Patents

Literature

41results about How to "Improve coal loading effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

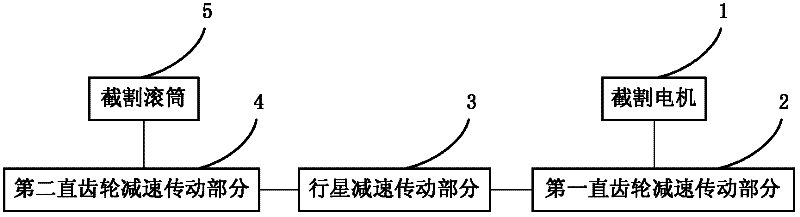

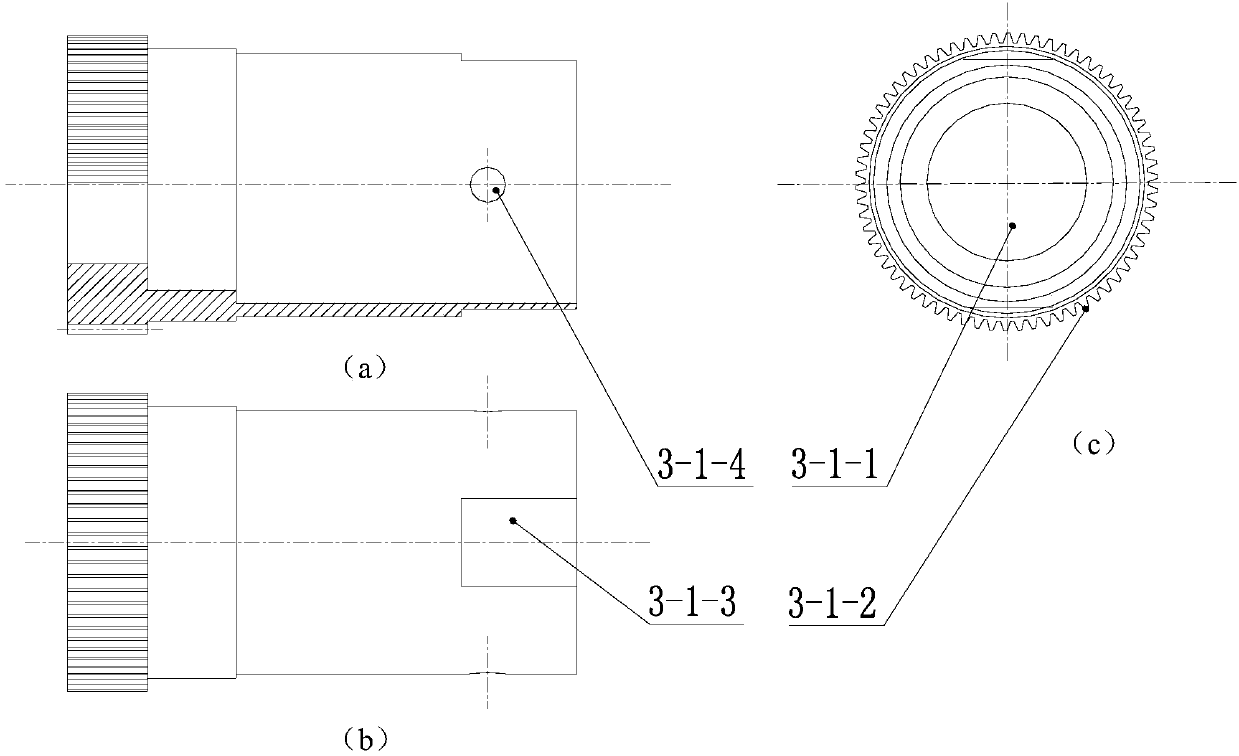

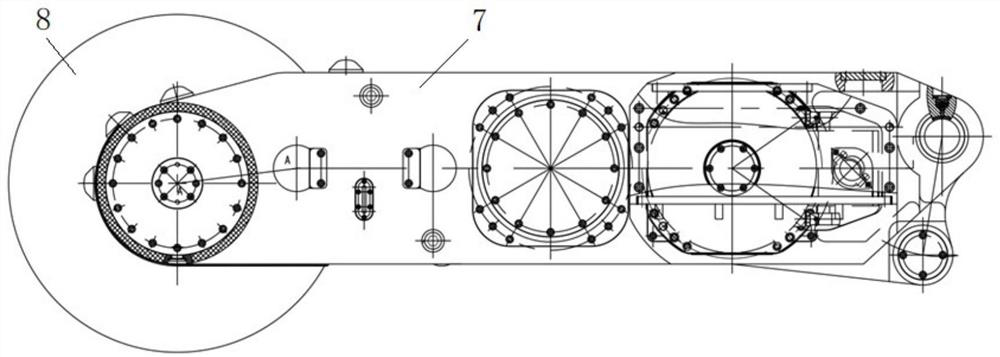

Coal cutter and rocker arm transmission system thereof

InactiveCN102434155ALarge transmission ratioReduce speedToothed gearingsDriving meansGear wheelEngineering

The invention relates to the field of mining machinery, and discloses a coal cutter and a rocker arm transmission system thereof. The rocker arm transmission system is arranged between a cutting roller and a cutting motor. The rocker arm transmission system comprises a first spur gear speed-reducing transmission part connected to the cutting motor, a second spur gear speed-reducing transmission part connected to the cutting roller, and a planet gear speed-reducing transmission part arranged between the first spur gear speed-reducing transmission part and the second spur gear speed-reducing transmission part. The rocker arm transmission system of the coal cutter has the advantage that the planet gear speed-reducing transmission part is arranged between the first spur gear speed-reducing transmission part and the second spur gear speed-reducing transmission part, and thus the rocker arm transmission system has a large transmission ratio; a rotating speed and a line speed of the cutting roller are reduced; a working face environment of the coal cutter is improved; a size of a structure cooperating with a cutting roller hub is reduced; the length of a cutting roller blade is increased; and coaling effects and coaling efficiency of a thin coal layer are improved.

