Patents

Literature

118results about How to "Reduce the center distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

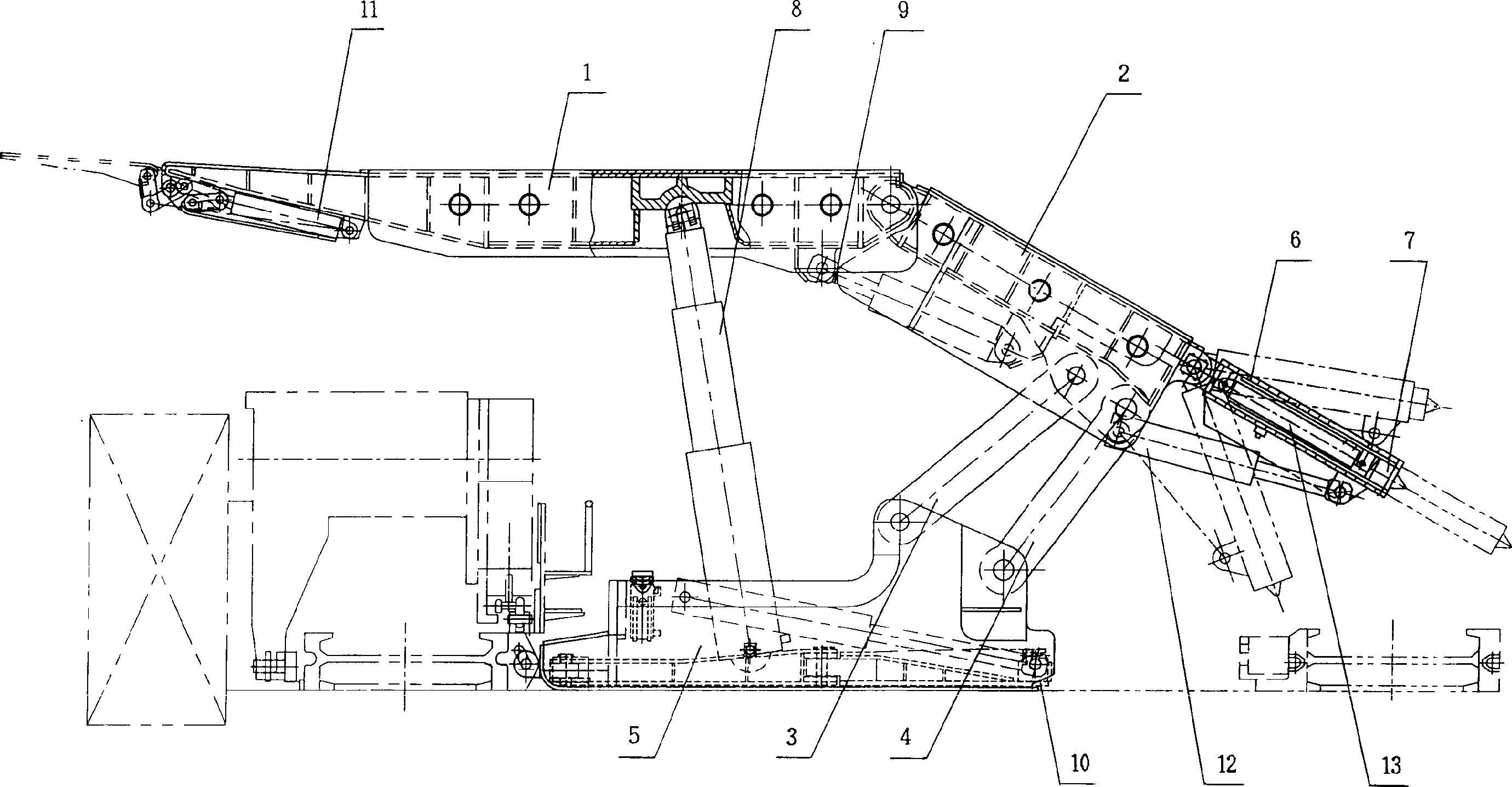

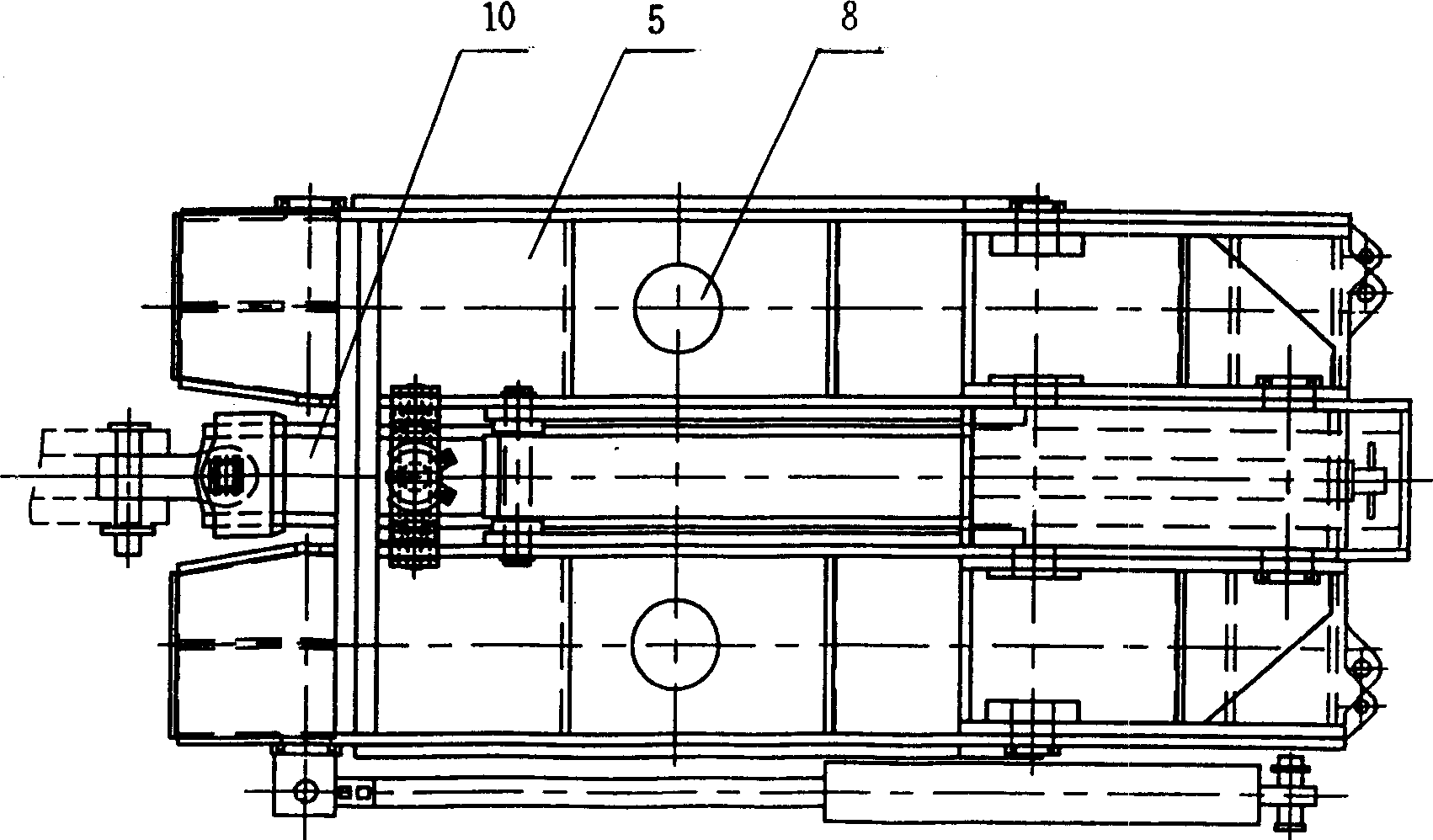

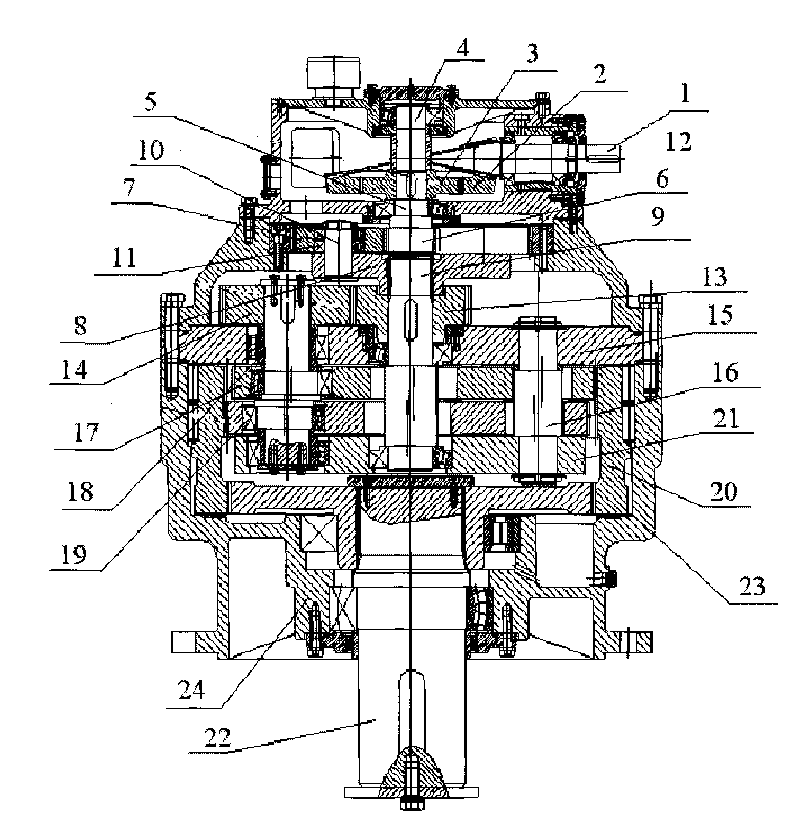

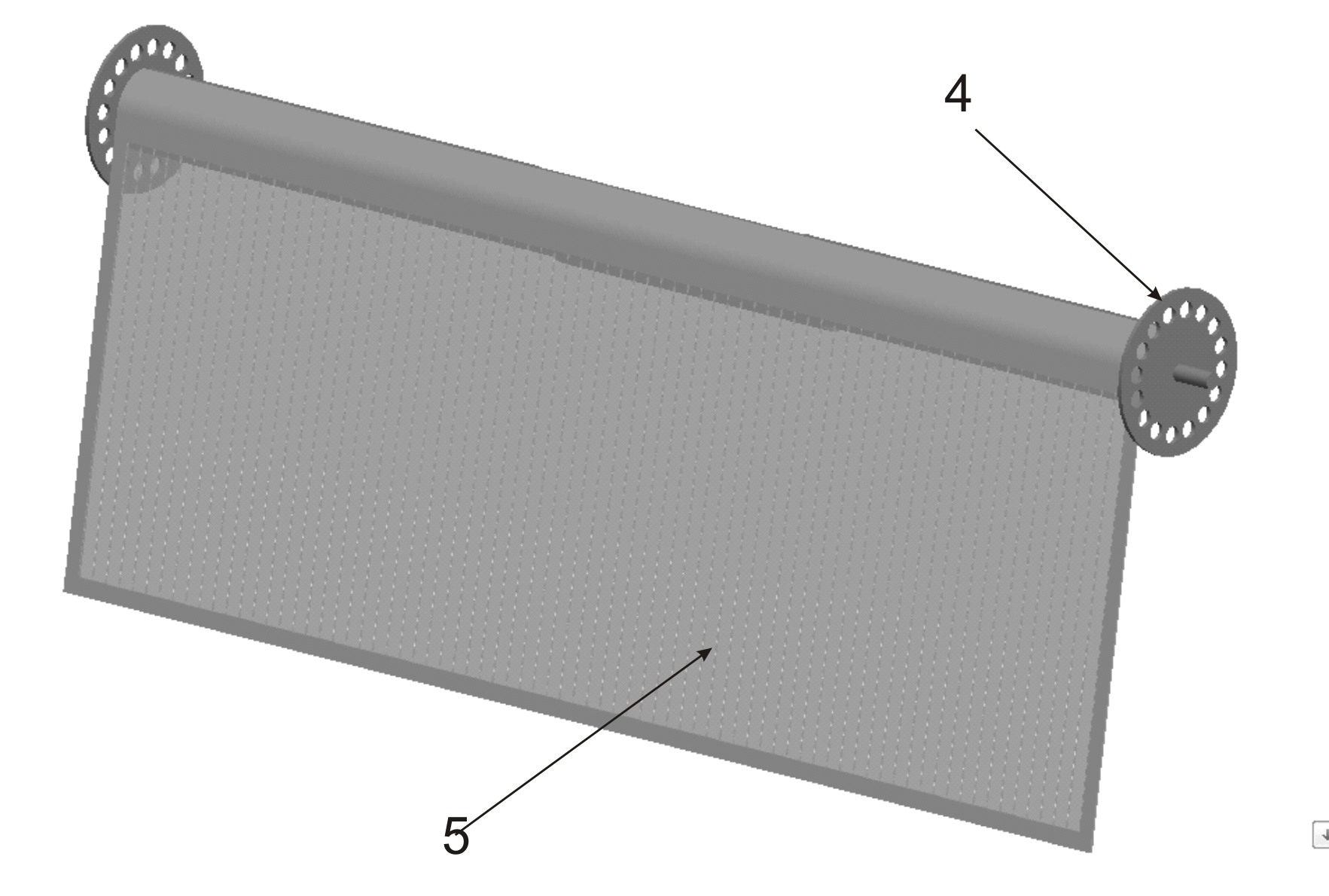

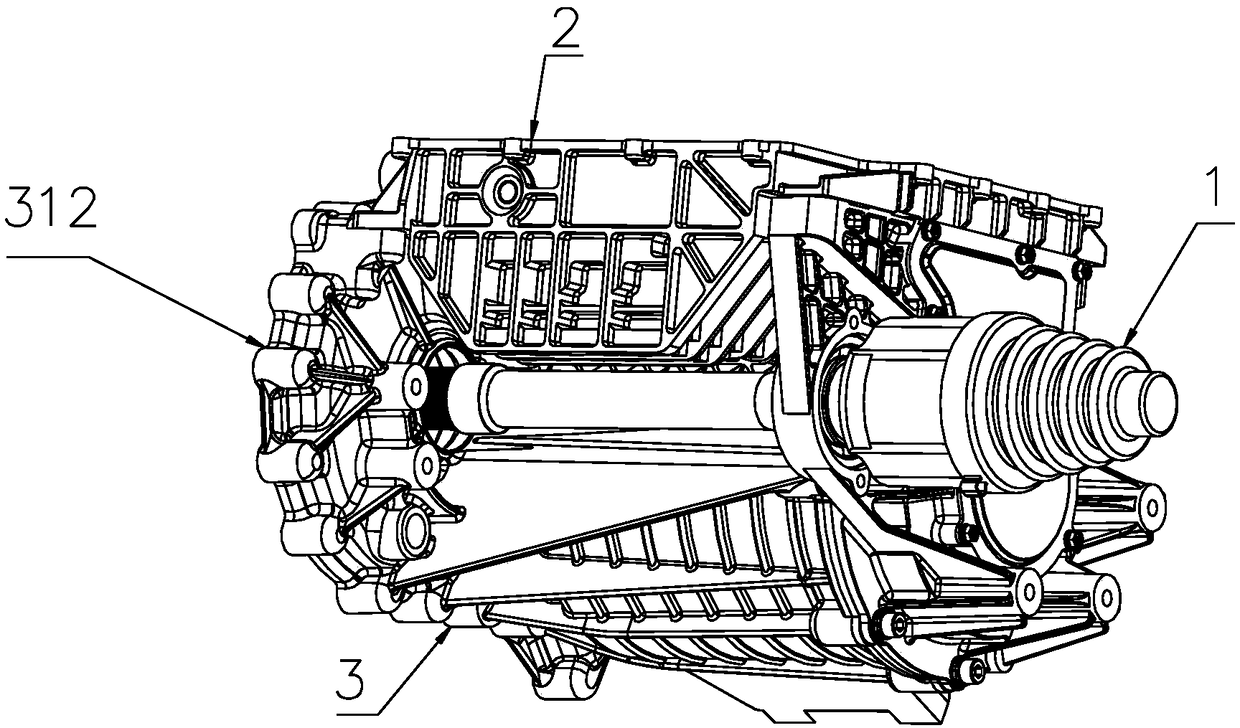

Derusting wall-climbing robot for ship

ActiveCN105035202AImprove wall adaptabilityIncreased internal tensionVessel cleaningHullsDrive wheelMarine engineering

The invention is applicable to the technical field of wall-climbing robots, and provides a derusting wall-climbing robot for a ship. The derusting wall-climbing robot aims at providing the technical problem that in the prior art, an existing derusting wall-climbing robot for the ship is poor in obstacle climbing capacity. The derusting wall-climbing robot for the ship comprises a washing plate, a caterpillar track making contact with the wall face of the ship, a drive assembly, a driven floating assembly with driven wheels, a floating connection assembly driving the washing plate to automatically move up and down relative to the wall face of the ship, and a pressing assembly providing pre-pressing force so as to press the caterpillar track. According to the derusting wall-climbing robot for the ship, driving wheels are driven by the drive assembly to drive the driven wheels to move, and therefore the caterpillar track is driven to walk on the wall face of the ship; when the derusting wall-climbing robot encounters obstacles in the walking process, the washing plate is driven by the floating connection assembly to climb the obstacles; meanwhile, the inner tension of the caterpillar track is increased, and therefore the center distance between the driving wheels and the driven wheels can be reduced and the caterpillar track can be tightly attached to the wall face of the ship to climb the obstacles, and the wall face adaptability of the derusting wall-climbing robot for the ship is improved.

