Distributed type coal mine gas pressure measuring system

A technology of coal mine gas and measurement system, which is applied in the field of coal mine equipment, can solve the problems of reduced utilization rate and increased cost of pressure measurement equipment, and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

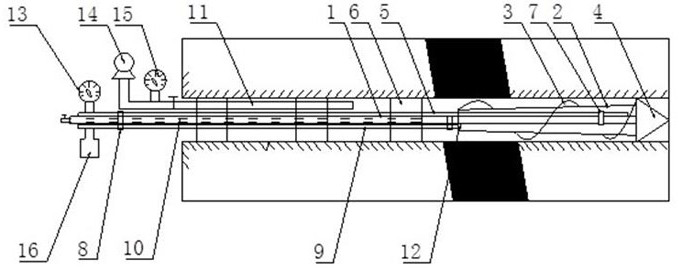

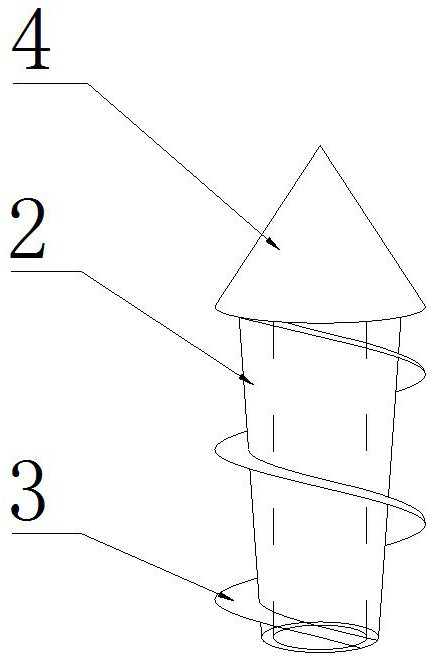

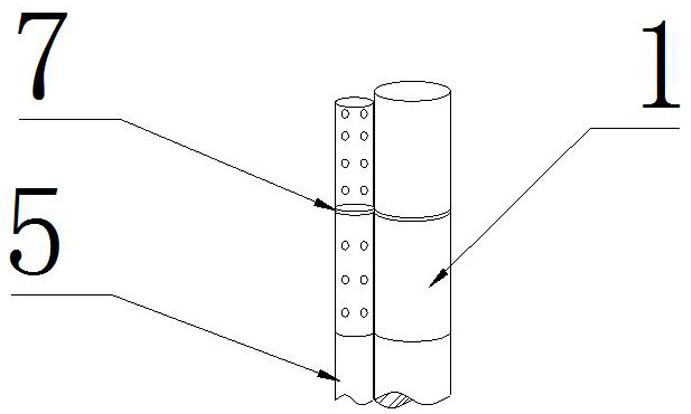

[0019] like Figure 1-5 A distributed coal mine gas pressure measuring system, including the pressure tube 5, drill pipe 1, the air tube 9, and the first water pipe 10, and the drill pipe 1 is provided with a double-shaft member 7, and a spiral is provided on the drill pipe 1. The rod 2 is provided with a drill bit 4 that is fixedly coupled to the spiral rod 2. The drill rod 1 is connected to the pressure pipe 5 through the double-shaft 7, and the drill pipe is provided with a first water pipe 10. There is a rubber water bag 6 in communication with the first water pipe 10.

[0020] A rubber water bladder 6 is provided with at least 1 in which the drill pipe is communicated with the first water pipe 10 is provided with a valve, and the drill rod 1 is divided into a solid structure in the spiral rod 2, and the drill pipe 1 is provided with The pressure tube 5 is connected to the three-axis 8 connected to the air tube 9 axis.

[0021] The spiral rod 2 is provided with a hollow structu...

Embodiment 2

[0025] A distributed coal mine gas pressure measuring system, which is compared with Example 1, the rubber water bag 6 is three, and the drilling hole is sealed by two aqueous layers, enhancing the sealing property, and the spiral rod 2 is installed with a grille. The grille can block a portion of the dust into the spiral rod 2 inside the retention of the pressure tube 5 is not blocked, and the water between the rubber water bags 6 is extracted after the pressure is completed, and then the water in the rubber water bag 6 is then discharged, and then drill The rod 1 is taken out from the drilling, and the hole is performed by the sealing device, and then the interior of the spiral rod 2 is cleaned by the air tube 9 or the pressure tube 5 to prevent the pressure pipe 5 from blocking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com