Owner:SANY HEAVY EQUIP

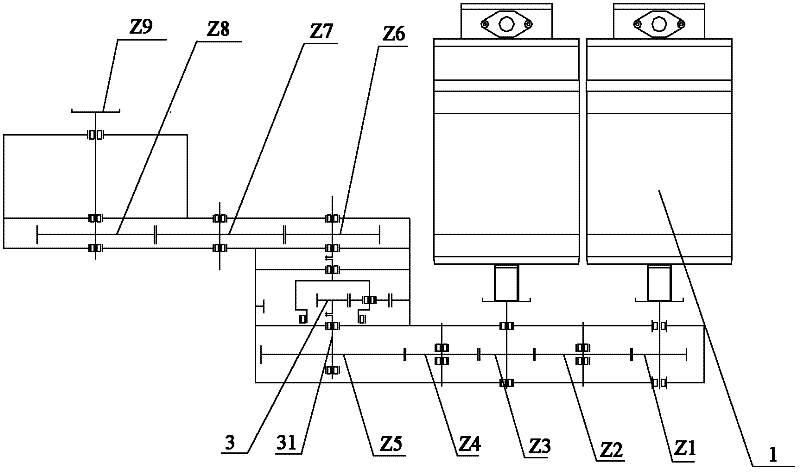

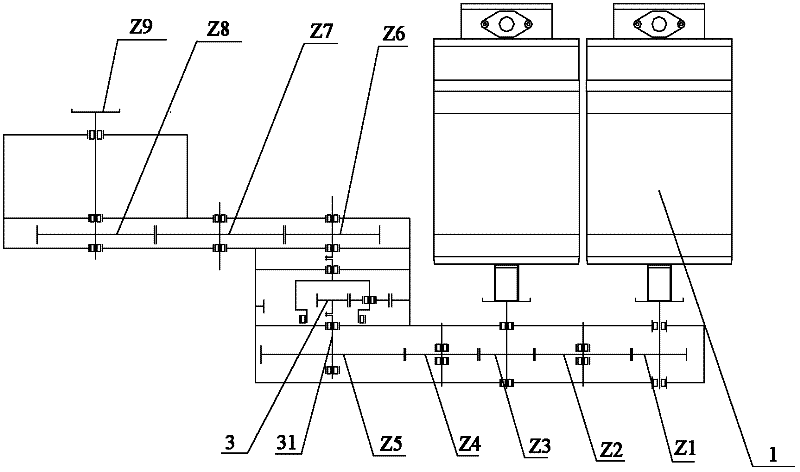

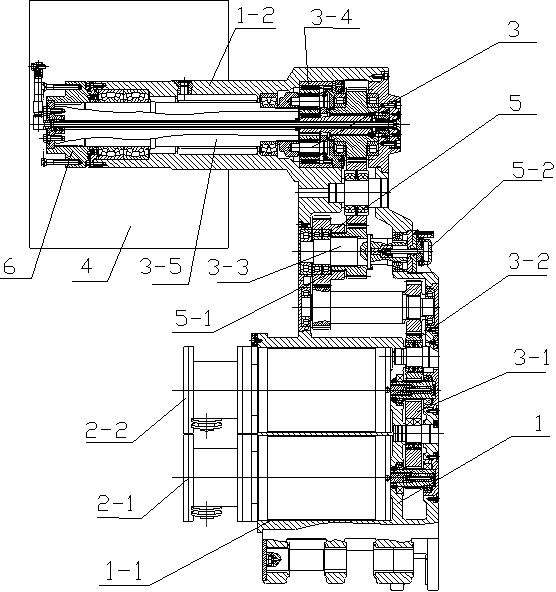

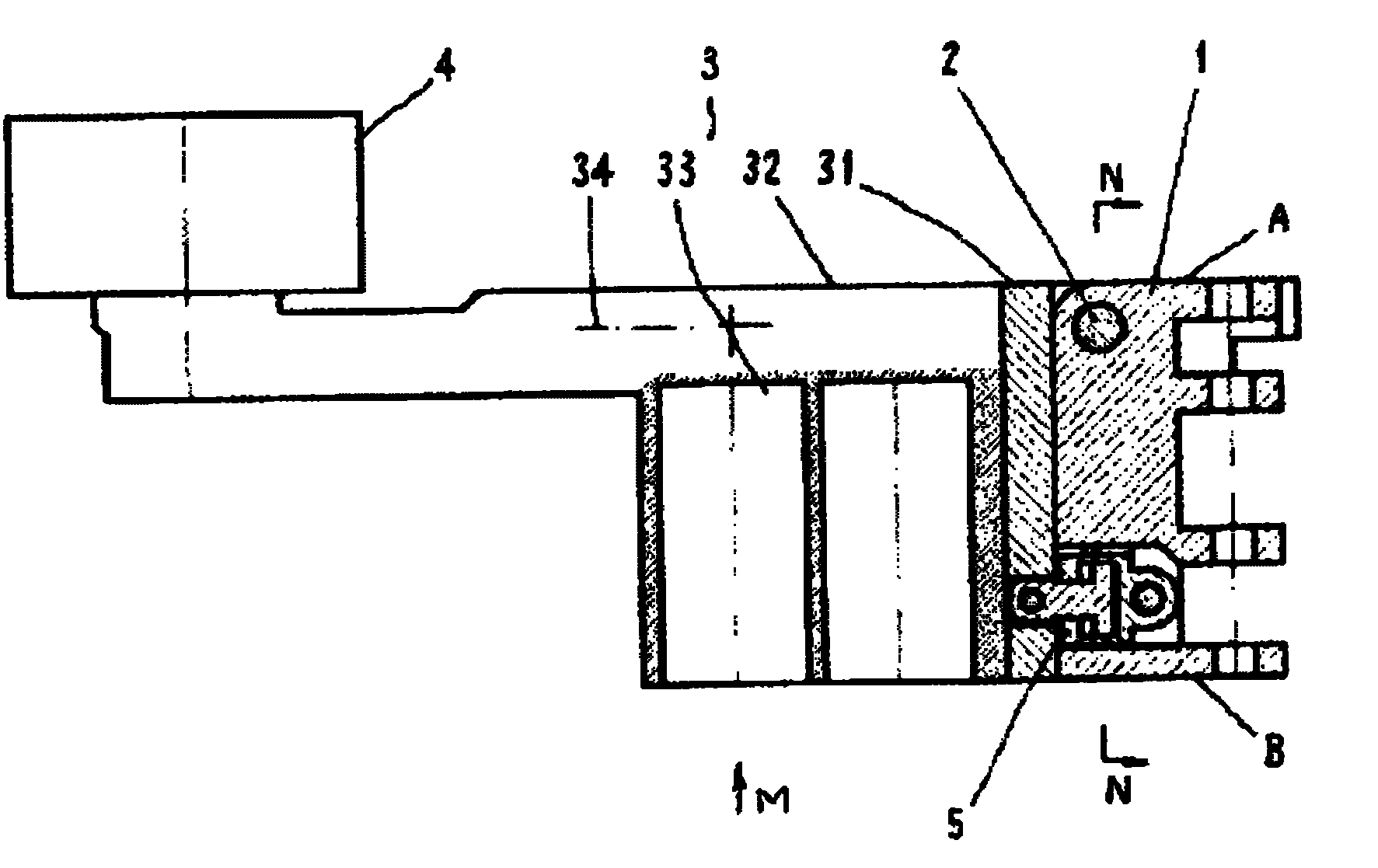

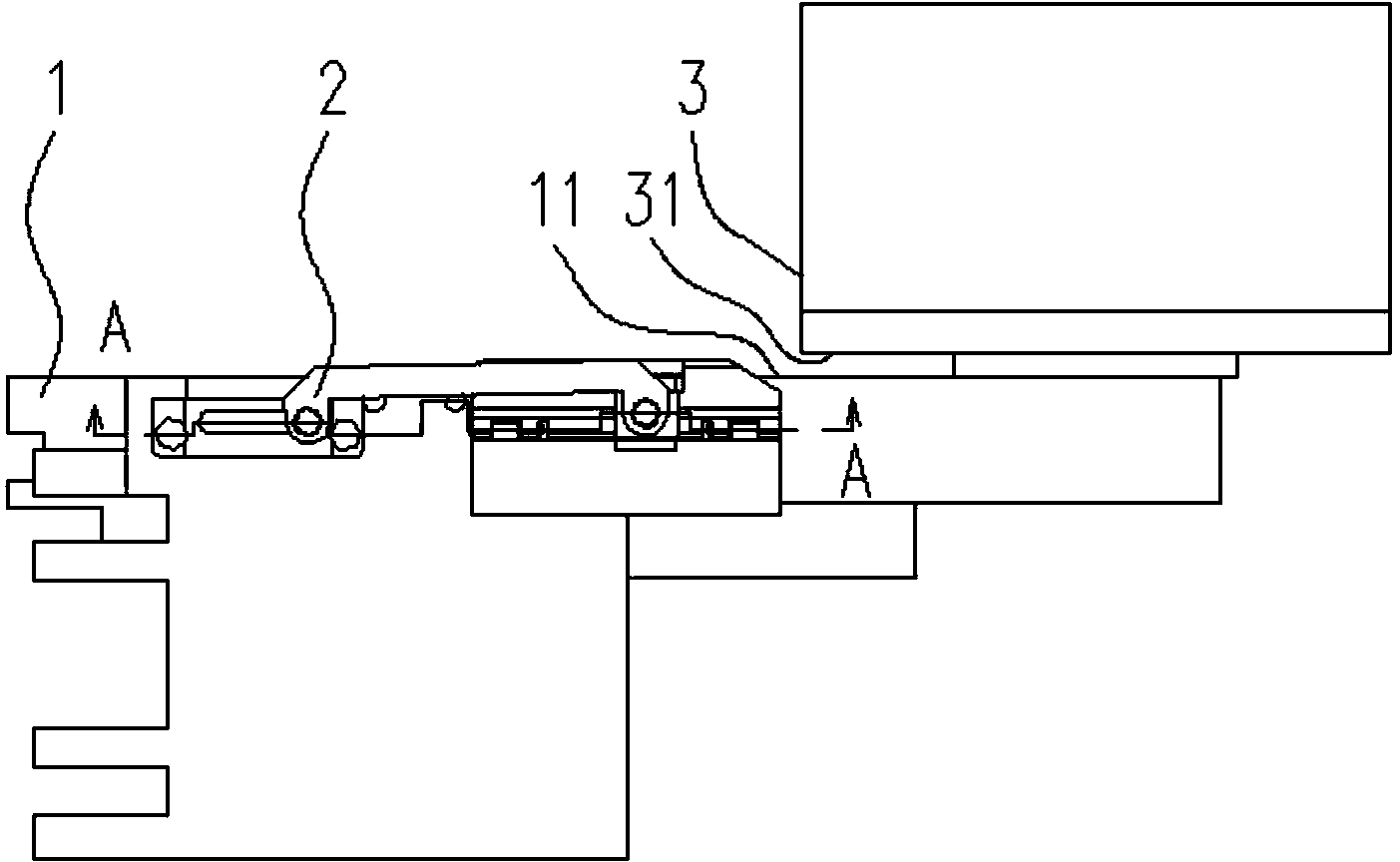

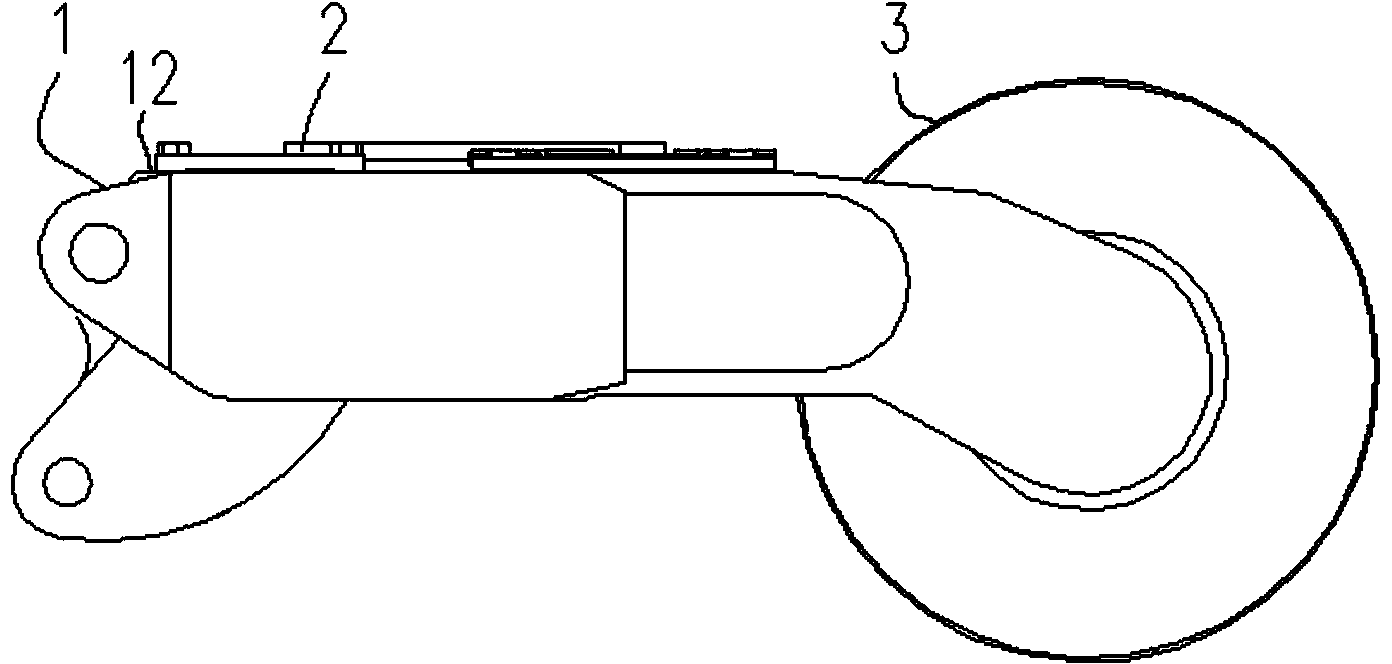

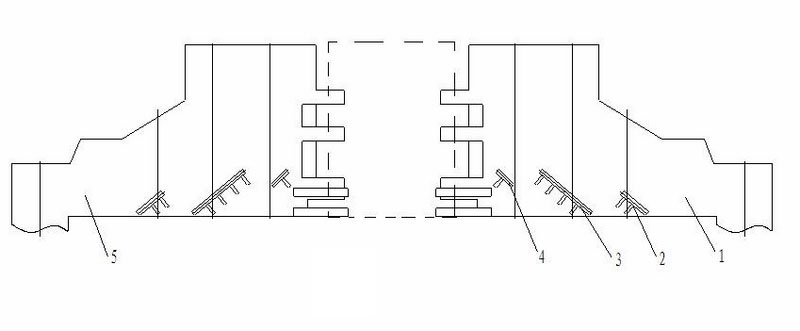

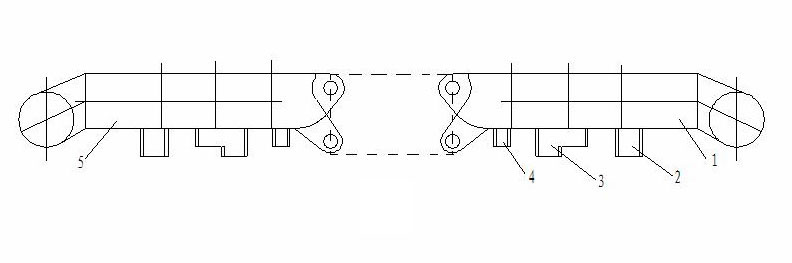

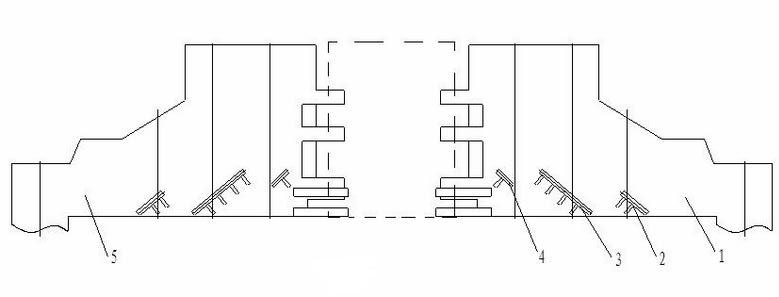

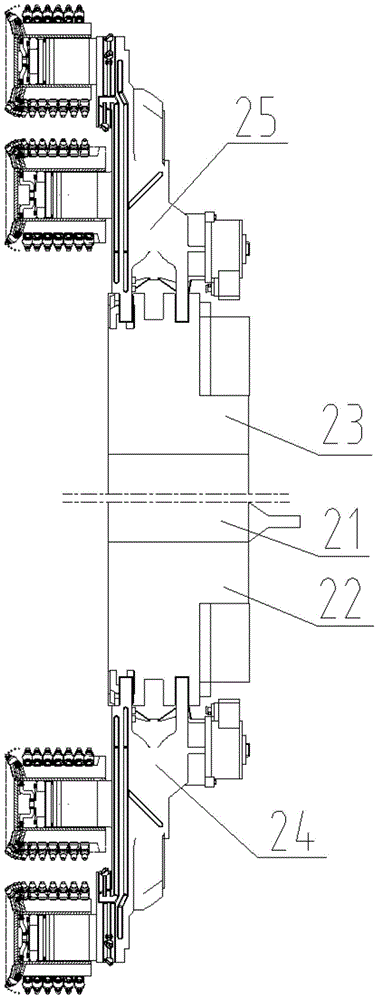

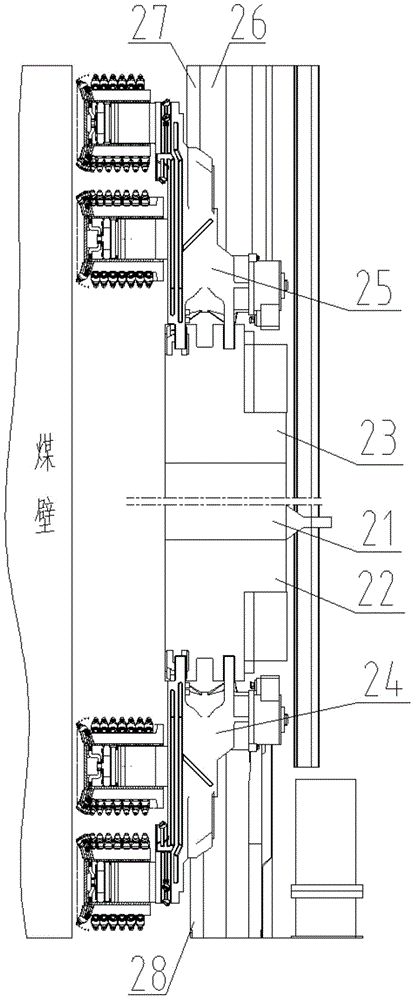

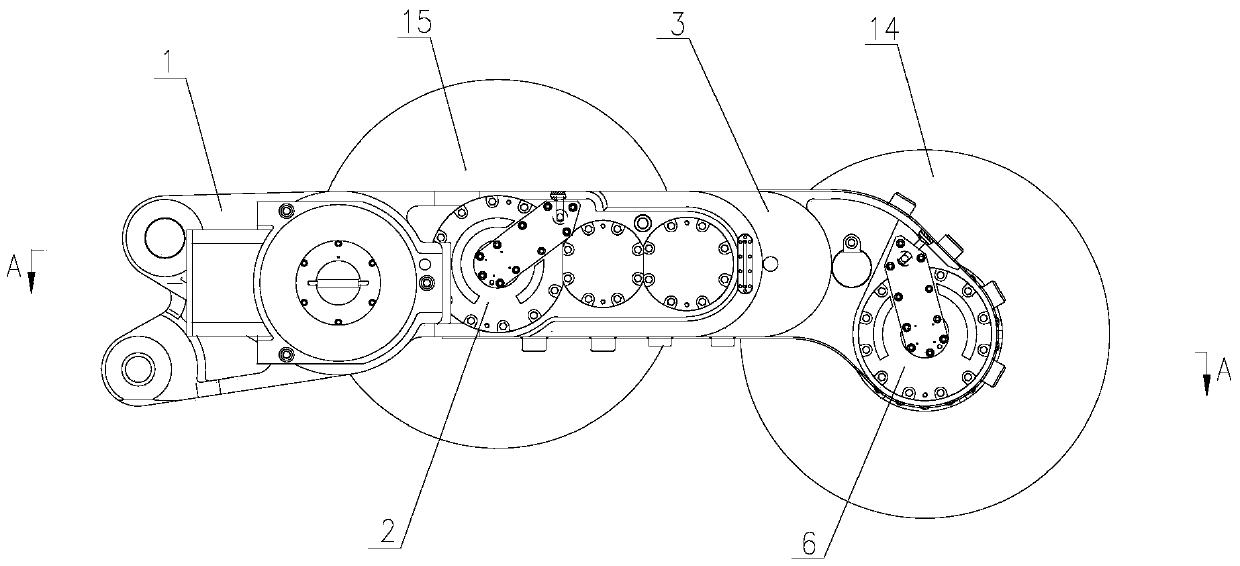

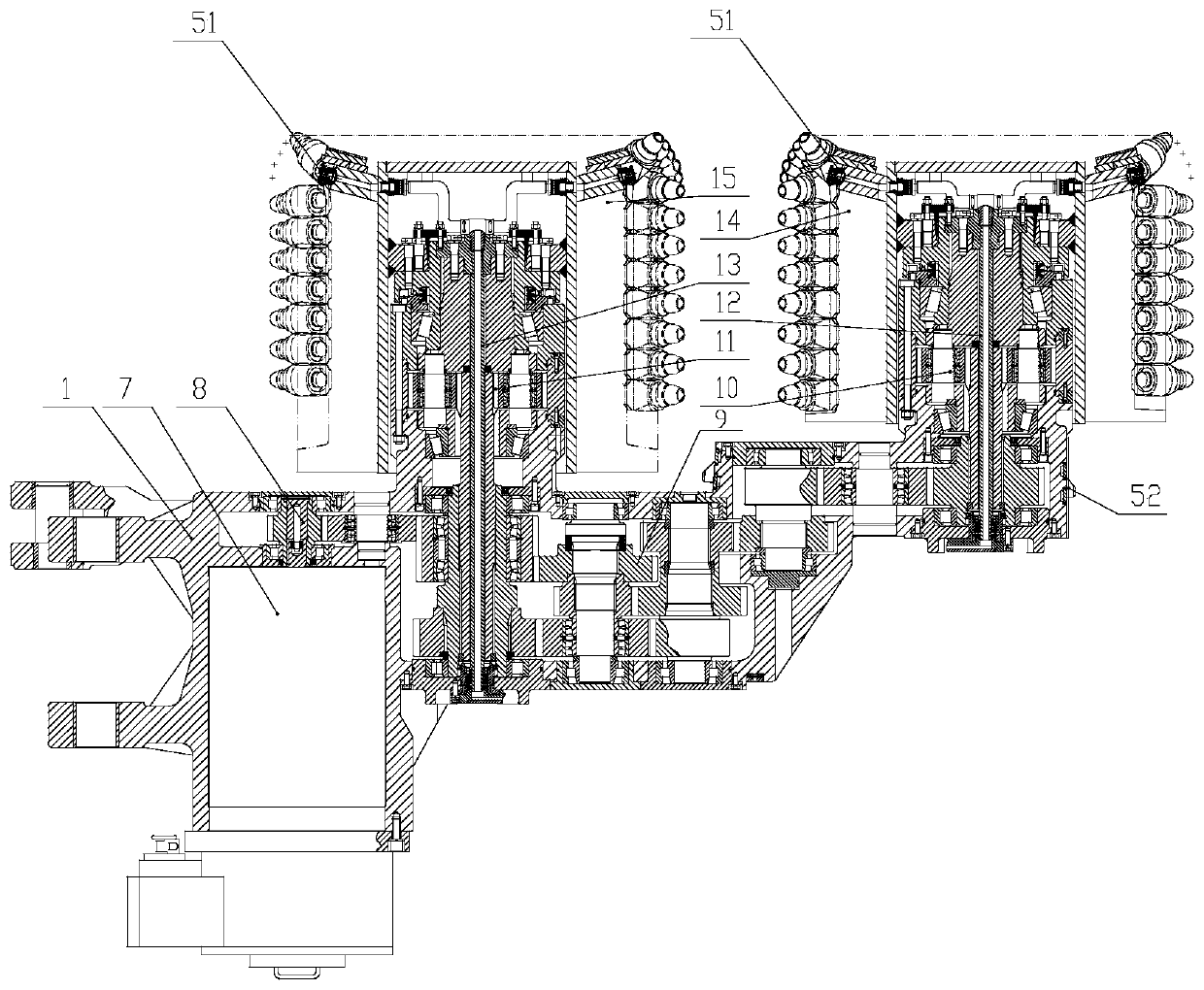

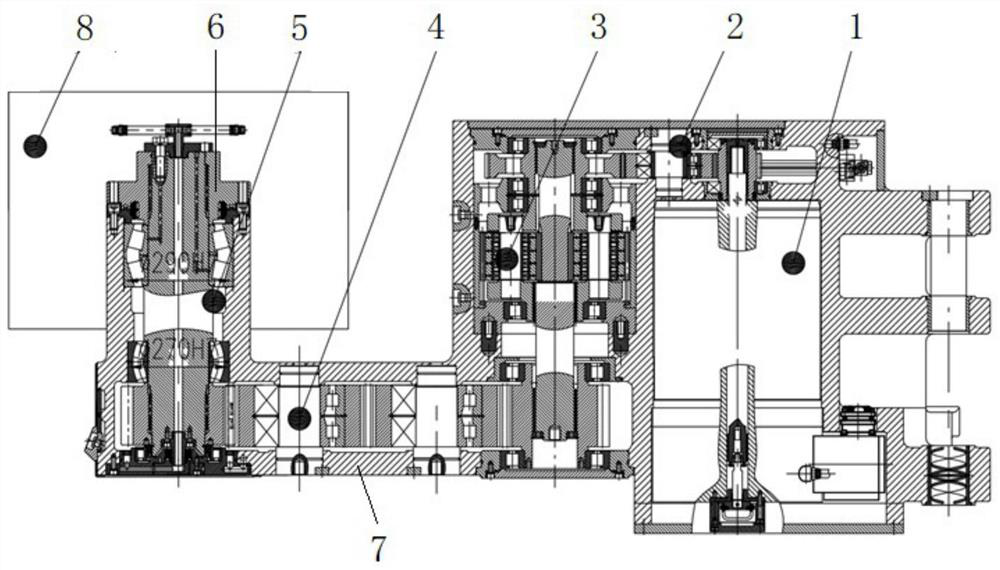

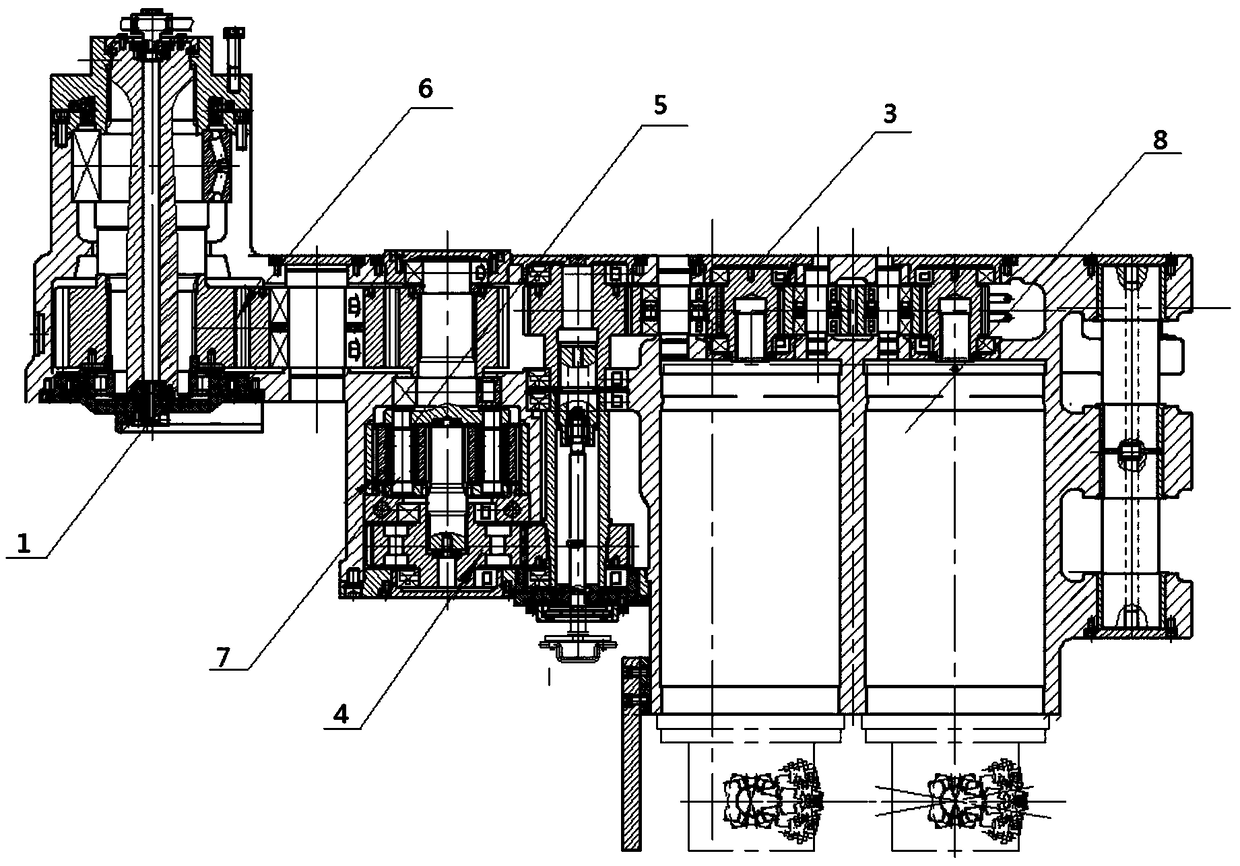

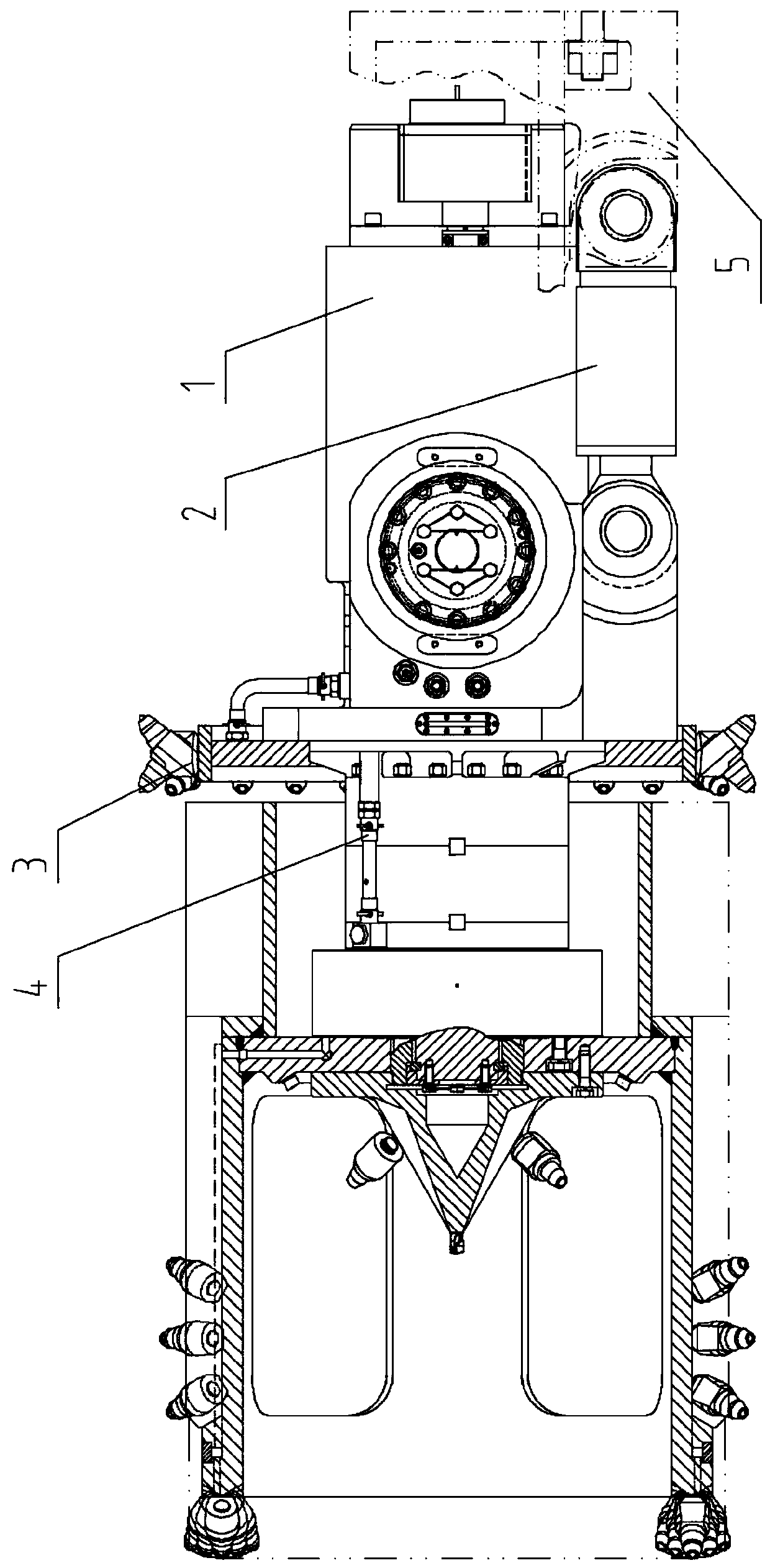

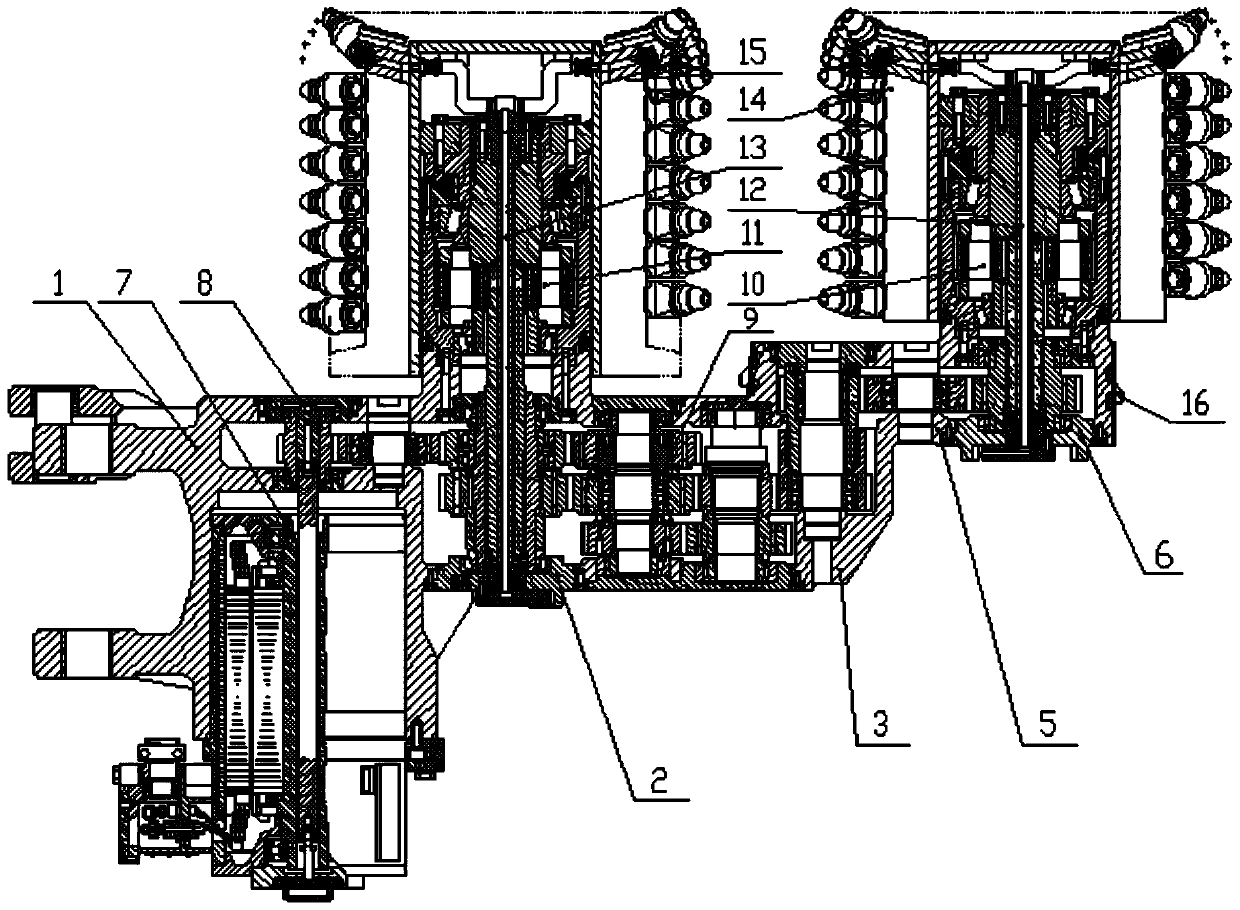

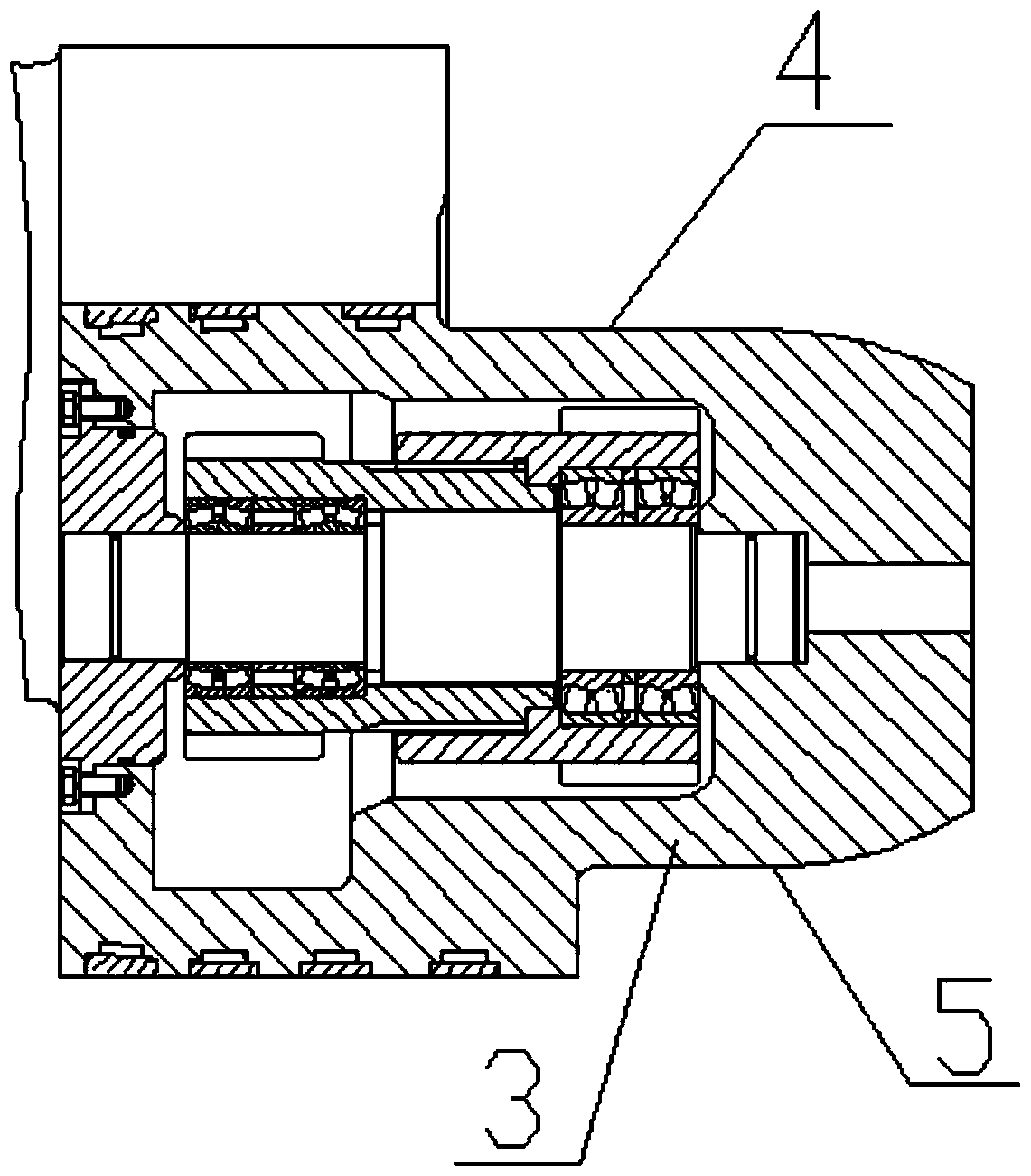

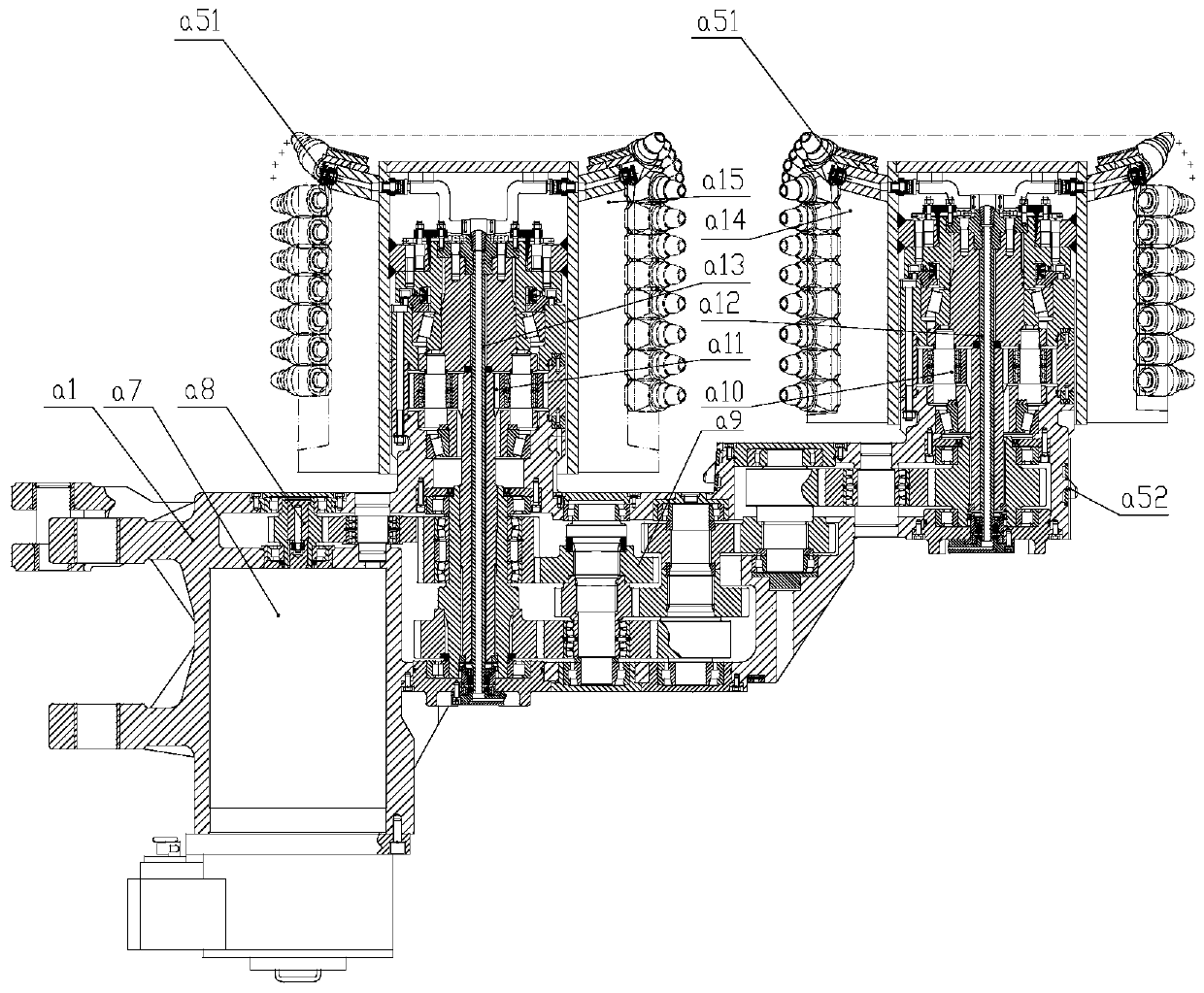

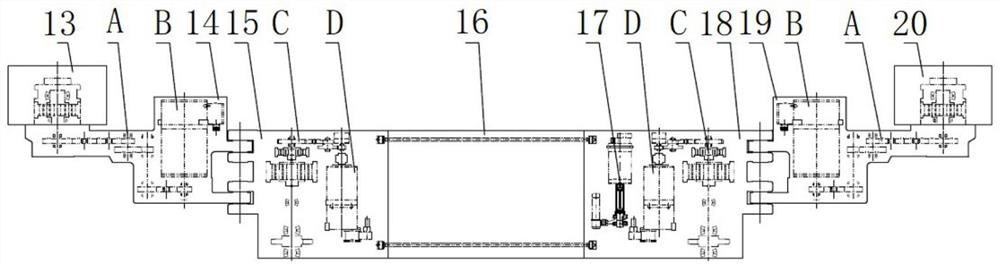

Double-motor U-shaped cutting portion of thin seam mining machine

InactiveCN102644461AIncrease cutting powerImprove coal loading effectMultiple motor speed/torque controlCutting machinesClutchRocker arm

A double-motor U-shaped cutting portion of a thin seam mining machine comprises a rocker arm casing, two cutting motors, a rocker arm reduction gearbox and a cutting roller. A motor installing cavity of the rocker arm casing and an extending end of the rocker arm casing are on the same side, and the contour of the motor installing cavity and the contour of extending end of the rocker arm casing are in a U shape, and the extending end of the rocker arm casing is elongated. The rocker arm reduction gearbox comprises a clutch, a third-stage idle gear, a fourth-stage cylindrical gear and a planetary gear mechanism, the clutch is arranged on a third-stage cutting shaft group of a transmission chain, the planetary gear mechanism is arranged at the tail end of the transmission chain, the two cutting motors transmit power to the rocker arm reduction gearbox through a first idle gear and a second idle gear, the power is transmitted to the cutting roller after speed reduction through the fourth-stage cylindrical gear and the planetary gear mechanism, an involute spline of the third-stage cutting shaft group of the transmission chain is disconnected by pulling a clutch handle, and the transmission chain is cut off so as to avoid accidents during overhaul. The cutting portion is large in installed power, strong in mining capability, good in coal charging effect, safe and reliable, and a large cutting deep roller can be installed to develop a hard-coal working surface.

Owner:CHINA UNIV OF MINING & TECH +1

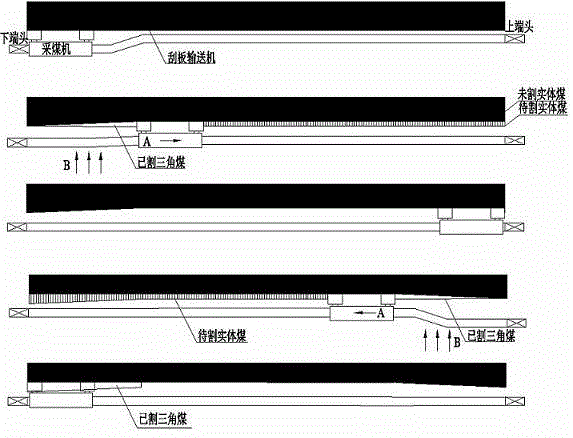

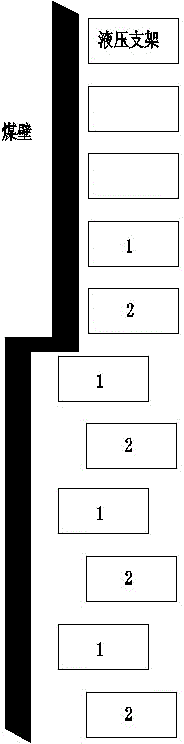

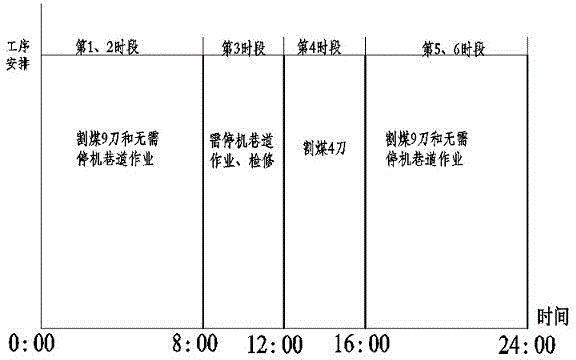

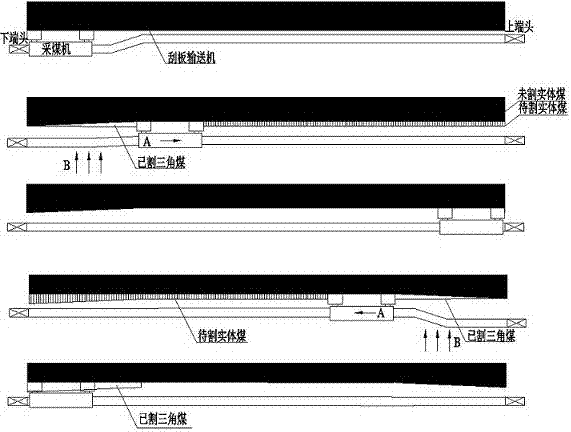

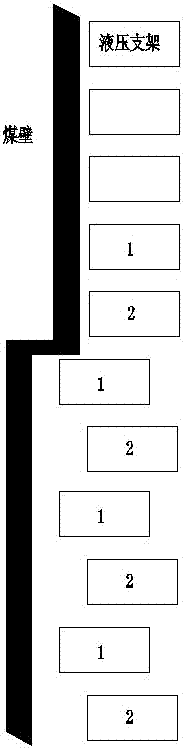

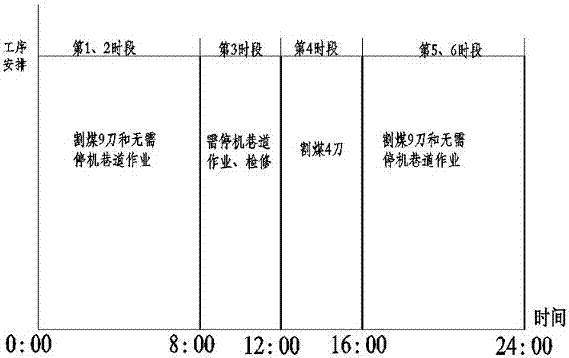

High-speed cutting longwall-mining method for low coal seams and medium-thickness coal seams

ActiveCN104564073AImprove boot rateExtension of timeUnderground miningSurface miningLongwall miningEngineering

The invention discloses a high-speed cutting longwall-mining method for low coal seams and medium-thickness coal seams. The cutting resistance is reduced by reducing a web, so that a normal coal cutting speed reaches 15-40 m / min; by using a low-web bidirectional high-speed coal cutting process for left triangular coals, after triangular coals are completely cut, returning to cut the other half of triangular coals is not required, but continuing to carry out ascending (descending) coal cutting is performed; and reciprocating mining is performed in such a way. By adopting the spaced quick moving of brackets, every two circulating brackets move at a synchronized interval. Through the timing optimization of production takts, by using a space-time coordinated continuous operating method, each workday is uniformly divided into six (or eight) time intervals, a maintenance operation and a shutdown-required roadway operation are arranged in the third time interval, and coal cutting and non-shutdown-required roadway operations are arranged in the rest of time intervals. According to the invention, the low-web bidirectional high-speed coal cutting process for left triangular coals, moving brackets in a grouped, spaced and staggered mode, and the space-time coordinated continuous operating method are adopted, so that the shortcomings of slow advance speed and low mining efficiency of low coal seams and medium-thickness coal seams are made up, thereby providing a feasible mining method for the high-speed cutting of low coal seams and medium-thickness coal seams.

