Movable buckling machine for manufacturing aluminum doors and windows or aluminum-clad wood doors and windows and like

An aluminum-clad, mobile technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of low production efficiency, labor and time-consuming, etc., and achieve the effect of convenient movement and good automatic locking effect of the buckle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

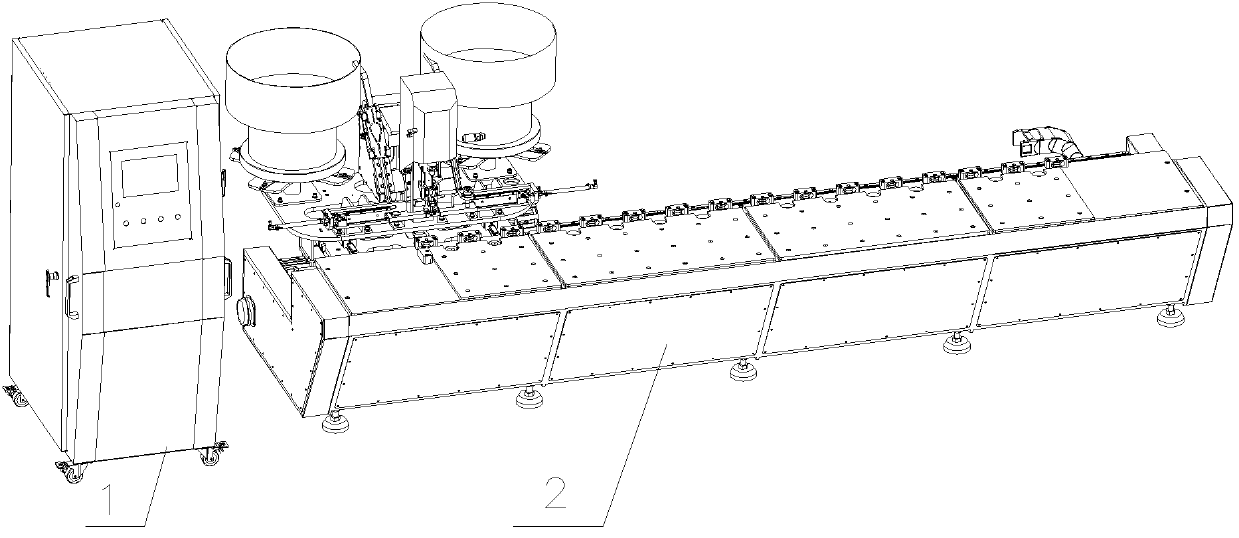

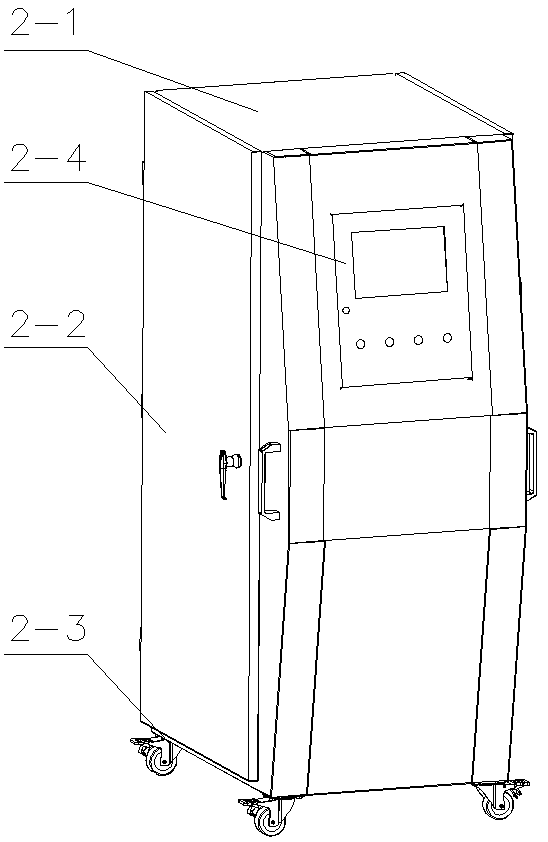

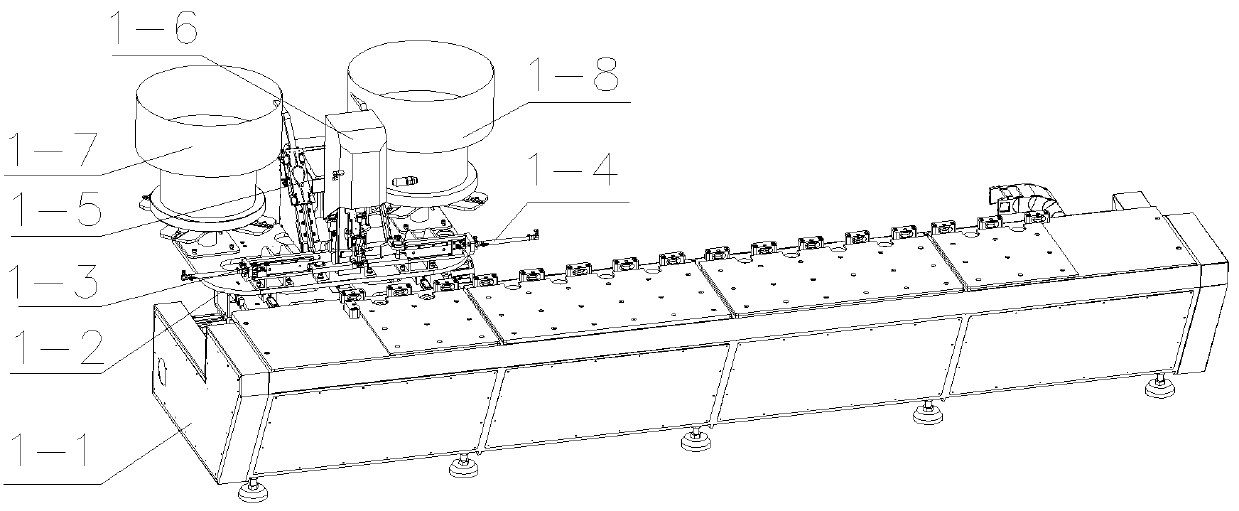

[0035] A mobile snap-fitting machine for making aluminum doors and windows or aluminum-clad wood doors and windows, etc., its composition includes: a control part 1 and a mechanical part 2, the described mechanical part includes a frame and a positioning group 1-1, and the described machine The frame and the positioning group are connected to the body group 1-2, the body group is connected to the left feeding group 1-3 and the right feeding group 1-4, and the left feeding group and the right feeding group are connected to the nail feeding group 1 -5, the nail feeding group is connected to the locking nail group 1-6, the locking nail group is connected to the left material guide group 1-7 and the right material guide group 1-8, and the control part includes the cabinet body 2- 1. The cabinet body is connected to the cabinet door 2-2, the bottom of the cabinet body is connected to the caster 2-3, and the cabinet body is connected to the screen 2-4.

Embodiment 2

