A Mechatronics Device for Detecting Dimensions of Mechanical Parts

A technology for mechanical parts and dimensions, which is applied in the field of mechatronics devices for detecting the dimensions of mechanical parts, can solve the problems of not being able to detect pipes of different specifications, affecting the detection efficiency of pipe wall thickness, etc., and achieves strong practicability, wide application range, detection Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

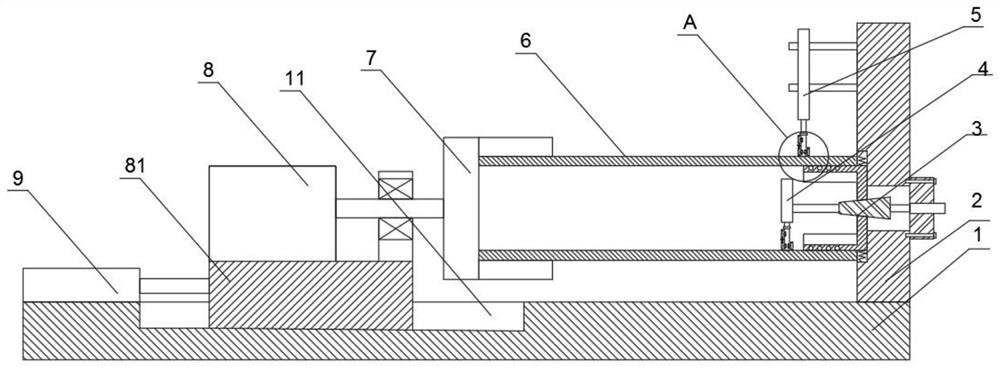

[0025] like figure 1 As shown, the embodiment of the present invention provides a mechatronic device for detecting the size of mechanical parts, including: a workbench 1; The detection structure I and the detection structure II whose directions are arranged on one side of the support plate 2 have the same structure. .

