Coal briquette separation equipment with automatic transmission function

An automatic transmission and function technology, applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of coal block blanking, easy to remain, and long blanking plates, etc., to facilitate cleaning and reduce workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

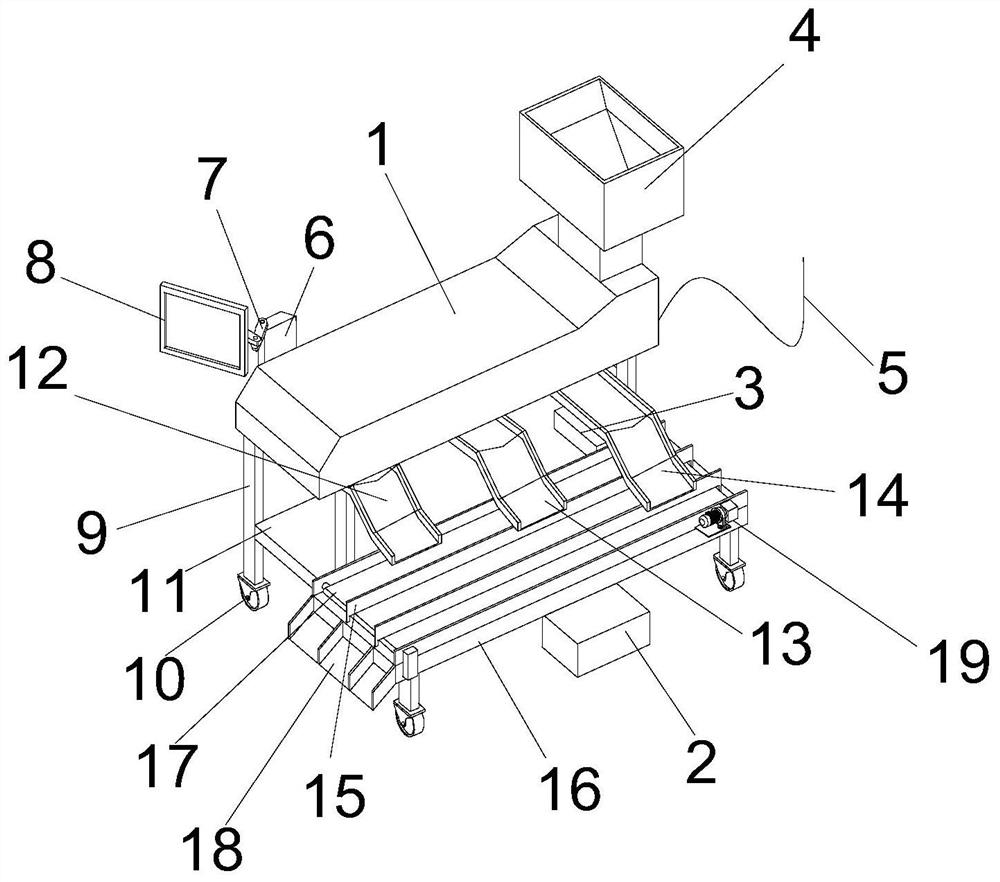

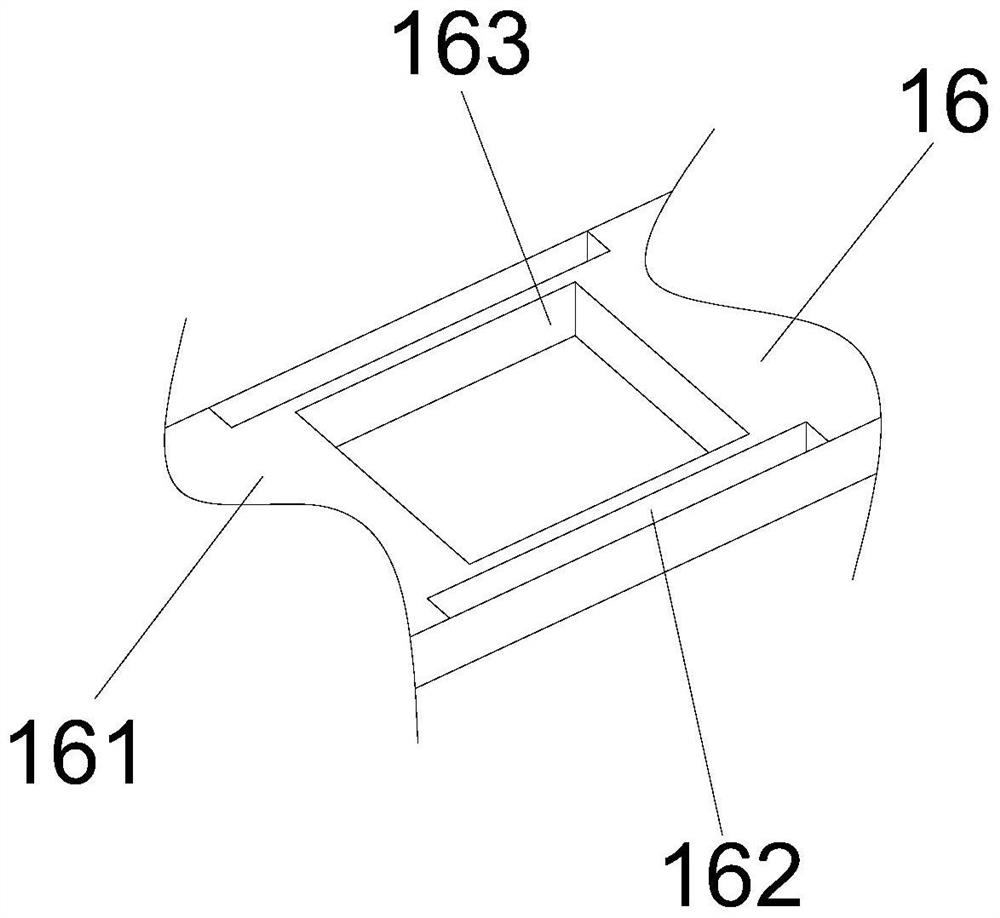

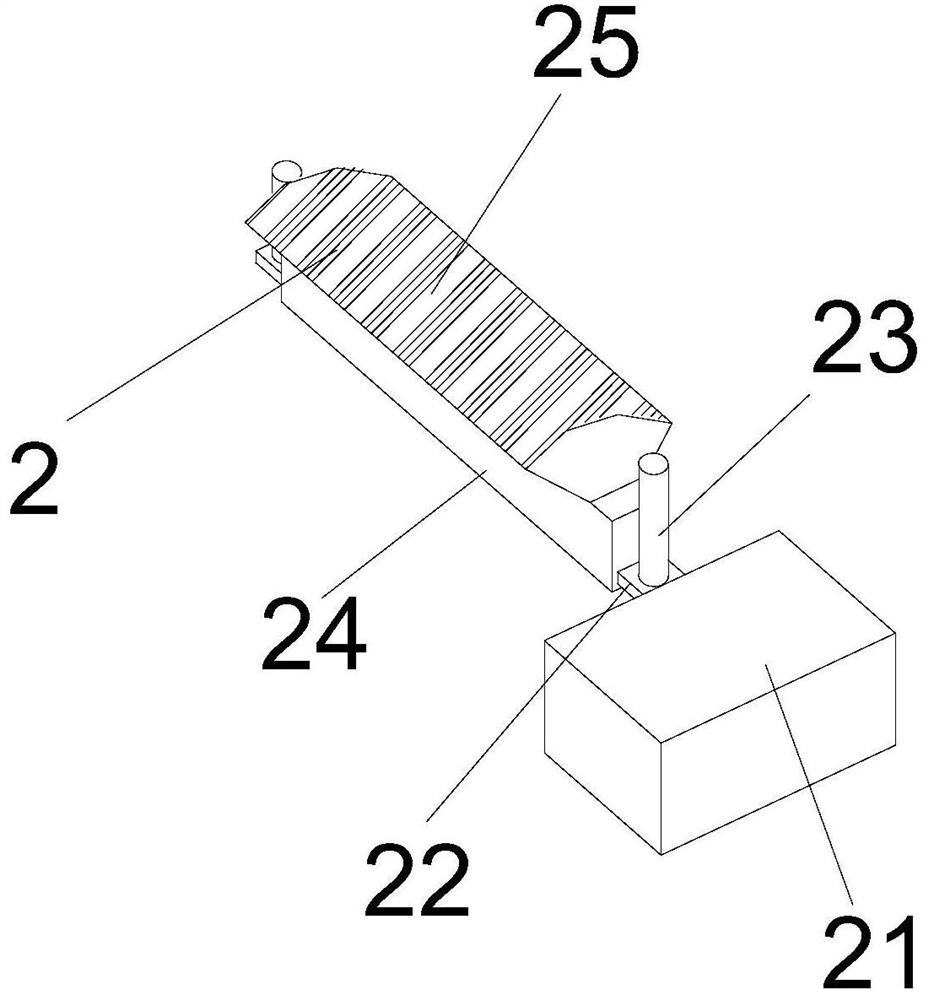

[0030] see figure 1 , the present invention provides a coal sorting device with automatic transmission function through improvement, including a body 1, the right end of the top of the body 1 is fixed with the feed hopper 4, the right side of the body 1 is provided with a power cord 5, and the rear of the body 1 The left end of the side is fixed integrally with the first fixed block 6, the top left end of the first fixed block 6 is rotationally connected with the rotating part 7, the left side of the rotating part 7 is fixed integrally with the display screen 8, the bottom of the body 1 is vertically provided with a leg 9, and the leg The bottom of 9 is fixed with the roller 10, the inner side of the leg 9 is fixed with the fixed plate 11, the left front end of the bottom of the body 1 is fixed with the first blanking plate 12, and the right end of the first blanking plate 12 is horizontally provided with a second blanking plate 13 , the right end of the second blanking plate ...

Embodiment 2

[0037] The present invention provides a kind of coal sorting equipment with automatic transmission function through improvement. The first motor 19 described in the present invention refers to an electromagnetic device that realizes electric energy conversion or transmission according to the law of electromagnetic induction. The circuit is represented by the letter M (the old standard is D). Its main function is to generate driving torque as a power source for electrical appliances or various machines. The generator is represented by the letter G in the circuit. Its main function is Convert mechanical energy into electrical energy.

[0038] The present invention provides a kind of coal block sorting equipment with automatic transmission function through improvement, and its working principle is as follows;

[0039] First, the user can firstly push the device so that the roller 10 can be better moved to the place where it needs to be used, and then connect the power cord 5 prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com