Agricultural greenhouse planting soil treatment crushing and refining equipment

A soil treatment and greenhouse technology, which is applied in the field of agricultural machinery, can solve the problems that the soil cannot be completely refined, cannot have enough oxygen, and the soil requirements for greenhouse planting are relatively high, and achieve the goal of being conducive to greenhouse planting, convenient movement, and smooth soil crushing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

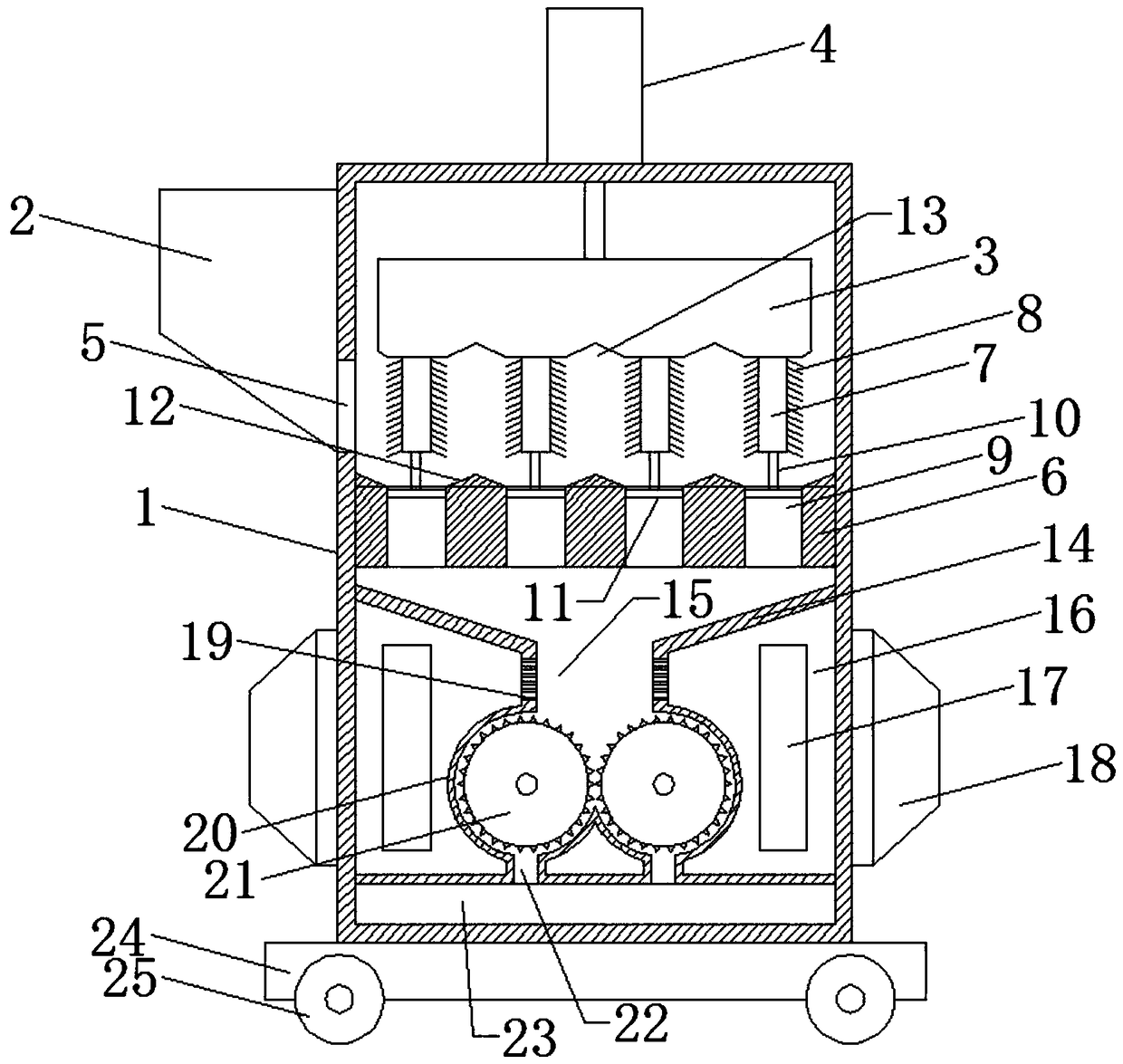

