Coal roadway rapid tunneling equipment

A fast, coal-way technology, applied in the direction of propulsion, driving devices, mining equipment, etc., can solve the problems of poor safety, low production efficiency, poor adaptability to working conditions, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

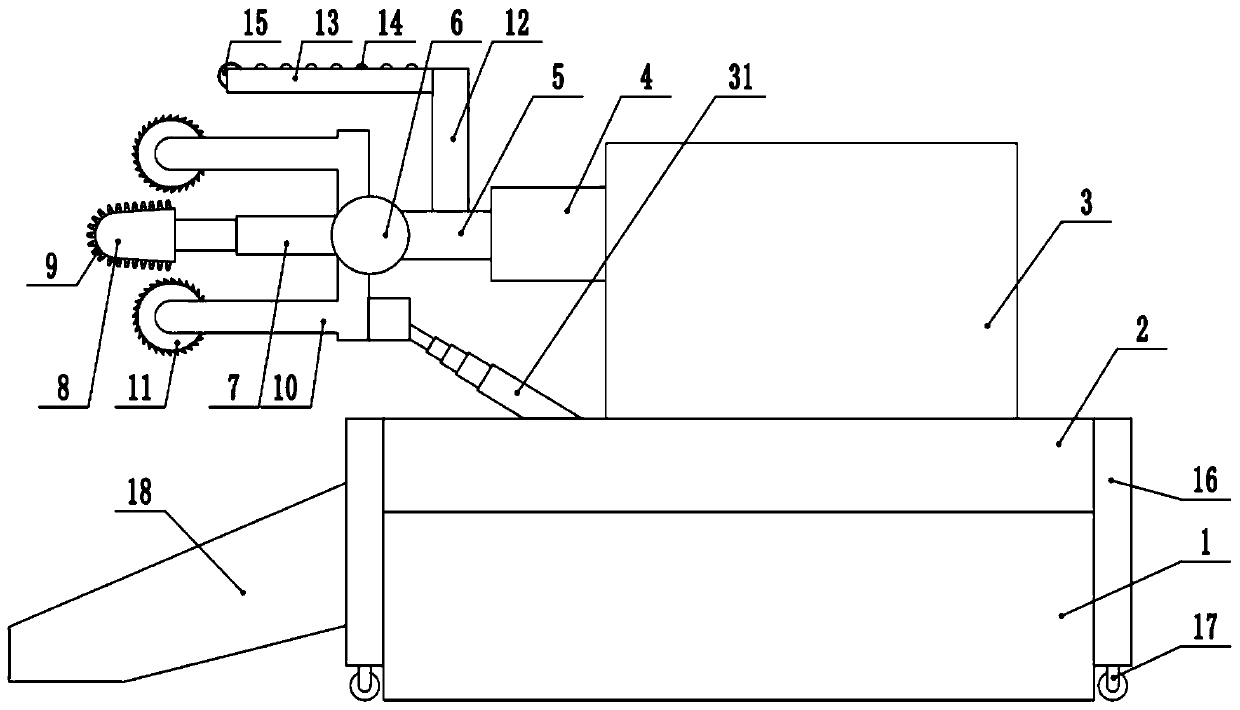

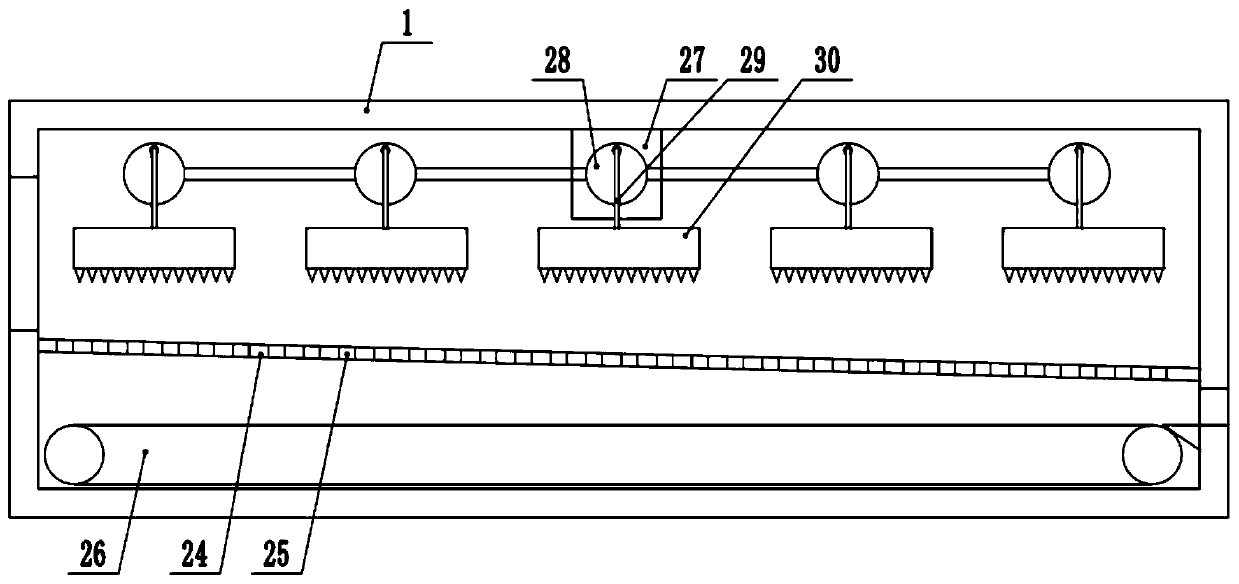

[0022] see Figure 1-3 , a coal roadway rapid excavation equipment, comprising a collection box 1, the top of the collection box 1 is fixedly connected to an equipment table 2, the top of the equipment table 2 is fixedly connected to an equipment box 3, one end of the equipment box 3 is fixedly connected to a fixing seat 4, and the fixing seat 4 One end away from the equipment box 3 is fixedly connected to the fixed column 5, and the end of the fixed column 5 away from the fixed seat 4 is connected to the rotating seat 6 in rotation, and the rotating seat 6 is fixedly connected to the driving rod 7, and the telescopic end of the driving rod 7 is connected to the main driving head 8 in rotation. The main tunneling head 8 is provided with a crushing cutter head 9, the top and the bottom end of the rotating base 6 are all fixedly connected to the side fixed rod 10, and the end of the side fixed rod 10 is rotatably connected to the auxiliary tunneling head 11. The top is rotatably...

