Coal-fired power plant online sludge drying and mixing combustion system and application method thereof

A coal-fired power plant, sludge drying technology, applied in the direction of combustion method, combustion type, combined combustion mitigation, etc., can solve the problem of reducing boiler thermal efficiency, wear and disturbance at the connection between the dust collector pipe and the dust collector, and increasing the induced draft fan Power consumption and other issues, to achieve the effect of reducing incomplete combustion, avoiding spillage and leakage, and reducing smoke exhaust loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

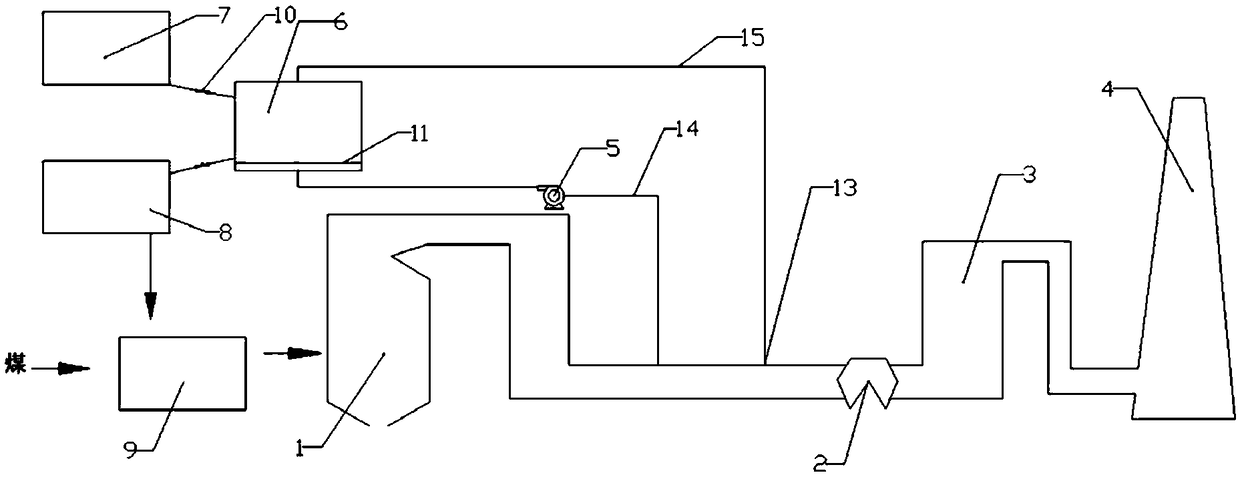

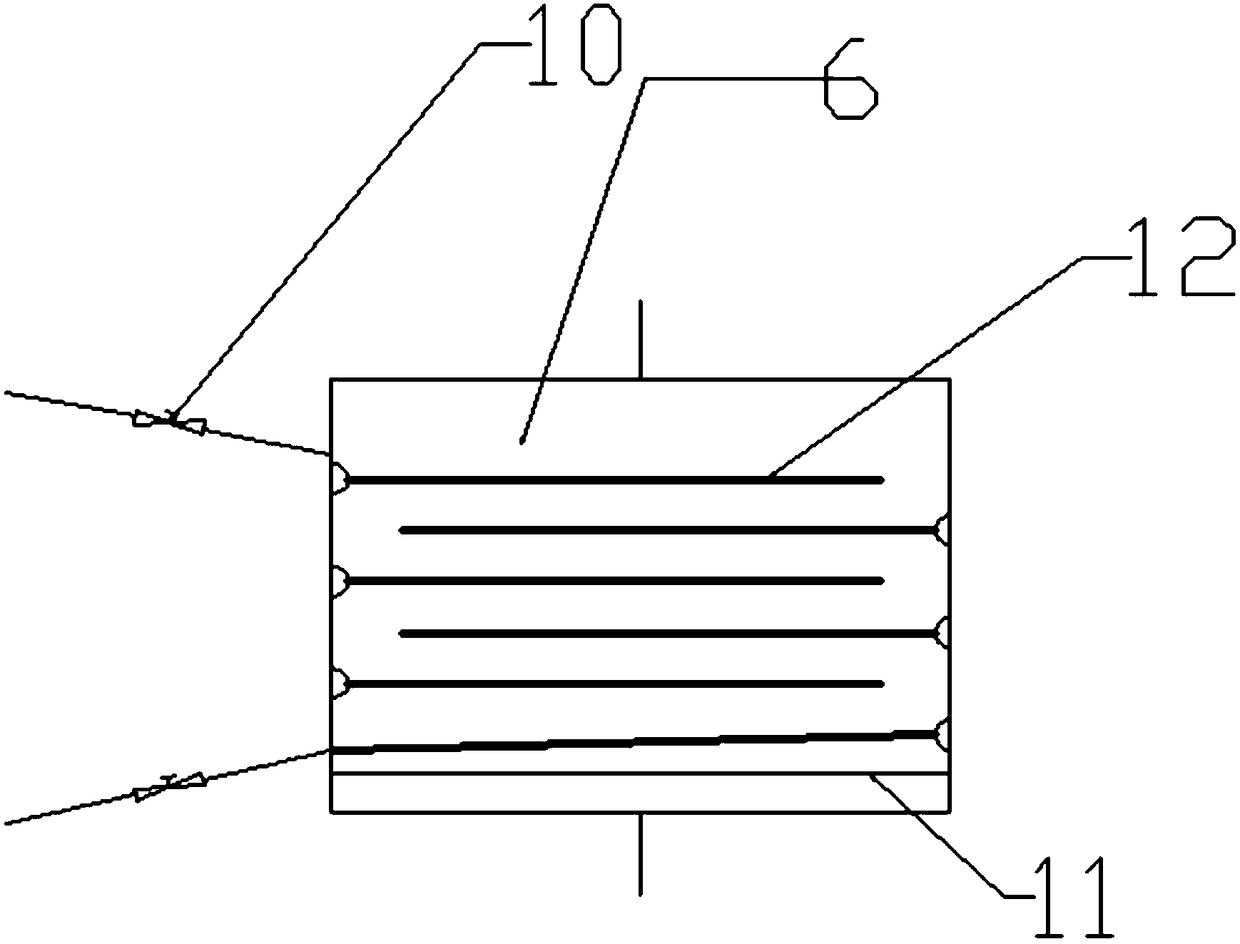

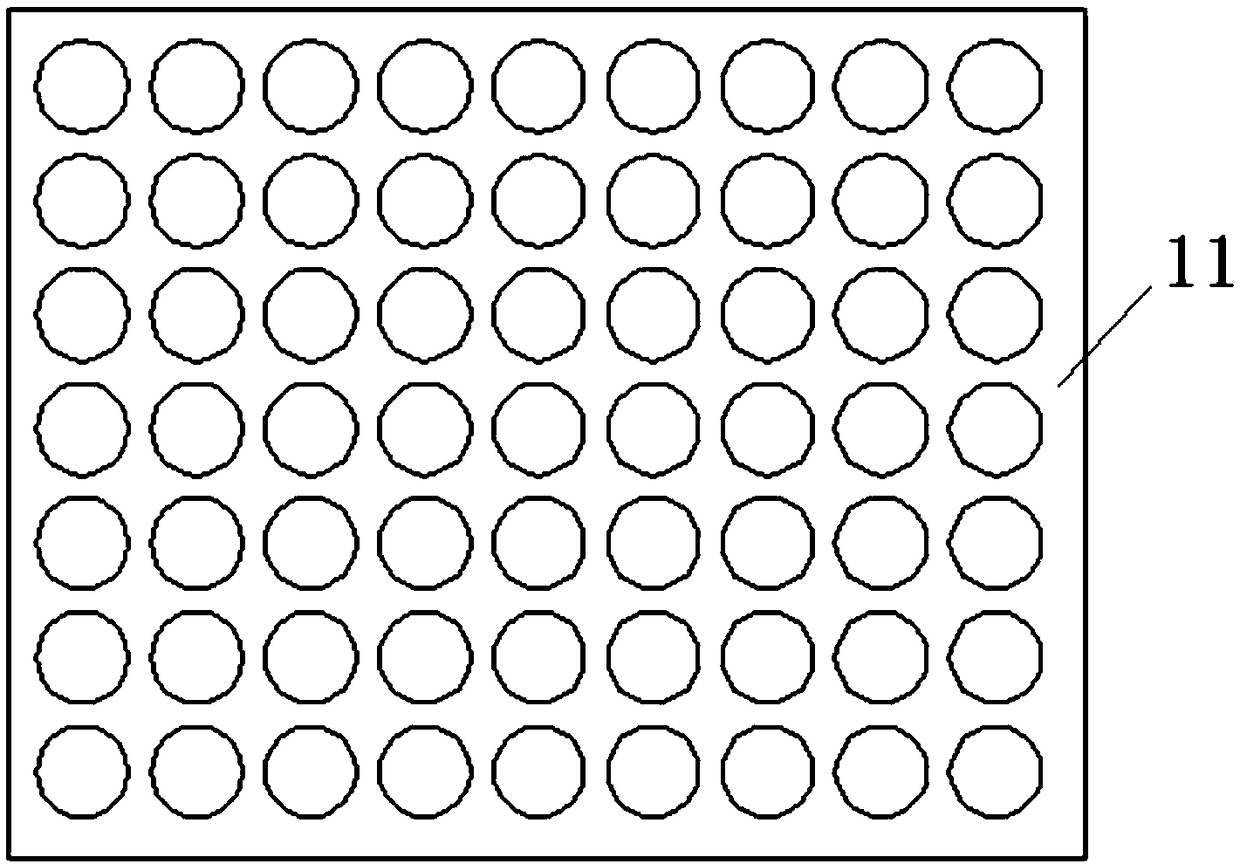

[0035] The invention provides an online sludge drying and blending system in a coal-fired power plant, such as figure 1 As shown, it includes a boiler hearth 1, a stacking bin 7, a drying bin 6, a bin to be mixed 8, an air extraction pipe 14, a return air pipe 15 and a chimney 4. The boiler hearth 1 is connected to the flue, and the dust collector 2 and the flue are arranged in the flue. The desulfurization tower 3, the air extraction pipeline 14 is arranged in front of the dust collector 2, the air extraction pipeline 14 is connected to the induced draft fan 5, the induced draft fan 5 is connected to the drying chamber 6, and the drying chamber 6 is provided with multi-layers for placing sludge Chain 12, the chain 12 is a rotary transmission chain, the chain 12 is arranged in multiple layers in the horizontal direction of the front and rear walls of the drying chamber 6, the chains 12 on the front and rear walls rotate in opposite directions, and the last stage of the chain 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com