake and hot blast stove, which is applied in heating systems, space heating and ventilation, household heating, etc., and can solve problems such as the inability to adjust the size of the firepower, insufficient combustion, and increased energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

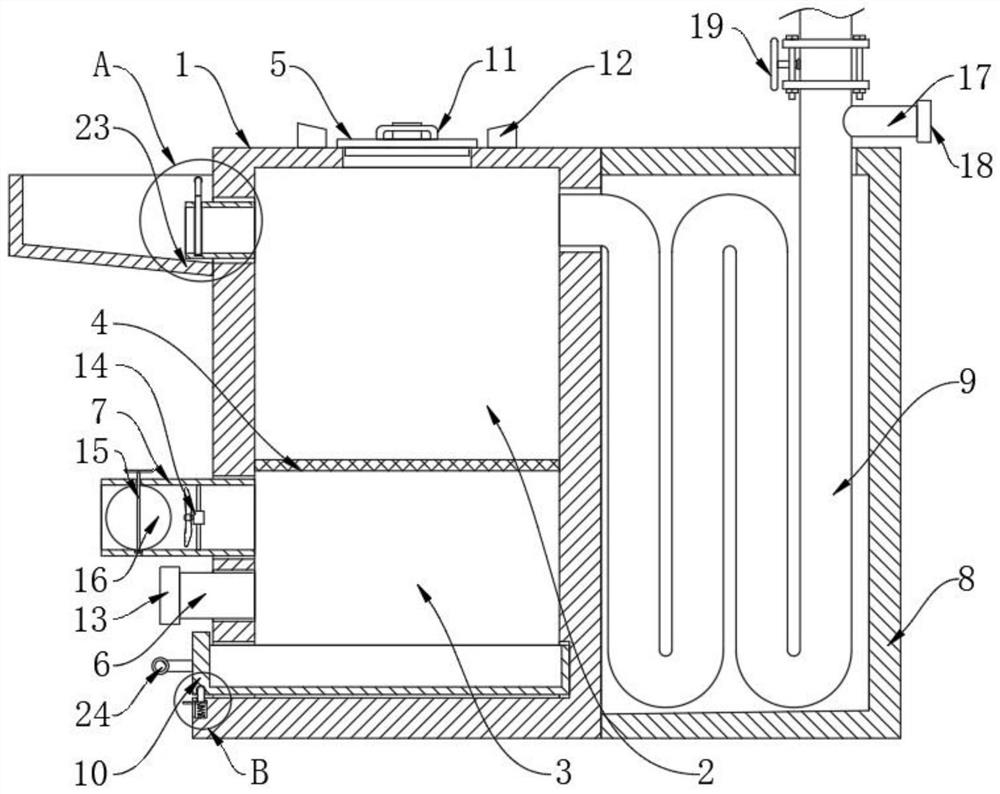

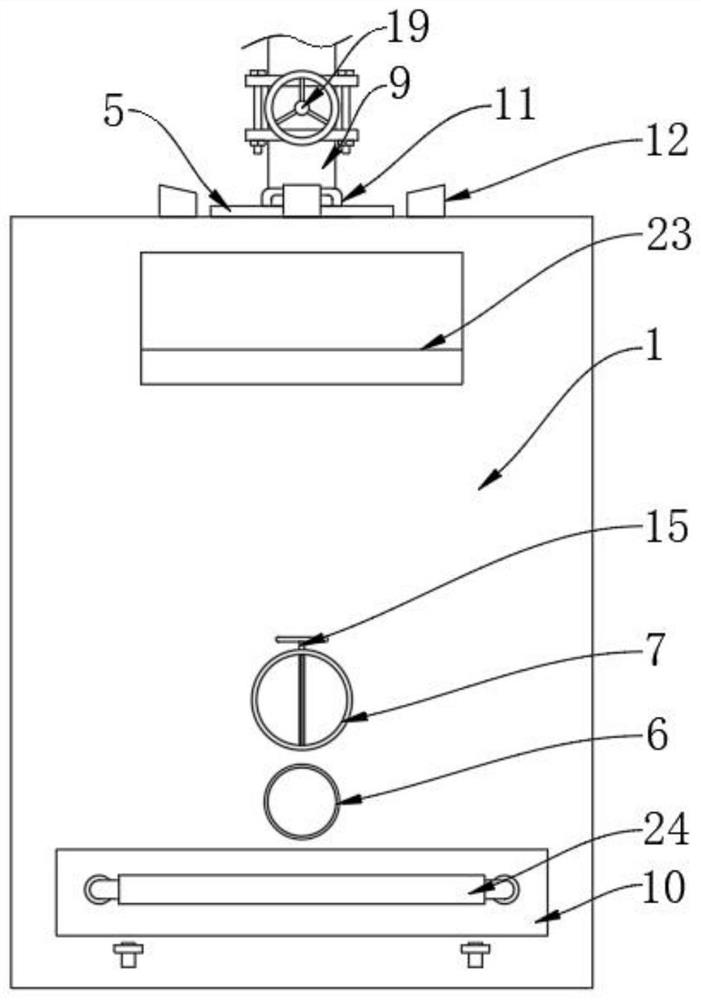

Method used

Image

Examples

Embodiment 2

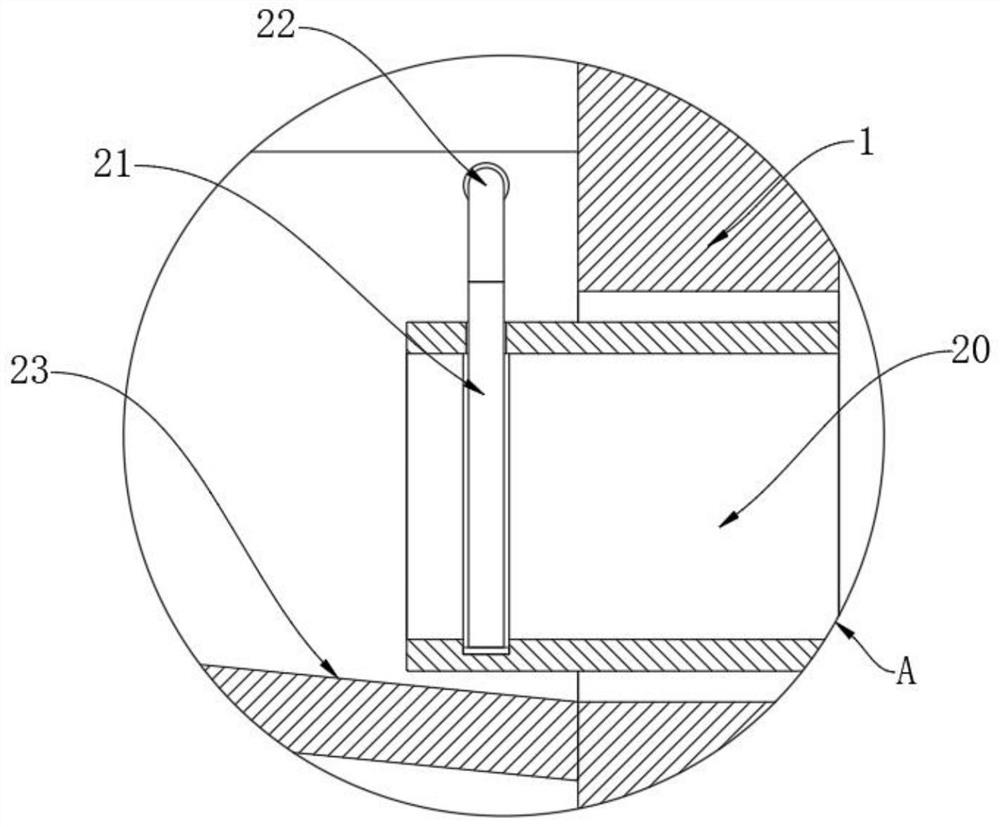

[0032] refer to Figure 3-4 , the inner wall of the fuel feed port is fixedly connected with a fuel feed pipe 20, the upper surface of the fuel feed pipe 20 is provided with a card slot, and the inner wall of the card slot is inserted with a fire baffle 21, and the upper surface of the fire baffle 21 A handle 22 is fixedly connected to facilitate the lifting of the fire baffle 21, and the side of the hot blast stove body 1 is fixedly connected with a lower hopper 23 that is convenient for receiving fuel. By setting the fire baffle 21, the phenomenon of tempering in the process of fueling can be prevented. .

[0033] The side of the ashes collection box 10 is fixedly connected with a handle 24 that facilitates the pulling out of the ashes collection box 10. The side of the hot blast stove body 1 is provided with a positioning groove, and the inwall of the positioning groove is slidably connected with a driving lever 25, and the upper surface of the driving lever 25 is Fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com