Owner:TIANDI SCI & TECH CO LTD +1

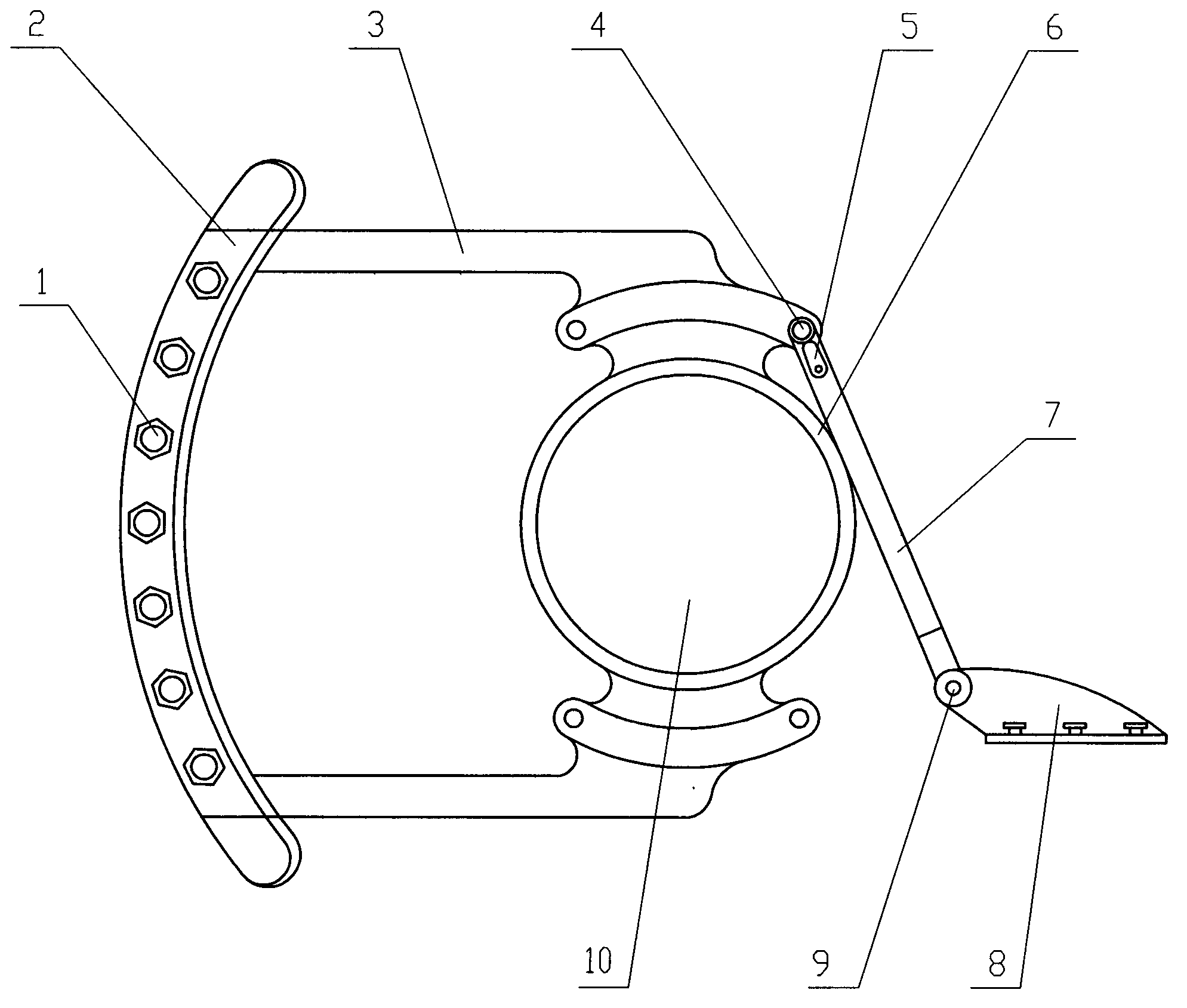

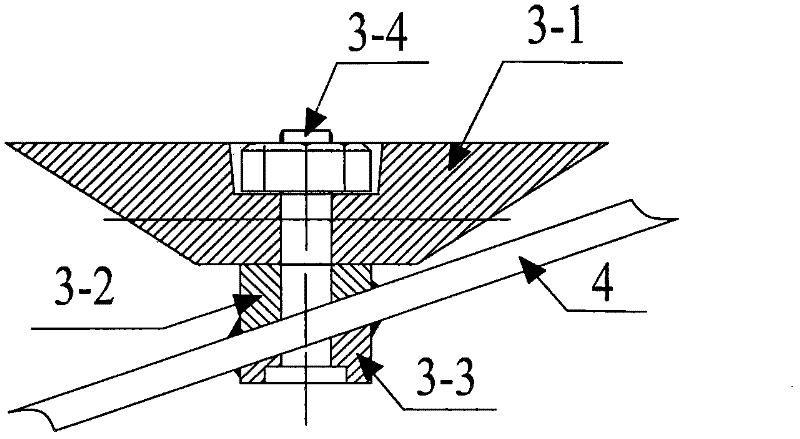

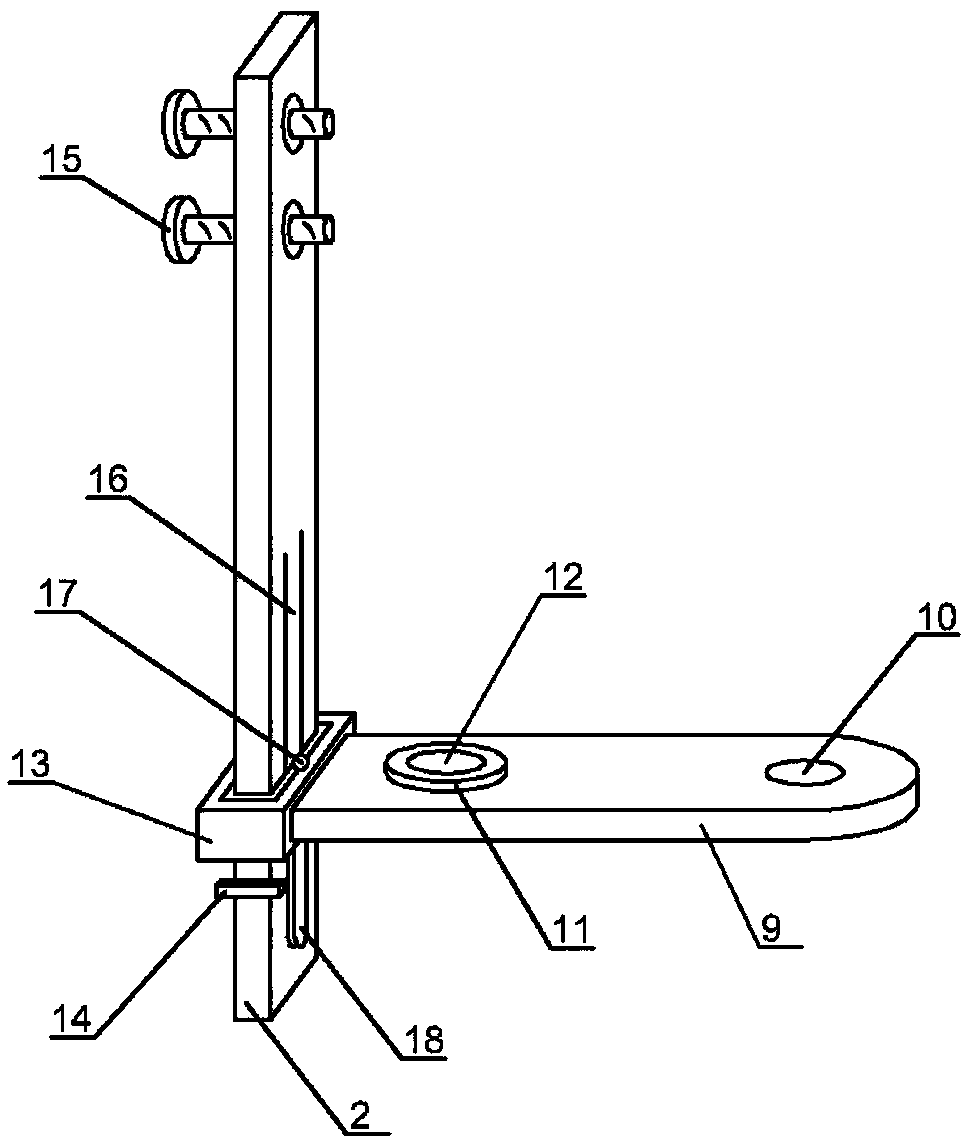

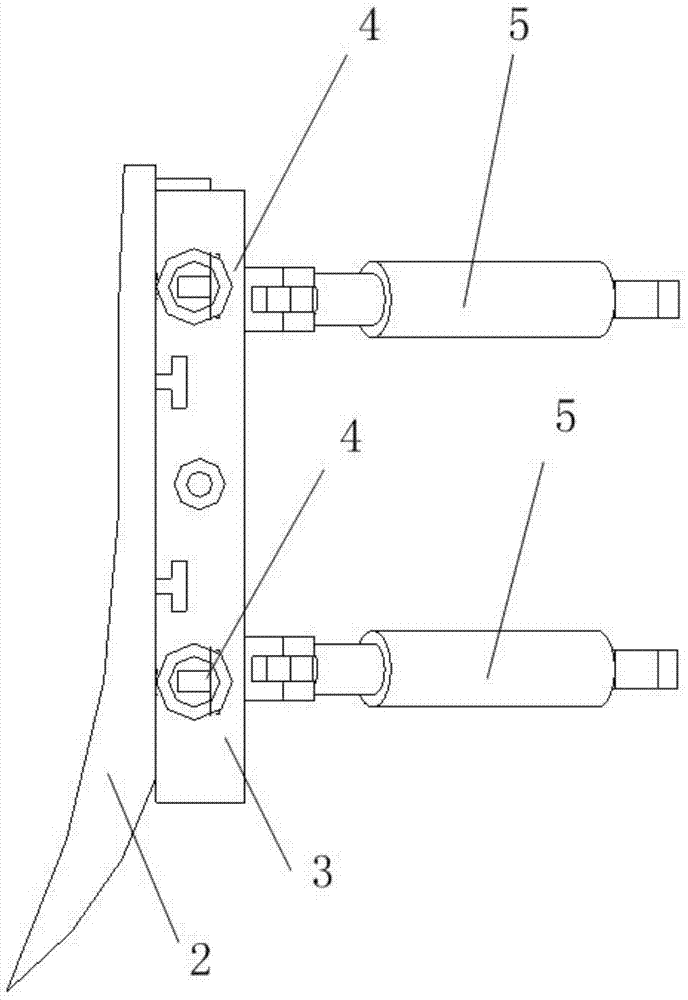

Spill plate of coal mining machine

InactiveCN103835717ASimple structureEasy to disassemble and replaceSlitting machinesEngineeringMechanical engineering

The invention relates to a spill plate of a coal mining machine. The spill plate comprises a body and a bracket arranged on the bracket. The spill plate is characterized in that the body is connected with a support by a connection rod; the bracket is fixedly connected with an arc-shaped plate by a screw; the body is fixedly connected with a pressing cover. Compared with the traditional spill plate of the coal mining machine, the spill plate of the coal mining machine has the advantages of simple structure and low energy consumption, and convenient to detach and replace and simple to operate. The bracket is connected with the arc-shaped plate and the connection rod to form a connection rod mechanism so that the arc-shaped plate can move in parallel relative to a bottom plate under any roller height in an adjustable range, and furthermore, the working of the coal mining machine is adapted and the good coal filling effect is guaranteed.

Owner:WUXI WASHING MACHINERY FACTORY

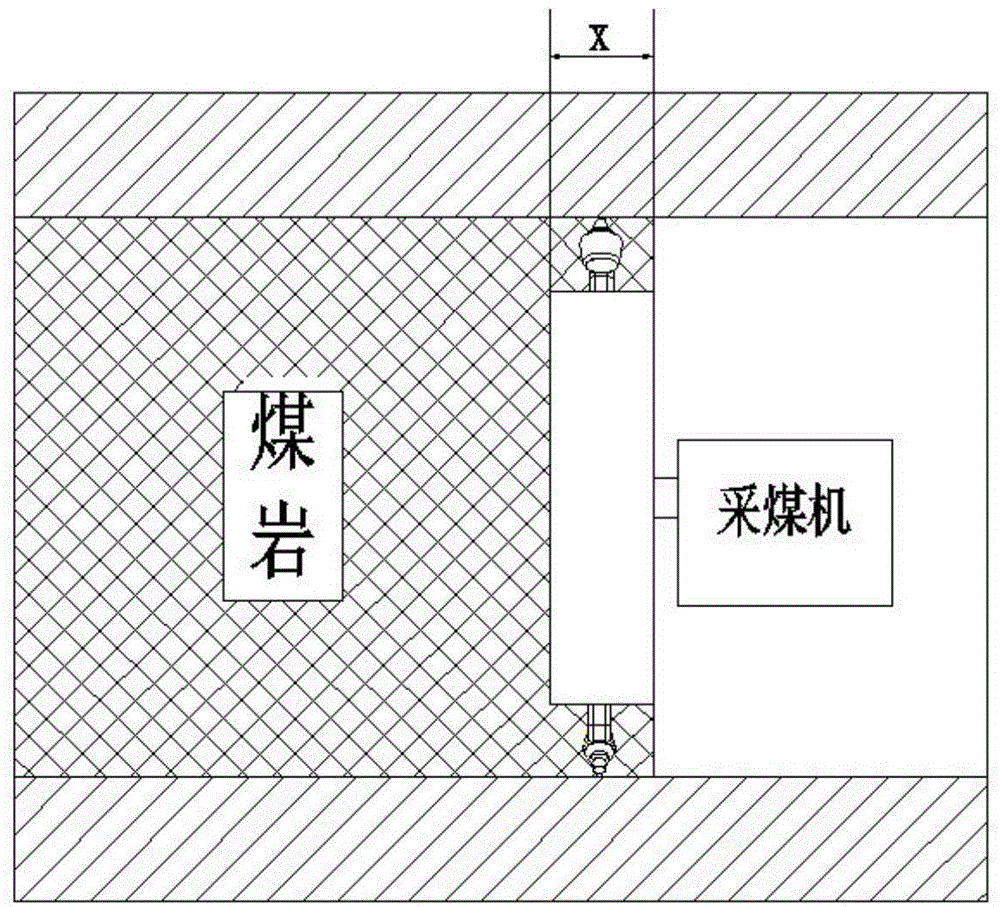

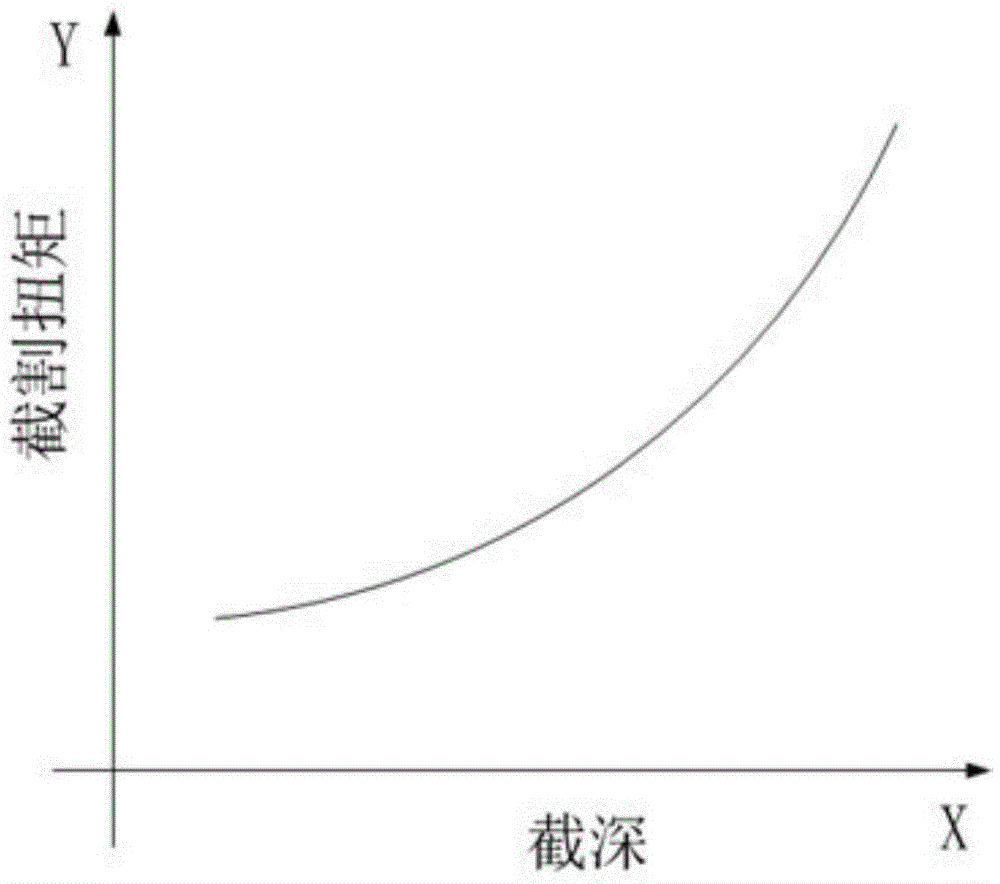

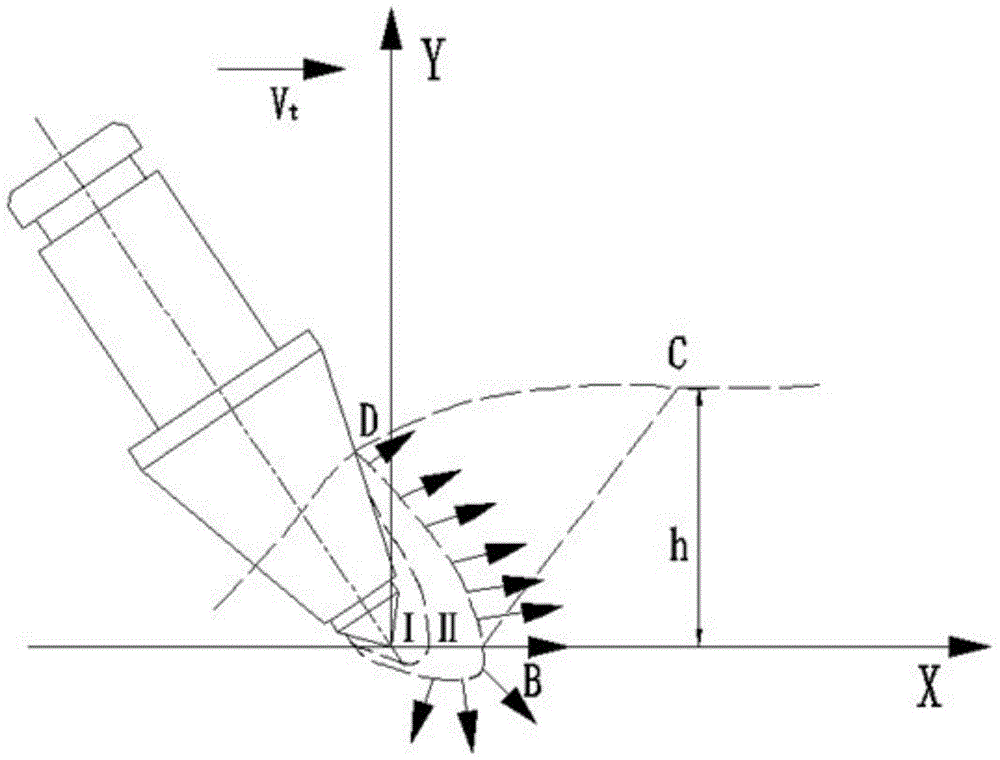

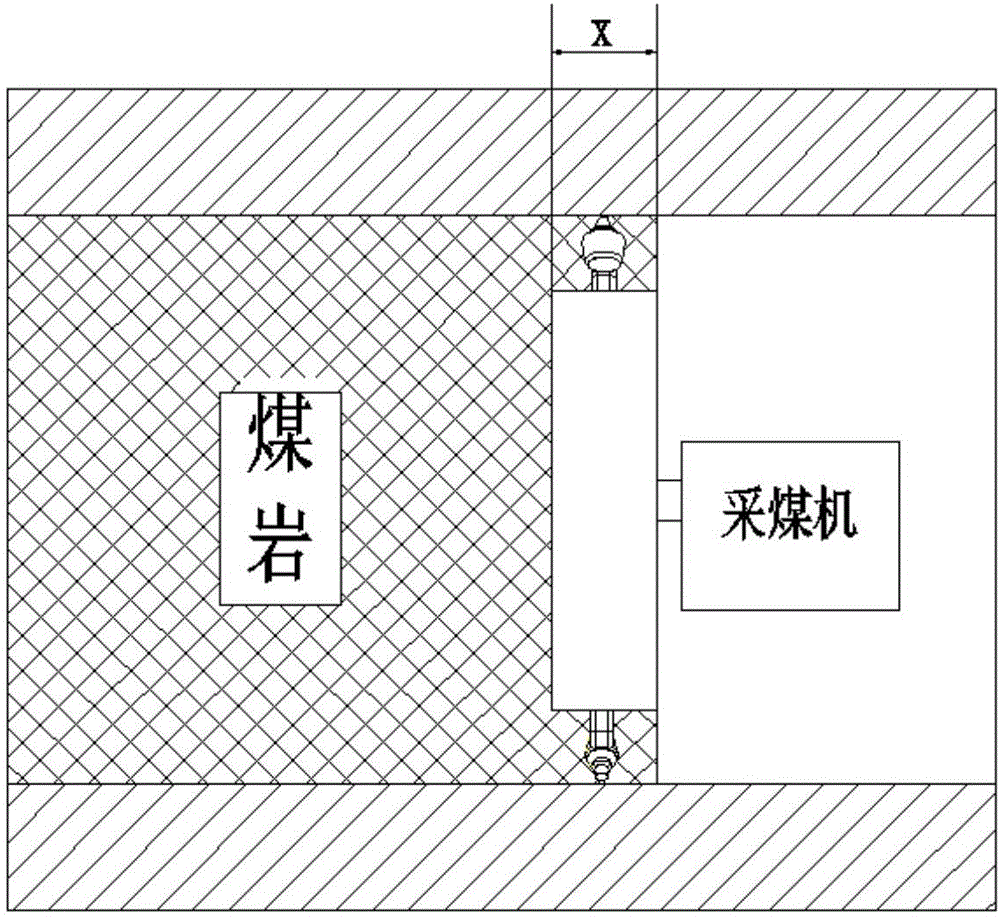

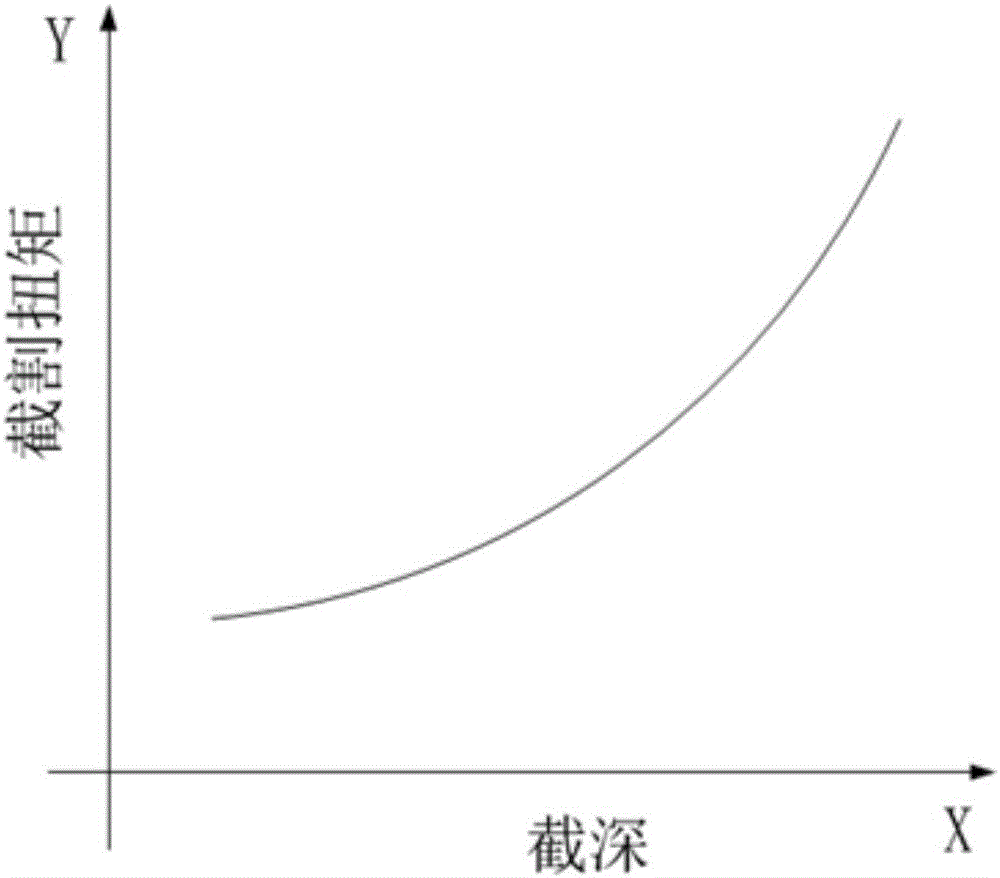

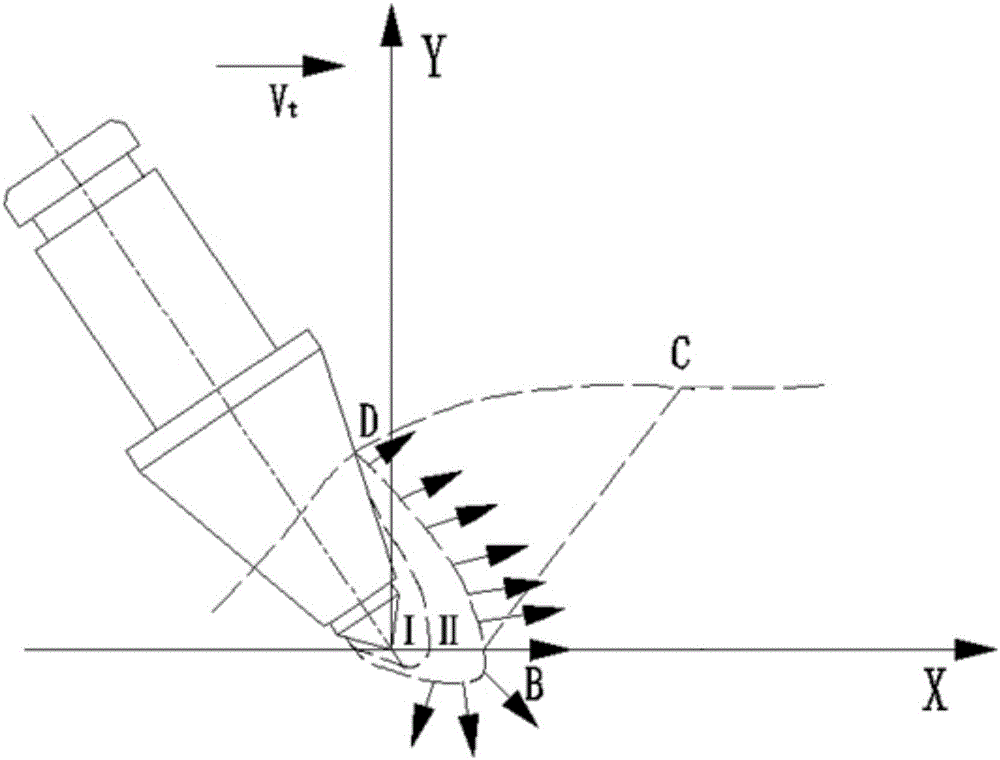

Method for designing geometrical size of coal cutter chain cutting part cutting tooth

InactiveCN104929636AUniform wearImprove adaptabilitySpecial data processing applicationsCutting machinesUnit sizeEconomic benefits

The invention provides a method for designing geometrical size of a coal cutter chain cutting part cutting tooth. The method comprises the following steps: step 1, determining the relation between cutting depth and cutting torque; steps 2, determining the relation between cutting tooth stress and the cutting depth; step 3, analyzing cutting force in a coal breaking process by the cutting tooth; step 4, determining the contact relation between cutting tooth and a coal wall; step 5, calculating the contact area between single cutting tooth and the coal wall in a cutting process; step 6, determining the relation between the cutting tooth contact area and the cutting depth; step 7, calculating the diameter of the cutting tooth body. The cutting force applied to unit size stressed surface of the cutting tooth in a cutting process tends to be equal, so that abrasion of the cutting force is more uniform, the adaptability of the cutting tooth is enhanced, the cutting efficiency of the cutting tooth is improved, the service life is prolonged, the reliability of a coal cutter is improved, a better economic benefit is obtained, and meanwhile, the coal loading effect of a cutting part can be improved.

