Improved fuel processing device for thermal power plant

A technology for fuel processing and thermal power plants, which is applied in the field of fuel processing devices for thermal power plants, and can solve problems such as affecting the life of the grinding structure, affecting the grinding efficiency, and being unable to fully support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

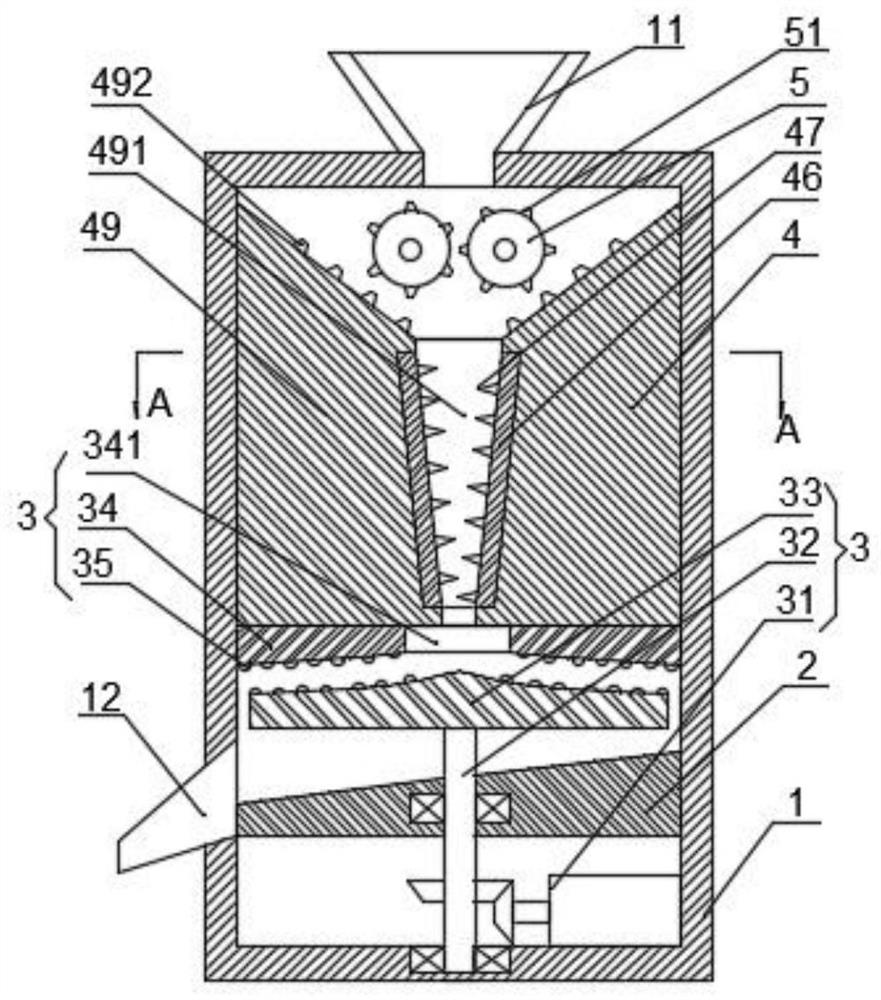

[0029] like figure 1 As shown, the embodiment of the present invention provides an improved fuel processing device for thermal power plants, comprising: a box body 1, the top is provided with a feed port 11, and the side wall of the lower part is provided with a discharge port 12; A grinding and crushing structure 4 and a grinding device 3 are arranged sequentially from top to bottom.