Owner:SHENZHEN INST OF ADVANCED TECH

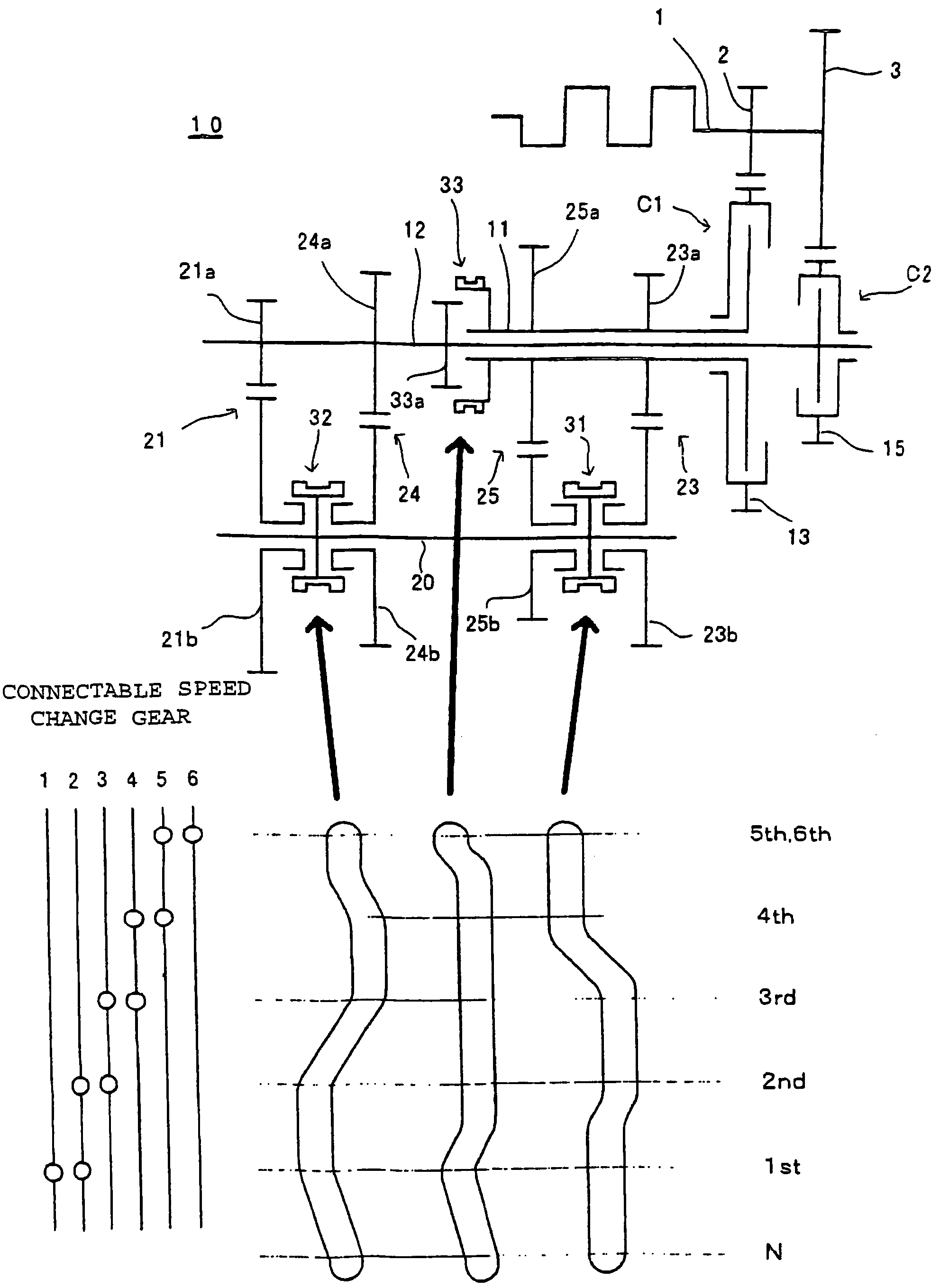

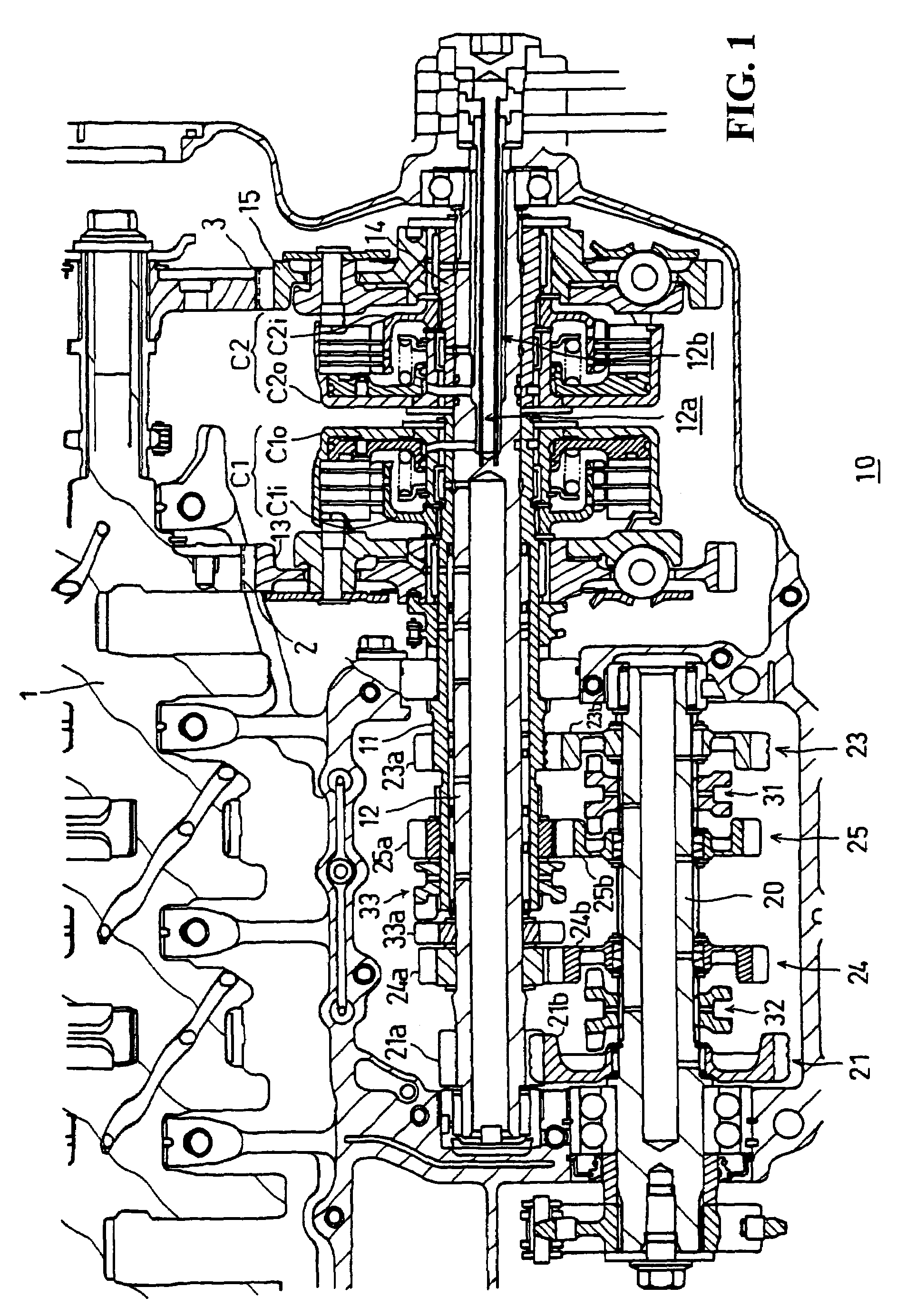

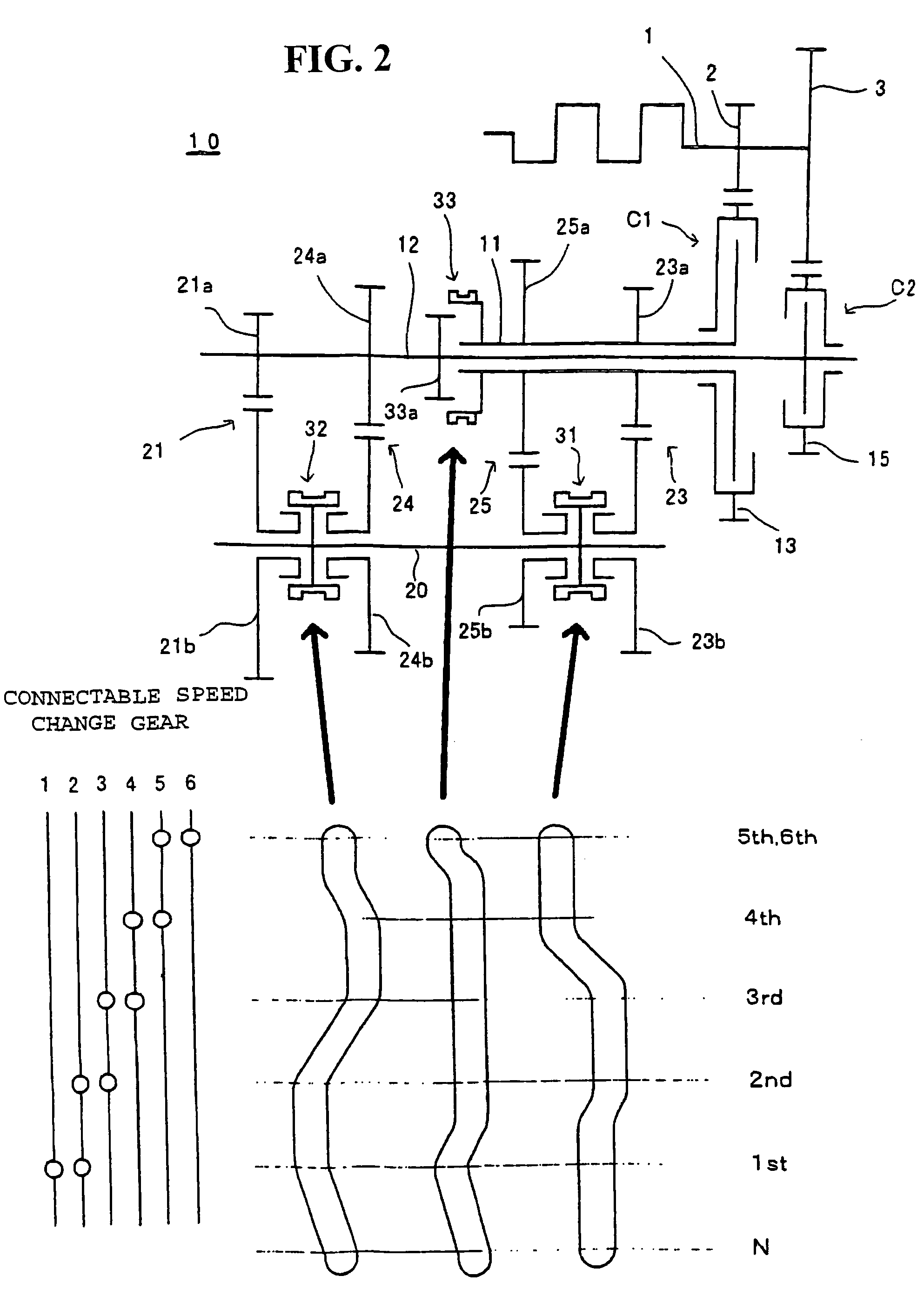

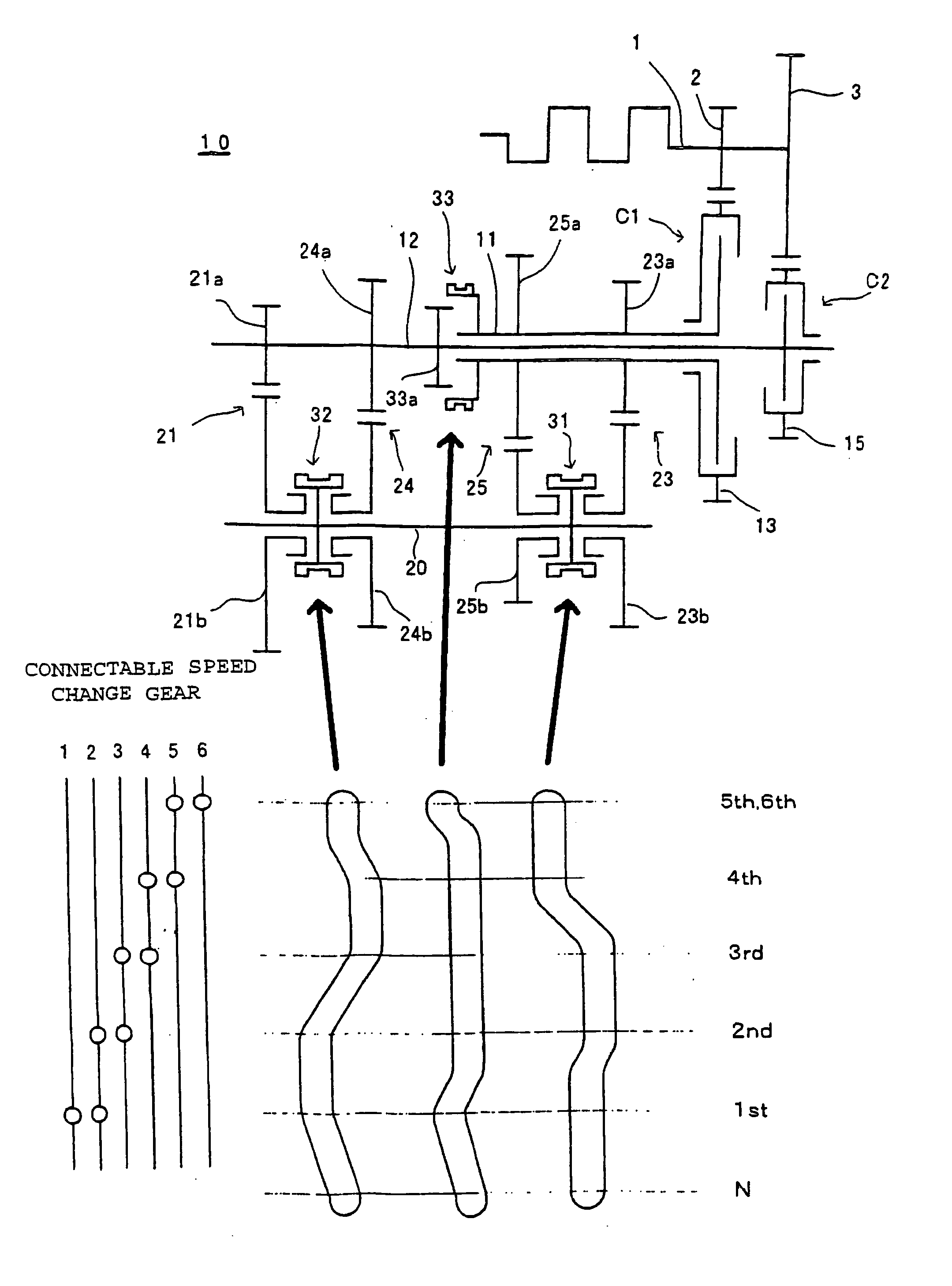

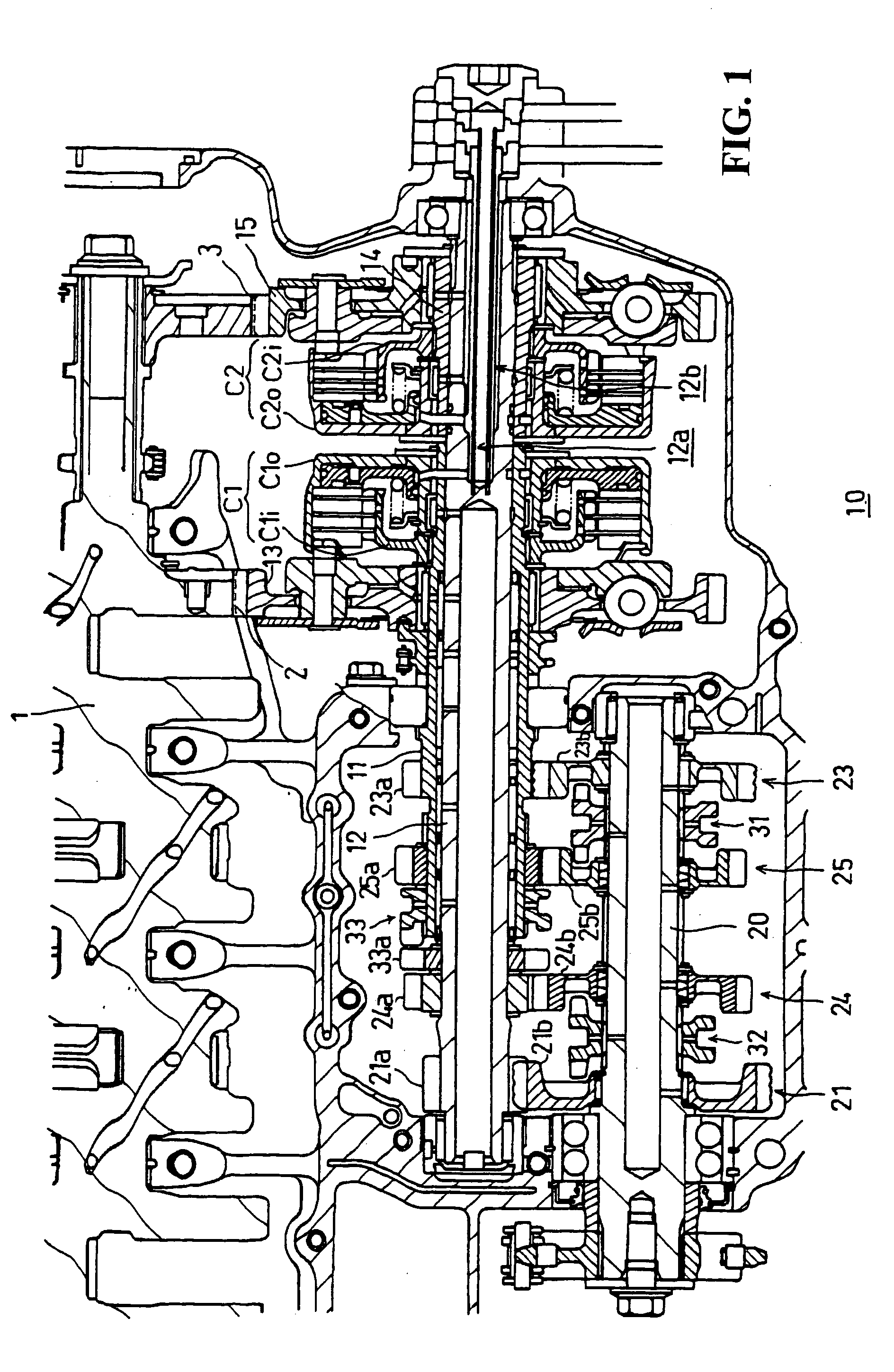

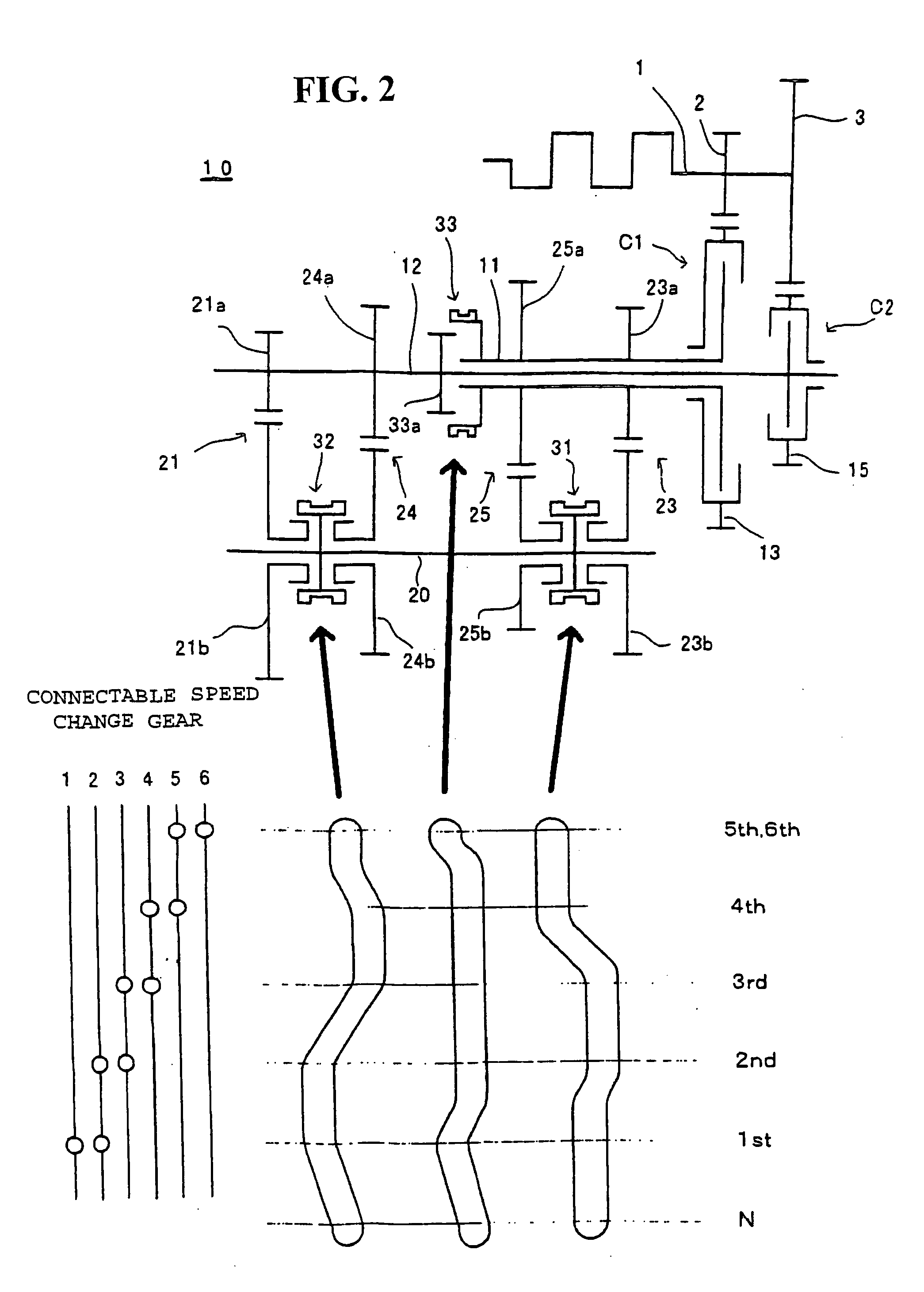

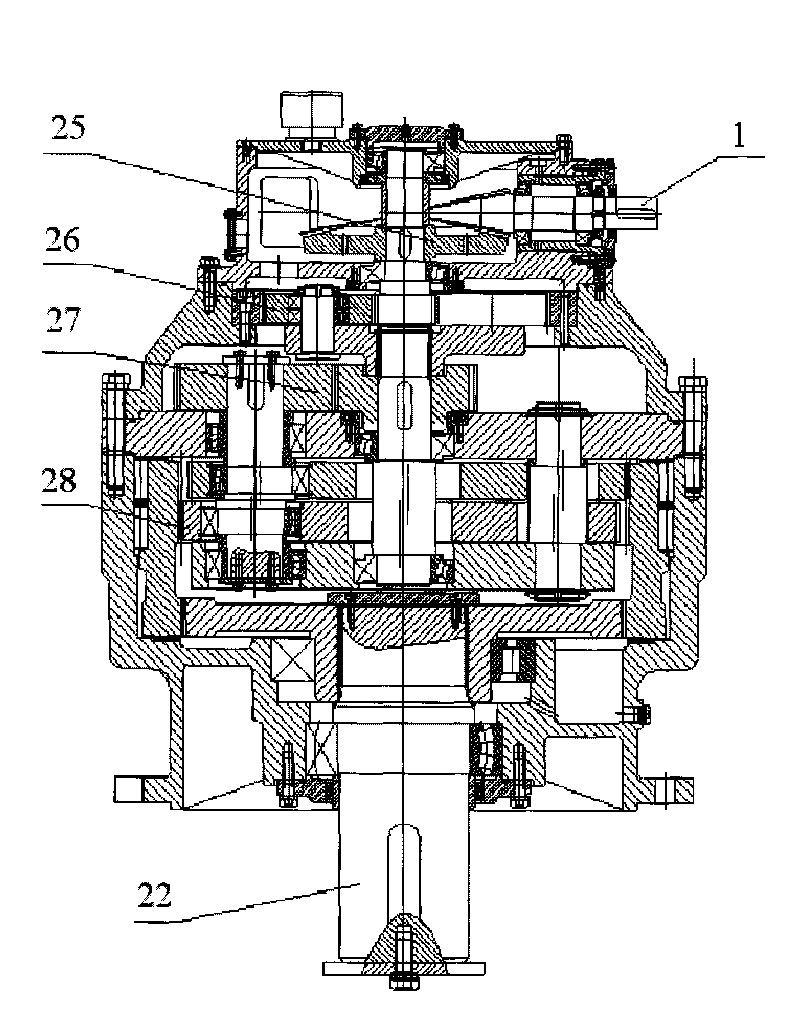

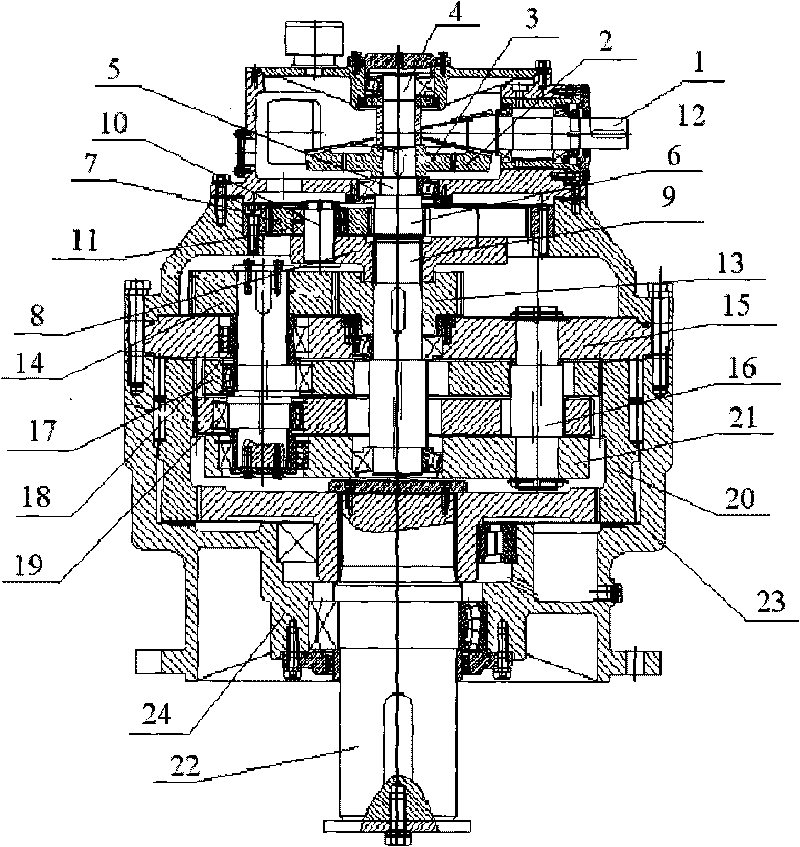

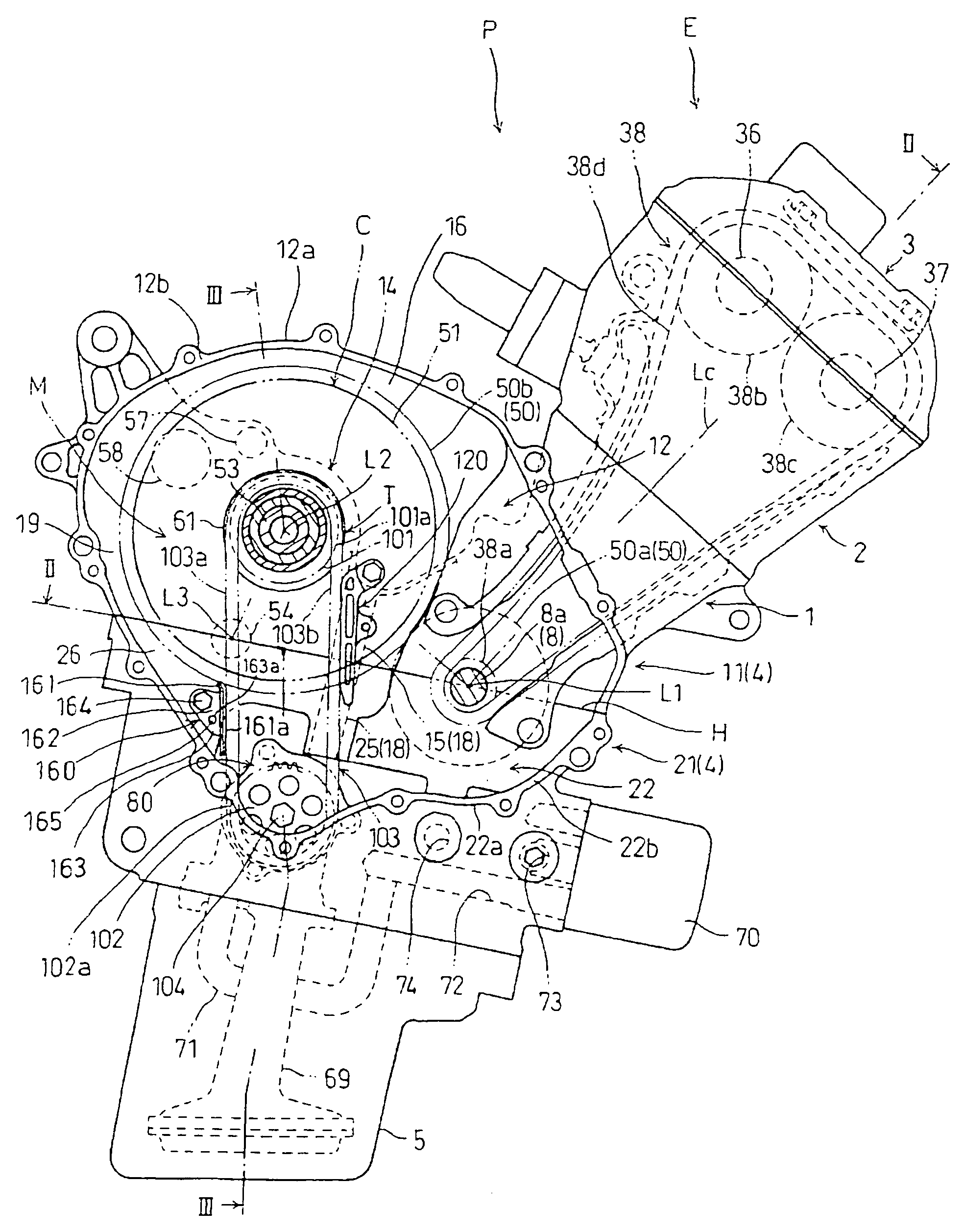

Twin-clutch transmission

ActiveUS7305900B2Reduce weight and sizeReduce the center distanceToothed gearingsGearing controlEngineeringClutch

A twin-clutch transmission wherein a center distance between input shafts and an auxiliary speed-change shaft can be shortened and the number of gears can be reduced. A twin-clutch transmission is provided which includes a first input shaft and a second input shaft, an auxiliary speed-change