Owner:CHINA UNIV OF MINING & TECH

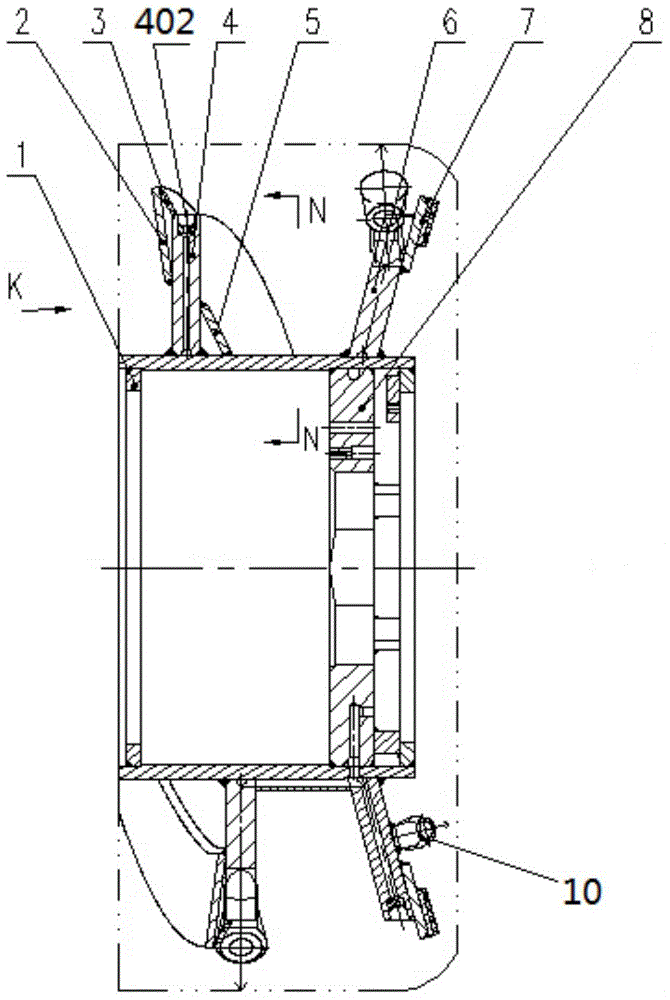

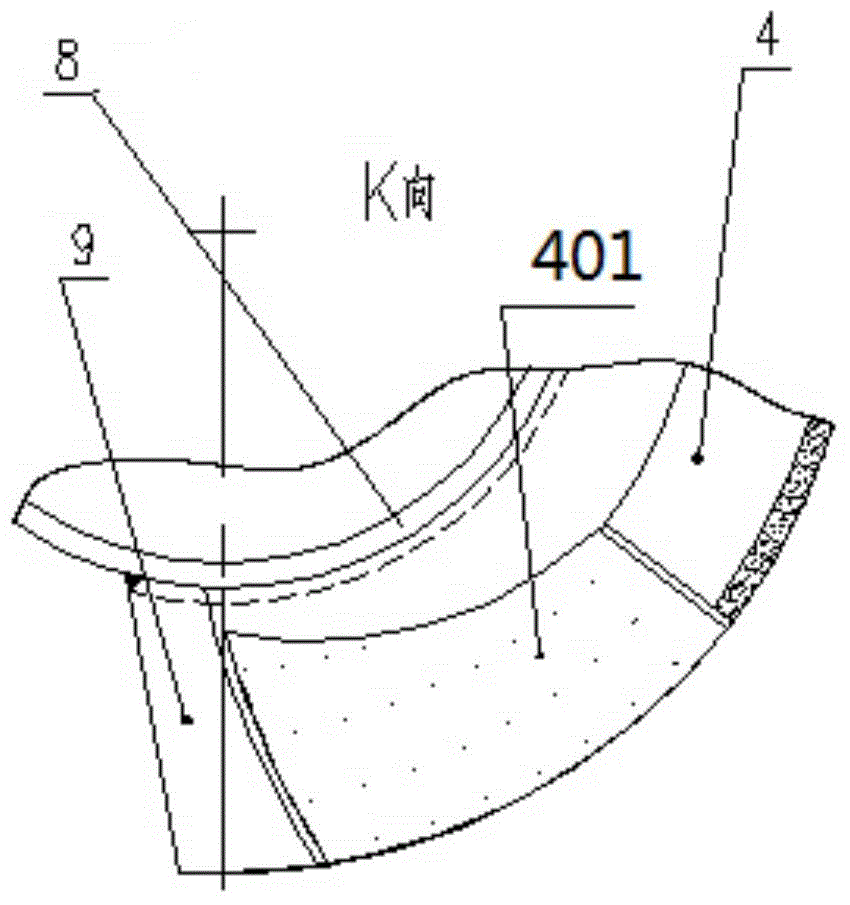

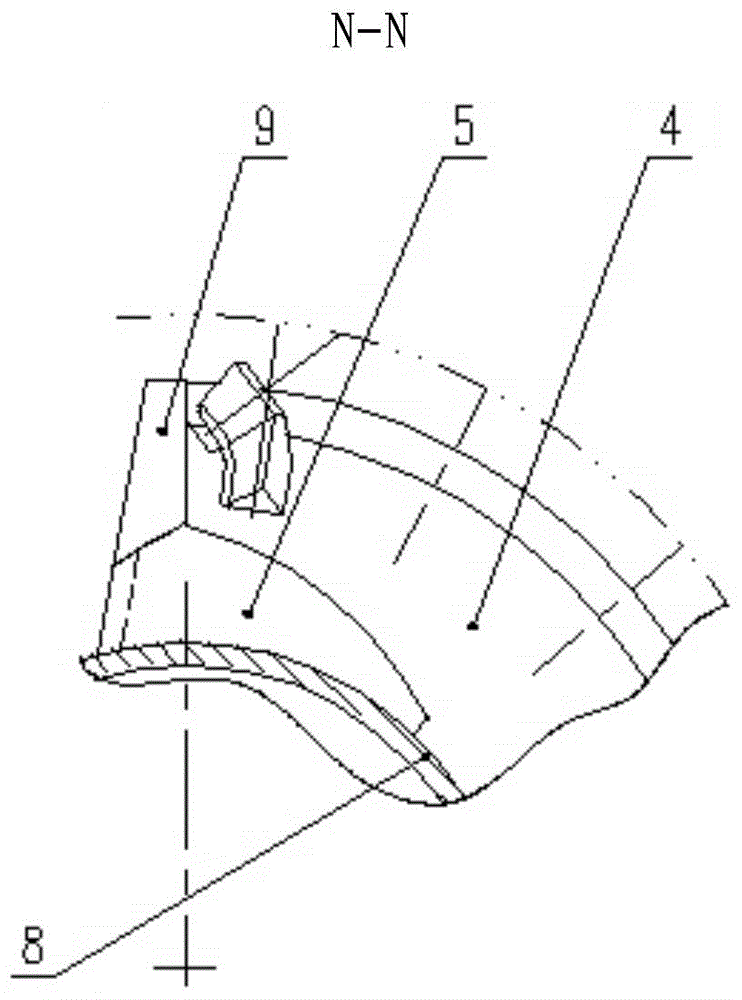

Powerful drum of coal cutter

The invention relates to a powerful drum of a coal cutter. The powerful drum comprises a drum body (8), a combined main blade (4) and an end disc (6), wherein small blades (9) are arranged at the tail part of the combined main blade (4); the bottoms of the small blades (9) are fixedly welded with the drum body (8); a water inlet channel (402) is formed inside the combined main blade (4); a group of spray holes (401) is formed in the side face of the tail part; the spray holes (401) are communicated with the water inlet channel (402); the spraying direction moves along the axial direction of the drum body; auxiliary blades (2) are arranged on the combined main blade (4); a sealing plate (3) is arranged between the auxiliary blades (2) and the combined main blade (4); a rib plate (5) is fixedly arranged between the combined main blade (4) and the drum body (8); the end disc (6) is welded on the drum body (8); and a wear-resistant plate (7) and small end disc cutting teeth (10) are arranged on the outer side of the end disc (6) along the axial direction of the drum body. According to the powerful drum of the coal cutter disclosed by the invention, the strength and wear resistance of the coal cutter drum are enhanced, and the service life of the drum is prolonged.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +1

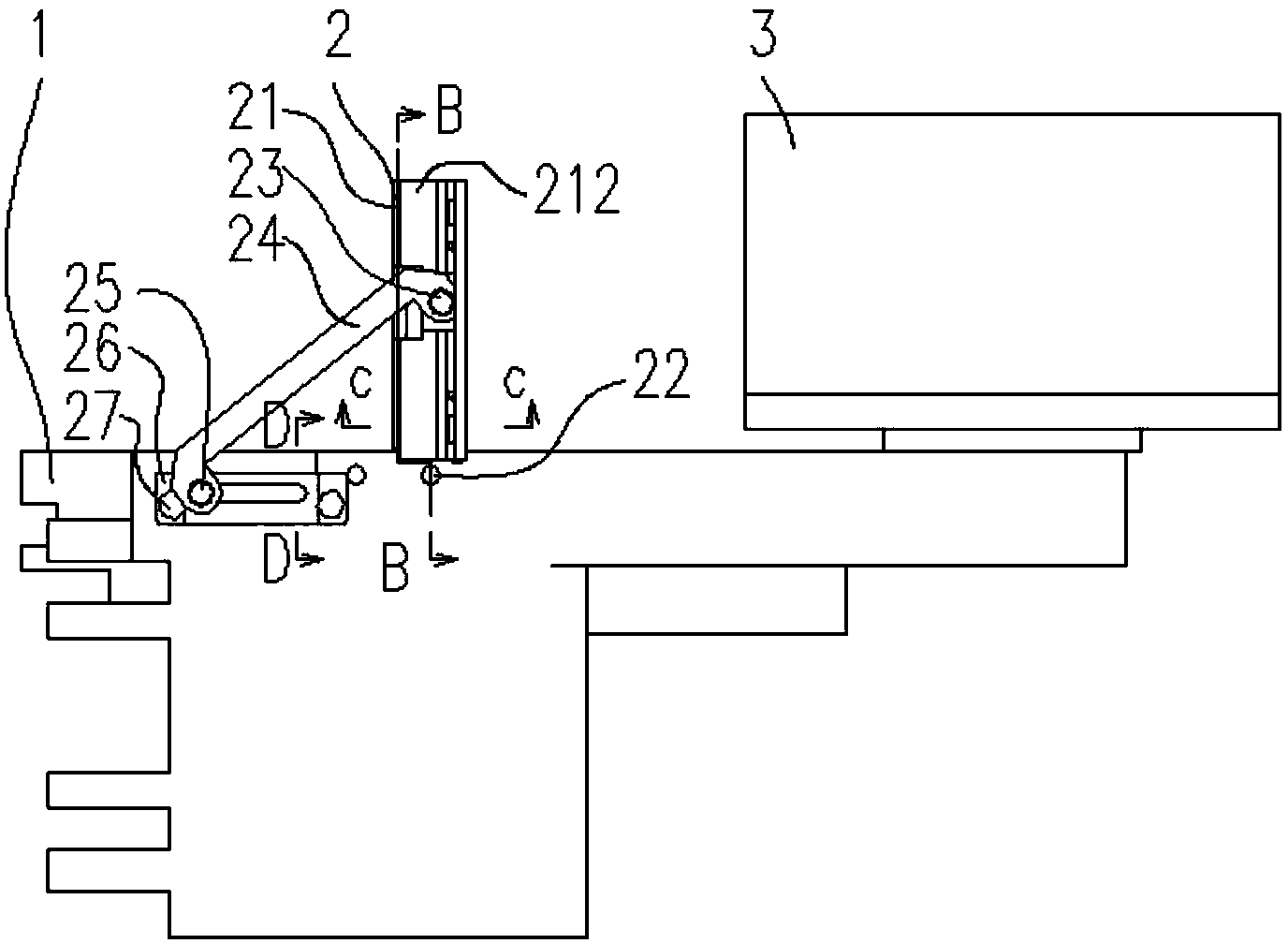

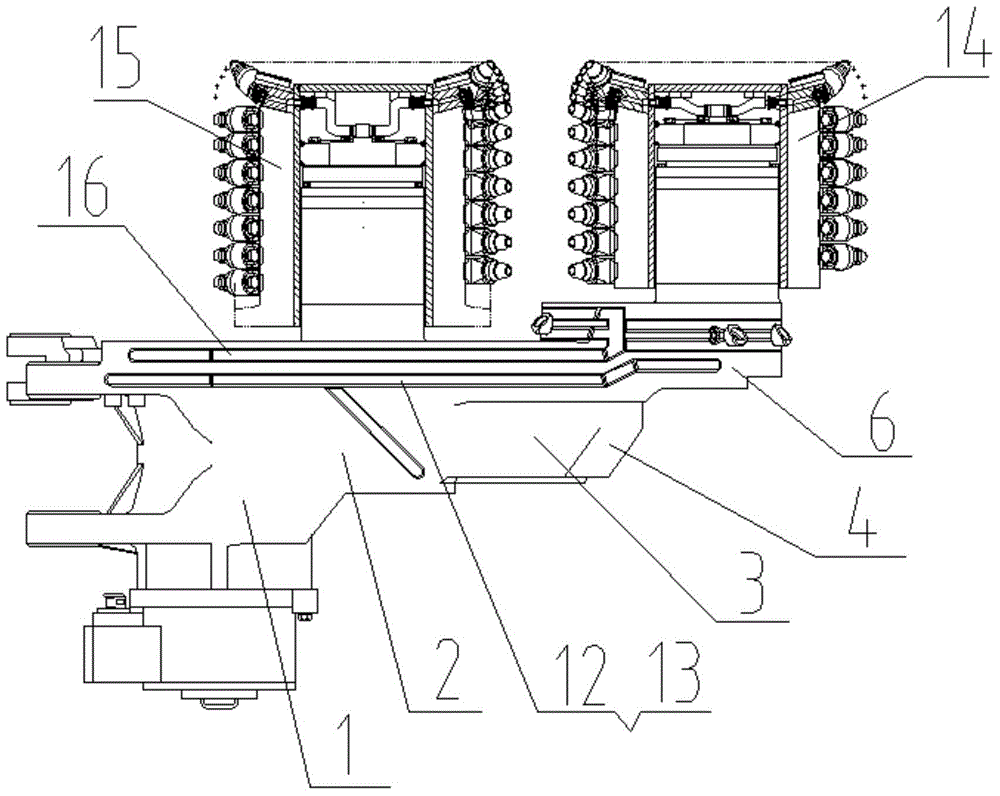

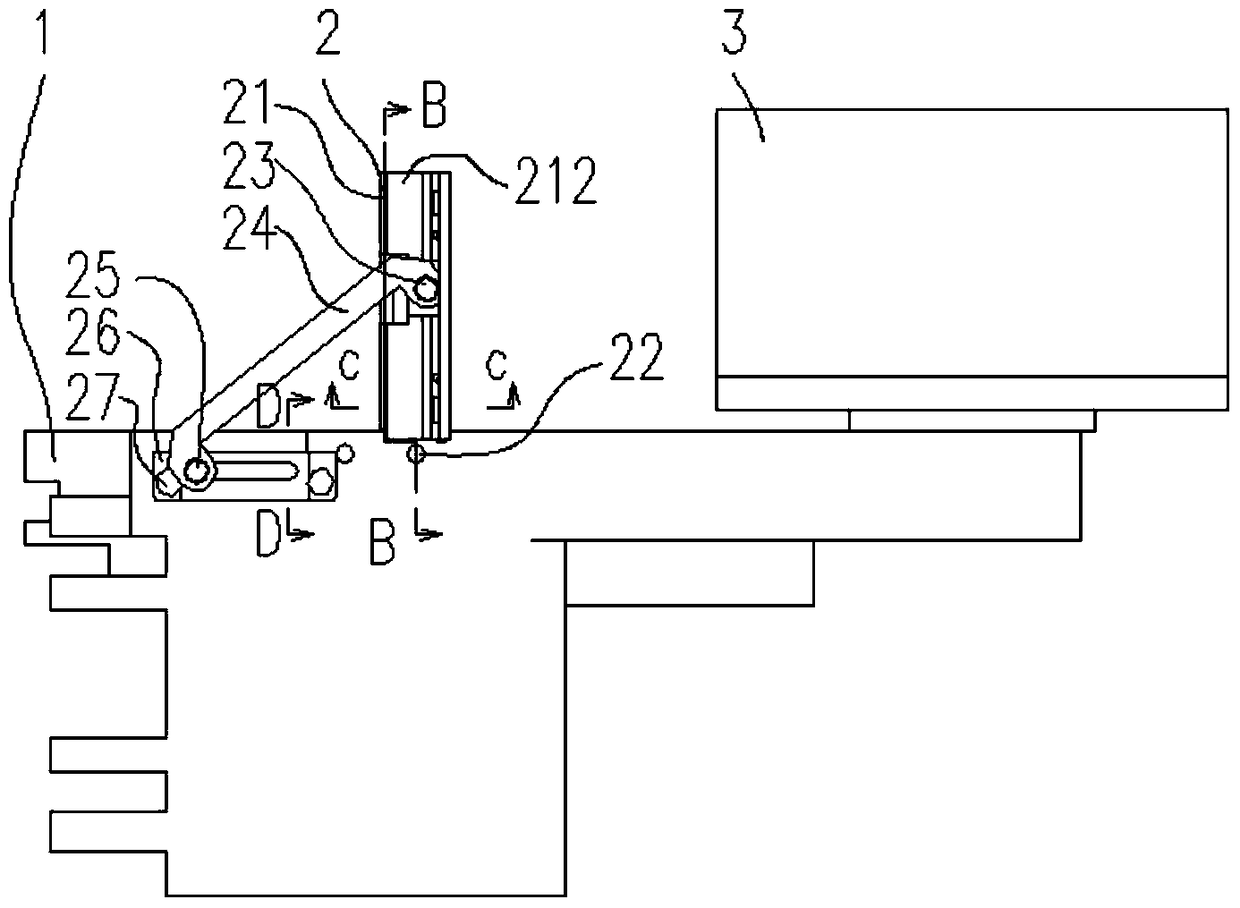

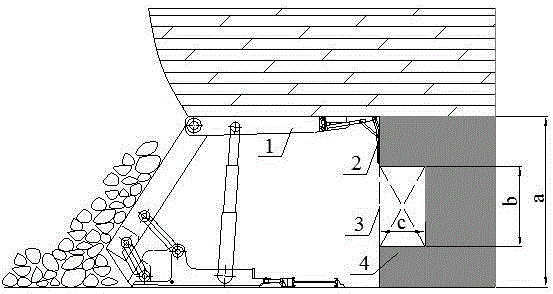

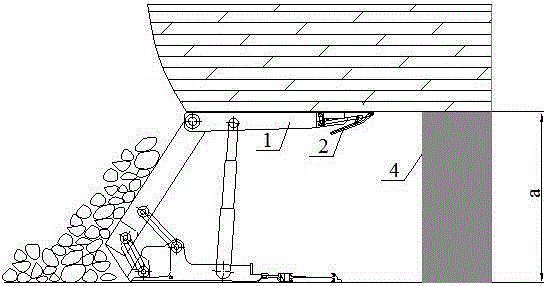

Deflectable cutting device of coal mining machine

InactiveCN103046927AOvercome distanceTo overcome the poor effect of clothing coalDriving meansCutting machinesEngineeringRocker arm

The invention provides a deflectable cutting device of a coal mining machine and mainly aims at solving the technical problems of low production efficiency and the like. According to the adopted technical scheme, the device is provided with a transitional frame; the tail end of the transitional frame is hinged with a machine body; the side A of the head end of the transitional frame is hinged with a rocker arm assembly, and the side B of the head end of the transitional frame is provided with an oil cylinder assembly; and one end of the oil cylinder assembly is hinged with the transitional frame, and the other end of the oil cylinder assembly is hinged with the rocker arm assembly. The deflectable cutting device is suitable for a high-power coal mining machine for thin and extremely thin coal seams under a complicated geological condition.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +1