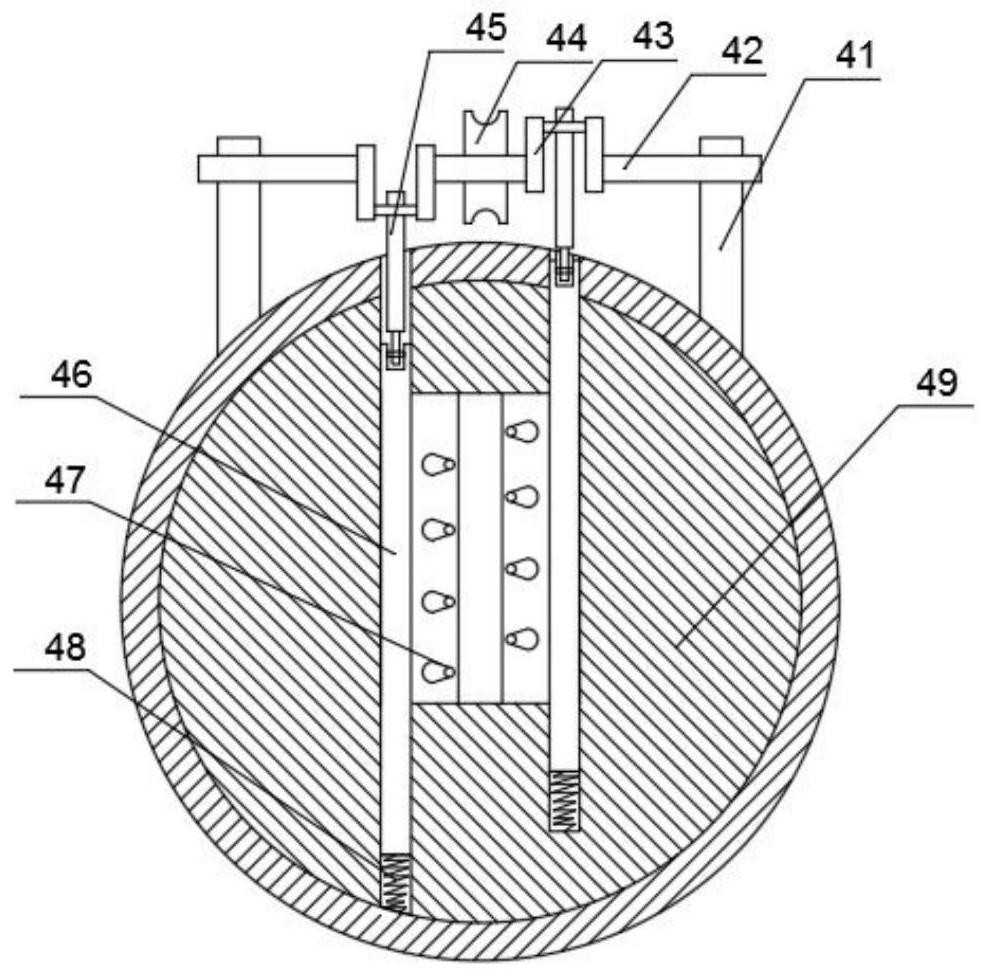

[0030] The rubbing and crushing structure 4 includes: a support body 49, the support body 49 is fixed in the casing 1 below the feed port 12, and the top of the support body 49 is provided with a slot 491 that runs through the support body 49; The guide structure is oppositely provided with two support plates 46, and a plurality of crushing heads 47 are uniformly arranged on the opposite surfaces of the two support plates 46; the drive structure 1 is arranged on the outside of the casing 1, and it is used to drive the two support plates 46 The guiding structure reciprocates horizontally in the...

Embodiment 2

[0035] On the basis of Embodiment 1, in order to make the crushing effect of the coal block better, the two support plates 46 are arranged obliquely, and the distance between the lower ends of the two support plates 46 is smaller than the distance between the upper ends of the two support plates 46 .

Embodiment 3

[0037] On the basis of Embodiment 1, a V-shaped groove is opened on the top of the support body 49, the slot 491 is opened on the inner bottom of the groove, and a plurality of protrusions are evenly distributed on the slope of the groove. From I492.

[0038] Wherein, in order to prevent the large lumps of coal from affecting the crushing effect of the rubbing and crushing structure 4, a crushing structure is provided in the groove, and the crushing structure includes two rollers 5 erected in the groove, and the circumferential direction of the rollers 5 is evenly distributed. A plurality of crushing heads 51 are provided, and the rotating shaft of one of the rollers 5 passes through the casing 1 and is connected with the output shaft of the motor 1 through a coupling, and the rotating shafts of the two rollers 5 are connected by a belt transmission.

[0039] Implemented 4

[0040] On the basis of Embodiment 1, a material guide plate 3 is also included, which is arranged obli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com