shaft, and a plurality of gear pairs. The first and second input shaft are connected, through a first clutch and a second clutch, respectively, to an input element, and disposed on the same axis. The auxiliary speed-change shaft is disposed parallel to the first and second input shafts. The plurality of gear pairs are provided between the first and second input shafts and the auxiliary speed-change shaft. An input path from the input element to the first clutch is different from that to the second clutch, and primary ratios of the input paths are set to values, respectively, different from each other.

Owner:HONDA MOTOR CO LTD

Twin-clutch transmission

ActiveUS20050211007A1Reduce weight and sizeReduce the center distanceToothed gearingsGearing controlEngineeringClutch

A twin-clutch transmission wherein a center distance between input shafts and an auxiliary speed-change shaft can be shortened and the number of gears can be reduced. A twin-clutch transmission is provided which includes a first input shaft and a second input shaft, an auxiliary speed-change shaft, and a plurality of gear pairs. The first and second input shaft are connected, through a first clutch and a second clutch, respectively, to an input element, and disposed on the same axis. The auxiliary speed-change shaft is disposed parallel to the first and second input shafts. The plurality of gear pairs are provided between the first and second input shafts and the auxiliary speed-change shaft. An input path from the input element to the first clutch is different from that to the second clutch, and primary ratios of the input paths are set to values, respectively, different from each other.