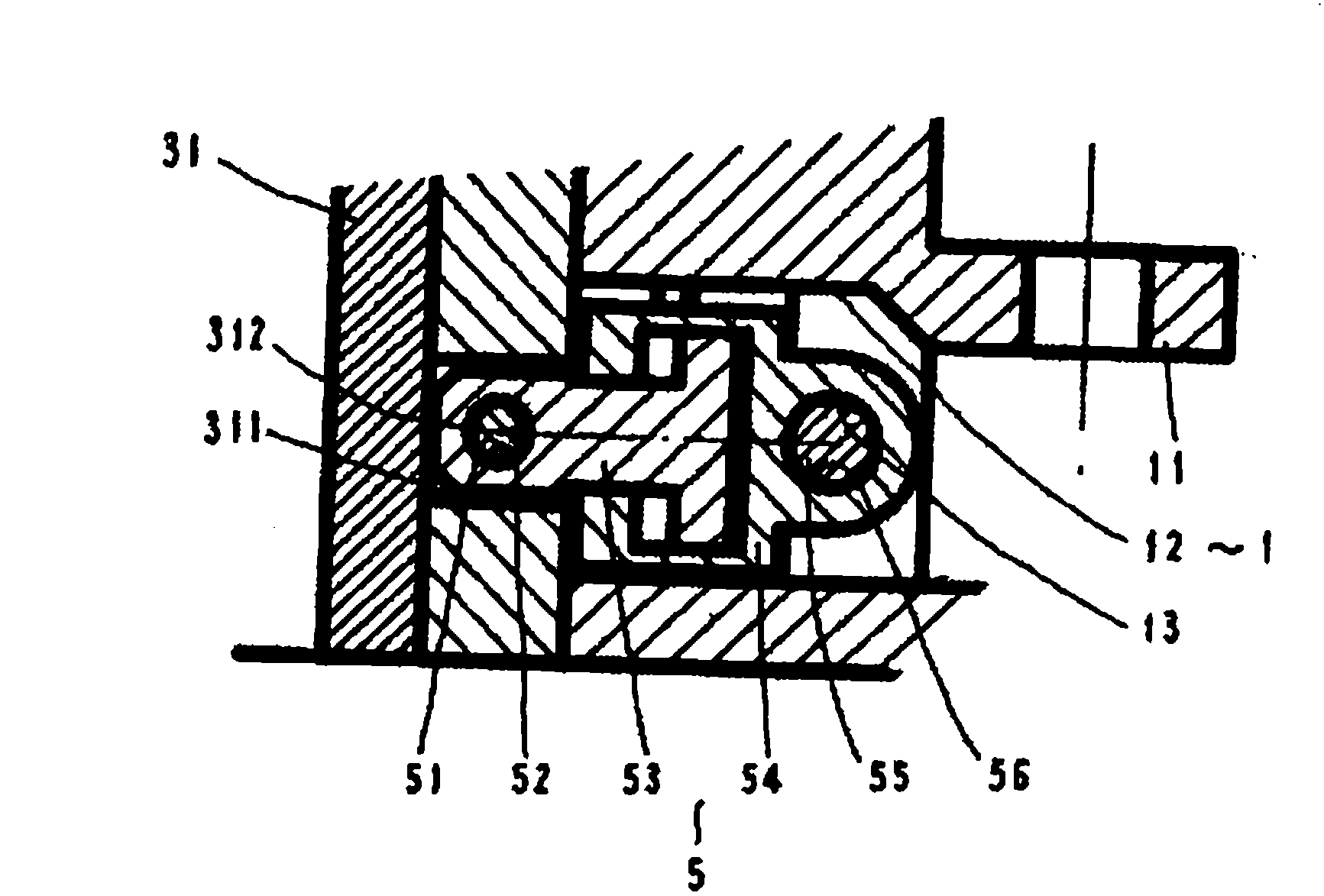

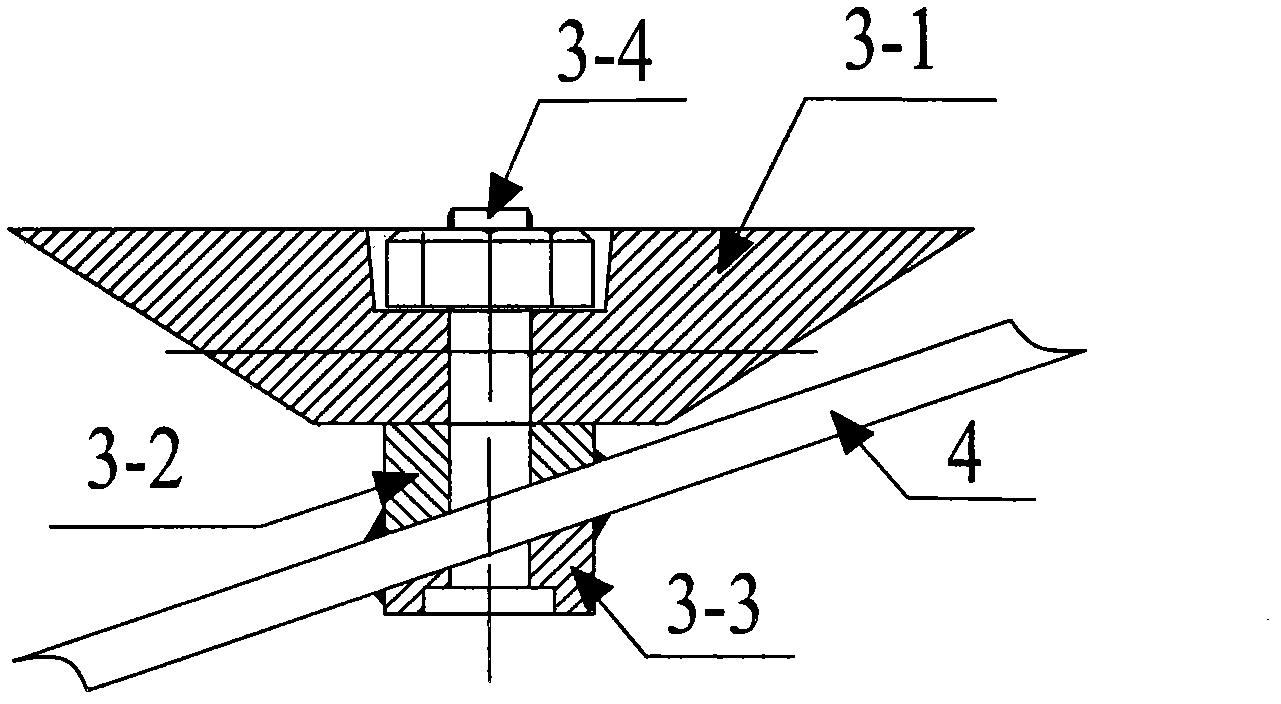

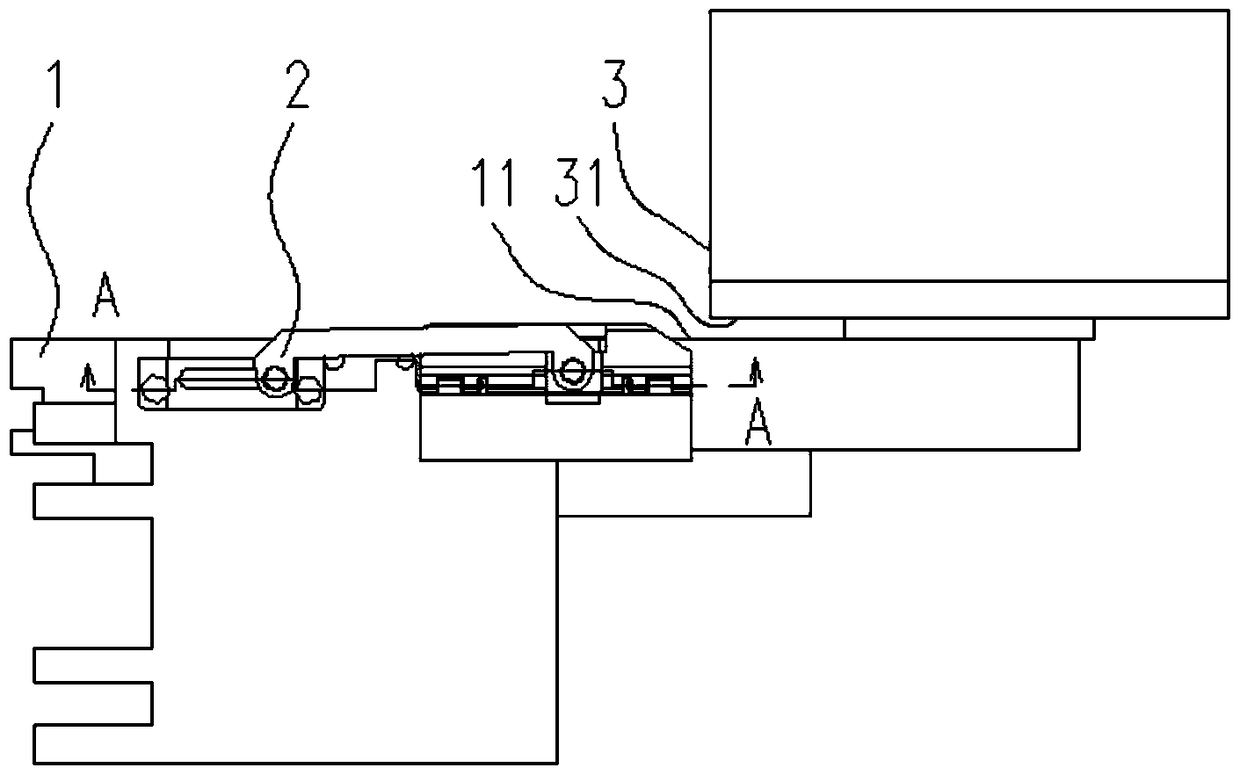

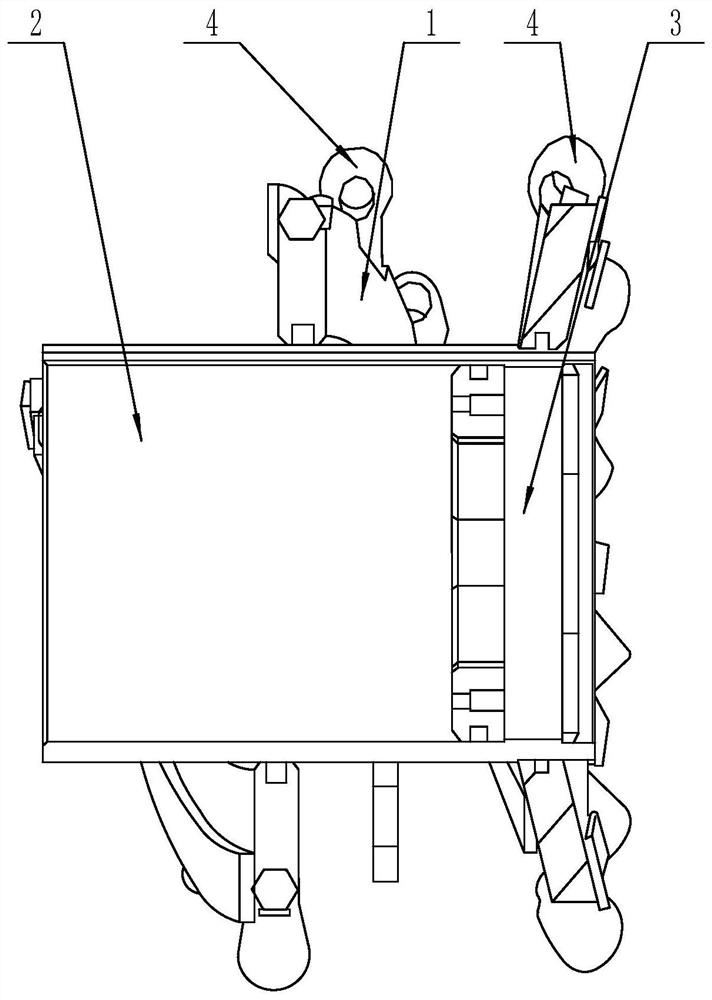

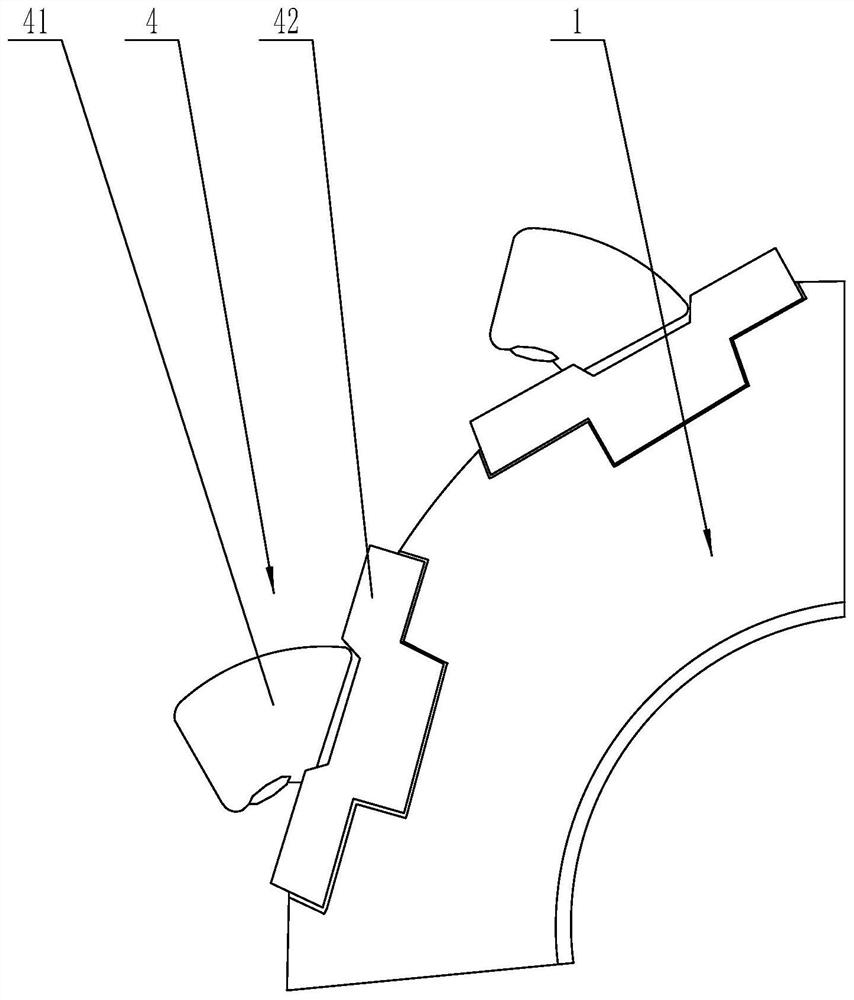

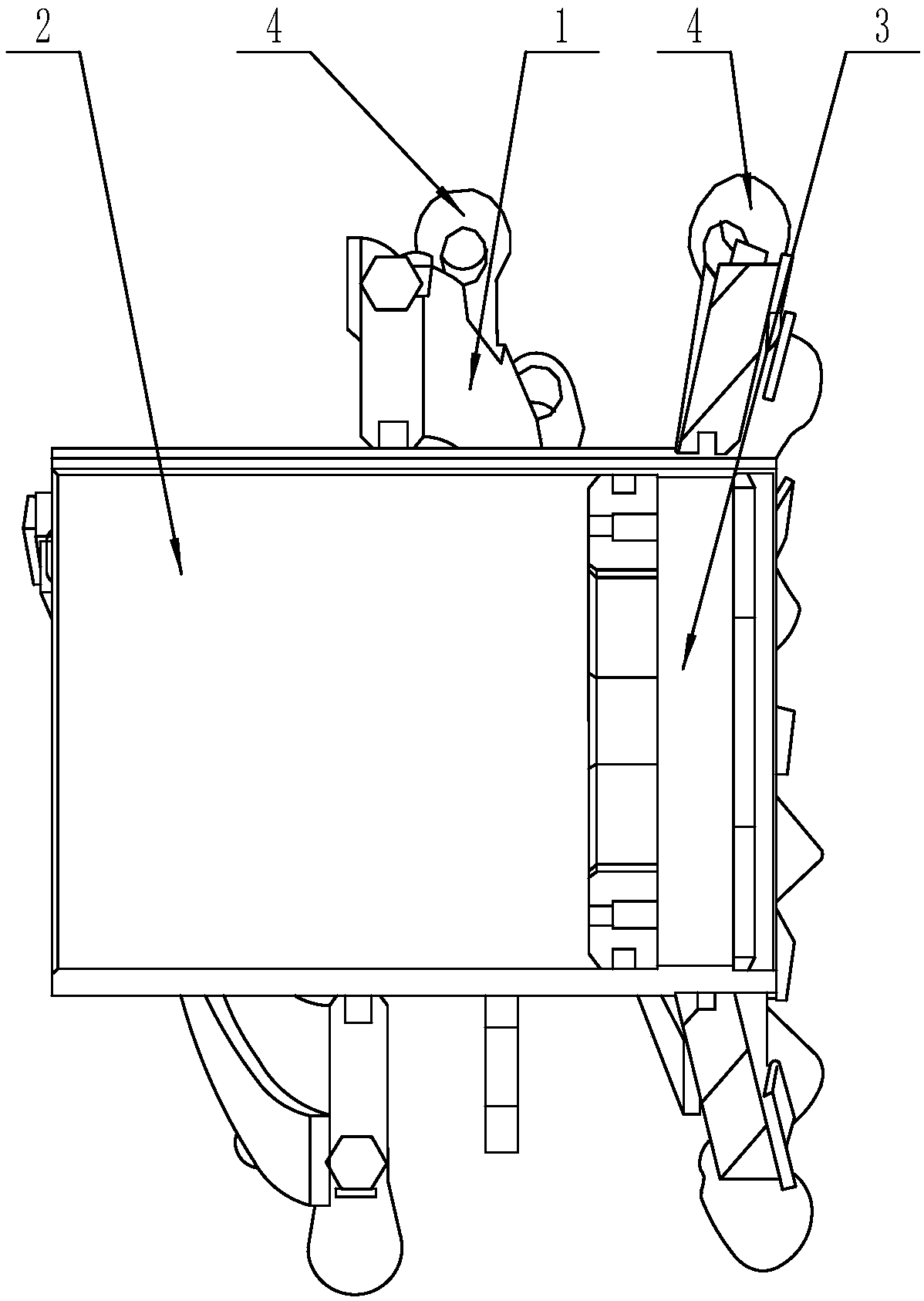

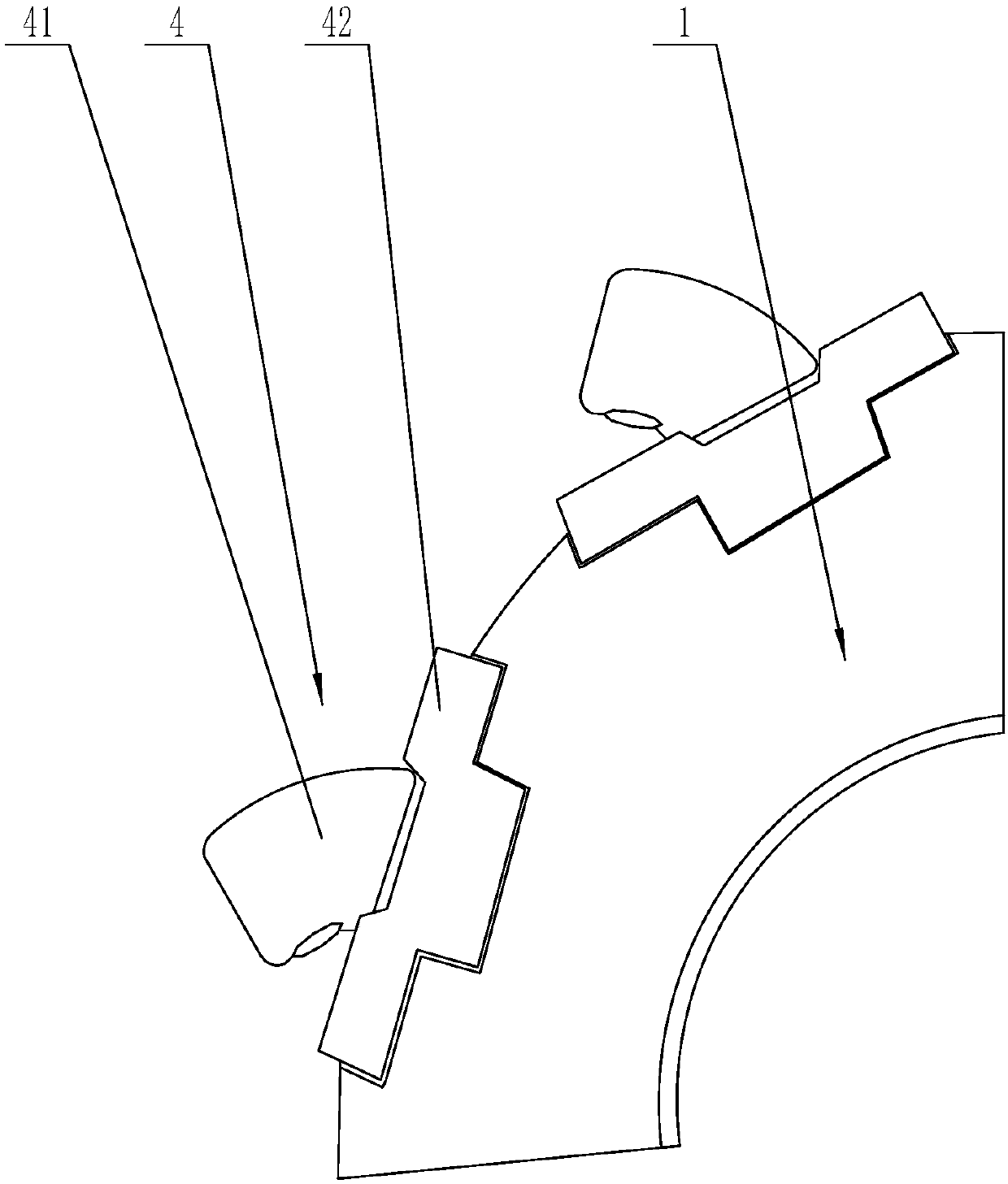

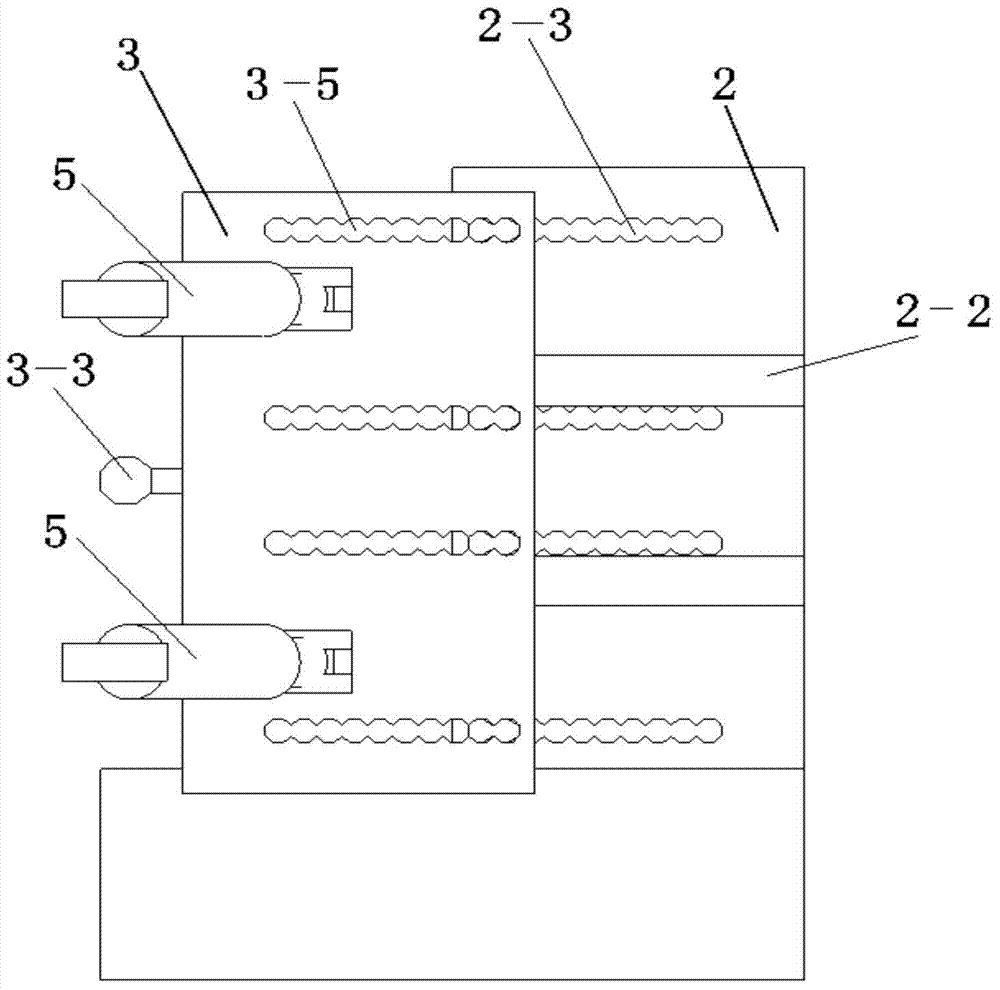

Thin-seam coal mining machine and chute type coal blocking mechanism thereof

ActiveCN104060988AImprove coal loading effectRealize the coal retaining functionSlitting machinesCutting machinesRocker armCharge effect

The invention discloses a thin-seam coal mining machine and a chute type coal blocking mechanism thereof. The coal mining machine comprises a rocking arm, the chute type coal blocking mechanism and a rotary drum, wherein the rocking arm comprises a rocking arm shell; the chute type coal blocking mechanism comprises a main coal blocking plate, a connecting rod, a chute pin, a chute plate and an auxiliary coal blocking plate; the main coal blocking plate of the chute type coal blocking mechanism is arranged in an interval formed between the end faces of the rotary drum and the rocking arm; the auxiliary coal blocking plate of the chute type coal blocking mechanism is arranged above the top surface of the rocking arm; the main coal blocking plate is connected with the rocking arm shell, is hinged with the connecting rod and is supported and limited by the connecting rod; the connecting rod is connected with a chute in the chute plate and can slide from a first end to a second end; the chute plate is fastened to the rocking arm shell and is located; the auxiliary coal blocking plate is hinged with the main coal blocking plate. According to the thin-seam coal mining machine, a coal charging effect can be improved; by utilizing the interval between the end faces of the rotary drum and the rocking arm and the space above the top surface of the rocking arm, a coal blocking function is realized without influencing the normal production operation.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +1

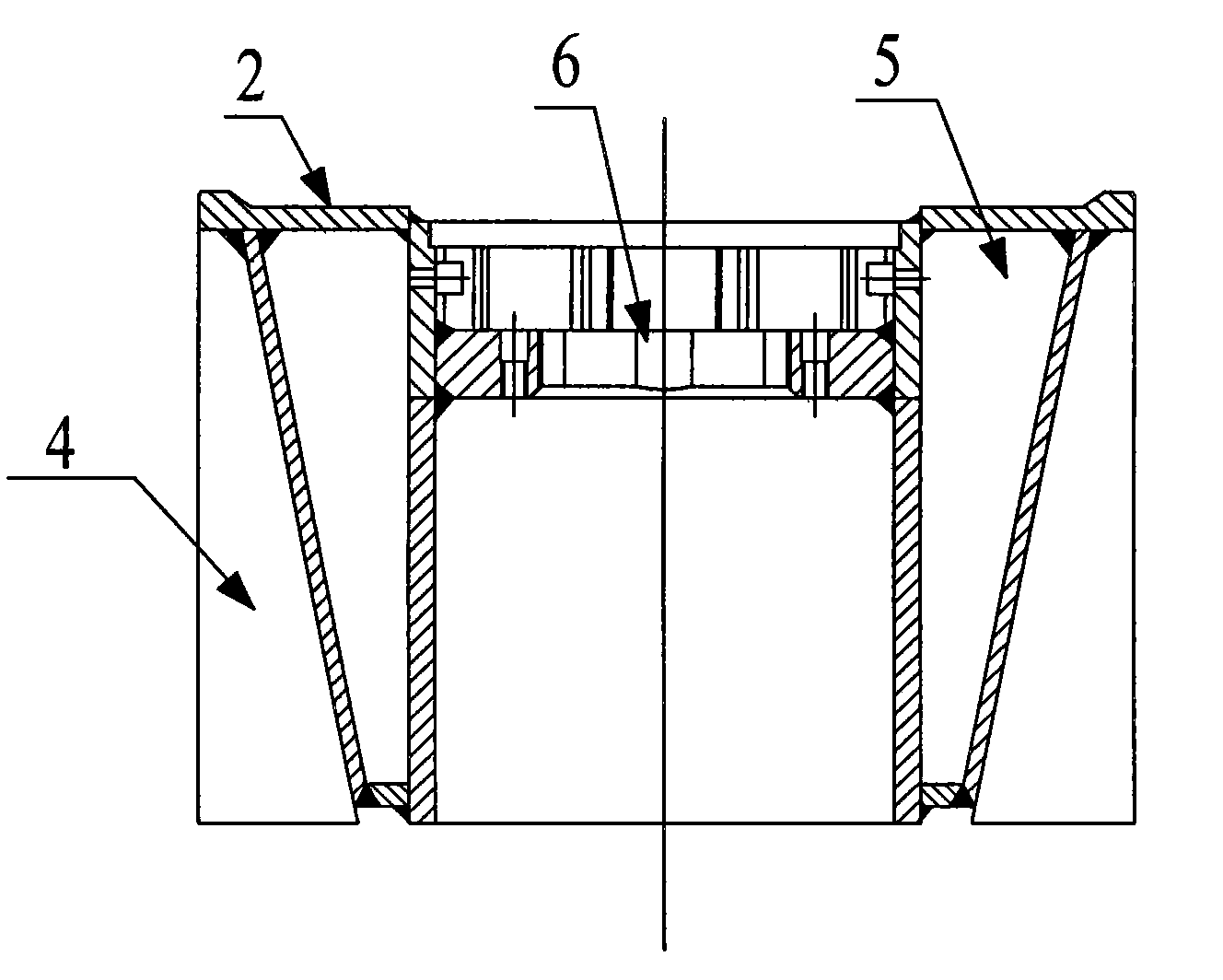

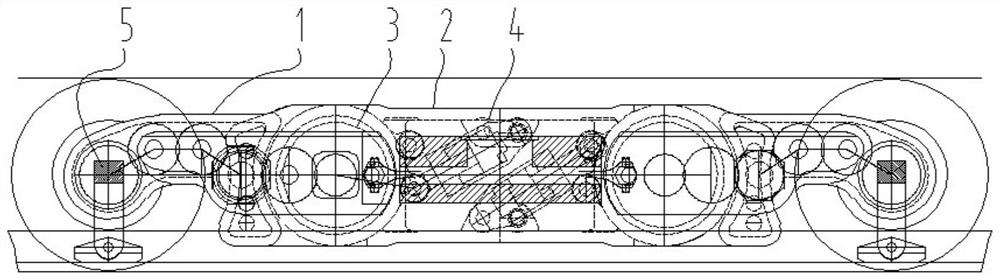

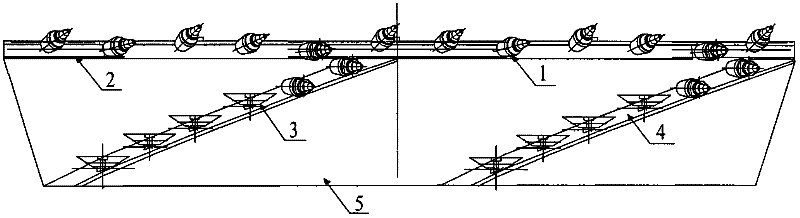

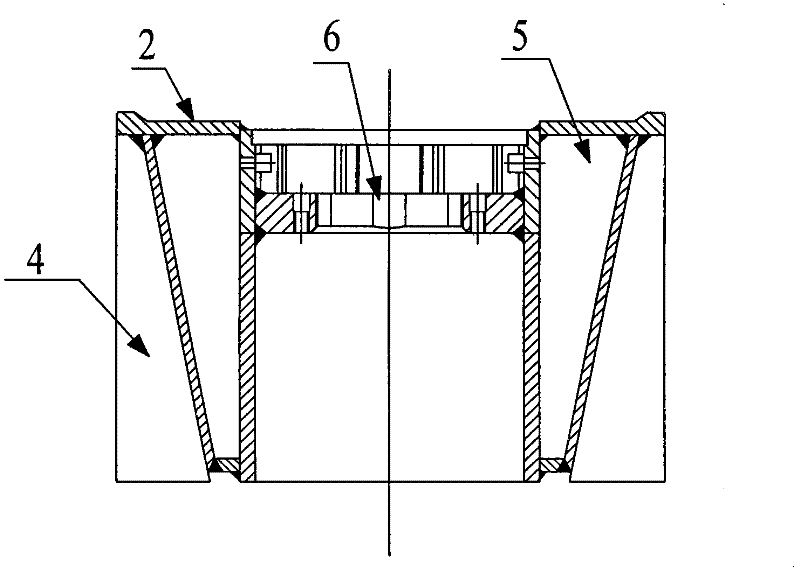

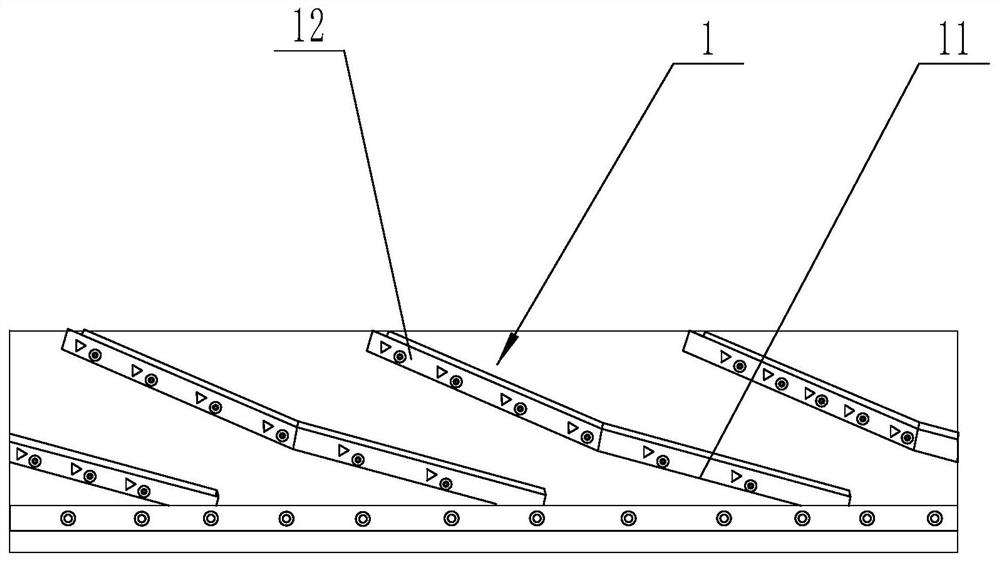

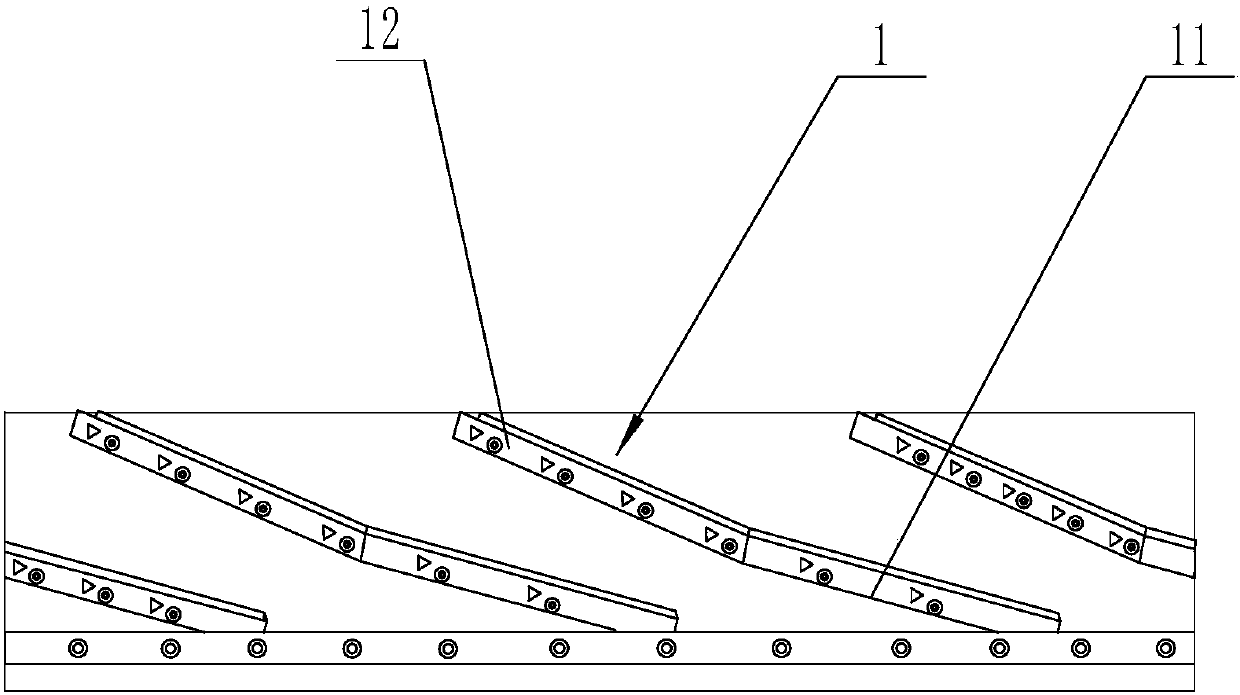

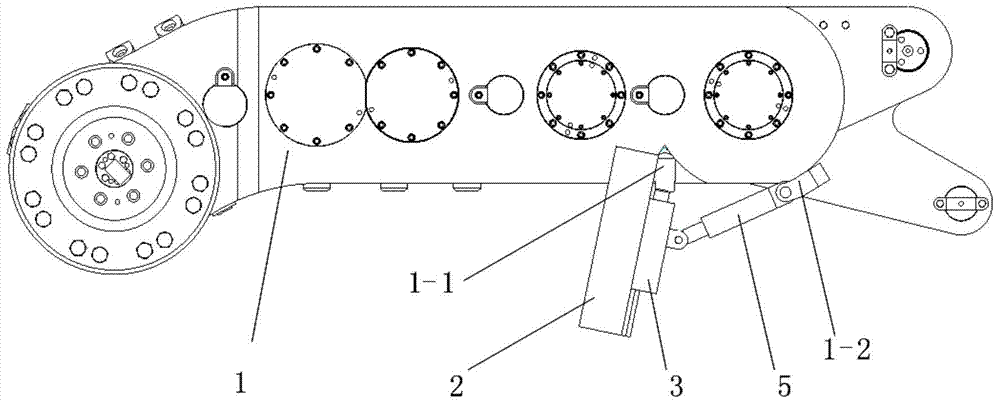

Roller for mixed row cutting tooth coal winning machine

InactiveCN101956552AImprove coal loading effectIncrease the rate of cutting lump coalCutting machinesHelical bladePulp and paper industry

The invention relates to a roller for a mixed row cutting tooth coal winning machine. The roller comprises a roller hub, an end disk, pickaxe-shaped cutting teeth and a square connecting sleeve, wherein the roller hub is trapezoidal; the roller hub is provided with a diameter-variable helical blade; the front part of the diameter-variable helical blade is provided with 1 to 2 rows of pickaxe-shaped cutting teeth arranged in a checkerboard way, while the rear part is provided with a plurality of disk cutter devices arranged in the checkerboard way; and the disk cutter devices comprise an upper connecting block, a lower connecting block and disk cutter cutting teeth; the upper connecting block and the lower connecting block are welded on the diameter-variable helical blade; and the disk cutter cutting teeth, the upper connecting block and the lower connecting block are integrated into a whole through bolts. According to the characteristics of compression resistance and low tensile resistance of coal beds, different axial coal dropping amounts along the roller, the gradual diameter change of the blade and the trapezoidal appearance, the coaling effect of the roller is improved by about 15 percent compared with that of the conventional cylindrical roller, and the lump coal cutting rate is improved by 7 percent; and the roller is suitable for mining low coal beds with the coal bed thickness of below 1.3m and the dip angle of between 0 and 25 degrees. The roller has the advantages of simple and compact structure, convenient operation, good cutting effect, good coaling effect and high rock breaking ability.

