Full-section shoveling and recycling device for digging, supporting and anchoring combined unit and using method

A combined unit and recovery device technology, applied in mining equipment, transportation and packaging, ground mining, etc., can solve the problem of not being able to adapt well to the turning conditions of the combination unit of excavation, support and anchor, and to the change of roadway width. Due to the problems of poor flexibility of the excavating, supporting and anchoring unit, it can achieve the effect of changing the width of the roadway, easily adapting to the working conditions of up and down slopes, and improving the flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

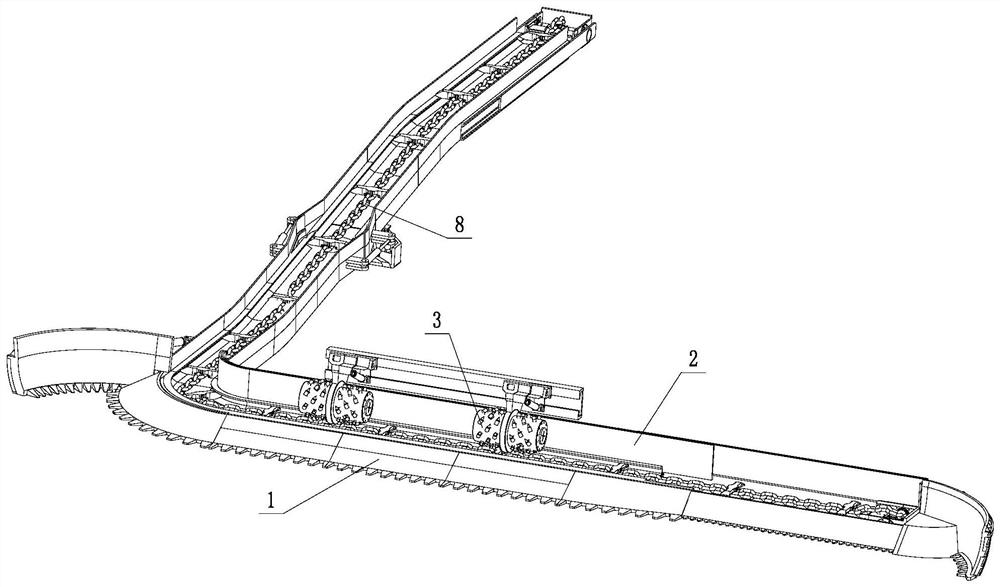

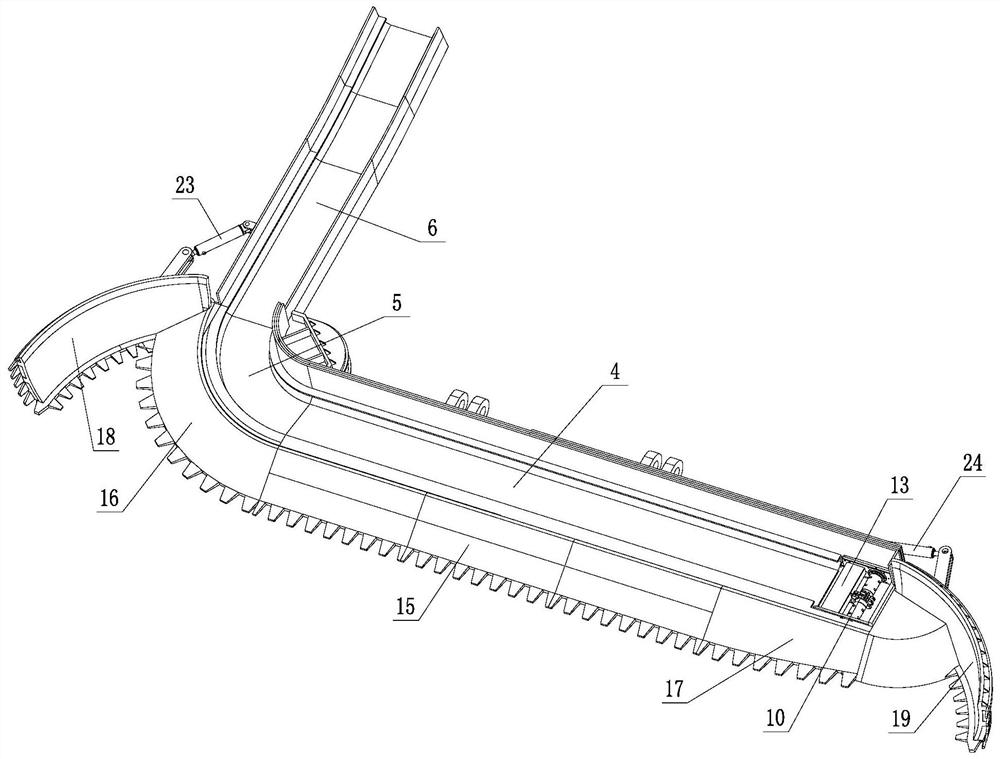

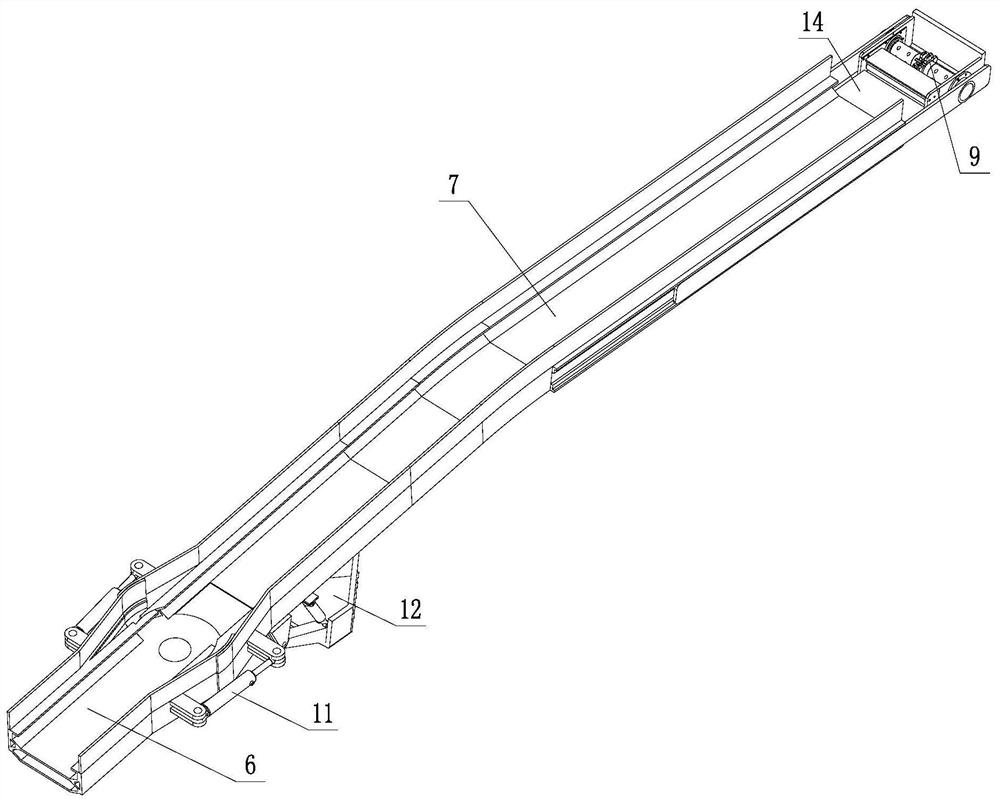

[0023] like Figure 1~5 As shown in the figure, a full-section shoveling and recovery device for a digging, supporting and anchoring combined unit includes a scraping mechanism 1, a transportation mechanism 2 and an auxiliary crushing mechanism 3; the transportation mechanism 2 adopts a right-angle turn structure, and one branch of the transportation mechanism 2 The arm is located at the front end of the excavation, support and anchor unit, and the other arm of the transport mechanism 2 is located at the side of the excavation, support and anchor unit; The front end of the transport mechanism 2; the auxiliary crushing mechanism 3 is located above the shovel mechanism 1, and the auxiliary crushing mechanism 3 is arranged at the front end of the excavation, support and anchor unit.

[0024] Described transport mechanism 2 comprises tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com