Coal grinding device for gasifier

A gasifier and pulverizing technology, which is used in grain processing, spring/shock absorber, vibration suppression adjustment, etc., can solve the problems that the grinding degree affects the combustion efficiency of pulverized coal, and the grinding efficiency is low, so as to improve the grinding effect, Improve grinding efficiency and facilitate discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

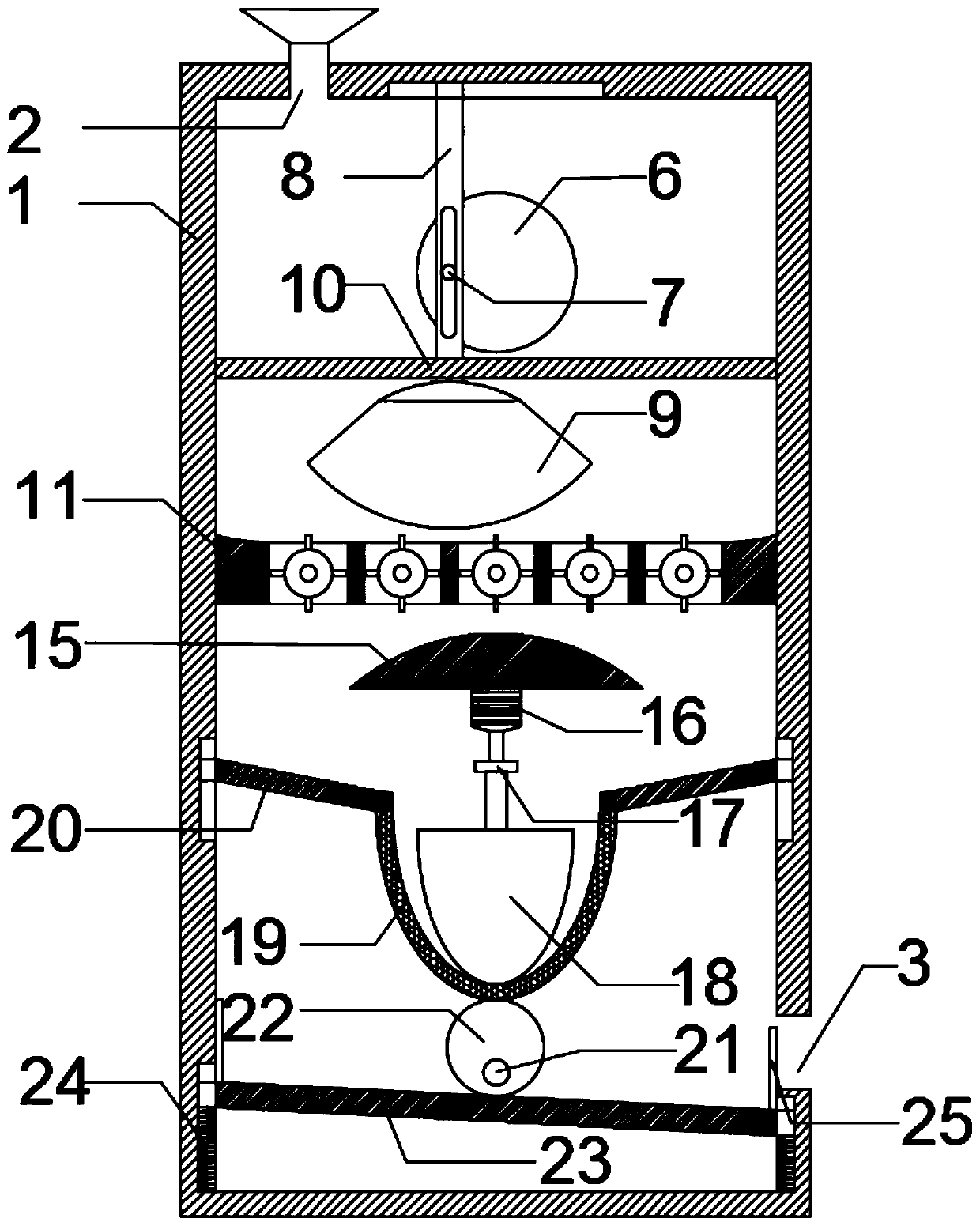

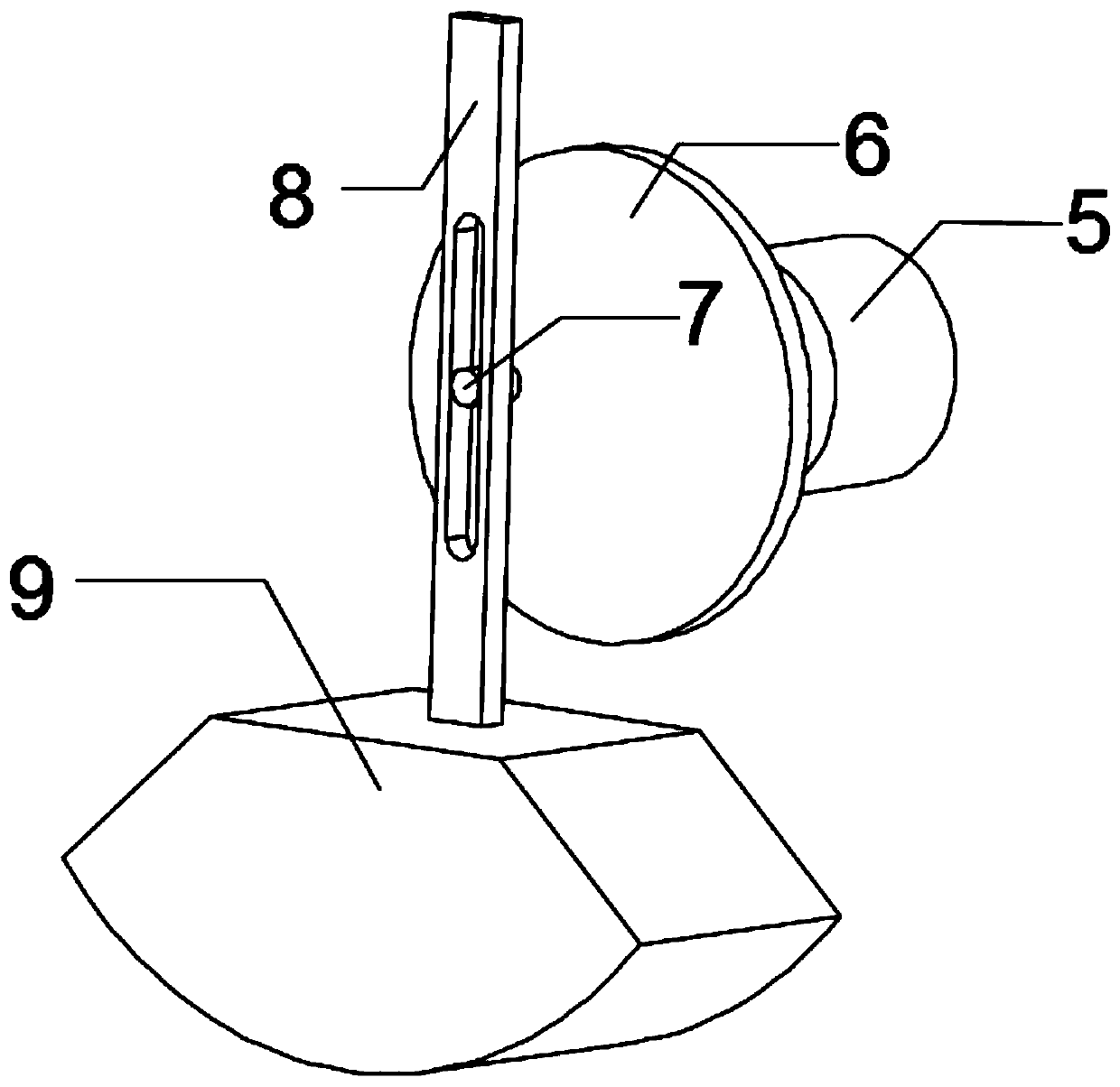

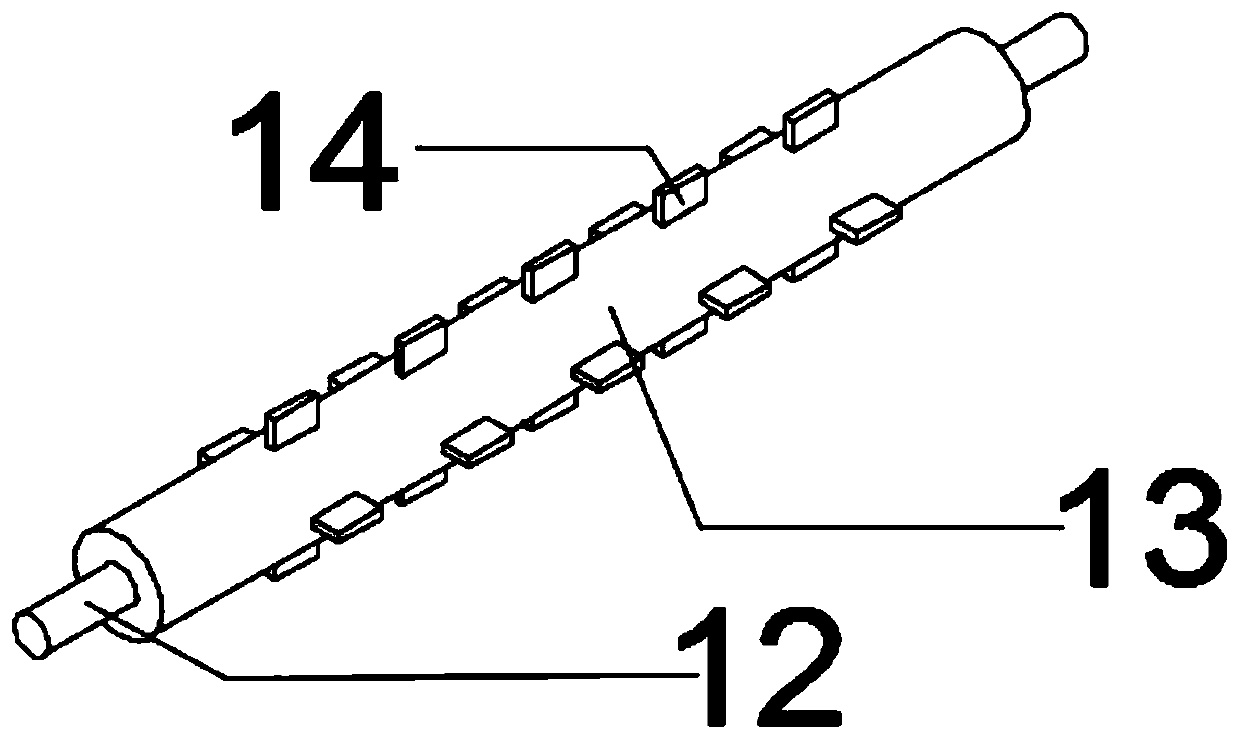

[0019] see Figure 1-3 , the present embodiment provides a coal pulverizing device for a gasifier, comprising a device housing 1, a feed port 2, a discharge port 3 and a milling