Owner:HONDA MOTOR CO LTD

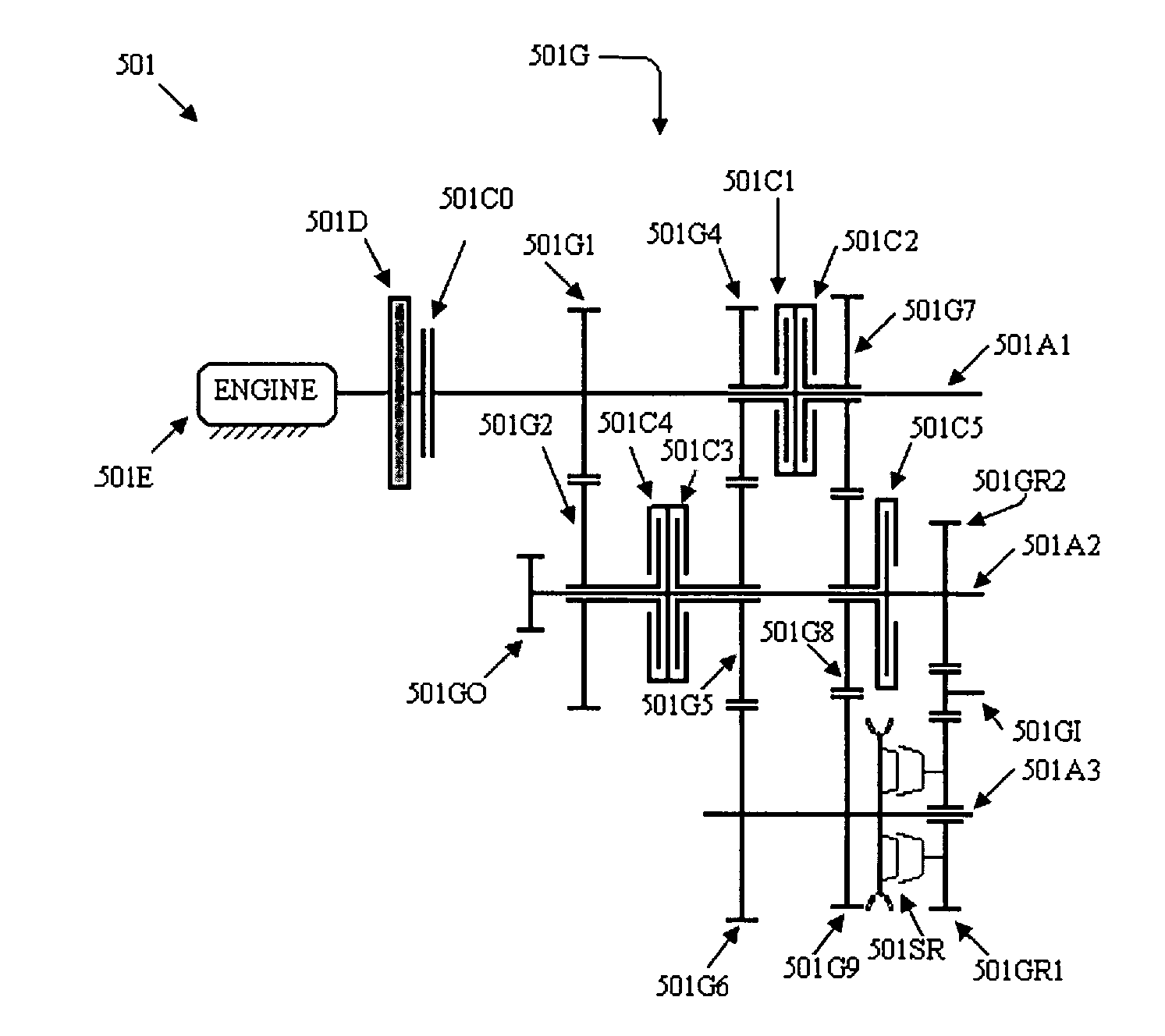

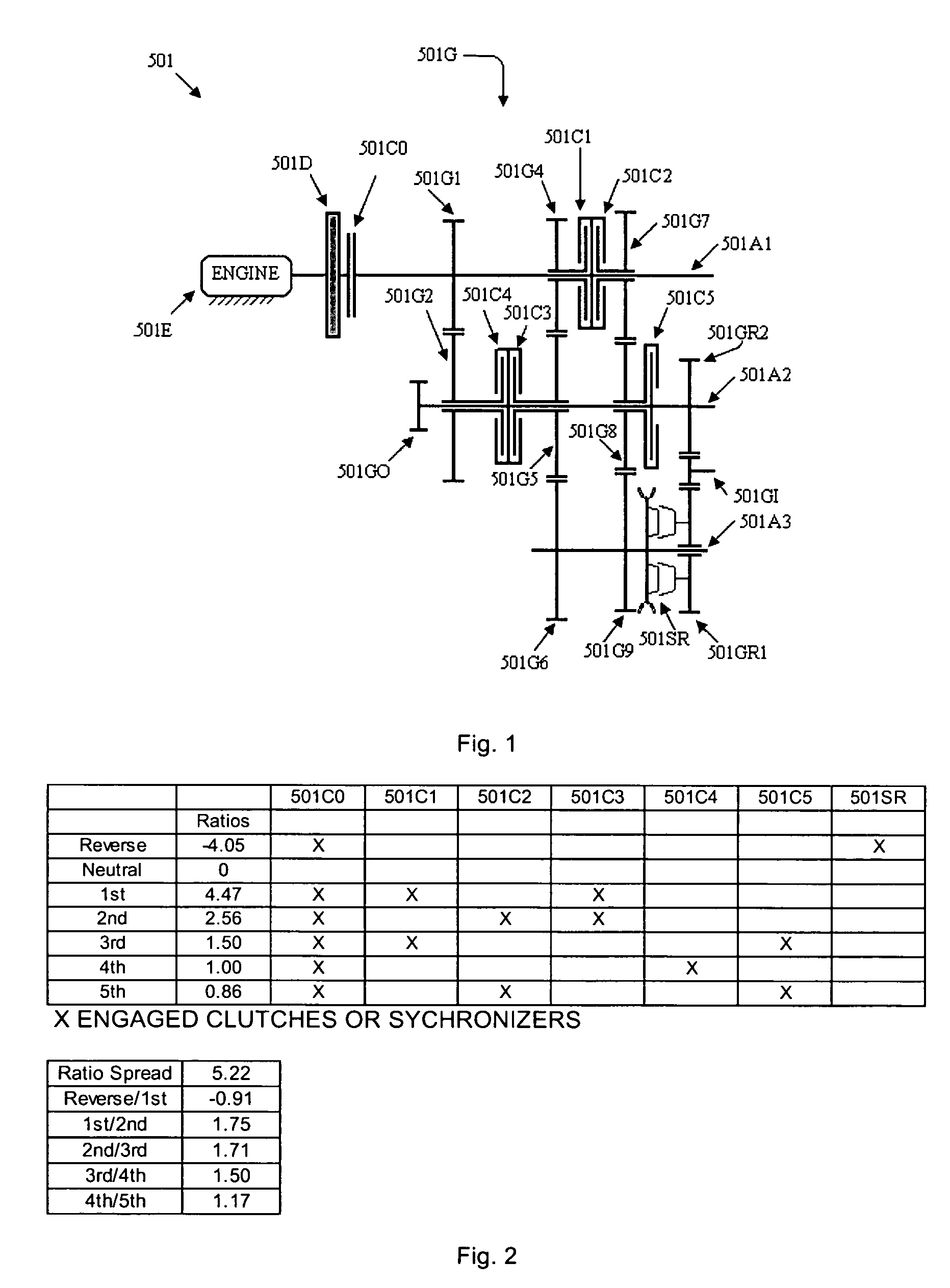

Transmission Gearbox Family in Parallel Shaft Transmission System

InactiveUS20090199666A1Increased durabilityShorten speedToothed gearingsTransmission elementsGear wheelMechanical snubber

This invention relates to a transmission gearbox family to provide five, six, seven, eight and nine speed ratios with a reverse speed ratio and a neutral condition in motor vehicles. The invention arranges a plurality of gearwheels in parallel shaft systems such that minimum number of gearwheels is obtained by either combination of clutches with synchronizers for transmission gearboxes with a torque converter and direct clutch to clutch gearboxes without a torque converter, or synchronizers for automated manual transmission gearboxes. For total number of the gearwheels involving in forward driving, five-speed transmission gearboxes have eight gearwheels, six-speed transmission gearboxes have minimum of nine gearwheels, seven-speed transmission gearboxes have minimum of nine gearwheels, eight-speed transmission gearboxes have minimum of nine gearwheels and nine-speed transmission gearboxes have minimum of nine gearwheels, respectively. Each family member has three parallel shafts with either selectively or continuously interconnected with the gearwheels through the engaged single or multiple torque transmitting mechanisms. The direct clutch-to-clutch gearboxes without a torque converter and automated manual gearboxes have a mechanical damper and a main clutch.

