A method for desulfurization of petroleum coke fuel for dry process cement rotary kiln

A dry process cement and petroleum coke technology, applied in the field of cement production, can solve the problems of slow combustion speed, high ignition temperature and ember temperature of petroleum coke, difficult calcination requirements of petroleum coke dry process cement rotary kiln, etc. Hidden dangers, the effect of reducing the concentration of sulfur dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

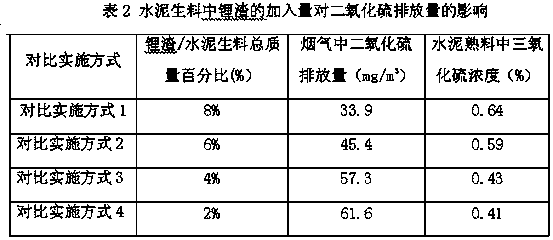

[0035] The present invention provides a petroleum coke fuel desulfurization method for dry-process cement rotary kiln. Petroleum coke is measured by an electronic tape scale and then fed into a petroleum coke mill until the sieve residue of 0.08mm square hole is less than 1%. After being measured by the electronic tape scale, it is fed into the rice husk grinder and crushed to rice husk powder with a particle size of less than 0.8mm. The weight percentage of petroleum coke and rice husk powder is 90%: 10%. The rice husk powder is produced by the petroleum coke grinding system. The exhaust fan is sucked into the bag filter and mixed with the petroleum coke powder that enters the bag filter at the same time, and then sent to the mixed fuel bin by the screw conveyor. The mixed fuel is measured by two rotor weighing scales and then sent by two screw pumps The mixed fuel is sent to the calciner and the rotary kiln head burner for combustion respectively. At the same time, lithium s...

Embodiment 2

[0038]The weight percentage of petroleum coke and rice husk powder in Example 1 was changed to 80%: 20%, and lithium slag was added according to 5% of the total mass of cement raw meal, and other processes were the same as in Example 1.

[0039] The mixed fuel and cement raw meal prepared by this embodiment, after the calcination process, the content of sulfur trioxide in the cement clinker is 1.4%; the concentration of sulfur dioxide in the exhaust gas discharged from the rotary kiln into the air is 7.5mg / m 3 .

Embodiment 3

[0041] In Example 1, the weight percentage of petroleum coke and rice husk powder was changed to 70%:30%, and lithium slag was added according to 3% of the total mass of cement raw meal, and other processes were the same as in Example 1.

[0042] The mixed fuel and cement raw meal prepared by this embodiment, after the calcination process, the content of sulfur trioxide in the cement clinker is 1.5%; the concentration of sulfur dioxide in the exhaust gas discharged from the rotary kiln into the air is 3.9mg / m 3 .

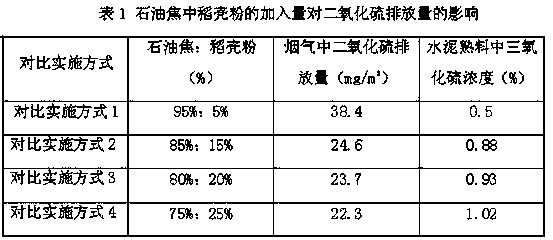

[0043] The concentration of sulfur dioxide in the flue gas emitted by conventional cement plants using petroleum coke as fuel is relatively high, usually higher than 100mg / m 3 , for some newly-built cement plants, due to better environmental protection measures, the concentration of sulfur dioxide will be lower than 100mg / m 3 , but usually higher than 50mg / m 3 , as environmental protection requirements are getting higher and higher, a large number of new cement pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com