Embodiment 2

[0025] see Figure 1-3 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that a supporting device is fixedly provided on the fixed column 5, and the supporting device includes a push rod 12 fixedly arranged at the top of the fixed column 5, and One side of the top of the rod 12 is fixedly connected to the support plate 13, and the top of the support plate 13 is rotatably connected to a plurality of pulleys 14, and the end of the support plate 13 away from the push rod 12 is rotatably connected to the leveling roller 15.

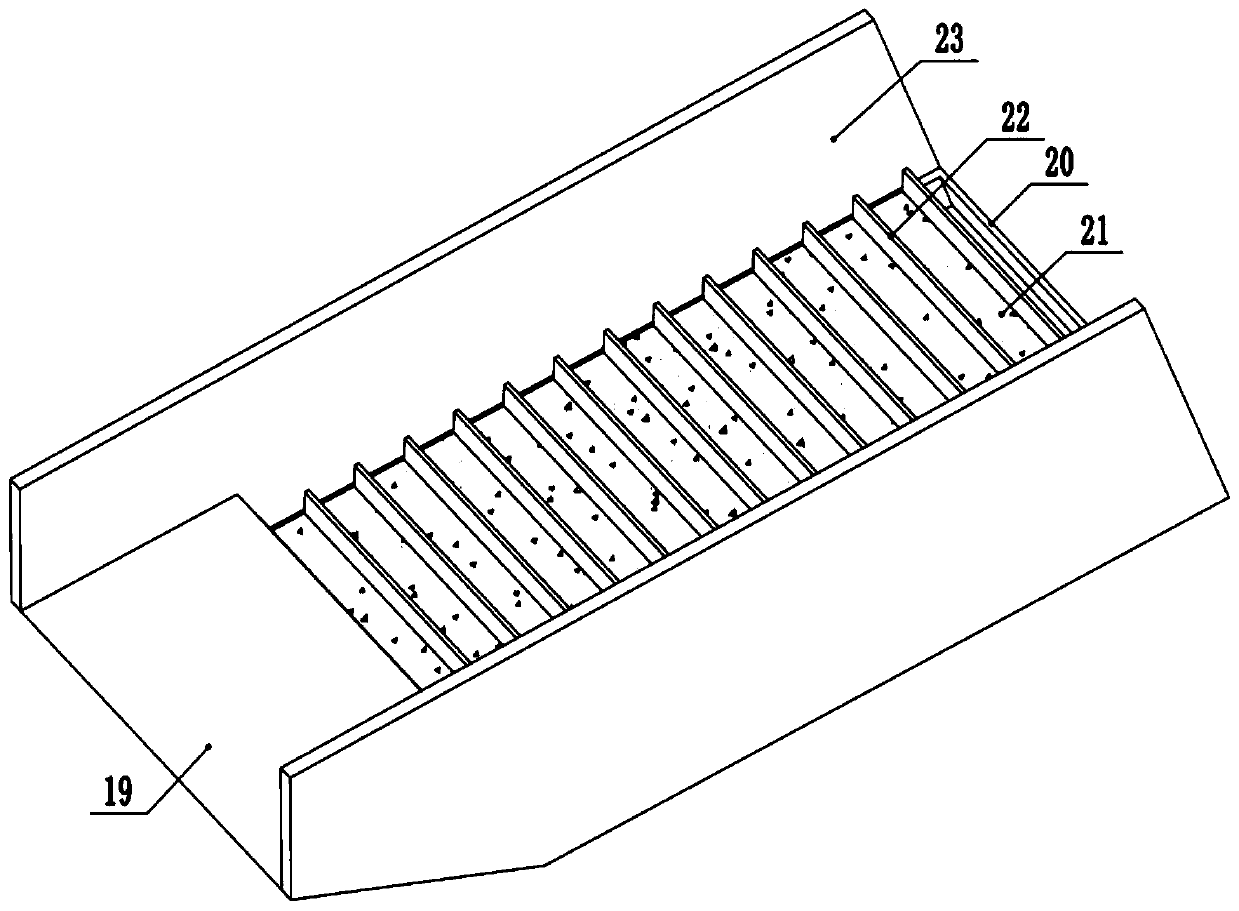

[0026] The present invention can realize the excavation function by arranging the main excavation head 8, can provide assistance to the excavation work by arranging the auxiliary excavation head 11, can transport the coal blocks produced in the excavation process by arranging the collecting device 18, and can transport the coal lumps produced in the excavation process by arranging the supporting device. The top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com