Owner:YANG CHING MIN +3

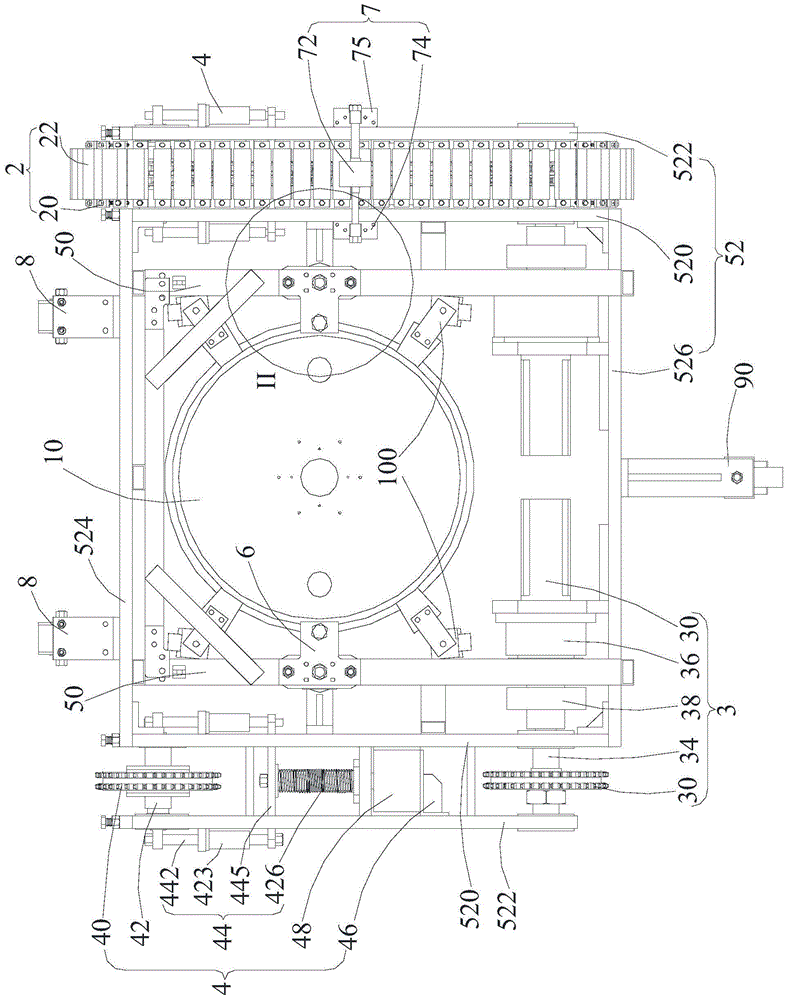

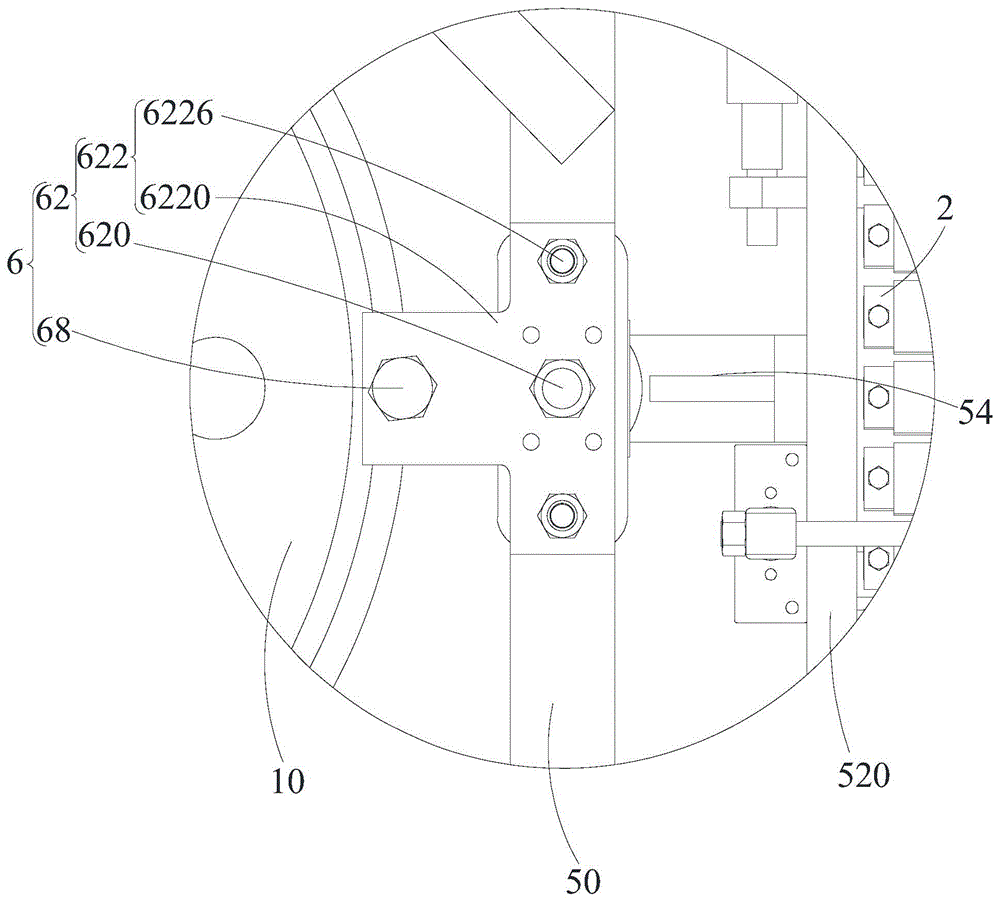

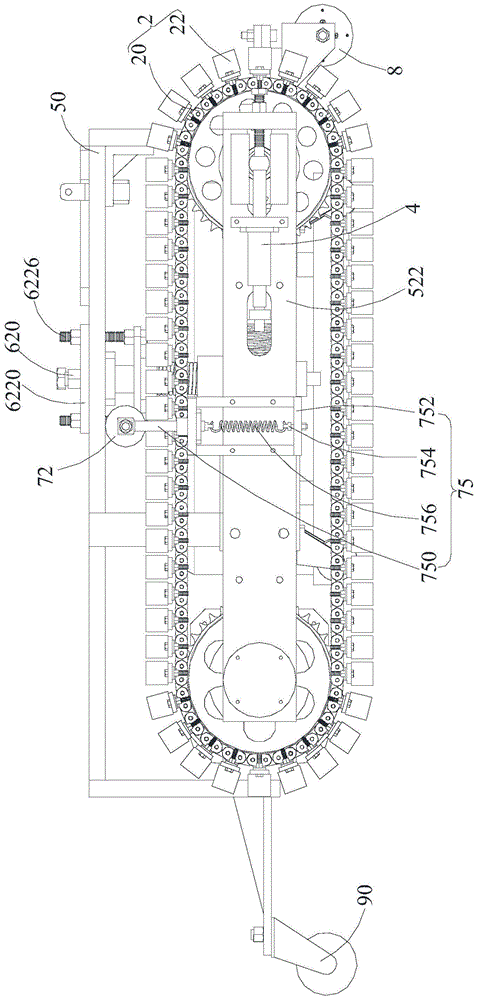

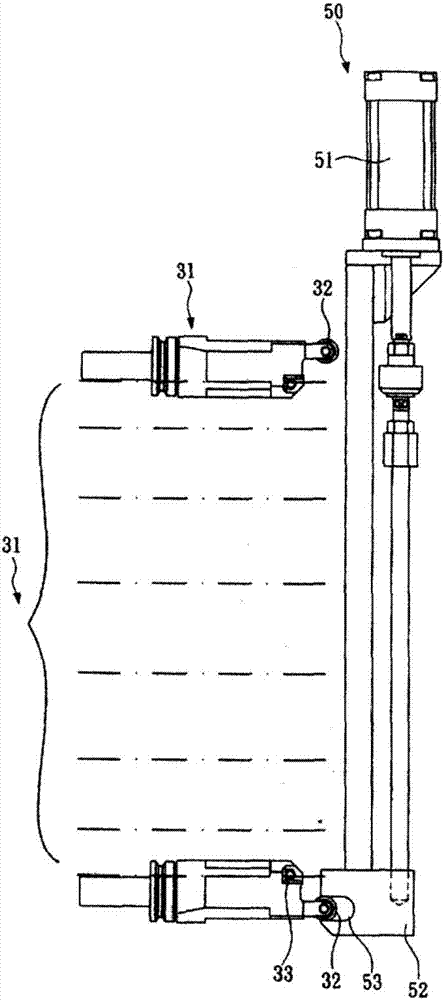

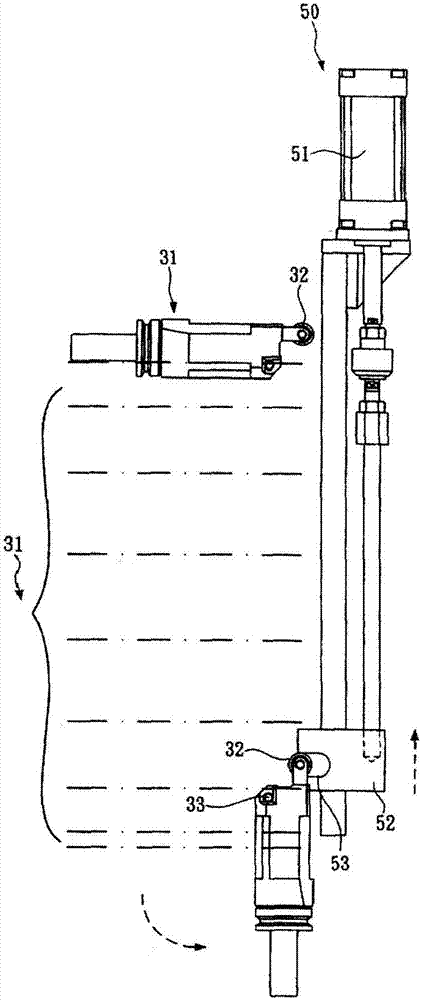

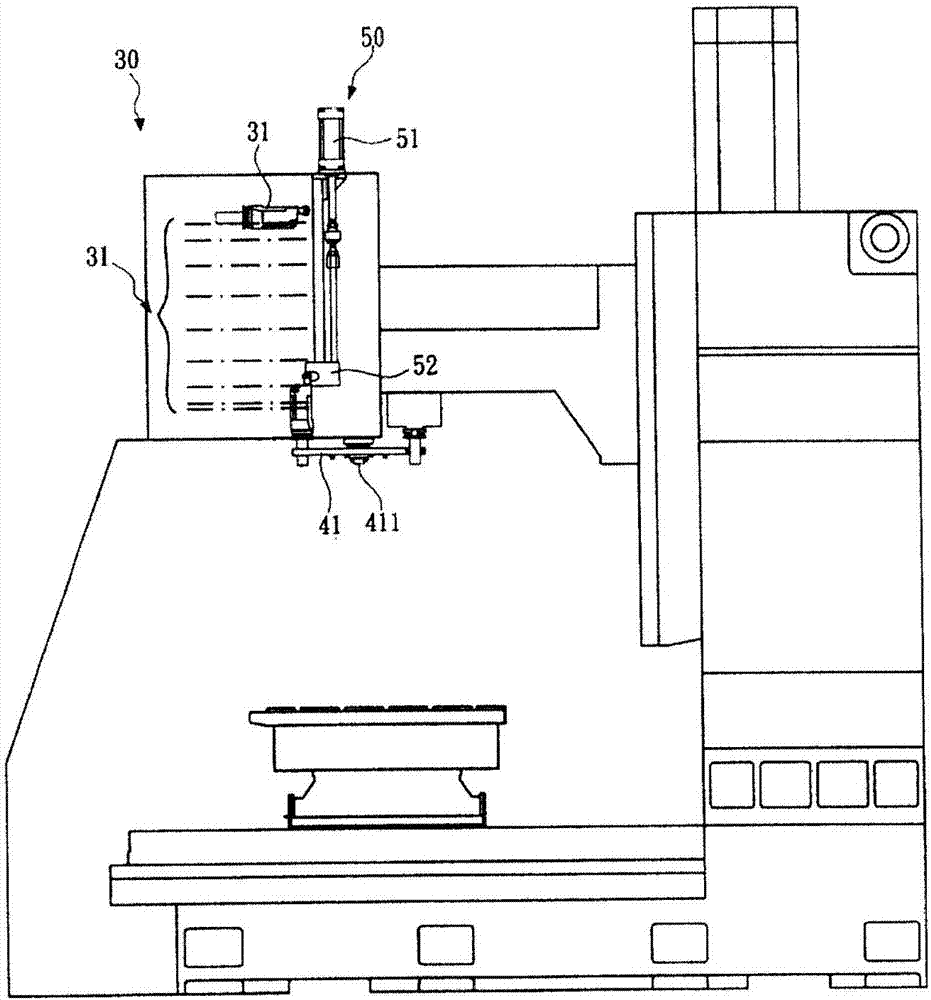

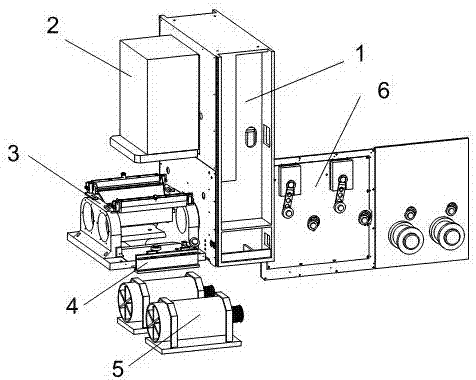

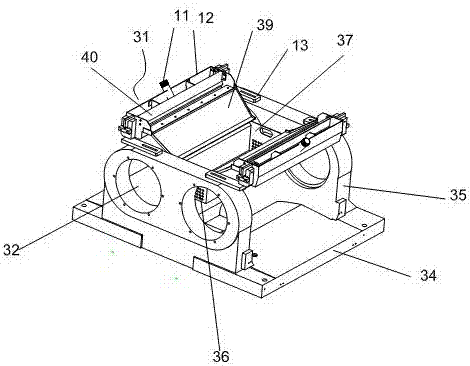

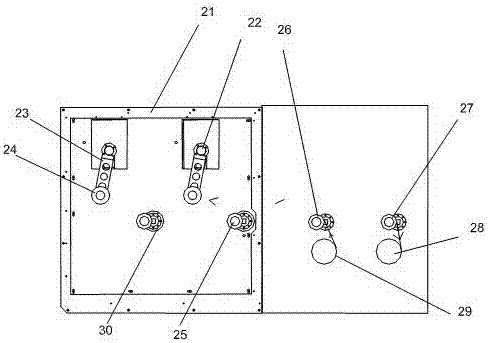

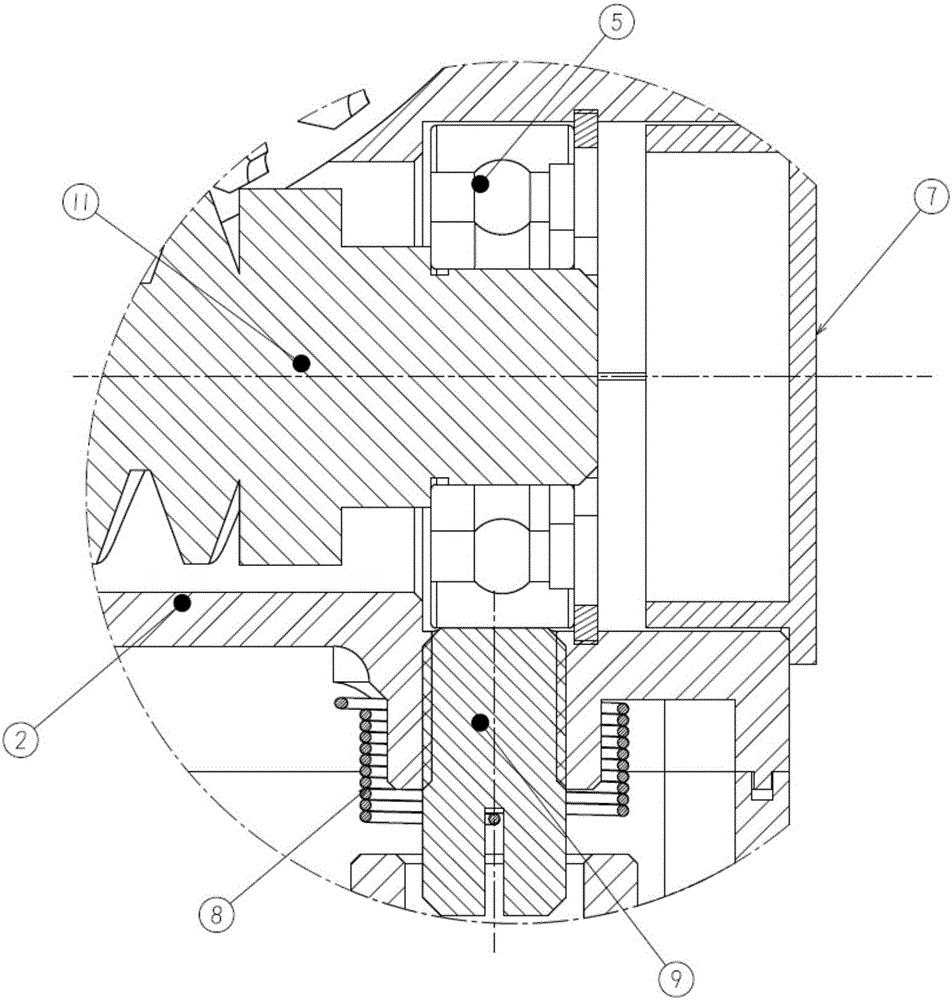

Tool changer assembly and machining center

ActiveCN107486745ASmall machine sizeShorten the lengthPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a tool changer assembly and a machining center. The tool changer assembly comprises a tool changer. The tool changer comprises a tool changer body and a tool sleeve used for installing a tool; the tool sleeve is rotationally connected to the tool changer body so as to overturn between the tool storing position and the tool changing position; the tool changer assembly further comprises a telescopic mechanism; the fixed end and the telescopic end of the telescopic