Positioning and surface grinding device provided with hoisting manipulator and used for new material machining

A technology of manipulators and new materials, applied in the direction of manipulators, grinding drive devices, grinding/polishing safety devices, etc., can solve the problems of small working range, effective range of motion, uneven feed speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

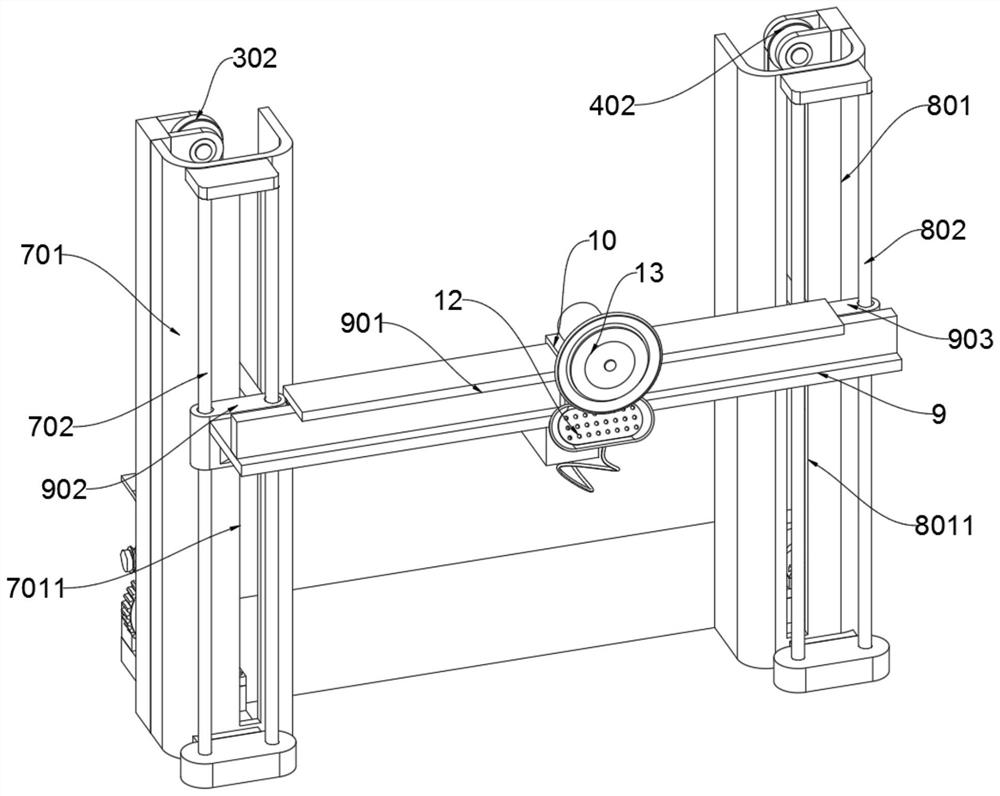

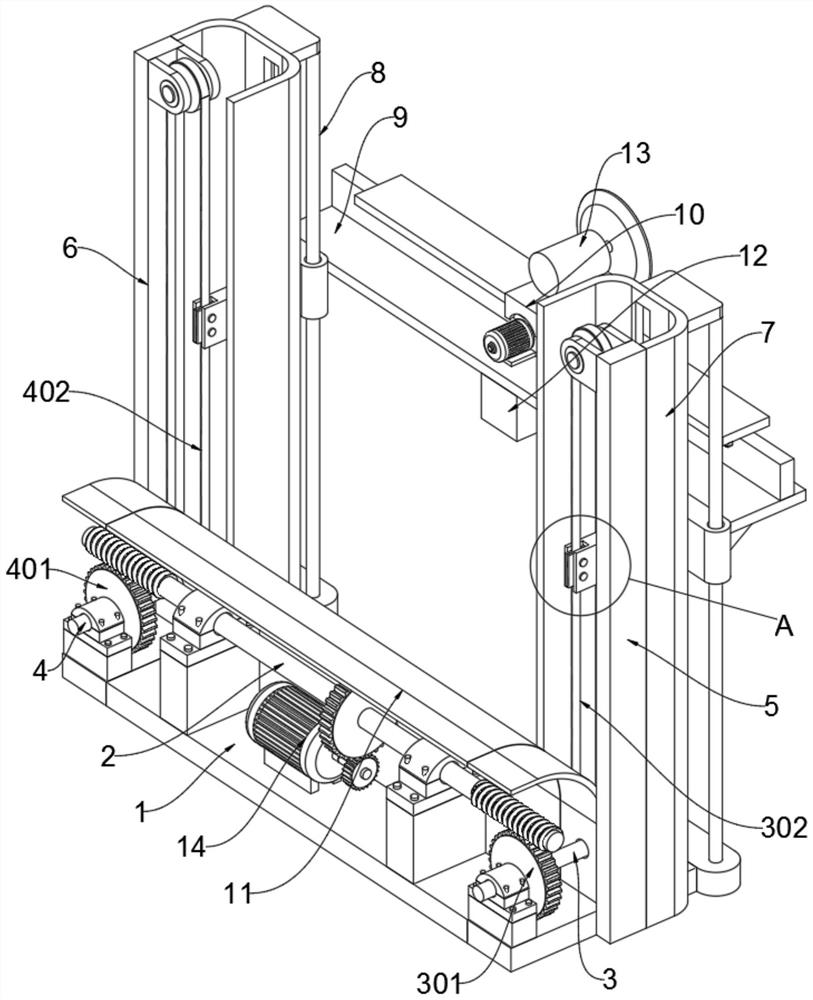

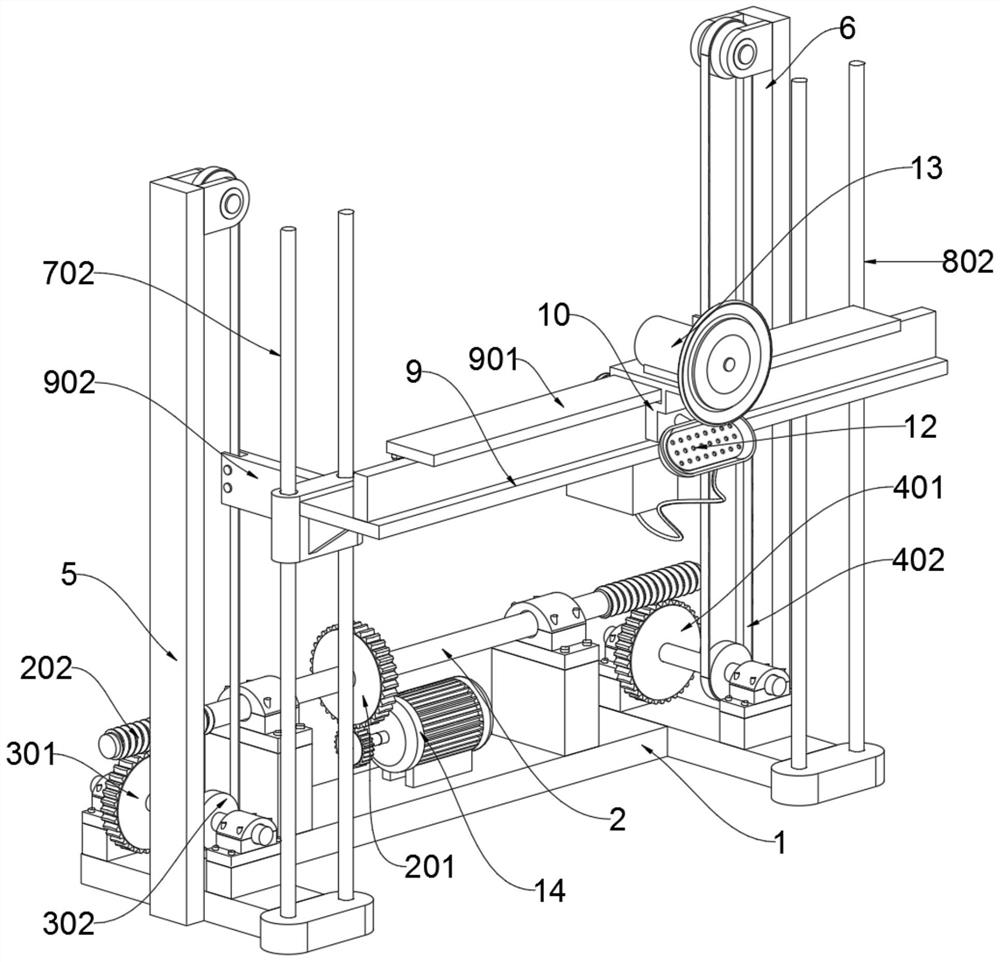

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034]The present invention provides a positioning grinding device equipped with a hoisting manipulator for processing new materials, comprising a lifting control shaft 2, a left lifting part 3, a right lifting part 4, a left inner column 5, a right inner column 6, a left outer column 7, Right outer column 8, lifting mechanical arm 9, horizontal manipulator 10, dust suction device 12, polishing machine 13; lifting control shaft 2 is movably connected above the bottom frame 1 through bearings, and the front side of the bottom frame 1 is connected with a dustproof Cover 11; the shaft of the left lifting part 3 is movably connected to the left side of the upper surface of the chassis 1 through bearings, and the left worm wheel 301 of the left lifting part 3 is meshed with the left side worm 202 of the lifting control shaft 2; The shaft is movably connected to the right side of the upper surface of the chassis 1 through be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com