Circumferentially distributed burner of natural gas channels

A natural gas, distributed technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of insufficient mixing of natural gas fuel, incomplete natural gas, etc., to improve the effective utilization rate, increase the contact area, cooling good condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

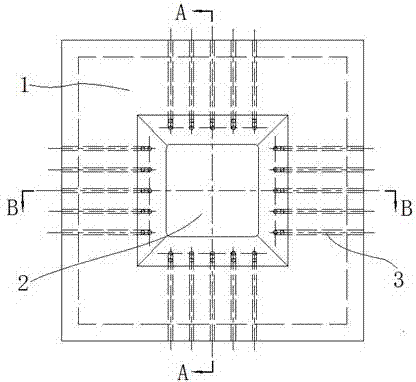

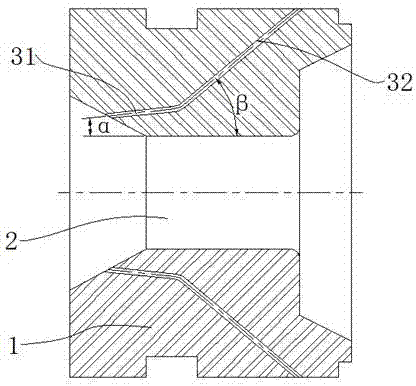

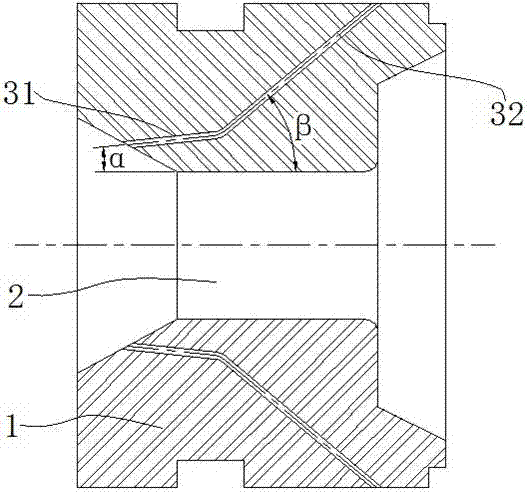

[0031] combine figure 1 , figure 2 and image 3 , a natural gas channel circumferentially distributed burner in this embodiment is mainly composed of a burner brick body 1, a combustion air channel 2 and a natural gas channel 3, and the natural gas channel 3 includes two parts: the nozzle section 31 and the insertion section 32.

[0032] The combustion-supporting air channel 2 in this embodiment is a quadrangular hollow structure and is arranged horizontally, and is located inside the burner brick body 1 . As an outstanding improvement of the present invention, the natural gas passages 3 of the burner are evenly distributed on the four sides of the quadrilateral combustion air passage 2, which plays a role in finely splitting the natural gas fuel. It is worth noting that the natural gas passages in the present invention 3 can adopt other shape structures such as circles in the prior art. As long as there are two or more natural gas channels 3 distributed along the outer pe...

Embodiment 2

[0035] The basic structure of this embodiment is the same as that of Embodiment 1, except that the natural gas passages 3 of the burner are only distributed on two opposite sides of the quadrilateral combustion air passage 2 periphery, and the distance between two adjacent combustion air passages 2 on the same side is 60 mm, the diameter of the natural gas channel 3 is Φ20 mm; the angle α between the nozzle section 31 at the front end of the natural gas channel 3 and the central axis of the combustion air channel 2 is 20°, and the angle α between the insertion section 32 and the central axis of the combustion air channel 2 The angle β is 30°.

Embodiment 3

[0037] The basic structure of this embodiment is the same as that of Embodiment 1, except that the natural gas passages 3 of the burner are only distributed on three sides of the quadrilateral combustion air passage 2 periphery, and the distance between two adjacent combustion air passages 2 on the same side is 40 mm, the diameter of the natural gas channel 3 is Φ5 mm; the angle α between the nozzle section 31 at the front end of the natural gas channel 3 and the central axis of the combustion air channel 2 is 3°, and the angle α between the insertion section 32 and the central axis of the combustion air channel 2 β is 60°.

[0038] After the burners in Examples 2 and 3 are applied to natural gas regenerative forging furnaces, the energy-saving effect is obvious, the emission of CO in the flue gas is reduced by about 8%, and the coal consumption per ton of steel is about 75Kg standard coal / t steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com