Owner:CHINA UNIV OF MINING & TECH +1

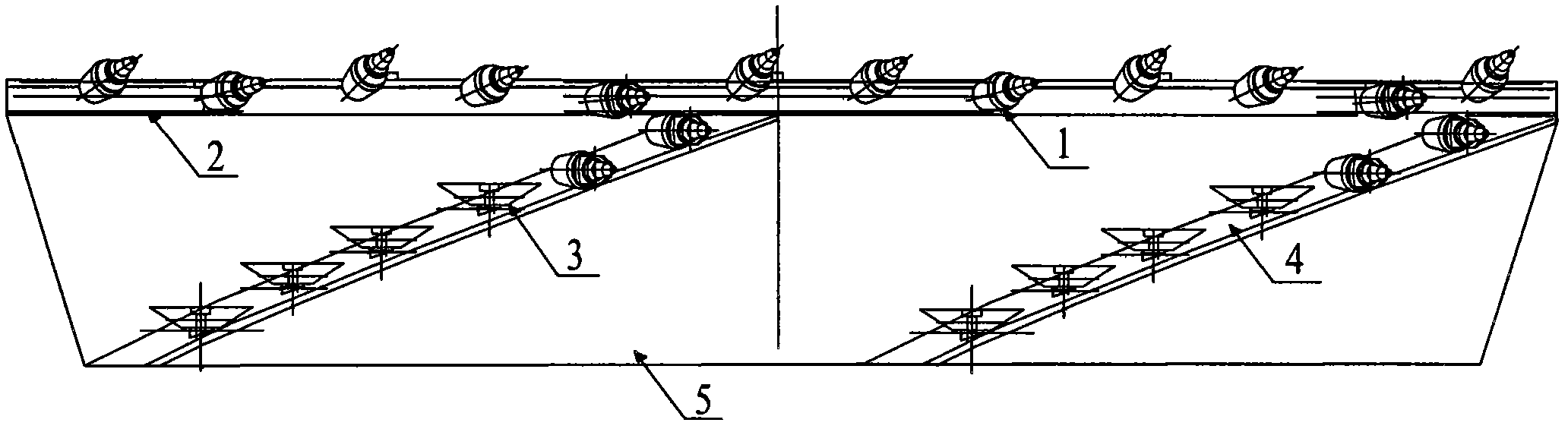

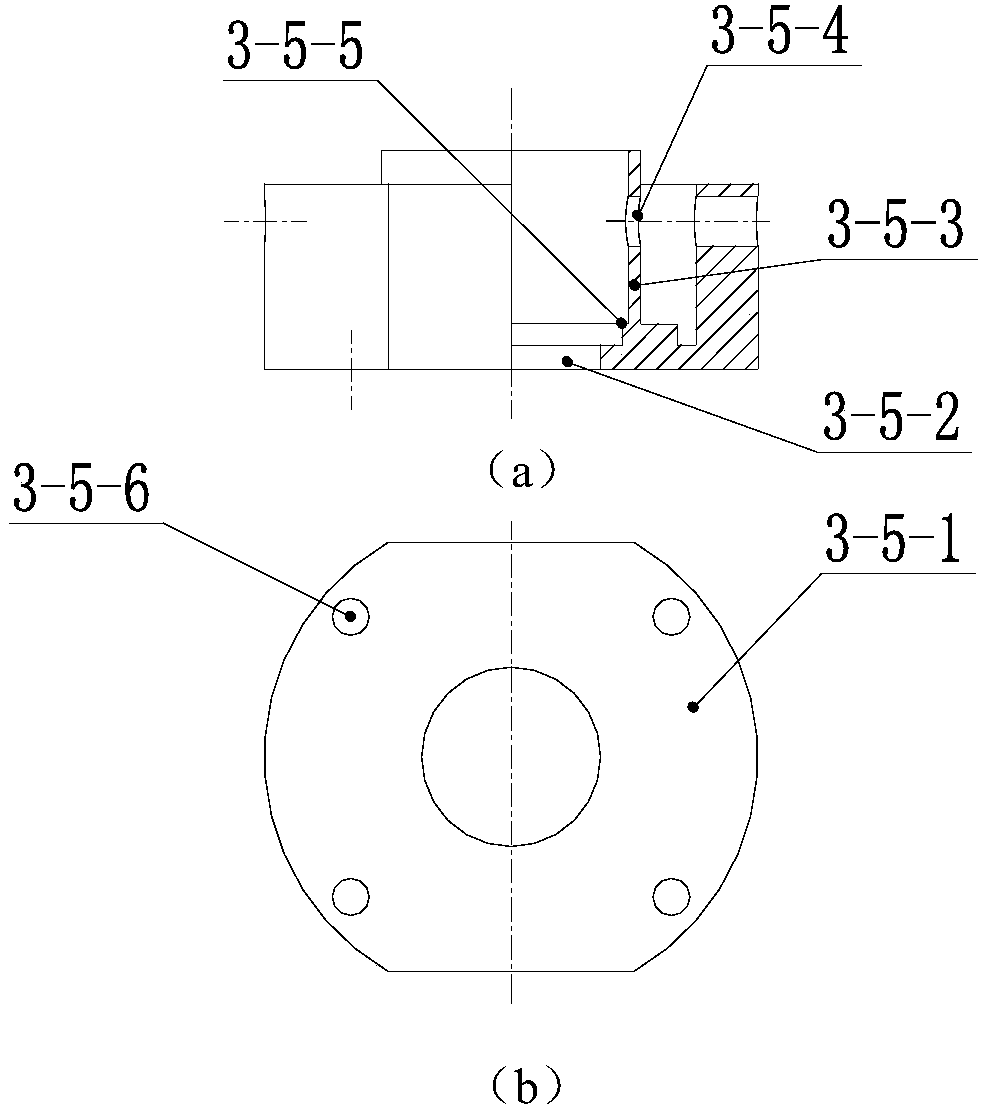

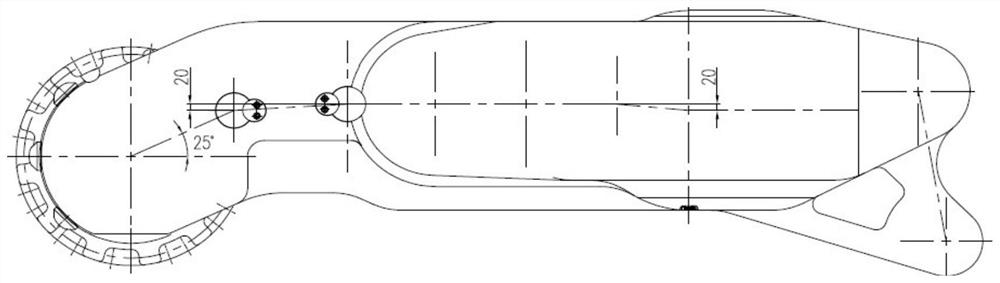

Auxiliary coal charging device of thin seam coal mining machine

The invention discloses an auxiliary coal charging device of a thin seam coal mining machine. The device mainly consists of a right coal mining machine rocker arm, a coal plough I, a coal plough II, a coal plough III and a left coal mining machine rocker arm, wherein the coal plough I, the coal plough II and the coal plough III are symmetrically and uniformly distributed below one side of the right coal mining machine rocker arm and one side of the left coal mining machine rocker arm in turn; the coal plough I consists of a steel plate and two reinforcing ribs; the coal plough II consists of a steel plate and four reinforcing ribs; the coal plough III consists of a steel plate and a reinforcing rib; and the coal plough I, the coal plough II and the coal plough III are connected with the right coal mining machine rocker arm and the left coal mining machine rocker arm in a 35-degree mode respectively. The device enhances the coal charging capability of the thin seam coal mining machine only by means of a roller, and particularly enhances the coal charging effect of a slipper riding shovel plate type thin coal mining machine more remarkably; and the device is simple in operation, convenient in use, safe and reliable.

Owner:HEBEI SHENFENG HEAVY MACHINERY

Coal cutter cutting part with differential speed separation roller

The invention discloses a coal cutter cutting part with a differential speed separation roller. A motor driving part comprises a left cutting motor and a right cutting motor, both the left cutting motor and the right cutting motor are arranged in a cutting part box, and transmission connection of the left cutting motor as well as the right cutting motor and a roller output part is achieved througha gear transmission part; and the roller output part comprises a high-speed output shaft, a low-speed output shaft, a middle supporting frame, a high-speed roller, a far-end supporting frame and a low-speed roller, a cutting roller is separated into two coaxially-rotated parts, and differential speed rotating of the two parts of the roller can be achieved. The front end low-speed roller is low inrotating speed, so that cut coal briquettes have good axial mobility, and the coal briquettes can be better conveyed into a revolving area of a wheel rotating blade of the high-speed roller, the rotating speed of the high-speed roller is far higher than that of the low-speed roller, therefore, the coal briquettes can obtain the higher tangential speed and axial speed through action of the high-speed roller so that coal can cross the distance from the tail end of the high-speed roller to a middle groove of a scraper machine, and the roller conveying and coal loading processes are better finished.

Owner:SHANDONG UNIV OF SCI & TECH

Bottom cleaning drum shearer for thin coal seams

ActiveCN104594892AImprove productivityAvoid formingSlitting machinesCutting machinesEdge structureEngineering

The invention provides a bottom cleaning drum shearer for thin coal seams. The drum shearer is characterized in that a cutting part shell comprises a first cutting drum transmission cavity shell, a transition section shell and a second cutting drum transmission cavity shell; the first cutting drum transmission cavity shell extends out of ledges of a middle groove and transition groove of a scraper conveyer towards the coal wall side via the transition section shell and bends towards the lower part; a top slope cut edge structure and a bottom slope cut edge structure are arranged at the rear end of the transition section shell; inner cavity flanges of first and second planetary mechanisms are respectively connected with inner cavity flanges of the first and second cutting drum transmission cavity shells by bolts; outer end face key grooves of the first and second planetary mechanisms are respectively positioned together with outer end face key grooves of the first and second cutting drum transmission cavity shells by end face flat keys. The drum shearer can be used for effectively solving the problem of triangle coal and satisfy the minimum mining height conditions and the adaptability to change of the thickness of coal seams, and conduces to improving the coal charging effects.

Owner:国科中迈(徐州)能源科技有限公司

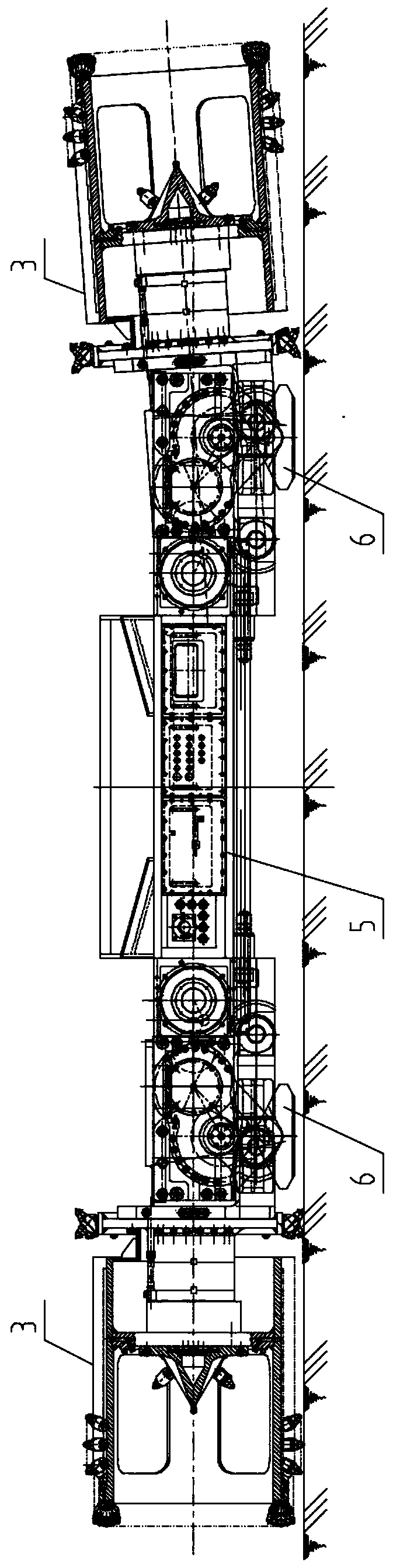

Thin seam coal mining machine

PendingCN114396267AShorten the left and right lengthSimple structureSlitting machinesCutting machinesMining engineeringElectric machinery

The invention relates to a thin seam mining machine which comprises a main body part shell and two swing arm shells hinged to the left end and the right end of the front portion of the main body part shell respectively, a cutting motor is arranged between each swing arm shell and the main body part shell to serve as a hinge pin shaft, and a cover plate is installed at an opening in the front end of the main body part shell. A closed oil cylinder installation cavity is defined by the swing arm shells, the main body shell, the cutting motor and the cover plate, oil cylinders driving the left swing arm shell and the right swing arm shell to swing are installed in the oil cylinder installation cavity, the rear portion of the main body shell is provided with a left coal flow rear channel and a right coal flow rear channel, the coal flow rear channels are grooves which extend from front to back and are provided with downward groove openings, and the coal flow rear channels are communicated with the oil cylinder installation cavity. And the rear end of the groove is closed. The large mining range and the large cutting power can be provided, the machine body can be shortened, and the coal flow loading effect is improved.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

