High-ignition-point fuel compression ignition and combustion regulation and control device based on flame jet flow control

A jet control and regulation device technology, applied in the direction of combustion engines, gaseous engine fuels, fuel systems, etc., can solve the problems of unfavorable promotion and application of low-carbon/zero-carbon fuels, complex structure of dual-fuel combustion systems, etc., and shorten the propagation of free radicals distance, is conducive to popularization and application, and strengthens the effect of turbulence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

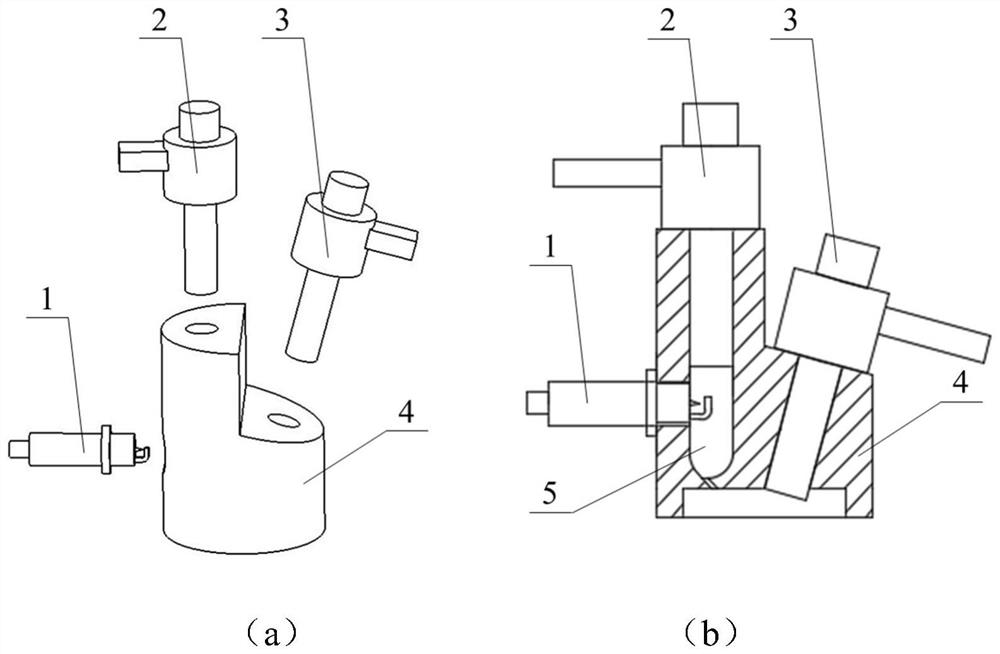

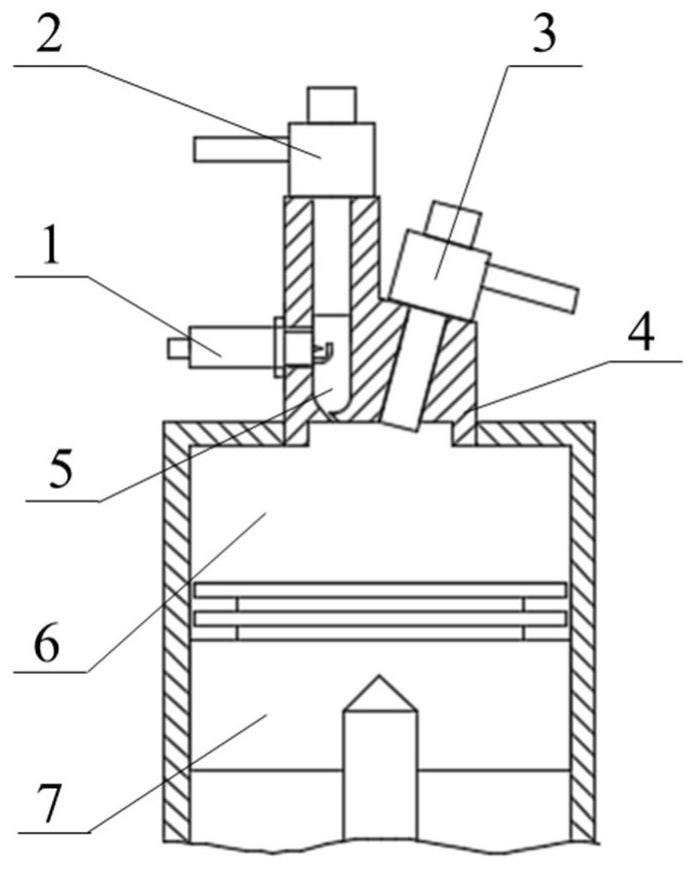

[0033] Such as figure 1 with figure 2 As shown, a high ignition point fuel compression ignition and combustion control device based on flame jet control provided by the present invention includes a pre-chamber main body 4, a pre-chamber injector 2, a pre-chamber spark plug 1 and a main combustion chamber injector 3 . Wherein, the inside of the pre-chamber main body 4 includes a pre-chamber cavity 5 with a small volume; the pre-chamber injector 2 and the pre-chamber spark plug 1 are respectively installed in two different positions on one side of the pre-chamber main body 4, and The head of the pre-chamber injector 2 and the head of the pre-chamber spark plug 1 extend into the inside of the pre-chamber cavity 5; In the combustion chamber 6.

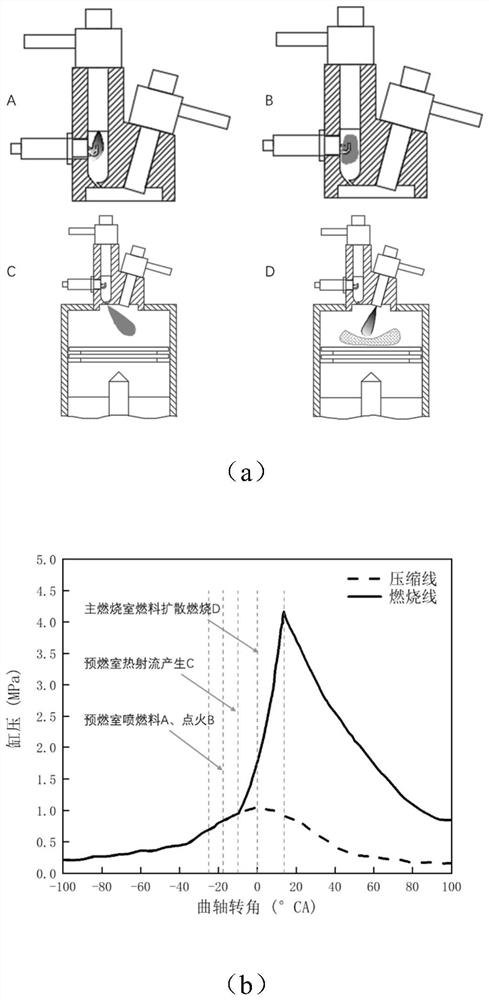

[0034] The present invention can realize reliable regulation and control of different ignition and combustion modes under di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com