mechanism; the upper and lower ends of the device housing 1 are respectively provided with feed Port 2 and discharge port 3; said device casing 1 is also provided with a grinding mechanism; also includes a crushing mechanism; said crushing mechanism is located in the device casing 1 and is located above the grinding mechanism; said crushing mechanism includes a crushing mechanism Plate 11, crushing rotating shaft 12, crushing drum 13 and a pushing mechanism; the crushing plate 11 is fitted and fixed inside the device casing 1; a plurality of crushing rotating shafts 12 are arranged to rotate on the device casing 1; A crushing drum 13 is fixed on the crushing rotating shaft 12; a plurality of crushing blocks 14 are equidistantly and symmetrically fixed on the crushing drum 13; and the crushing drum 13 i...

Embodiment 2

[0027] This embodiment is further improved on the basis of Embodiment 1. The improvement is: in order to prevent the pulverized coal from accumulating in the lower sliding groove, causing the discharge bottom plate 23 to be unable to move, both ends of the discharge bottom plate 23 are provided with stoppers. plate 25, and the baffle plate 25 fits with the inner wall of the device housing 1; the width of the baffle plate 23 is greater than the width of the lower sliding groove, and the length is greater than the length of the lower sliding groove, which can prevent coal dust from accumulating in the lower sliding groove Inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com