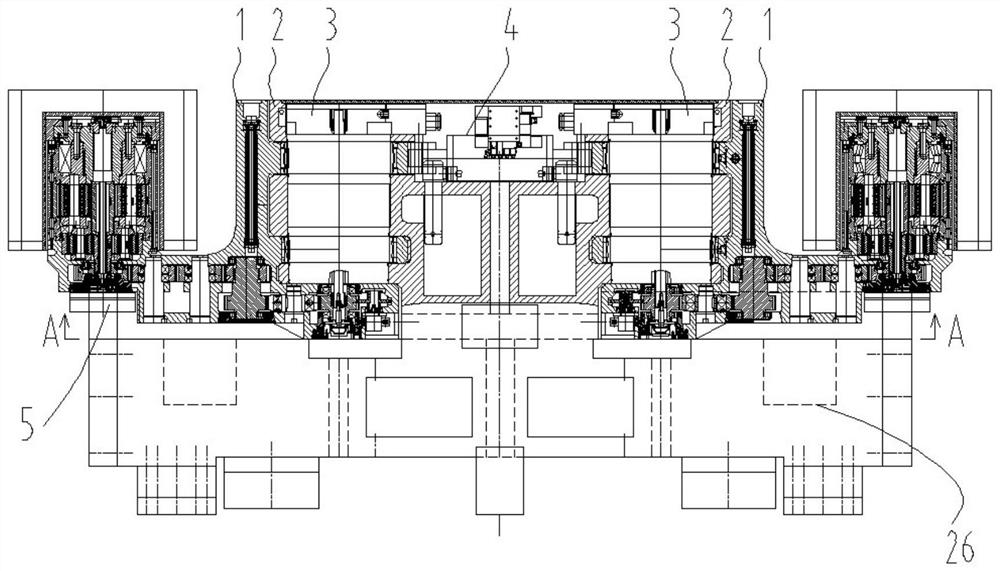

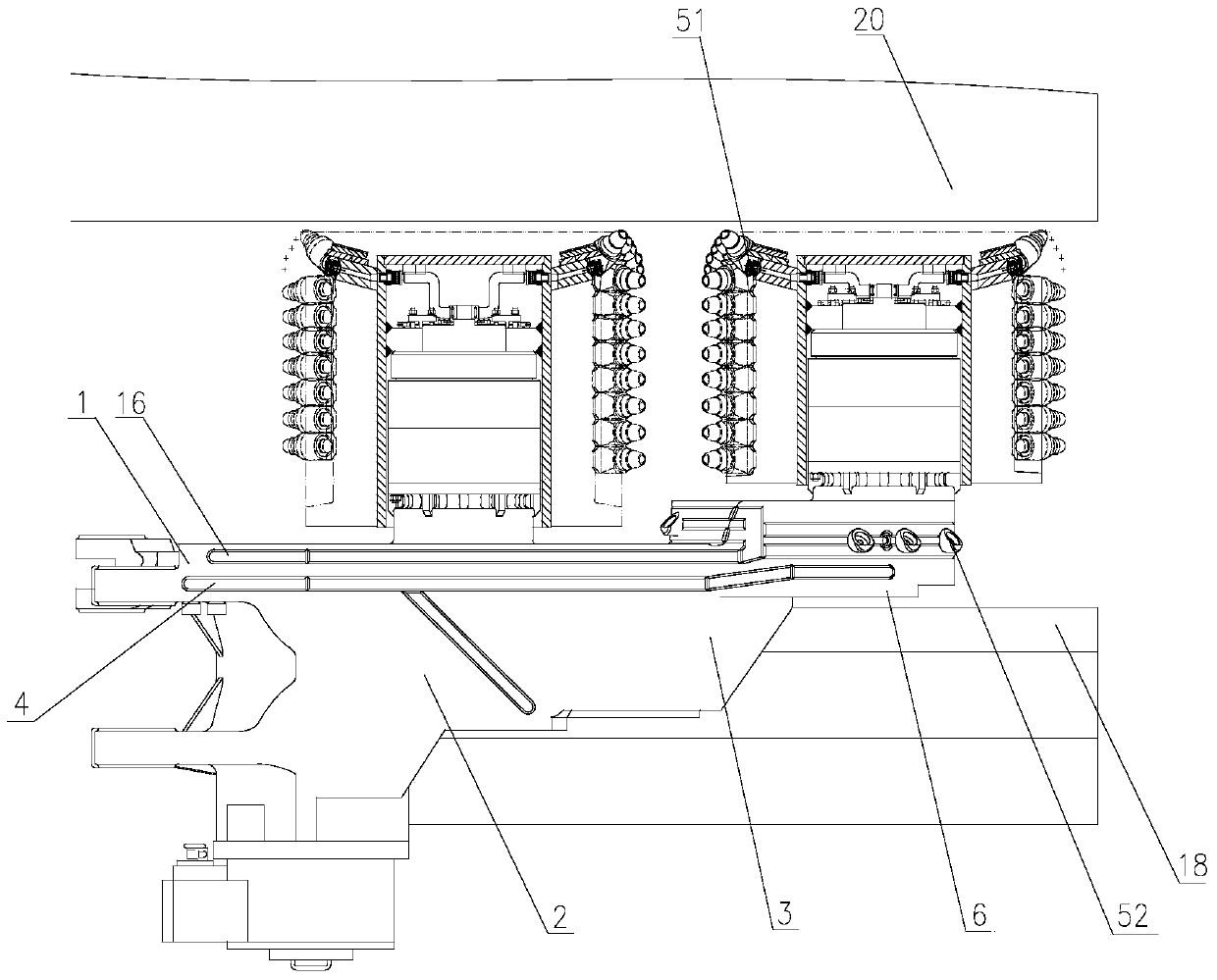

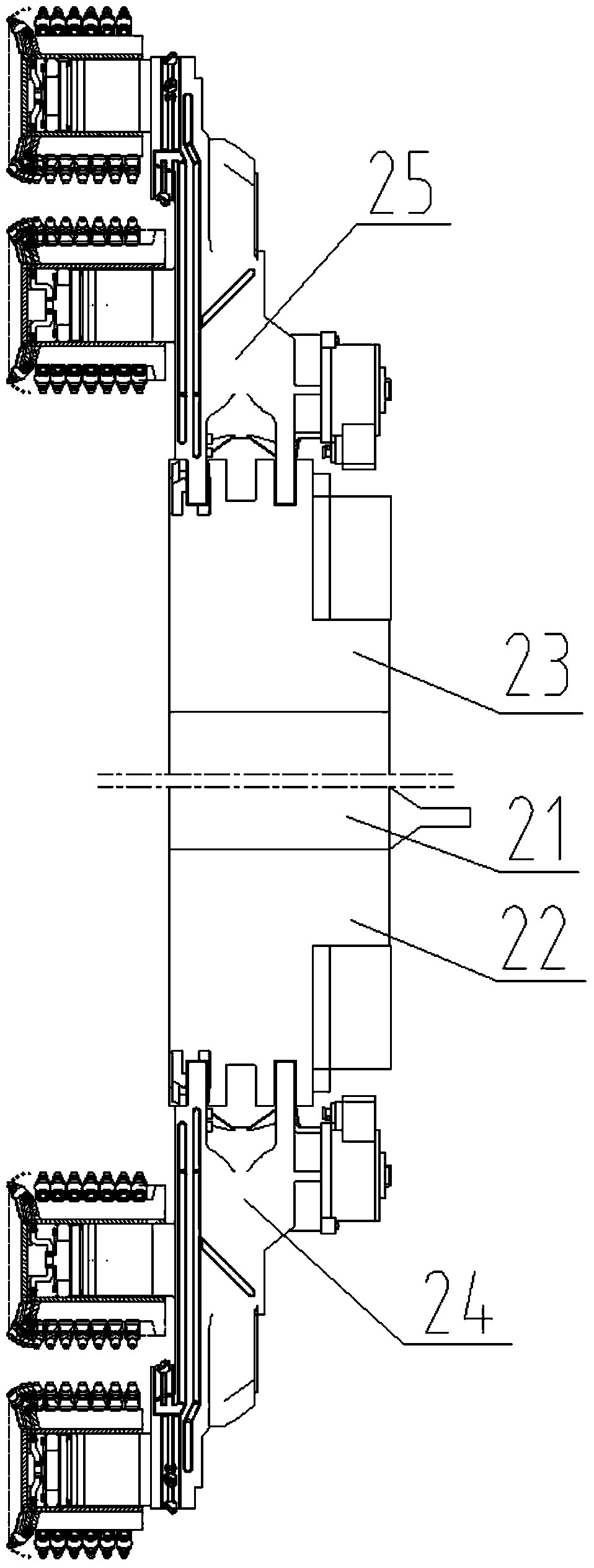

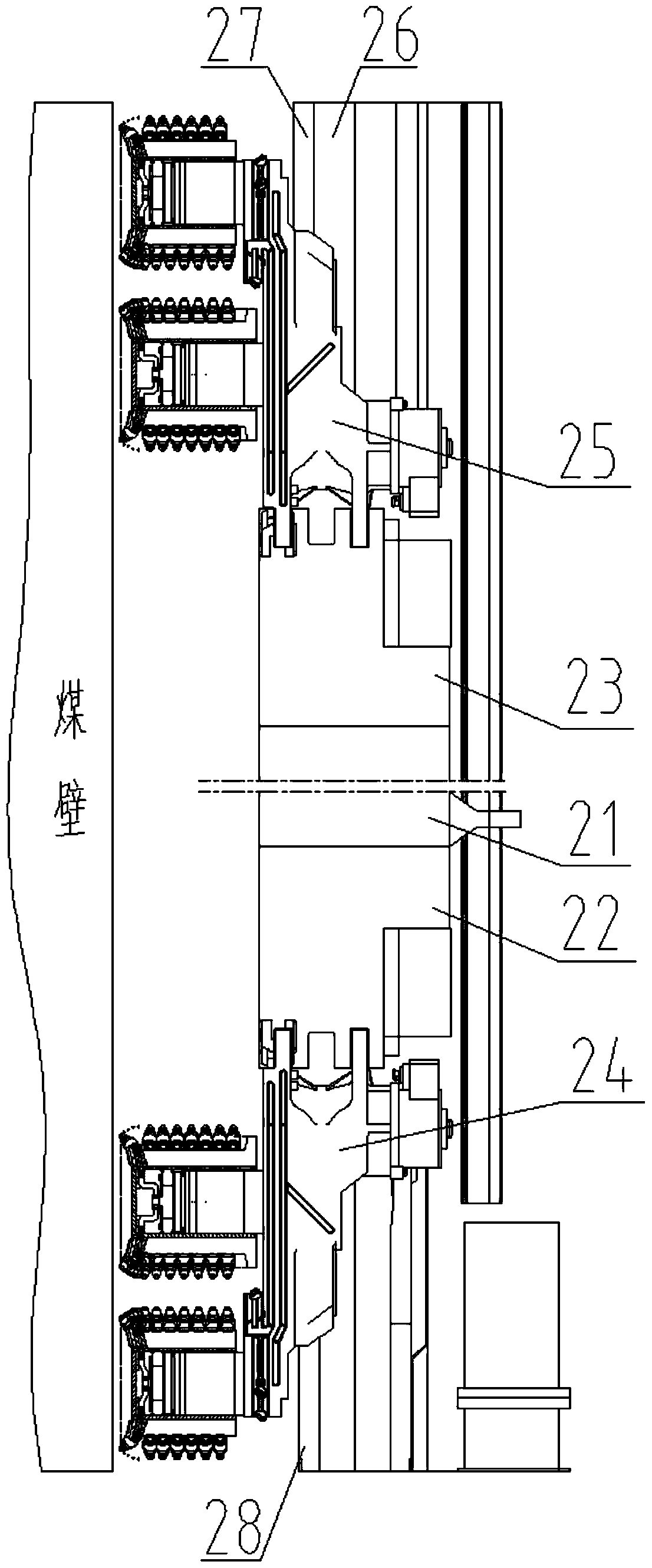

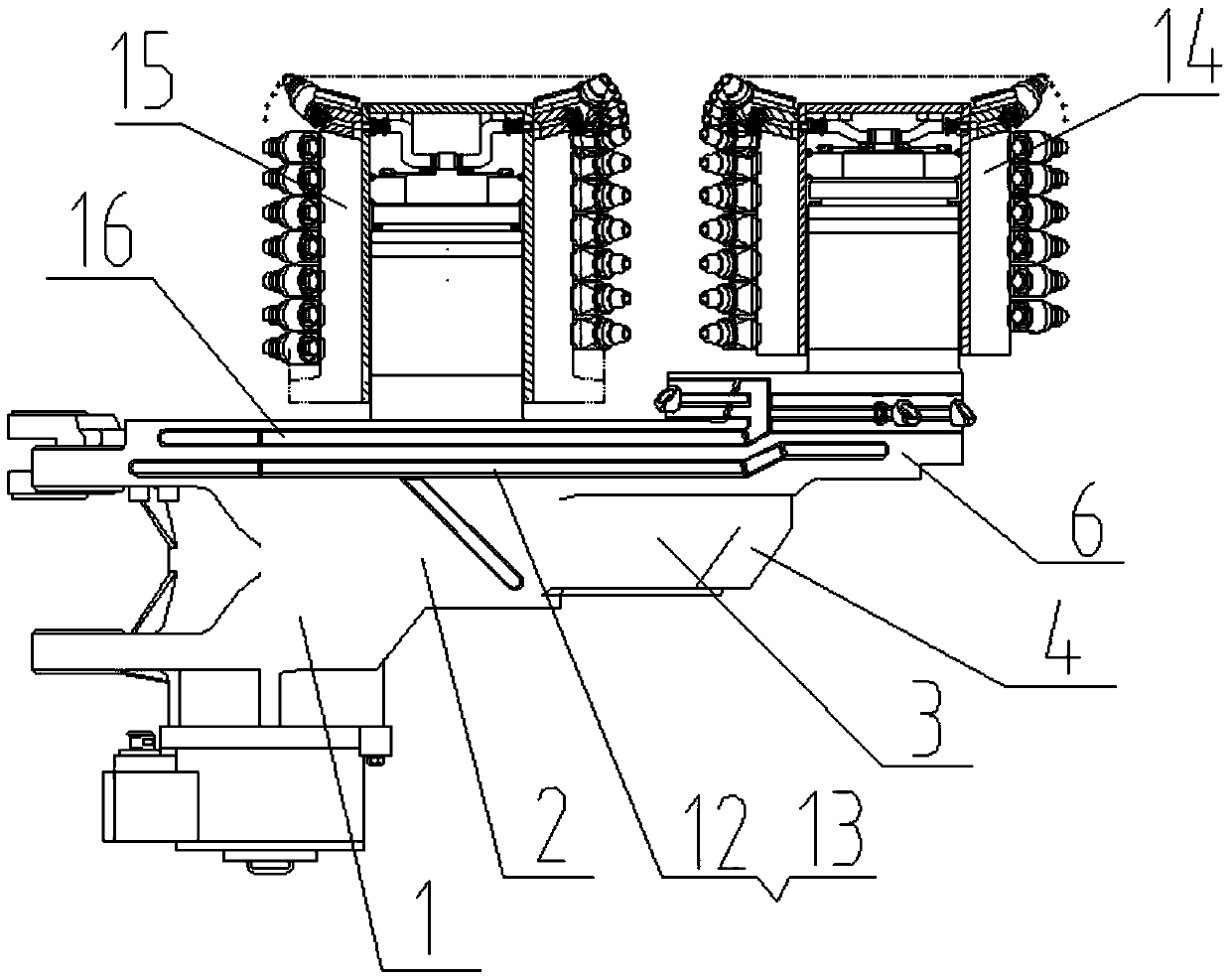

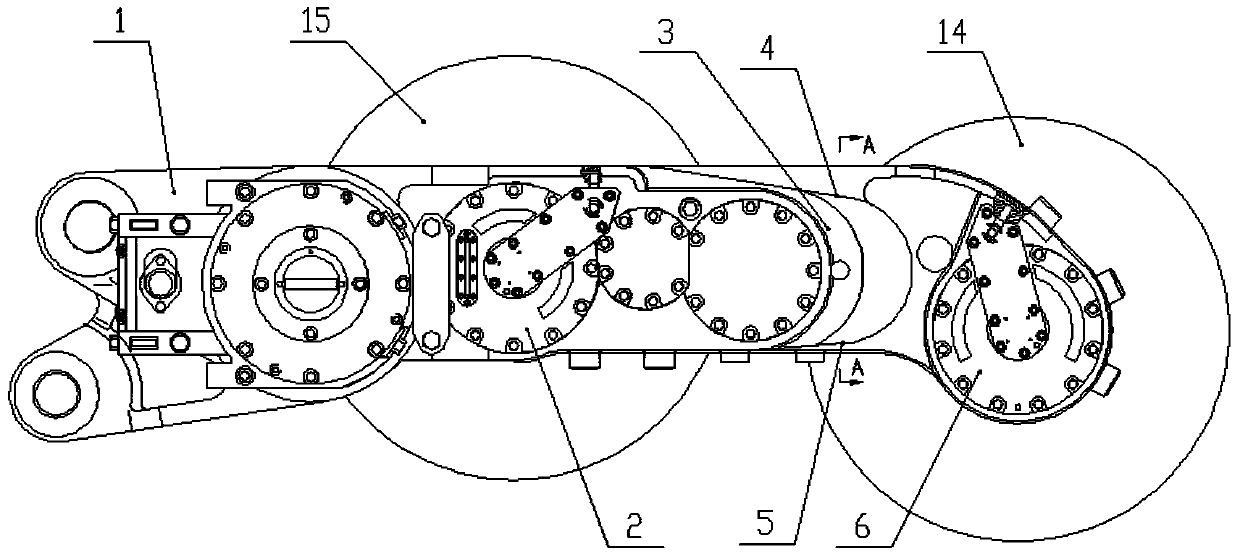

Cutting part of a bottom-clearing drum shearer

ActiveCN104594895BEnough undercoverReduce the center distanceDriving meansCutting machinesThermodynamicsMechanical engineering

The invention discloses a cutting part of a bottom-clearing roller shearer, each cutting part includes two cutting drums, a first cutting drum (14) and a first cutting drum transmission chamber casing (6) The transition section housing (3) extends to the coal wall (20), and the rear part of the first cutting drum transmission chamber housing (6) extends beyond the middle groove of the scraper conveyor and the groove side (18) of the transition groove, and at the same time The casing (6) of the first cutting drum transmission chamber is bent downward. The first cutting drum of the present invention has enough undercover to avoid the formation of "triangular coal" at the head and tail of the scraper conveyor, and the second cutting drum has a smaller production distance to improve the coal loading effect and ensure sufficient load bearing Strength: Under the same coal mining height, two cutting drums with smaller diameters are selected to be used in pairs to ensure the full height of one-time mining, prolong the service life of the cutting drum, optimize the overall performance of the cutting part, and have good adaptability to changes in coal seam thickness , Reduce costs and process requirements.

Owner:国科中迈(徐州)能源科技有限公司

A thin coal seam bottom cleaning drum shearer

ActiveCN104594892BImprove productivityAvoid formingSlitting machinesCutting machinesThermodynamicsStructural engineering

The invention provides a thin coal seam bottom clearing type drum shearer. The cutting part housing is composed of the first cutting drum transmission chamber housing, the transition section housing and the second cutting drum transmission chamber housing. The first The casing of the cutting drum transmission chamber extends to the side of the coal wall through the transition section casing to the outside of the middle trough of the scraper conveyor and the side of the transition trough and bends downward. The bottom bevel trimming structure, the inner cavity flanges of the first planetary mechanism and the second planetary mechanism are respectively connected with the inner cavity flanges of the first cutting drum transmission chamber shell and the second cutting drum transmission chamber shell by bolts, The outer end surface key grooves of the first planetary mechanism and the second planetary mechanism are respectively positioned with the outer end surface key grooves of the first cutting drum transmission chamber housing and the second cutting drum transmission chamber housing through end surface flat keys. The invention can effectively solve the problem of triangular coal, meet the minimum mining height condition and the adaptability of coal seam thickness changes, and improve the coal loading effect.

Owner:国科中迈(徐州)能源科技有限公司

Roller for mixed row cutting tooth coal winning machine

InactiveCN101956552BImprove coal loading effectIncrease the rate of cutting lump coalCutting machinesHelical bladePulp and paper industry

The invention relates to a roller for a mixed row cutting tooth coal winning machine. The roller comprises a roller hub, an end disk, pickaxe-shaped cutting teeth and a square connecting sleeve, wherein the roller hub is trapezoidal; the roller hub is provided with a diameter-variable helical blade; the front part of the diameter-variable helical blade is provided with 1 to 2 rows of pickaxe-shaped cutting teeth arranged in a checkerboard way, while the rear part is provided with a plurality of disk cutter devices arranged in the checkerboard way; and the disk cutter devices comprise an upperconnecting block, a lower connecting block and disk cutter cutting teeth; the upper connecting block and the lower connecting block are welded on the diameter-variable helical blade; and the disk cutter cutting teeth, the upper connecting block and the lower connecting block are integrated into a whole through bolts. According to the characteristics of compression resistance and low tensile resistance of coal beds, different axial coal dropping amounts along the roller, the gradual diameter change of the blade and the trapezoidal appearance, the coaling effect of the roller is improved by about 15 percent compared with that of the conventional cylindrical roller, and the lump coal cutting rate is improved by 7 percent; and the roller is suitable for mining low coal beds with the coal bed thickness of below 1.3m and the dip angle of between 0 and 25 degrees. The roller has the advantages of simple and compact structure, convenient operation, good cutting effect, good coaling effect andhigh rock breaking ability.

Owner:CHINA UNIV OF MINING & TECH +1

A high-speed cutting longwall mining method for thin and medium-thick coal seams

ActiveCN104564073BRaise the ratioHigh-speed coal cutting guaranteeUnderground miningSurface miningLongwall miningEngineering

The invention discloses a high-speed cutting longwall-mining method for low coal seams and medium-thickness coal seams. The cutting resistance is reduced by reducing a web, so that a normal coal cutting speed reaches 15-40 m / min; by using a low-web bidirectional high-speed coal cutting process for left triangular coals, after triangular coals are completely cut, returning to cut the other half of triangular coals is not required, but continuing to carry out ascending (descending) coal cutting is performed; and reciprocating mining is performed in such a way. By adopting the spaced quick moving of brackets, every two circulating brackets move at a synchronized interval. Through the timing optimization of production takts, by using a space-time coordinated continuous operating method, each workday is uniformly divided into six (or eight) time intervals, a maintenance operation and a shutdown-required roadway operation are arranged in the third time interval, and coal cutting and non-shutdown-required roadway operations are arranged in the rest of time intervals. According to the invention, the low-web bidirectional high-speed coal cutting process for left triangular coals, moving brackets in a grouped, spaced and staggered mode, and the space-time coordinated continuous operating method are adopted, so that the shortcomings of slow advance speed and low mining efficiency of low coal seams and medium-thickness coal seams are made up, thereby providing a feasible mining method for the high-speed cutting of low coal seams and medium-thickness coal seams.

Owner:TIANDI SCI & TECH CO LTD +1

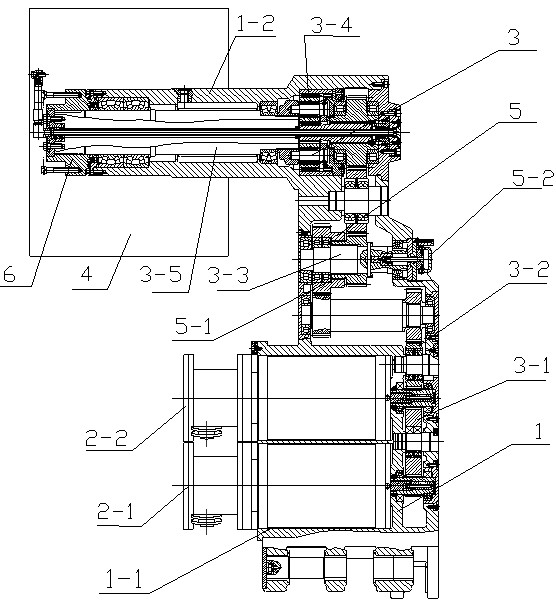

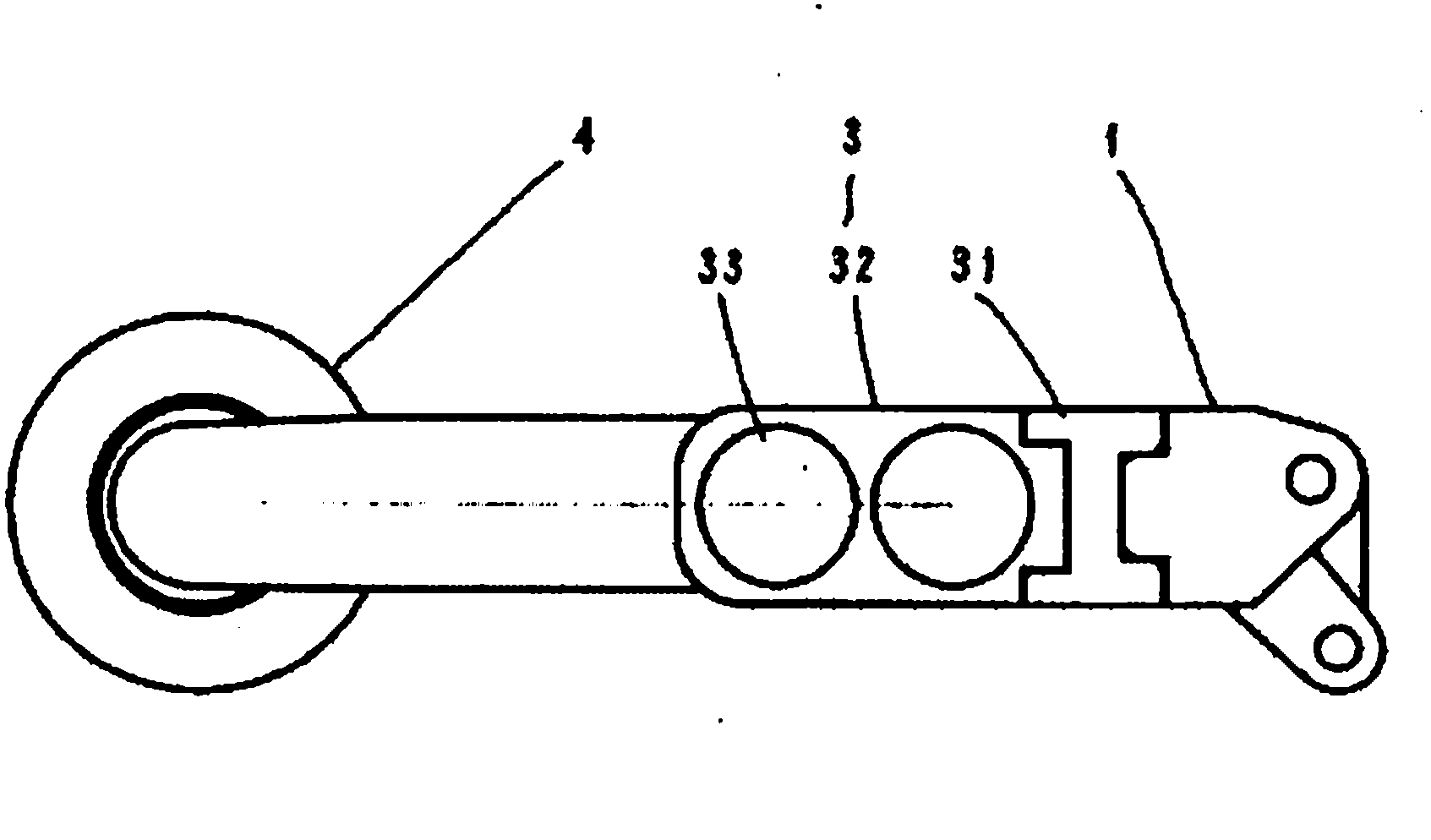

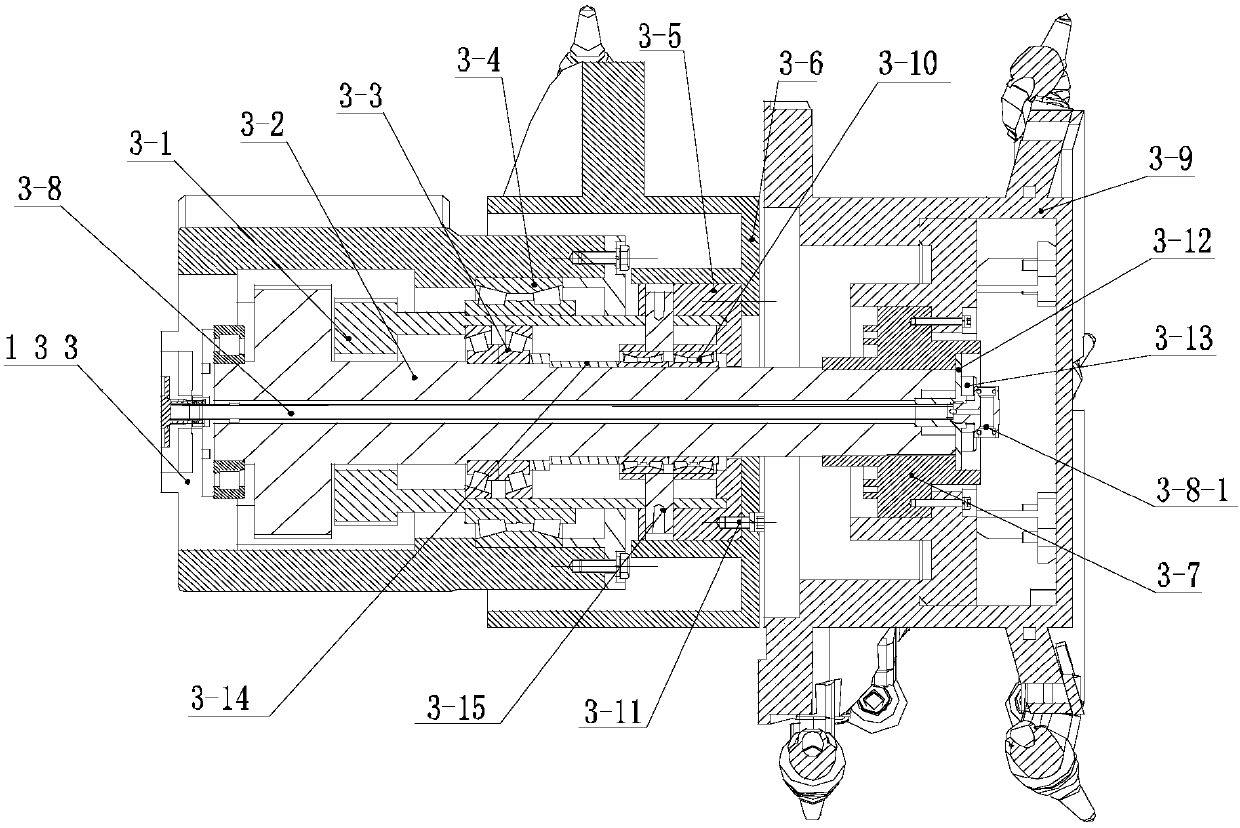

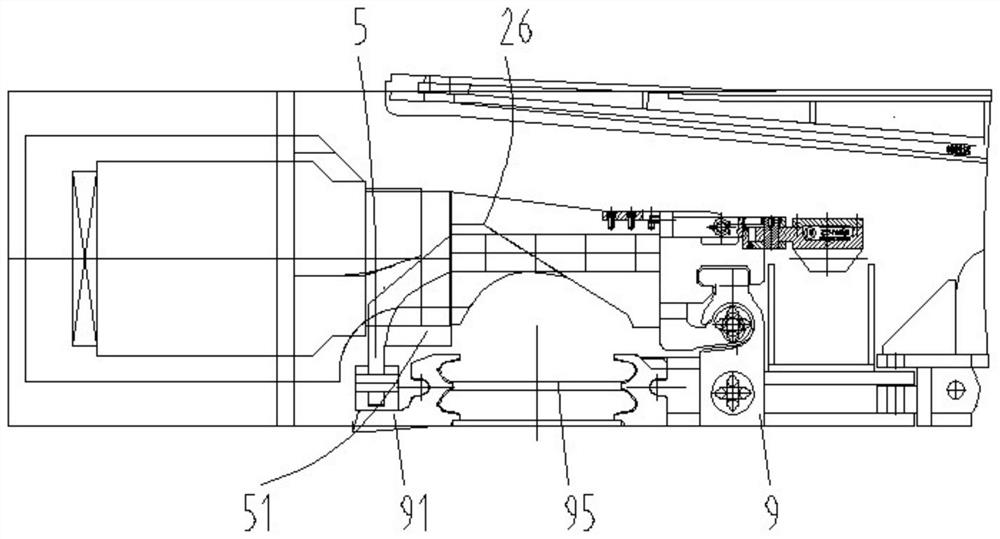

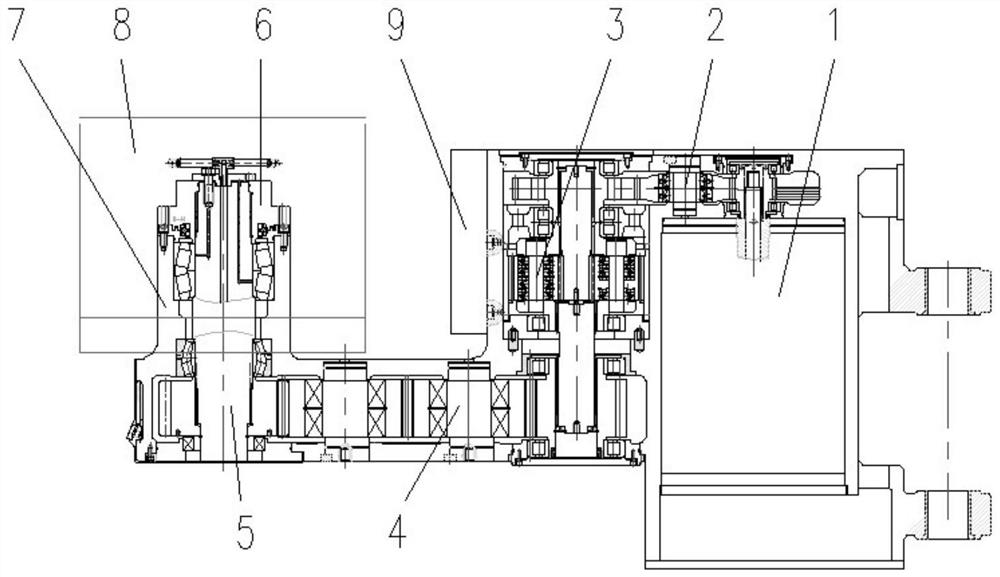

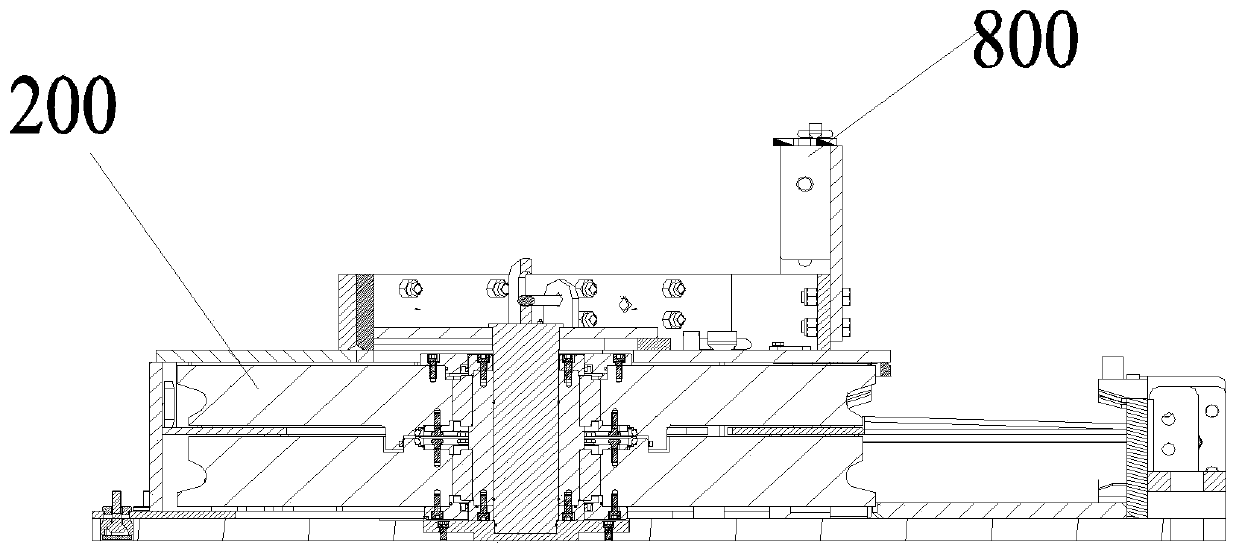

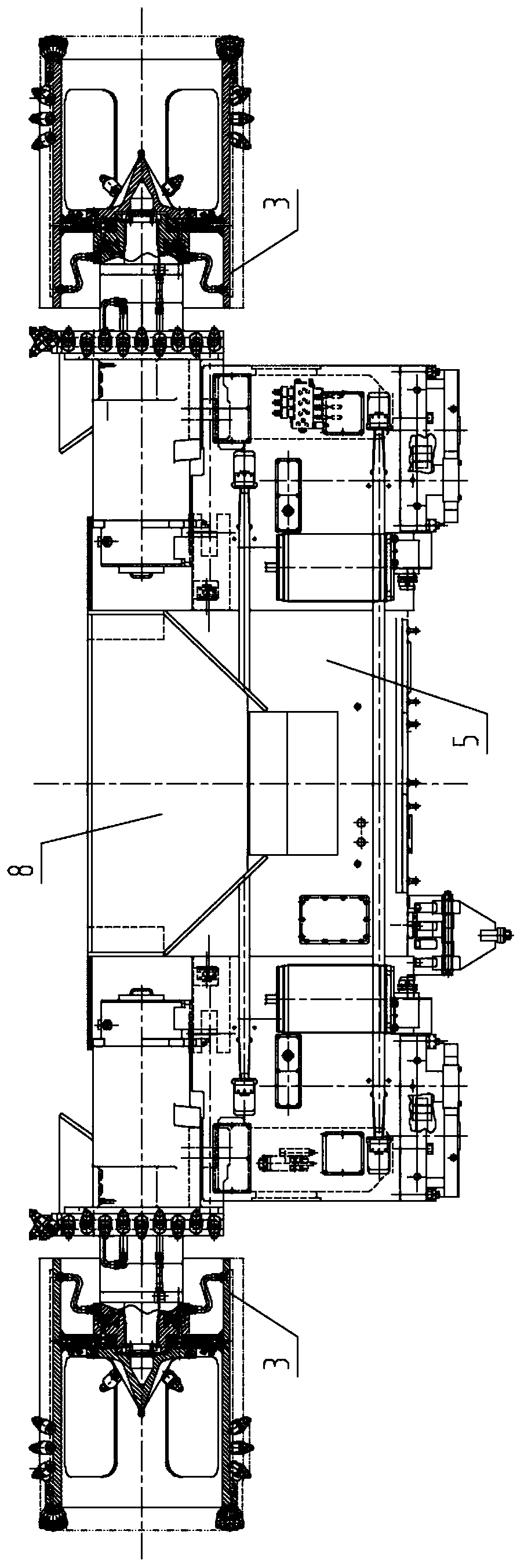

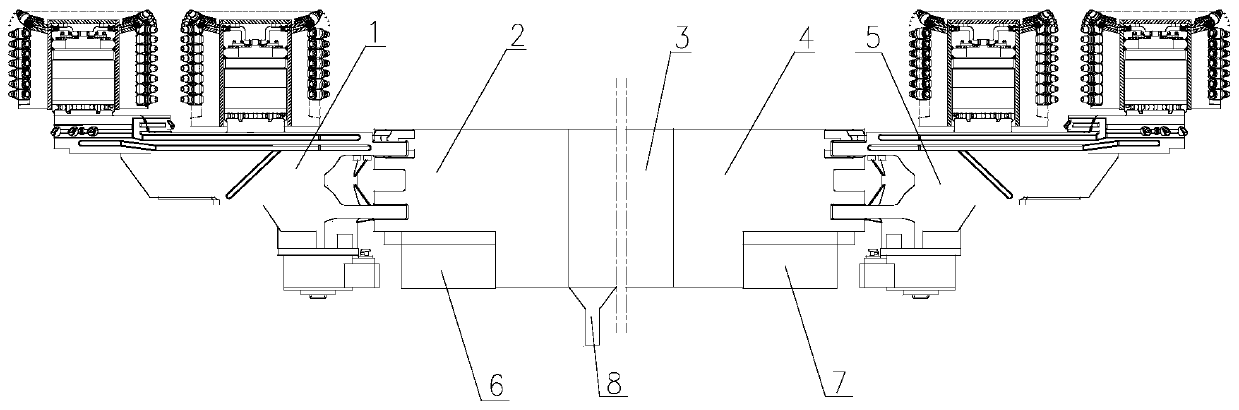

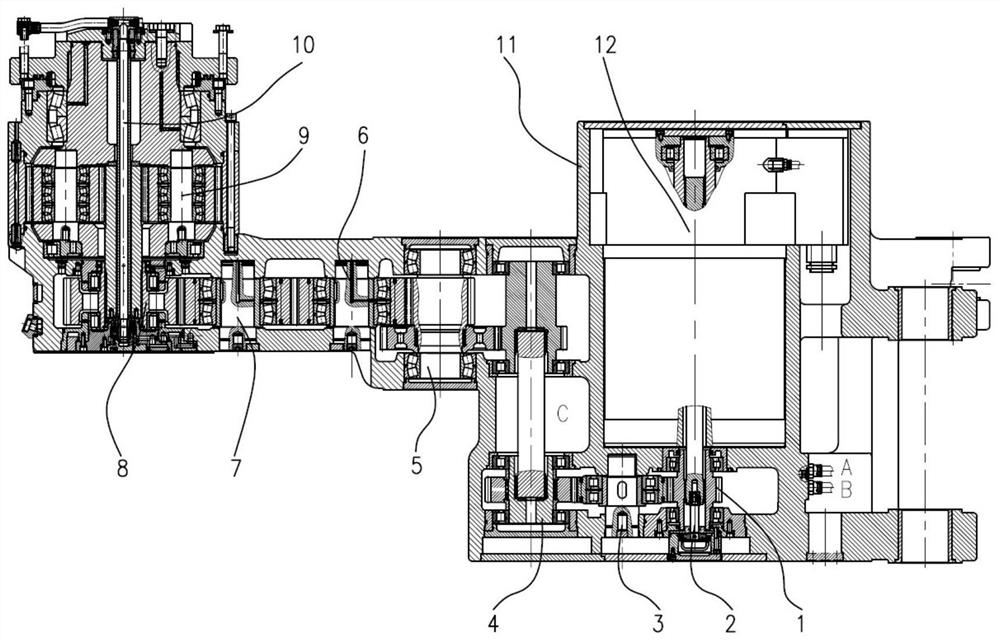

High-power thin coal seam coal mining machine rocker arm with front-mounted planetary reducer