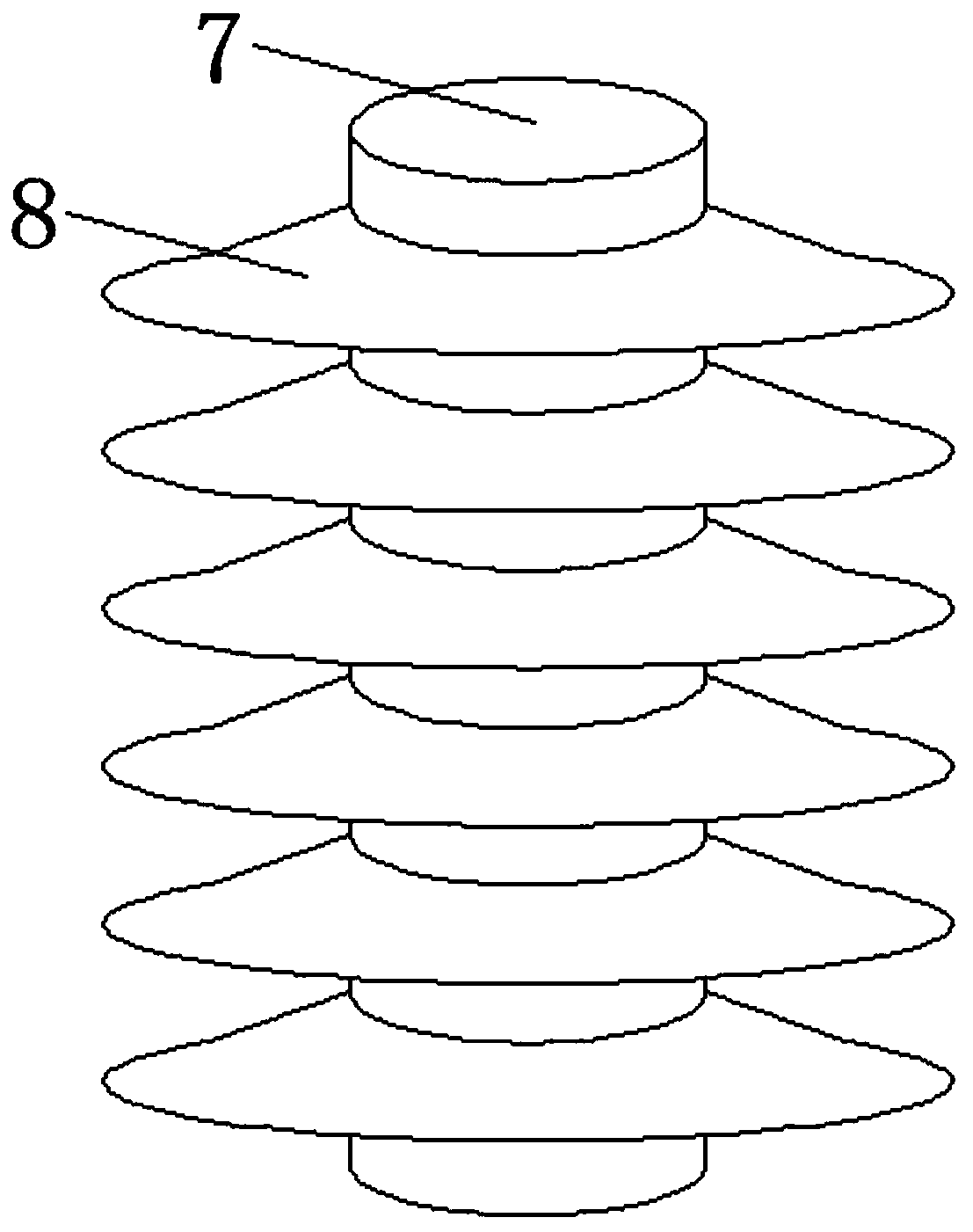

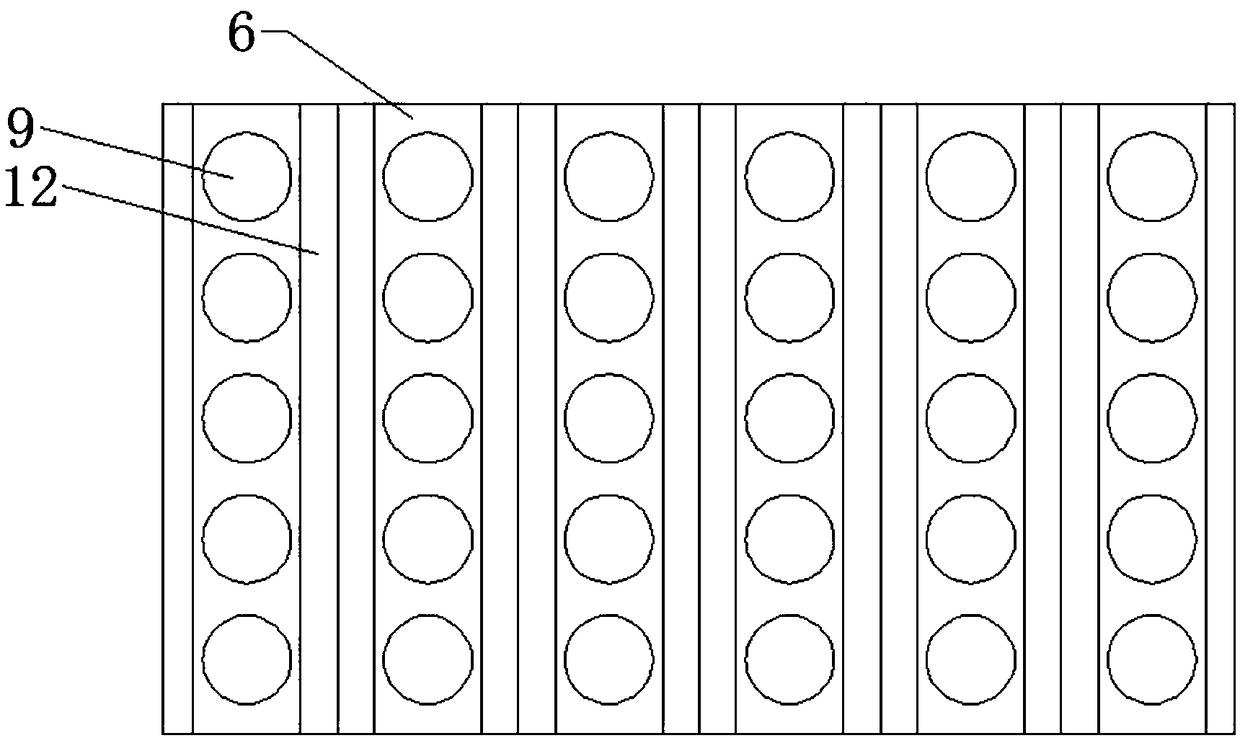

[0017] Please refer to the figure, in the embodiment of the present invention, a crushing and refining equipment for soil treatment for agricultural greenhouse planting includes a housing 1, a feed hopper 2, a driving device 4, a base 24 and a roller 25; the housing 1 is fixed On the base 24, the rollers 25 are installed on the four corners of the base 24 respectively, so that the equipment can be moved conveniently; A horizontal extruding block 3 is fixed on the output end of the driving device 4, and the extruding block 3 is driven to move up and down by the driving device 4, and an extruding plate 6 fixed on the inner wall of the housing 1 is arranged below the extruding block 3, The extruding block 3 moves downward and extrudes on the extruding plate 6 to squeeze and pulverize the soil falling into it; on the side wall of the housing 1 corresponding above the extruding plate 6, a feed port 5 is opened, and the feeding The port 5 communicates with the feed hopper 2 fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com