Coal briquette crushing device used for coal mining

A pulverizing device and coal block technology, applied in the application, solid separation, cocoa and other directions, can solve the problems of low pulverization efficiency and poor pulverization quality, and achieve the effect of improving efficiency, improving the degree of pre-pulverization, and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

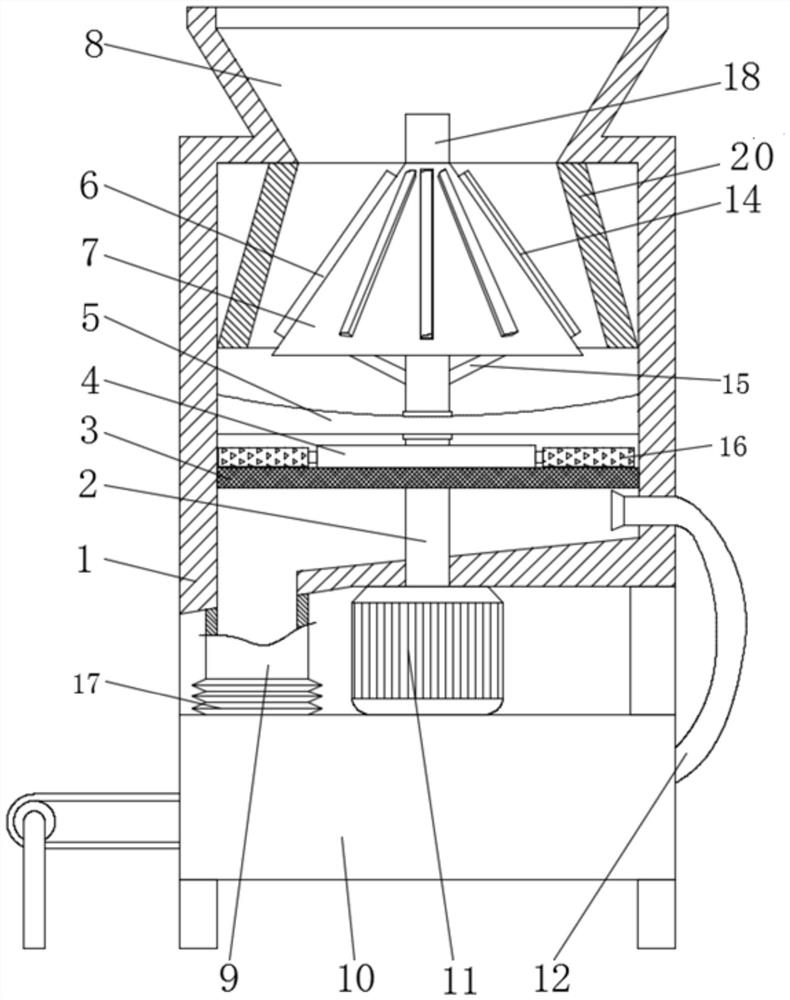

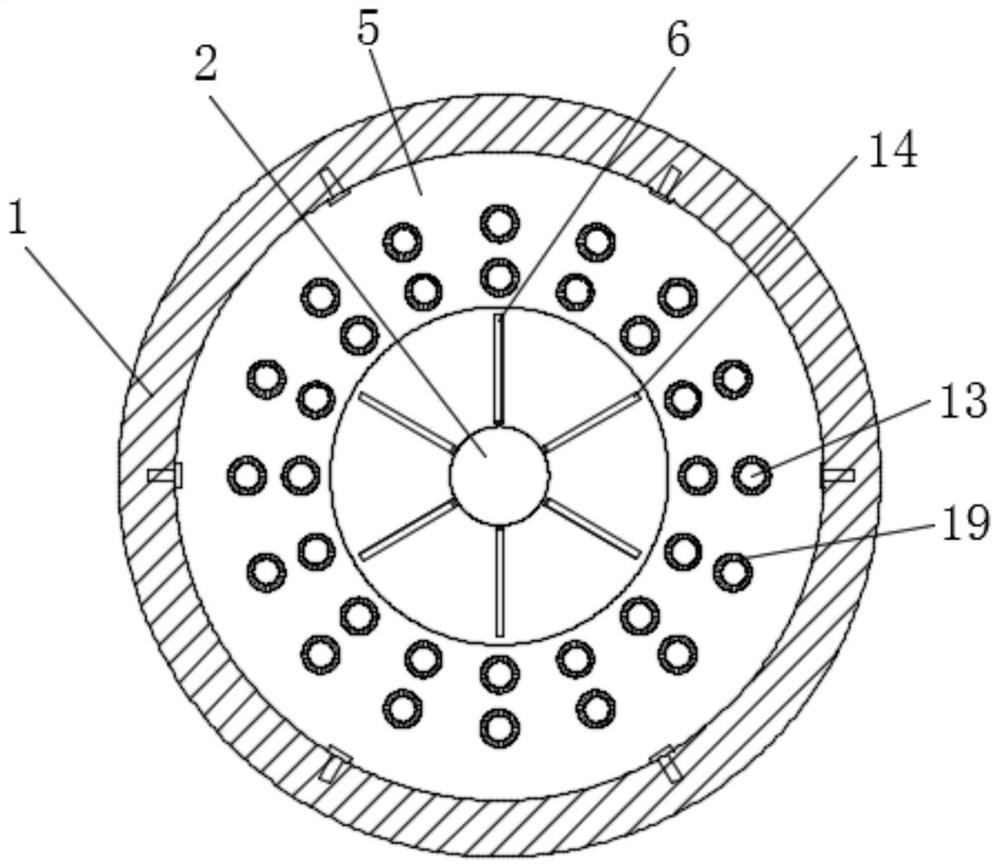

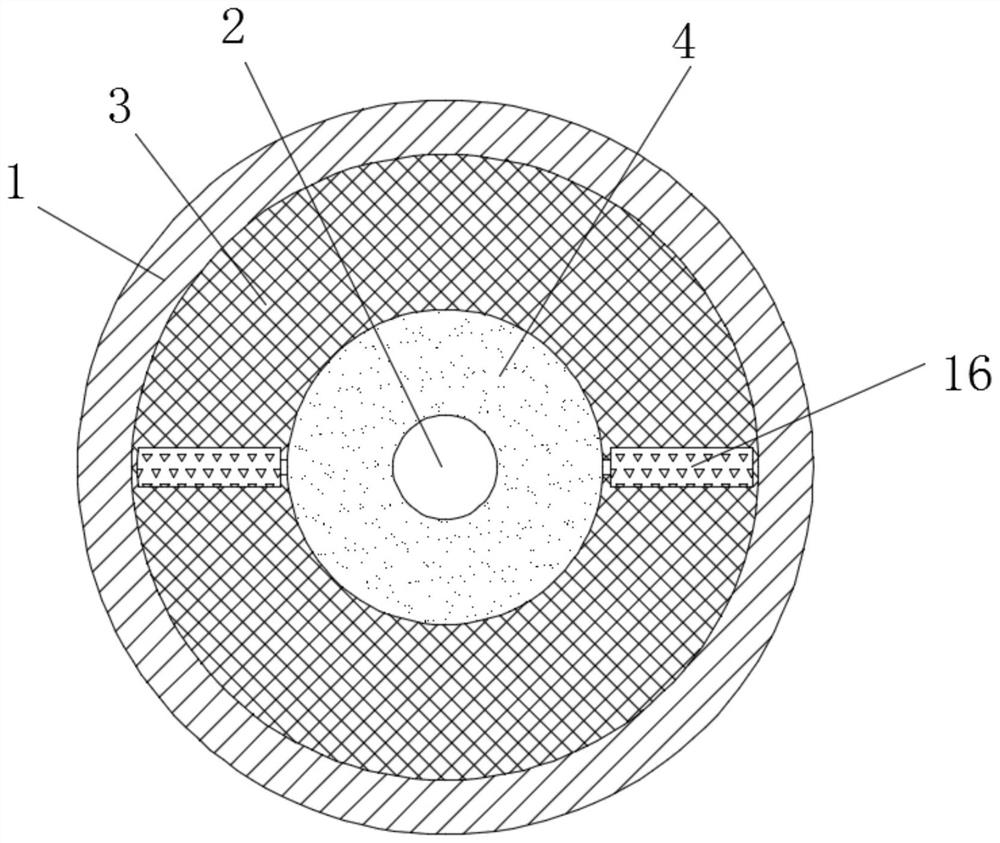

[0028] see Figure 1-3 , a coal crushing device for coal mining, comprising a machine body 1, a crushing chamber is arranged inside, the top and bottom of the crushing chamber are respectively provided with a feed port 8 and a discharge port 9, and the crushing chamber is arranged from top to bottom There are pre-crushing mechanism and grinding mechanism, the bottom of body 1 is provided with driving motor 11, the output shaft of driving motor 11 is connected to central shaft 2, and the upper end of the central shaft extends into the crushing chamber to connect with pre-crushing mechanism and grinding mechanism respectively.

[0029] The pre-crushing mechanism includes an inverted cone-shaped impact baffle 20 and a pre-crushing cone 7, the pre-crushing cone 7 is coaxially connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com