Underground coal mine working face mining, selecting and filling integrated system and use method

A coal mining face and face technology, applied in chemical instruments and methods, filling materials, solid separation, etc., can solve the problems of heavy solid waste treatment burden, ineffective transportation and lifting, etc., to improve screening efficiency and increase production Efficiency, the effect of ensuring economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

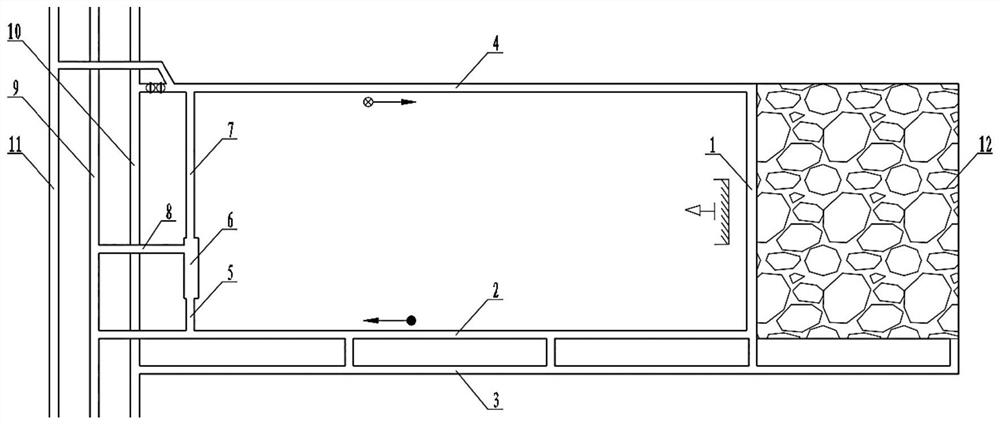

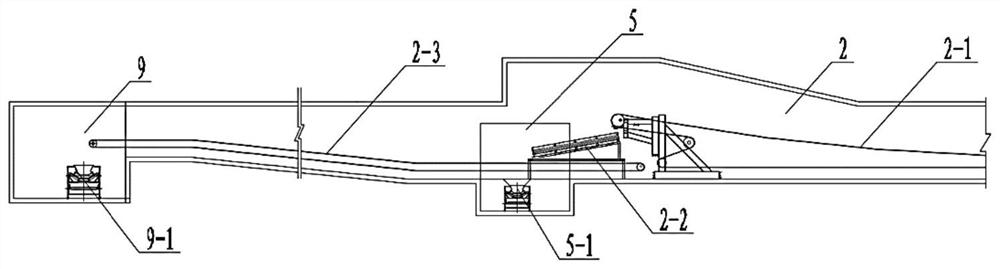

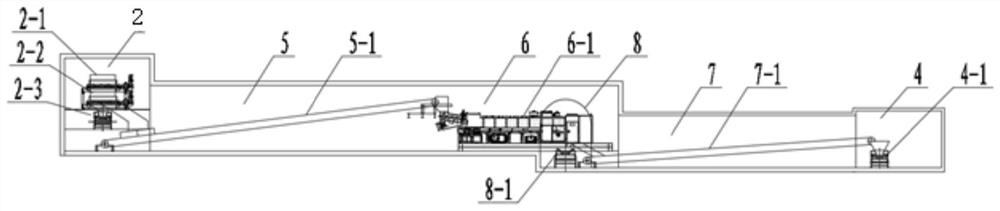

[0039]The invention provides an integrated system of mining, selection and filling in the underground working face of coal mine, such as figure 1 As shown, it includes the coal mining face 1, the main transportation lane 2 of the working face, the return air lane 4 of the working face, the main transportation lane 9, the return air lane 11, the goaf 12 of the working face and the intelligent dry separation in the coal mine. unit alley;

[0040] The input end of the main transport lane 2 of the working face is set on one side of the coal mining face 1, and the output end of the main transport lane 2 of the working face is connected to the main transport lane 9;

[0041] The input end of the air return lane 4 on the working face is connected to the main air return lane 11; the output end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com