Preparation method of carbon powder combined broadband compound wave-absorbing material

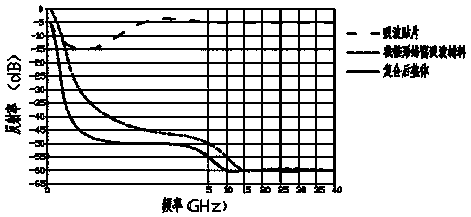

A technology of wave absorbing material and composite carbon, applied in the field of material processing, can solve the problems of insufficiency and narrow frequency band, and achieve the effect of improving wave absorbing performance, high absorption rate and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

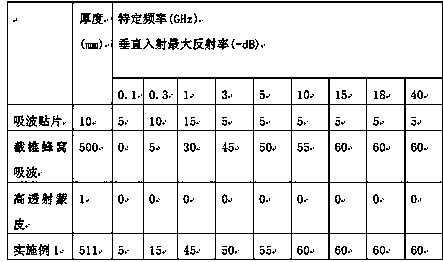

Embodiment 1

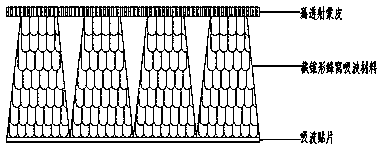

[0022] A preparation method of composite carbon powder broadband composite wave-absorbing material, which is composed of a wave-absorbing patch, a wave-absorbing honeycomb and a high-transmission skin, wherein the wave-absorbing honeycomb intercalation layer is formed between the wave-absorbing patch and the high-transmission skin Between the two, it can be fixed by adhesive bonding;

[0023] The wave-absorbing honeycomb is in the shape of a truncated hammer.

[0024] The wave-absorbing patch is a silica gel wave-absorbing patch, and its preparation method is:

[0025] Take 880 parts by weight of carbonyl iron powder absorbent, 95 parts of silica gel and 1 part of silica gel vulcanizing agent, knead them evenly with a two-roller machine, pack them out to make 10mm prefabricated sheets, and then put them into a vacuum plate Vulcanize and mold in a vulcanizing machine, the vulcanization condition is 150°C, vulcanize for 900 seconds, and make a silicone wave-absorbing patch with...

Embodiment 2

[0035] A preparation method of composite carbon powder broadband composite wave-absorbing material, which is composed of a wave-absorbing patch, a wave-absorbing honeycomb and a high-transmission skin, wherein the wave-absorbing honeycomb intercalation layer is formed between the wave-absorbing patch and the high-transmission skin Between the two, it can be fixed by adhesive bonding;

[0036] The wave-absorbing honeycomb is in the shape of a truncated hammer.

[0037] The wave-absorbing patch is a silica gel wave-absorbing patch, and its preparation method is:

[0038] Take 920 parts by weight of carbonyl iron powder absorbent, 102 parts of silica gel and 3 parts of silica gel vulcanizing agent, knead evenly with a two-roller machine, pack out the sheets, and make 10mm prefabricated sheets, and then put them into a vacuum plate Vulcanization molding in a vulcanizing machine, the vulcanization condition is 150 ° C, vulcanization for 900 seconds, and a silicone wave-absorbing p...

Embodiment 3

[0049] A preparation method of composite carbon powder broadband composite wave-absorbing material, which is composed of a wave-absorbing patch, a wave-absorbing honeycomb and a high-transmission skin, wherein the wave-absorbing honeycomb intercalation layer is formed between the wave-absorbing patch and the high-transmission skin Between the two, it can be fixed by adhesive bonding;

[0050] The wave-absorbing honeycomb is in the shape of a truncated hammer.

[0051] The wave-absorbing patch is a silica gel wave-absorbing patch, and its preparation method is:

[0052] Take 900 parts by weight of carbonyl iron powder absorbent, 99 parts of silica gel and 2 parts of silica gel vulcanizing agent, knead them evenly with a two-roller machine, pack them out to make 10mm prefabricated sheets, and then put them into a vacuum plate Vulcanize and mold in a vulcanizing machine, the vulcanization condition is 150°C, vulcanize for 900 seconds, and make a silicone wave-absorbing patch wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com