[0037] A mobile buckle machine for making aluminum doors and windows or aluminum-clad wood doors and windows, etc. according to embodiment 1, the frame and positioning group include sheet metal 1-1-1, and the sheet metal connection pallet 1-1-2, the supporting plate connects the nylon cover A, 1-1-3 and the nylon cover B, 1-1-4, the nylon cover A and the nylon cover B are both Connect the bearing seat 1-1-5, the bearing seat 1-1-6 is installed in the bearing seat, the cylinder 1-1-7 is arranged in the frame and the positioning group, and the cylinder drives the suction cup to move 1-1 -8, the sheet metal connecting slideway 1-1-9.

[0038] The workpiece leans against the bearing on the pallet (the bearing is fixed by the bearing seat), and then the cylinder drives the suction cup

[0039] Raises and absorbs the workpiece.

Embodiment 3

[0041]A mobile snap-fitting machine for making aluminum doors and windows or aluminum-clad wood doors and windows, etc. according to embodiment 1, the body group includes connecting plate one 1-2-1 and connecting plate two 1-2-2, the The first connecting plate is connected to the female seat 1-2-3, the second connecting plate is connected to the body 1-2-4, the body is connected to the slider one, 1-2-5, the second connecting plate is Connect slide rail 1-2-6, described slide rail connects slide block two, 1-2-7, described body connects bracket box 1-2-8, described connecting plate one and described bracket box There is a drag chain 1-2-9 between them, the connecting plate 2 is connected to the motor base A, 1-2-10 and the shaft support 1-2-11, and the motor base A is connected to the servo motor A, 1 -2-12, the servo motor A is connected to the lead screw 1-2-13, the shaft support is connected to the motor seat B, 1-2-13, and the lead screw is connected to the servo motor B, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com