PendingCN113250692ASpatial impact of passing coalPlay the role of auxiliary coal loadingDriving meansCutting machinesReduction driveElectric machine

The invention relates to a high-power thin coal seam coal mining machine rocker arm with a front-mounted planetary reducer. The high-power thin coal seam coal mining machine rocker arm comprises a rocker arm shell, a cutting motor, a first-stage straight tooth transmission system, a planetary reduction mechanism, a second-stage straight tooth transmission system and a long output shaft, wherein the cutting motor, the first-stage straight tooth transmission system, the planetary reduction mechanism, the second-stage straight tooth transmission system and the long output shaft are installed in the rocker arm shell and are in transmission connection in sequence; a high-speed end installation part and a low-speed end installation part of the rocker arm shell extend front and back and are opposite in a left-right spaced mode, so that the rocker arm shell is in a U shape; the axis of the cutting motor and the axis of the planetary reduction mechanism extend front and back and are installed in two adjacent cavities spaced by one wall in the high-speed end installation part side by side in a left-right mode; the first-stage straight tooth transmission system is arranged in front of the cutting motor and the planetary reduction mechanism; the second-stage straight tooth transmission system is located behind the planetary reduction mechanism and arranged in an inner cavity in the U-shaped bottom of the rocker arm shell; and the long output shaft extends front and back and is installed in an inner cavity of the low-speed end installation part. The high-power thin coal seam coal mining machine rocker arm can be matched with a small-diameter roller, can provide large cutting force and has a good coal loading effect.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

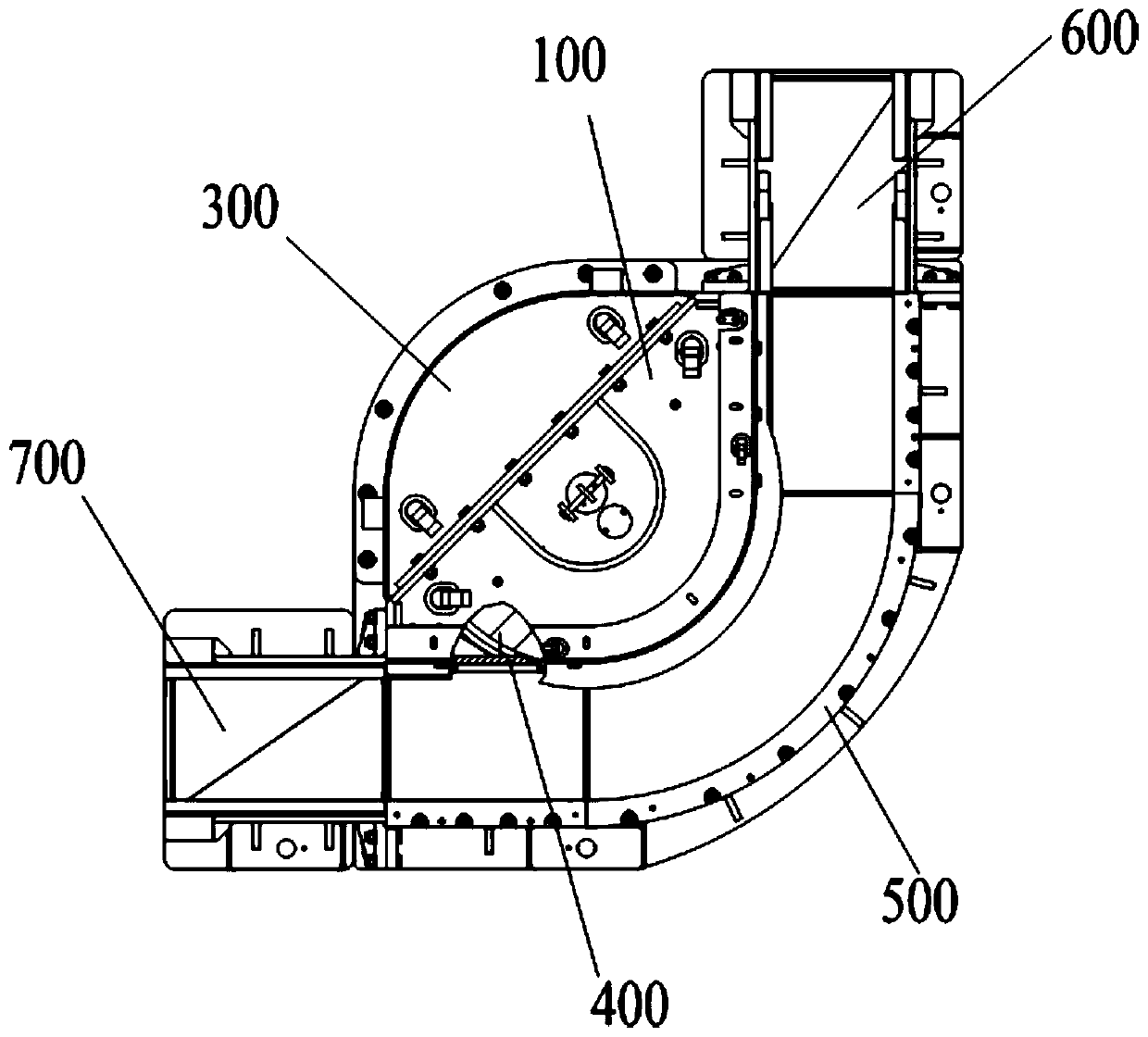

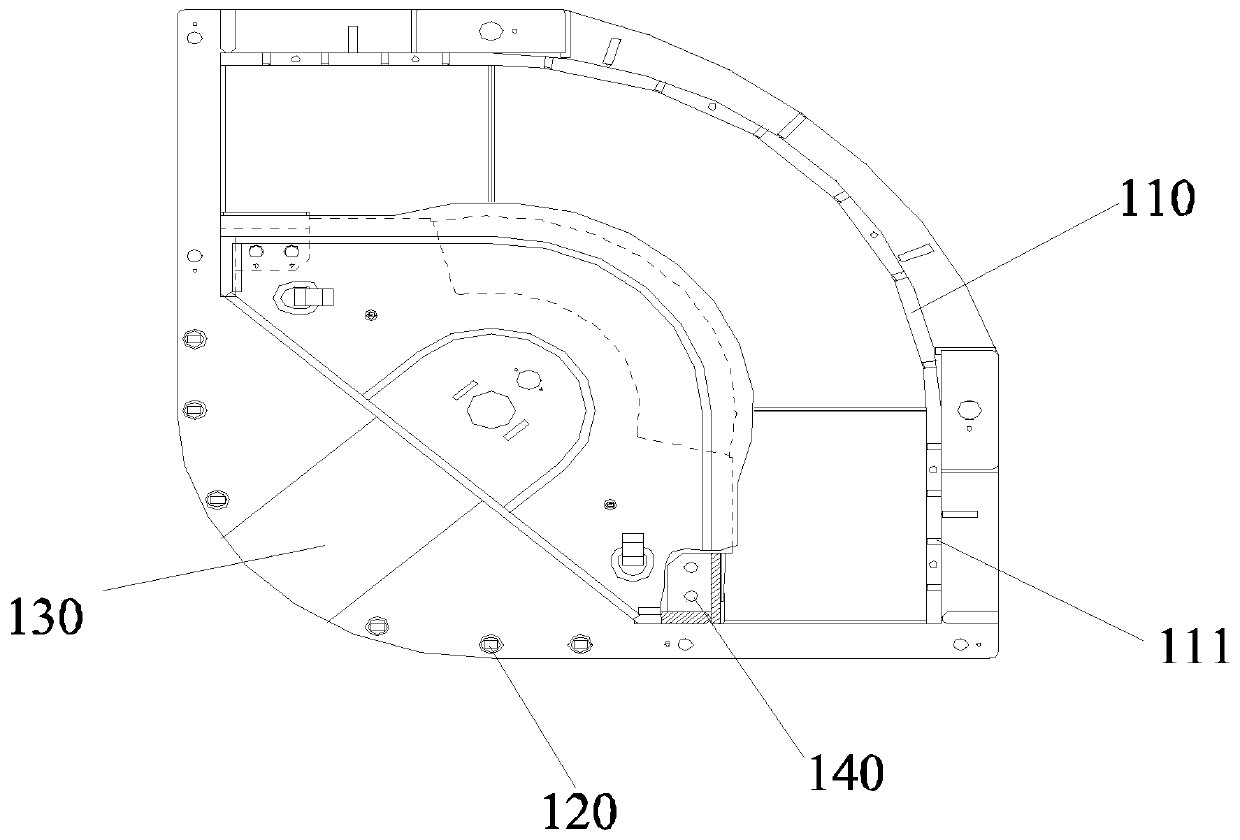

Right-angle turning scraper conveyor and rotary disc mechanism thereof

The invention discloses a right-angle turning scraper conveyor and a rotary disc mechanism thereof. The right-angle turning scraper conveyor comprises a rotary disc box, a rotary disc assembly, transition grooves and guide blocks, wherein the rotary disc assembly is arranged in the rotary disc box and used for providing turning support for scraper chains, the transition grooves are formed in the two ends of a rotary disc, and the guide blocks are arranged at the joints of the two ends of the rotary disc box and used for guiding scrapers to move from the transition grooves to the rotary disc box; and the rotary disc assembly comprises an upper rotary disc and a lower rotary disc which rotate coaxially and provide turning support for the upper scraper chain and the lower scraper chain correspondingly. According to the right-angle turning scraper conveyor and the rotary disc mechanism thereof, a rotary disc type guide structure is adopted, continuous right-angle turning movement of the scrapers is achieved, coal flow can turn smoothly, and the concentration of bottom chain coal return and underground coal dust can be reduced; the right-angle turning rotary disc is not provided with adriving part, and equipment maintenance is facilitated; and a lap joint mechanism of a scraper conveyor and a reversed loader is omitted, power energy consumption is reduced, the reliability of a transmission part is improved, the service life of the transmission part is prolonged, post configuration is reduced, the ventilation section of the position is increased, and the labor environment is improved.

Owner:SHANDONG ENERGY HEAVY EQUIP MFG GRP CO LTD

Thin coal seam shearer and its chute type coal retaining mechanism

ActiveCN104060988BImprove coal loading effectRealize the coal retaining functionSlitting machinesCutting machinesMechanical engineeringCharge effect

The invention discloses a thin-seam coal mining machine and a chute type coal blocking mechanism thereof. The coal mining machine comprises a rocking arm, the chute type coal blocking mechanism and a rotary drum, wherein the rocking arm comprises a rocking arm shell; the chute type coal blocking mechanism comprises a main coal blocking plate, a connecting rod, a chute pin, a chute plate and an auxiliary coal blocking plate; the main coal blocking plate of the chute type coal blocking mechanism is arranged in an interval formed between the end faces of the rotary drum and the rocking arm; the auxiliary coal blocking plate of the chute type coal blocking mechanism is arranged above the top surface of the rocking arm; the main coal blocking plate is connected with the rocking arm shell, is hinged with the connecting rod and is supported and limited by the connecting rod; the connecting rod is connected with a chute in the chute plate and can slide from a first end to a second end; the chute plate is fastened to the rocking arm shell and is located; the auxiliary coal blocking plate is hinged with the main coal blocking plate. According to the thin-seam coal mining machine, a coal charging effect can be improved; by utilizing the interval between the end faces of the rotary drum and the rocking arm and the space above the top surface of the rocking arm, a coal blocking function is realized without influencing the normal production operation.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +1

A Design Method for the Geometric Dimensions of the Cutting Teeth of the Chain Cutting Part of a Coal Shearer

InactiveCN104929636BUniform wearImprove adaptabilitySpecial data processing applicationsCutting machinesUnit sizeEconomic benefits

The invention provides a method for designing geometrical size of a coal cutter chain cutting part cutting tooth. The method comprises the following steps: step 1, determining the relation between cutting depth and cutting torque; steps 2, determining the relation between cutting tooth stress and the cutting depth; step 3, analyzing cutting force in a coal breaking process by the cutting tooth; step 4, determining the contact relation between cutting tooth and a coal wall; step 5, calculating the contact area between single cutting tooth and the coal wall in a cutting process; step 6, determining the relation between the cutting tooth contact area and the cutting depth; step 7, calculating the diameter of the cutting tooth body. The cutting force applied to unit size stressed surface of the cutting tooth in a cutting process tends to be equal, so that abrasion of the cutting force is more uniform, the adaptability of the cutting tooth is enhanced, the cutting efficiency of the cutting tooth is improved, the service life is prolonged, the reliability of a coal cutter is improved, a better economic benefit is obtained, and meanwhile, the coal loading effect of a cutting part can be improved.

Owner:CHINA UNIV OF MINING & TECH

Spiral blades for shearer drums, shearer drums and shearers

ActiveCN107829732BReduce volatilityEven by forceSlitting machinesCutting machinesThermodynamicsSpiral blade

The invention relates to the technical field of coal production, in particular to a coal cutter drum, a spiral blade for the same and a coal cutter. The spiral blade comprises a first blade and a second blade which are sequentially connected from one end close to a working face to one end away from the working face, and spiral lead angle of the first blade is smaller than that of the second blade.The spiral lead angle of the first blade in the spiral blade is small than that of the second blade, the first blade can increase cutting tooth capacity, and the drum is stressed uniformly in the process of cutting, thereby being little in fluctuation and conducive to cutting; the second blade increases coal containing space, friction between coal and the blades is reduced, and coal throwing speed is increased, so that coal loading capacity of the drum is improved, manual labor is reduced, and coal mining efficiency is improved.

Owner:SANY HEAVY EQUIP CO LTD

Coal cutter drum, spiral blade for same and coal cutter

ActiveCN107829732AReduce volatilityEven by forceSlitting machinesCutting machinesSpiral bladePulp and paper industry

The invention relates to the technical field of coal production, in particular to a coal cutter drum, a spiral blade for the same and a coal cutter. The spiral blade comprises a first blade and a second blade which are sequentially connected from one end close to a working face to one end away from the working face, and spiral lead angle of the first blade is smaller than that of the second blade.The spiral lead angle of the first blade in the spiral blade is small than that of the second blade, the first blade can increase cutting tooth capacity, and the drum is stressed uniformly in the process of cutting, thereby being little in fluctuation and conducive to cutting; the second blade increases coal containing space, friction between coal and the blades is reduced, and coal throwing speed is increased, so that coal loading capacity of the drum is improved, manual labor is reduced, and coal mining efficiency is improved.

Owner:SANY HEAVY EQUIP

Thin coal seam coal mining machine rocker arm

The invention discloses a thin coal seam coal mining machine rocker arm. The thin coal seam coal mining machine rocker arm comprises a rocker arm body and a shock absorbing module, a first-stage horizontal gear transmission is arranged at the right end of the interior of the rocker arm body, the first-stage horizontal gear transmission is sequentially connected to a second-stage horizontal gear transmission, a third-stage planetary reduction transmission and a fourth-stage horizontal gear transmission. The thin coal seam coal mining machine rocker arm has the beneficial effects that rocker armmotors adopt a small-diameter double-motor arrangement structure, the thickness of the rocker arm is effectively reduced, and after the torque is output by the double motors, the power is transmittedto a roller through the four stage gear transmissions; a planetary reducer is arranged at the third-stage transmission position, is away from a roller vibration source, and effectively reduces the impact load of the rocker arm planetary reducer, and the reliability is improved; and the final stage adopts the structure of the horizontal gear output to improve the impact resistance performance andreduce the diameter of a roller output shaft, the height of roller blades is increased, and the coal loading effect of the roller of a thin coal seam coal mining machine is improved.

Owner:SHANDONG LINENG LUXI MINING IND CO LTD +1

Drilling and planing part of thin coal seam drilling and planing combined coal mining machine

The invention discloses a drilling and planing part of a thin coal seam drilling and planing combined coal mining machine. Two sets are symmetrically arranged front and back relative to a coal miningmachine fixing box, the two sets of thin coal seam drilling and planing combined coal mining machine drilling and planing parts are installed on the front portion and the rear portion of the coal mining machine fixing box through drilling and planing box shells respectively, each drilling and planing part of the thin coal seam drilling and planing combined coal mining machine comprises a transmission device and a drilling and planing coal mining device, and each drilling and planing coal mining device comprises a hollow drilling part, a crushing drilling part and a coal planing disc part. Thedrilling and planing part of the thin coal seam drilling and planing combined coal mining machine adopts two-stage planetary reduction transmission, and the modes of high-speed stage planetary carrierfloating and low-speed stage sun wheel shaft floating are adopted in the two-stage planetary reduction transmission process, so that the drilling and planing combined coal mining machine is compact in structure, small in size, large in transmission ratio and stable in operation; the mode that drilling and planing combined coal mining is conducted through the drilling and planing coal mining device is adopted, the thin coal seam mining production efficiency can be improved on the premise that the machine body length is effectively shortened, the coal loading effect is improved, the lump coal rate is increased, and the drilling and planing part of the thin coal seam drilling and planing combined coal mining machine is particularly suitable for thin coal seam mining.

Owner:JIANGSU ZHONGJI MINE EQUIP

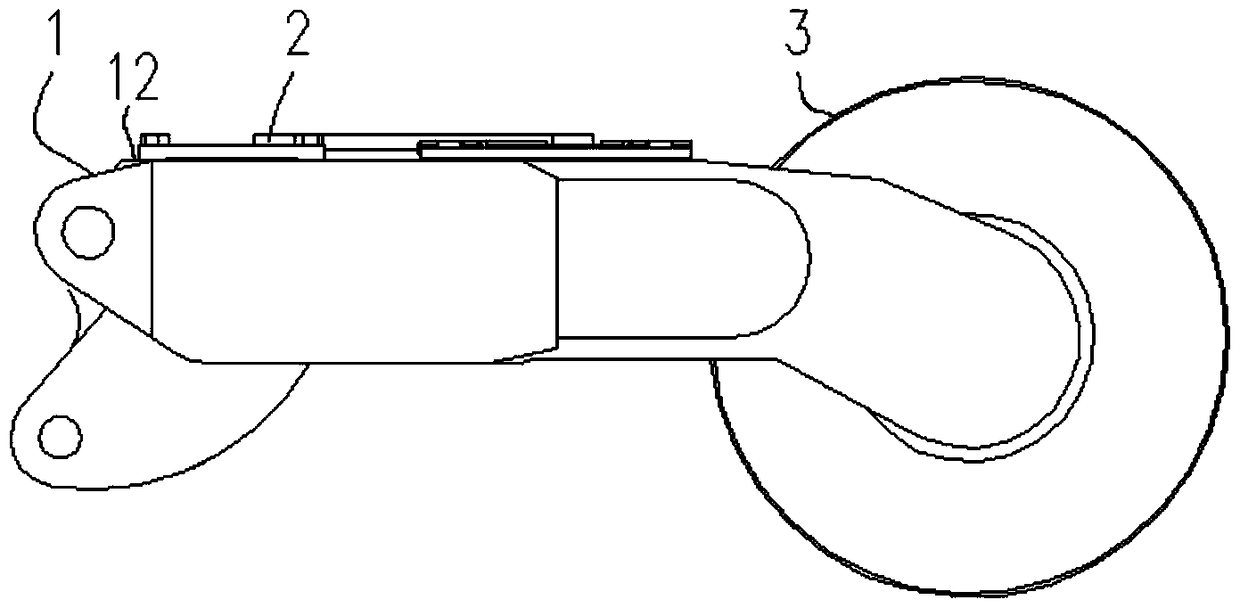

Adjustable coal shoveling plate applied to cutting part of coal mining machine

ActiveCN103485781BEasy to installFlexible structureSlitting machinesCutting machinesHydraulic cylinderMining engineering

An adjustable coal shoveling plate used in the cutting part of a coal shearer is characterized in that it includes a rocker arm and a coal shoveling plate mechanism; the coal shoveling plate mechanism includes a coal shoveling plate, a fixed plate, a set of lifting hydraulic cylinders and a set of The tilt adjustment hydraulic cylinder, the fixed plate and the rocker arm are connected by a ball hinge; the lifting hydraulic cylinder is placed in the installation groove on the fixed plate, one end is fixed with the fixed plate by a pin, and the other end is hinged with the coal shoveling plate; one end of the tilt adjustment hydraulic cylinder It is hinged with the fixed plate, and the other end is hinged with the rocker arm; the coal shoveling plate and the fixed plate form a slide rail slider mechanism; the coal shoveling plate mechanism provided by the invention is easy to install, flexible in structure, and can be applied to any type of coal shearer The rocker arm is cut to realize the automatic cleaning of accumulated coal rocks, which avoids the obstruction caused by the accumulated coal rocks to the shearer, reduces the resistance when the scraper conveyor is pushed forward, and improves the coal loading of the shearer. Effect.

Owner:国科中迈(徐州)能源科技有限公司

Cutting part of a thin coal seam bottom-clearing drum shearer

ActiveCN104594893BImprove productivityAvoid formingDriving meansCutting machinesThermodynamicsEngineering

The invention provides a cutting part of a thin coal seam bottom clearing type drum shearer. The cutting part shell is composed of a first cutting drum drive chamber shell, a transition section shell and a second cutting drum drive chamber shell. , the casing of the first cutting drum transmission chamber extends to the side of the coal wall through the transition section casing to the outside of the middle groove of the scraper conveyor and the side of the transition groove and bends downward. The rear end of the transition section casing is provided with a top bevel cut The side structure and the bottom bevel trimming structure, the inner cavity flanges of the first planetary mechanism and the second planetary mechanism are connected with the inner cavity method of the first cutting drum transmission chamber shell and the second cutting drum transmission chamber shell through bolts respectively. The outer end face key grooves of the first planetary mechanism and the second planetary mechanism are respectively positioned with the outer end face key grooves of the first cutting drum transmission chamber housing and the second cutting drum transmission chamber housing through end face flat keys. The invention can effectively solve the problem of triangular coal, meet the minimum mining height condition and the adaptability of coal seam thickness changes, and improve the coal loading effect.

Owner:国科中迈(徐州)能源科技有限公司

Rapid Coal Mining Technology in Fully Mechanized Mining Face with Large Mining Height

A large-mining-height fully-mechanized-face fast coal mining technology is suitable for large-mining-height fully-mechanized-face fast coal mining with a roof of a coal seam higher than medium hard level and firmness coefficient of the coal seam more than 1.0. Coal is first cut in the middle part of the coal seam, a front roller of a coal mining machine is then used for cutting top coal, a rear roller of the coal mining machine is used for cutting bottom coal, and simultaneously a hydraulic support of a coal cutting achieving part is moved, after the hydraulic support is moved, a face guard of the hydraulic support is opened to enable the face guard to be tightly attached to a coal wall. Every cycle operation goes on sequentially in a cycling mode according to the working procedures, the middle part of the coal seam is cut first, and the top coal at the upper part depends on the face guard to support so that wall caving of the coal wall and roof fall of the end face can be effectively prevented. Due to the fact that a coal cutting height is reduced, coal cutting speed is remarkably improved, and simultaneously coal of large sizes cannot be produced. Therefore, the large-mining-height fully-mechanized-face fast coal mining technology fundamentally resolves the problem that large-mining-height fully-mechanized-face large-sized coal hinders working-face coal cutting, coal charging and coal carrying, removes potential dangers of manually breaking large-sized coal, and is simple in technological operation, safe, reliable and high in efficiency.

Owner:CHINA UNIV OF MINING & TECH

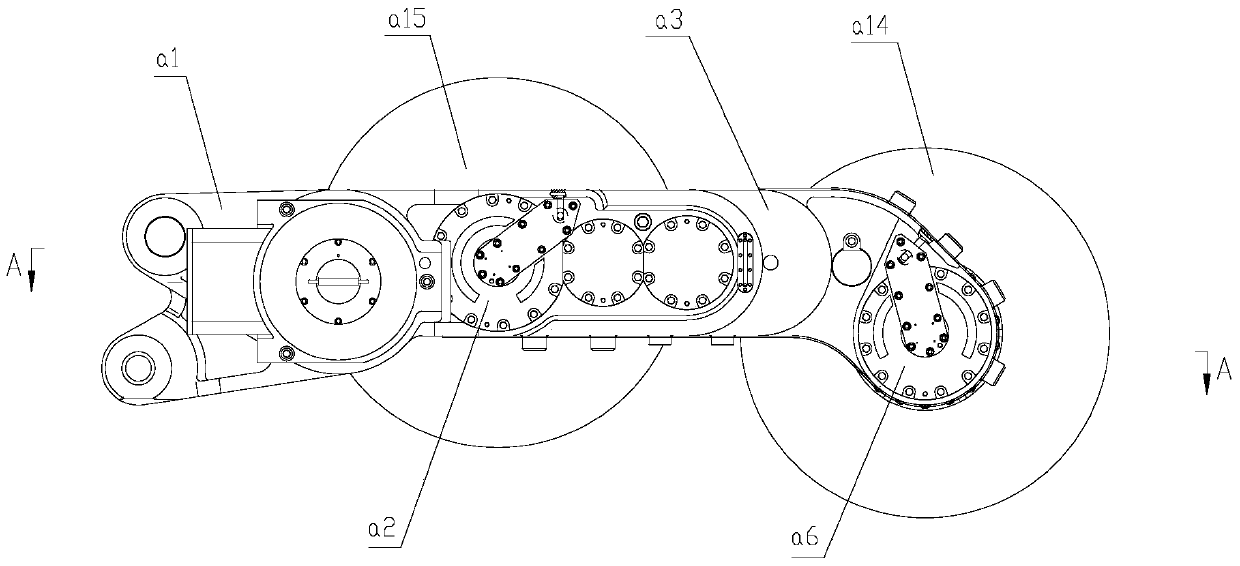

A bottom-clearing drum shearer

ActiveCN104594894BImprove load-bearing strengthBigger than the coal mouthSlitting machinesCutting machinesMining engineeringMechanical engineering

The invention discloses a bottom-clearing roller coal mining machine. Each cutting part of the coal mining machine includes two cutting drums, the first cutting drum (a14) and the first cutting drum transmission chamber casing (a6 ) extends to the coal wall (15) through the transition section shell (a3), and the rear part of the first cutting drum drive chamber shell (a6) extends beyond the middle trough of the scraper conveyor and the trough side (10) of the transition trough , and at the same time the first cutting drum drive chamber casing (a6) bends downward. The first cutting drum of the present invention has enough undercover to avoid the formation of "triangular coal" at the head and tail of the scraper conveyor, and the second cutting drum has a smaller production distance to improve the coal loading effect and ensure sufficient load bearing Strength; at the same coal mining height, two cutting drums with smaller diameters are used in pairs to ensure the full height of one-time mining, prolong the service life of the cutting drum, optimize the overall performance of the cutting part, and have good adaptability to changes in coal seam thickness. Reduce cost and process requirements.

Owner:国科中迈(徐州)能源科技有限公司

H-shaped cutting device and high-power thin seam coal mining machine

The invention relates to an h-shaped cutting device and a high-power thin seam coal mining machine. The h-shaped cutting device comprises a box body, and a cutting motor and a cutting transmission system which are installed in the box body, wherein the cutting transmission system comprises first to seventh gear shaft groups and a planetary reduction mechanism which are in transmission connection in sequence; the power output end of the cutting motor points to the rear and is coaxially connected with the first gear shaft group; the output end of the seventh gear shaft set points to the front and is coaxially connected with a sun gear of the planetary reduction mechanism; the front part of the cutting motor and the box body part where the cutting motor is located extend forwards in an overhanging mode to exceed the front ends of the third gear shaft group, the fourth gear shaft group, the fifth gear shaft group, the sixth gear shaft group and the seventh gear shaft group; the cutting motor and the planetary reduction mechanism are arranged side by side in a spaced mode in the left-right direction; and a left cutting device and a right cutting device of the high-power thin seam coal mining machine both adopt the h-shaped cutting devices. According to the h-shaped cutting device and the high-power thin seam coal mining machine provided by the invention, the contradiction among the machine surface height, the installed power, the coal passing space and the whole machine adaptability and stability of the thin seam coal mining machine can be solved, and the adaptability of the coal mining machine and the mining efficiency of a thin seam are improved.

Owner:SHANGHAI TIANDI MINING EQUIP TECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com