A Design Method for the Geometric Dimensions of the Cutting Teeth of the Chain Cutting Part of a Coal Shearer

A technology of geometric dimensions and design methods, applied in cutting machinery, calculation, earthwork drilling and mining, etc., can solve problems that affect the normal production operations of coal enterprises, reduce production efficiency and economic benefits, and greatly wear and tear cutting teeth, and achieve Increase coal loading effect, improve cutting efficiency, and uniform wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the drawings.

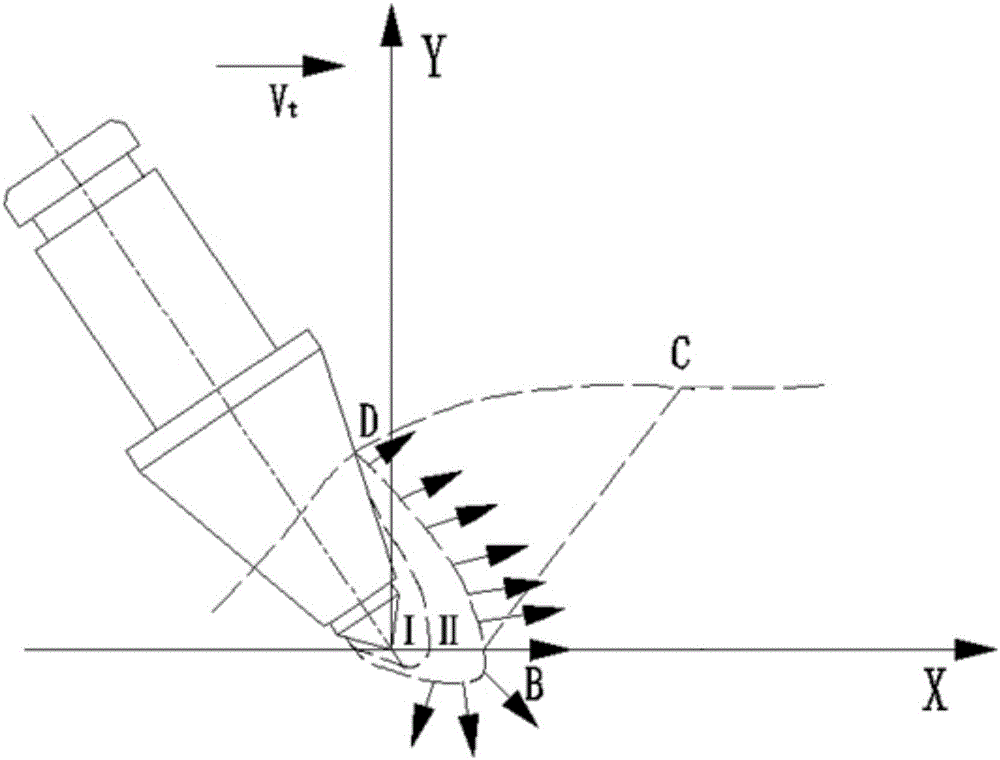

[0036] The cutting teeth used on the shearer are mainly wedge-shaped cutting teeth and pick-type cutting teeth. The coal-breaking mechanism of the two is similar, but due to the weak coal-breaking ability of the wedge-shaped cutting teeth, they are gradually eliminated. The cutting ability of the cutting tooth is relatively strong, so the present invention is mainly designed for the conical cutting tooth.

