A bottom-clearing drum shearer

A technology for shearers and drums, applied in the field of bottom-clearing drum shearers, can solve problems such as increased costs and reduced working efficiency of shearers, prolong service life, reduce mechanical manufacturing costs and process requirements, and improve installation The effect of the coal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

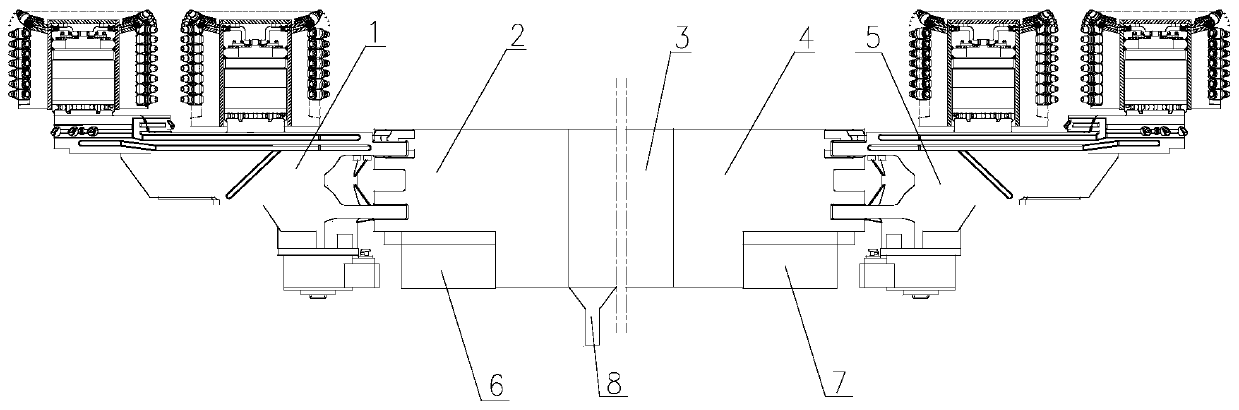

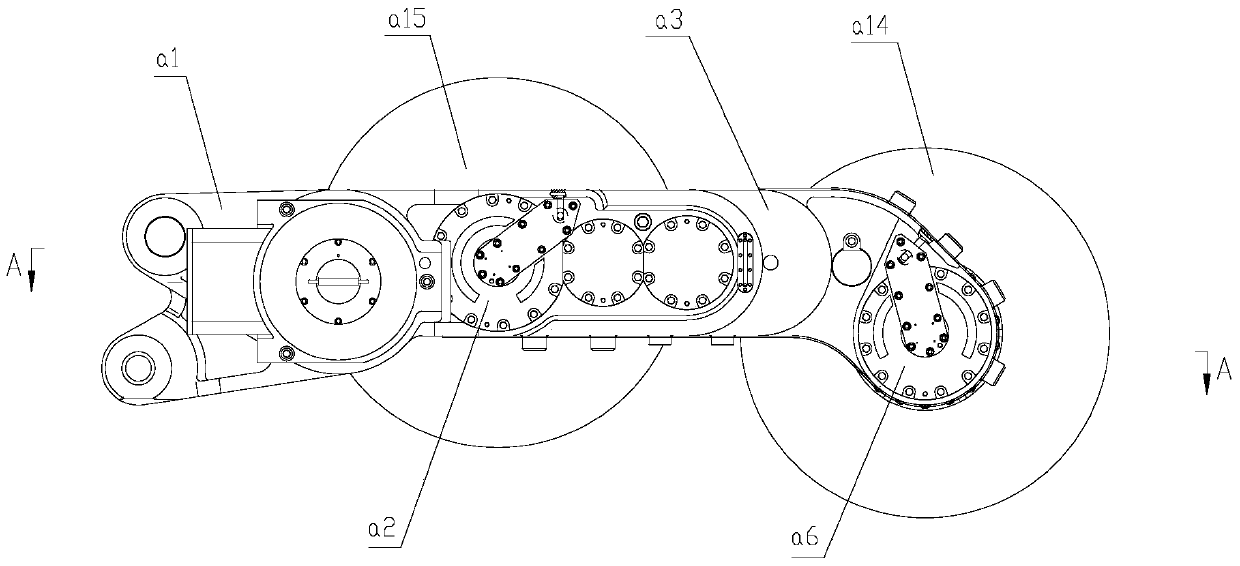

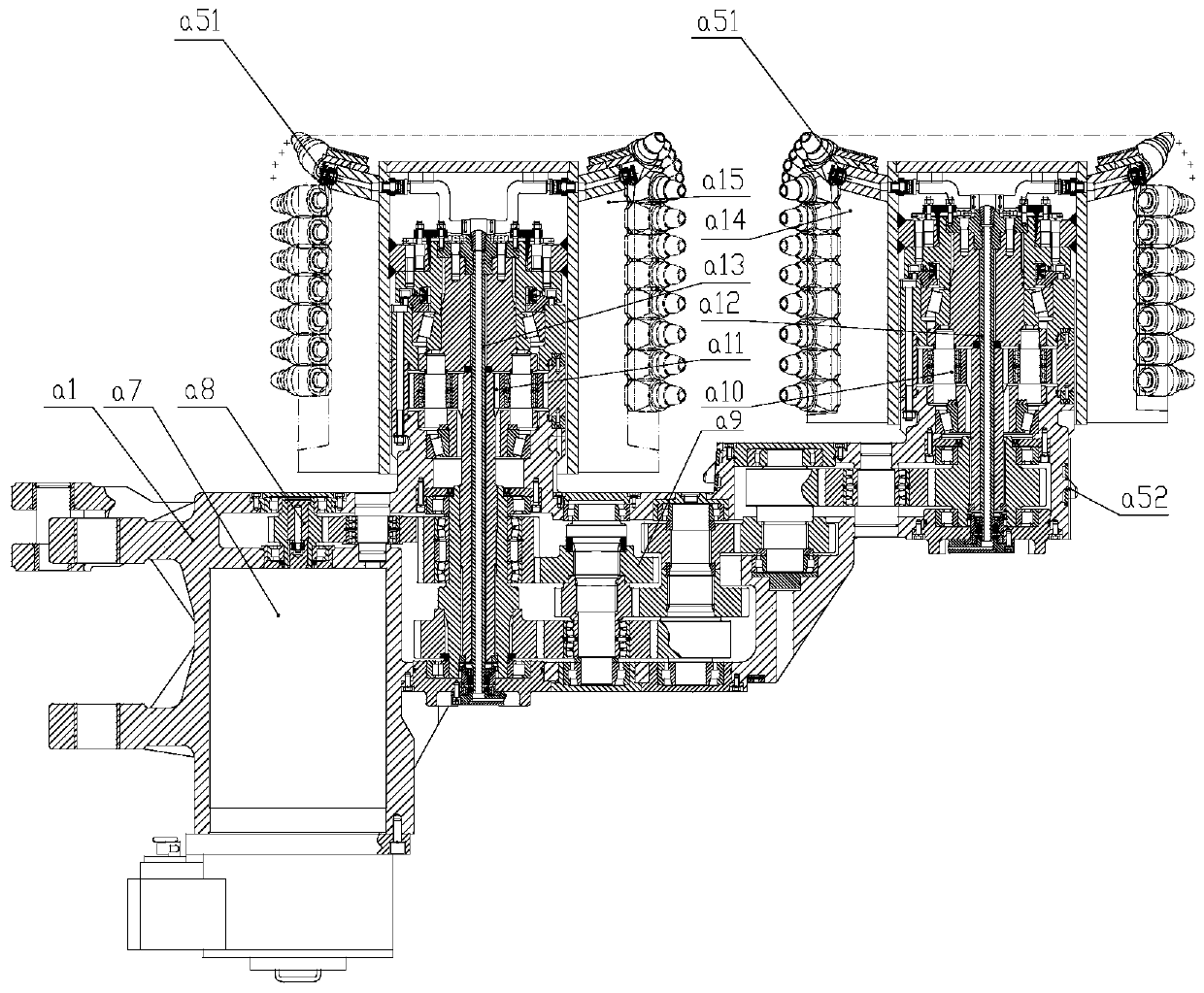

[0021] like Figure 1 to Figure 5 As shown, a bottom-clearing roller shearer includes a structurally symmetrical left cutting part 1 and a right cutting part 5, a structurally symmetrical left traction part 2 and a right traction part 4, a structurally symmetrical left walking part 6 and The right traveling part 7, the middle control box 3, the left cutting part 1 is hinged with the left drawing part 2 through the connecting ear, the right cutting part 5 is hinged with the right drawing part 4 through the connecting ear, and the left traveling part 6 and the right traveling part 7 are respectively It is fixedly installed on the side of the left traction part 2 and the right traction part 4, and the left traction part 2 and the right traction part 4 are respectively fixedly docked on both sides of the middle control box 3, and each cutting part includes a cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com