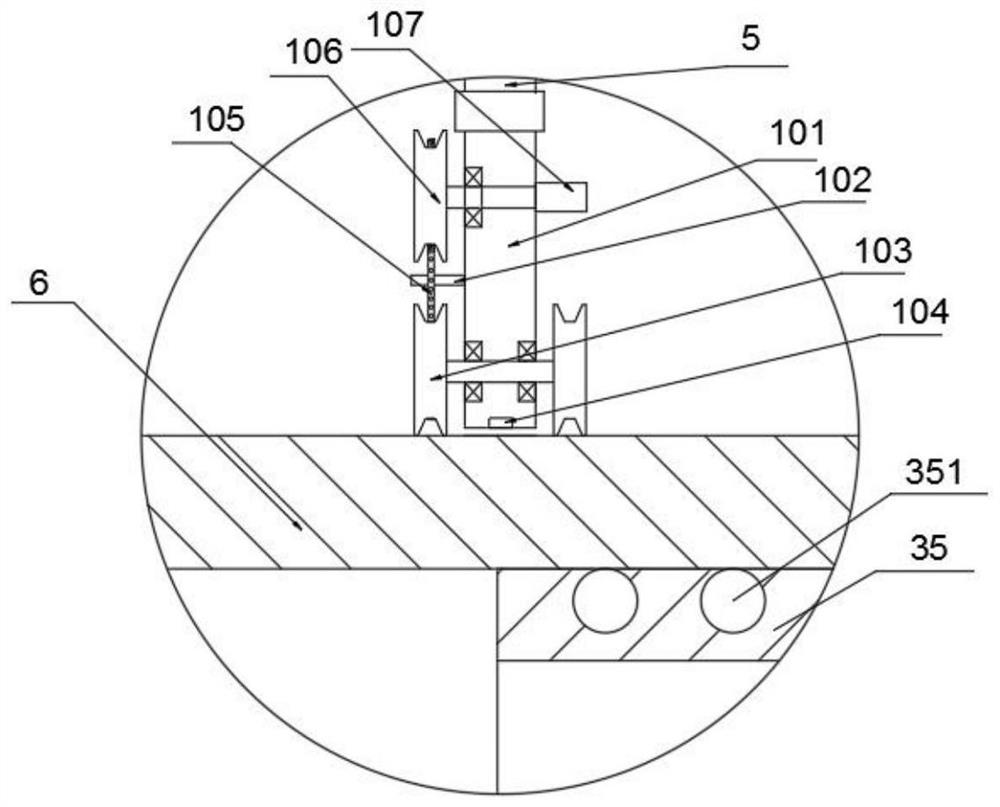

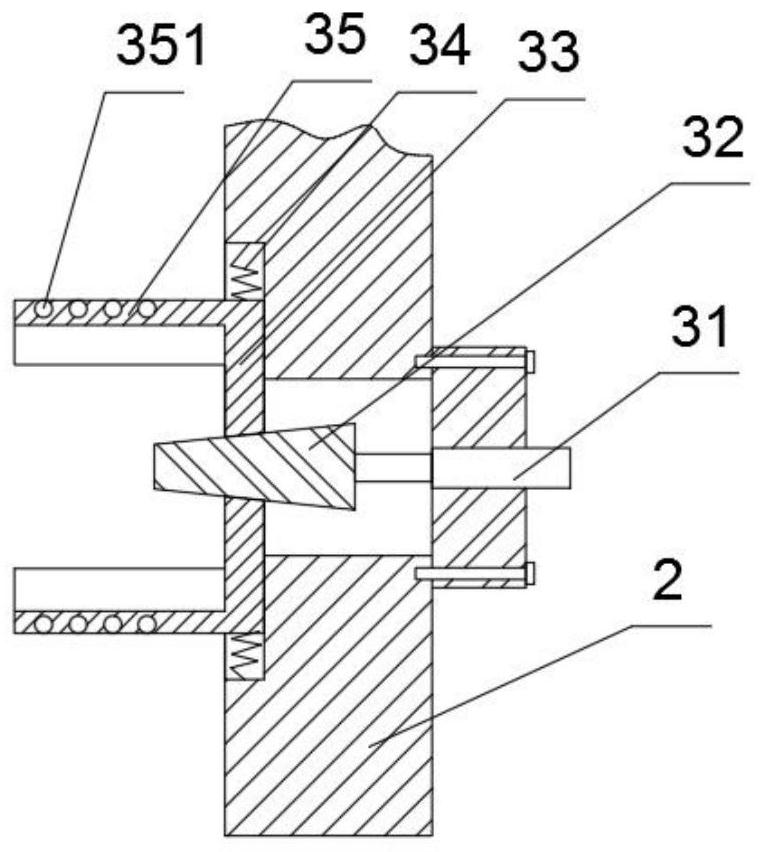

[0026] like figure 2 As shown, the detection structure I includes: a telescopic structure I5, the telescopic end of which is arranged vertically downward, and the telescopic end thereof is connected with a support rod 101, the end of the support rod 101 away from the telescopic structure I5 is provided with a distance measuring sensor 104, and a distance measuring sensor is provided The end of the support rod 101 of 104 is also provided with a roller 103; the winding wheel 106 is rotatably arranged at one end of the support rod 101 close to the telescopic end of the telescopic structure I5, and the winding wheel 106 and the roller 103 are located on the sa...

Embodiment 2

[0030] On the basis of Embodiment 1, the driving mechanism includes a stepping motor 8 arranged on the worktable 1, and the output end of the stepping motor 8 is connected with a three-jaw chuck 7 for clamping the pipe, and the three-jaw chuck 7 faces the support The board 2 is provided with one side of the detection structure II, and the controller and the stepping motor 8 are electrically connected.

Embodiment 3

[0032] On the basis of Embodiment 1, in order to adapt to the detection of pipes 6 of different lengths, an adjustment structure 9 provided on the workbench 1 is also included, and the adjustment structure 9 is used to adjust the distance between the three-jaw chuck 7 and the support plate 2 . distance.

[0033] The adjustment structure 9 includes a telescopic mechanism II horizontally fixed on the workbench 1, the telescopic end of the telescopic mechanism II is connected with a slider I81 for fixing the stepping motor 8, and the slider I81 is slidably arranged on the workbench 1 in the chute 11 opened on the 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com