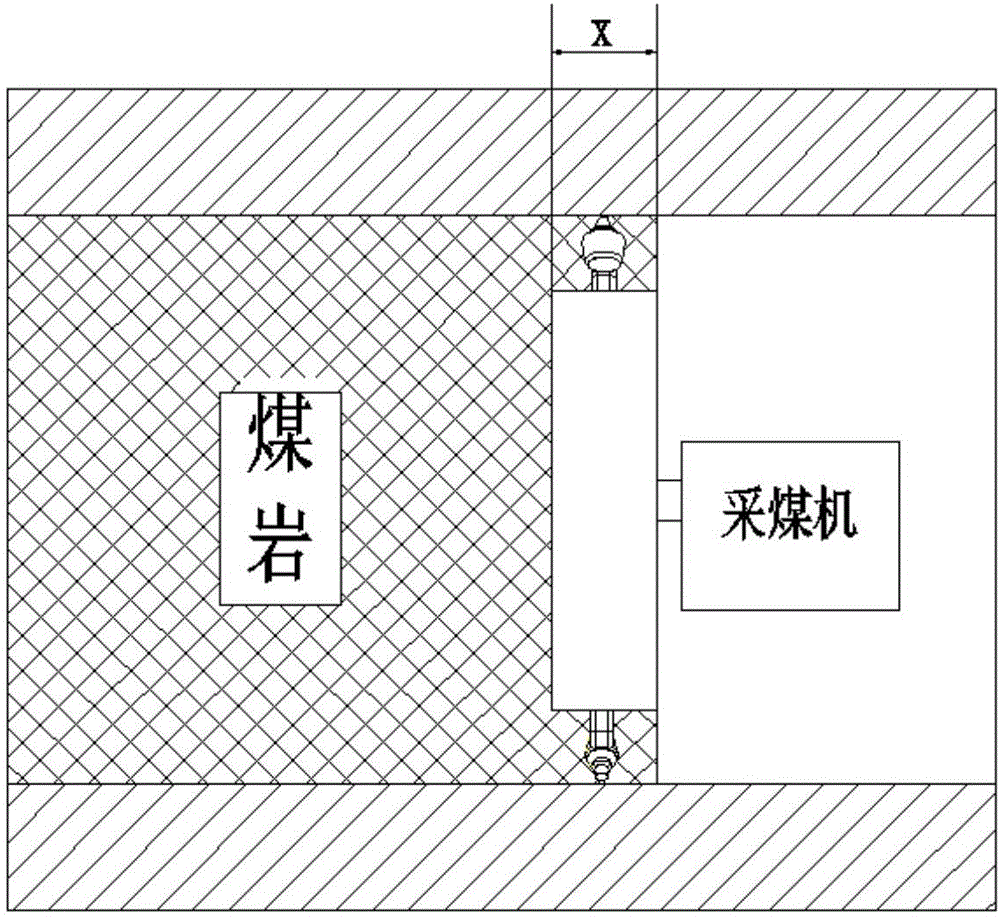

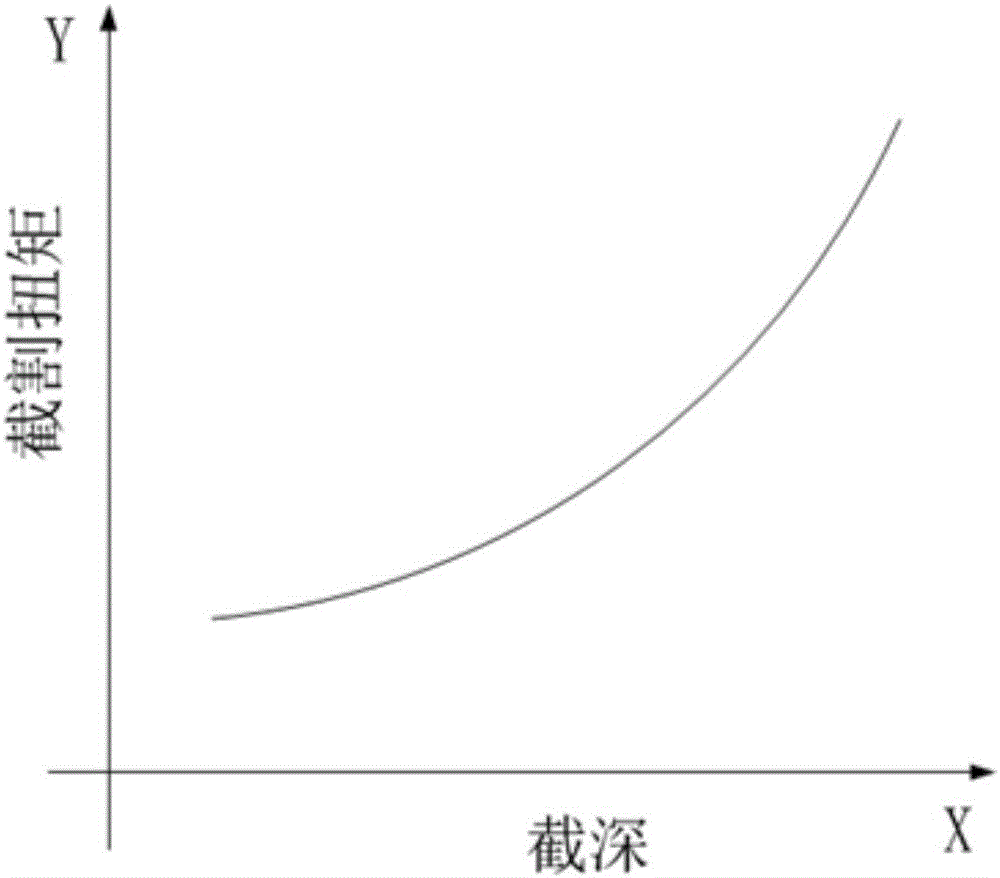

[0037] Such as Figure 5 to Figure 9 As shown, a method for designing the geometric dimensions of the cutting teeth of a chain cutting section of a shearer, the chain cutting section includes an annular crawler chain link formed by a plurality of crawler chain link units connected by a chain pin Cutting device 1, at least three support and transmission units, a pin 7 fixed on the base of the fixing device 6; the support and transmission unit includes a drive gear 2, a hydraulic moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com