mechanism are rotationally connected to the tool changer body and the tool sleeve correspondingly through a corresponding rotating pair; when the telescopic mechanism extends / shrinks, the tool sleeve is pushed away from / pulled close to the tool changer body; and meanwhile, each rotating pair works to make the tool sleeve overturn relative to the tool changer body. According to the tool changer assembly, by means of a small-size tool reversing mechanism, a tool reversing block in the prior art is saved, a tool disk is pre-arranged, differenced from a traditional tool changer, the front and back distance is greatly shortened, the center distance between machine tool main shafts is also reduced, the machine tool volume is reduced, the tool changing position is closer to a tool arm, it is easy to reduce the length of the tool arm used in cooperation with the tool changer assembly, and therefore the tool arm structure is optimized.

Owner:SUZHOU GFD AUTOMATION TECH

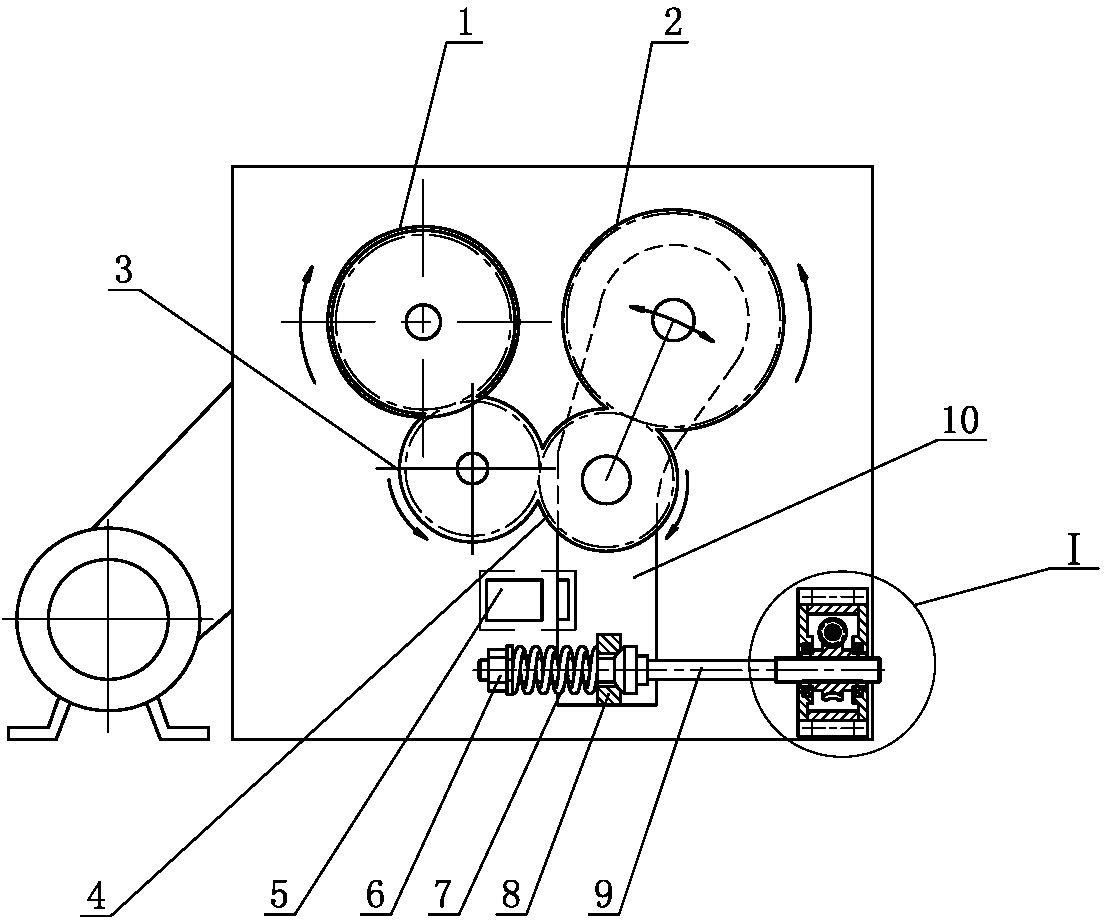

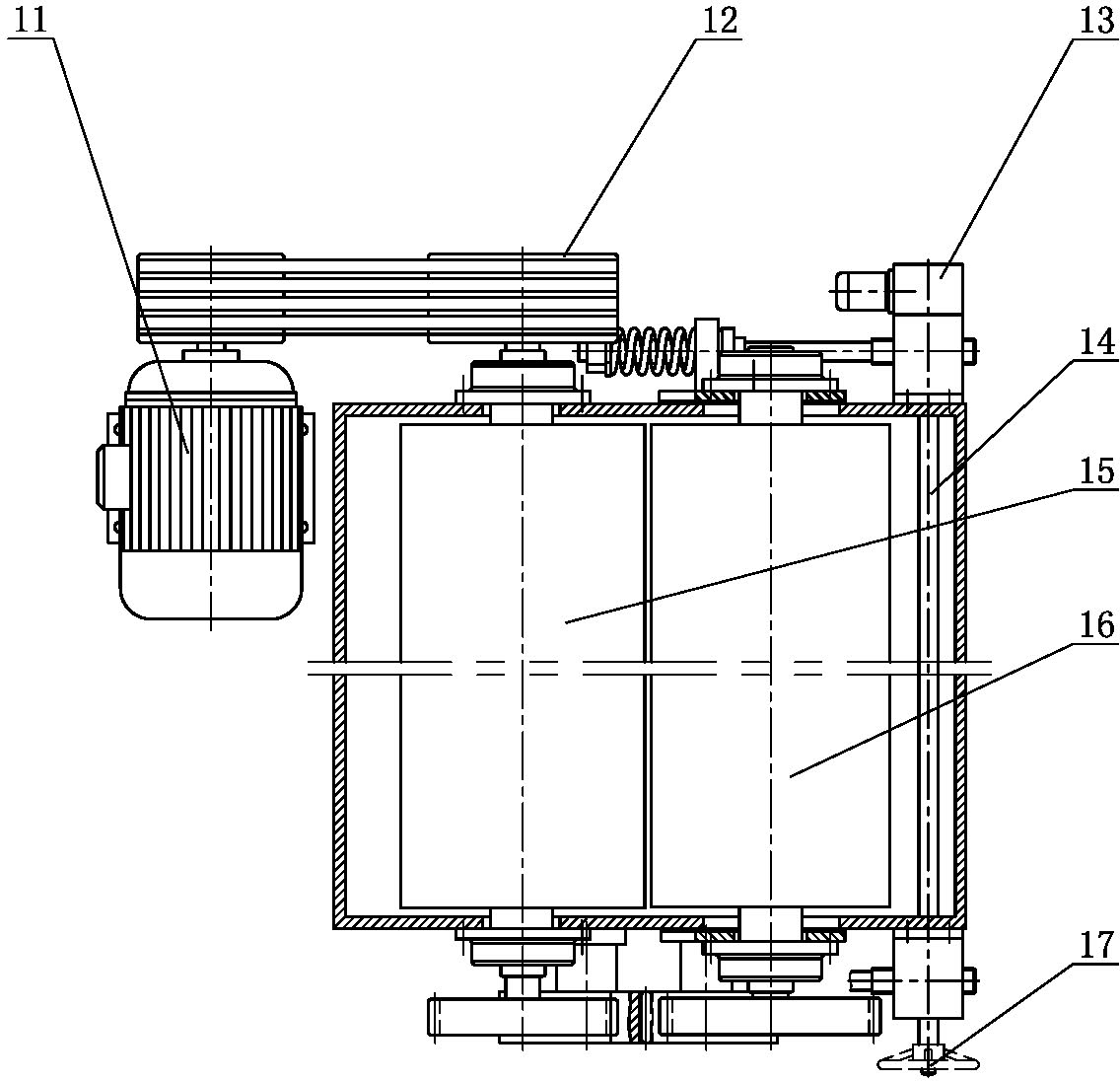

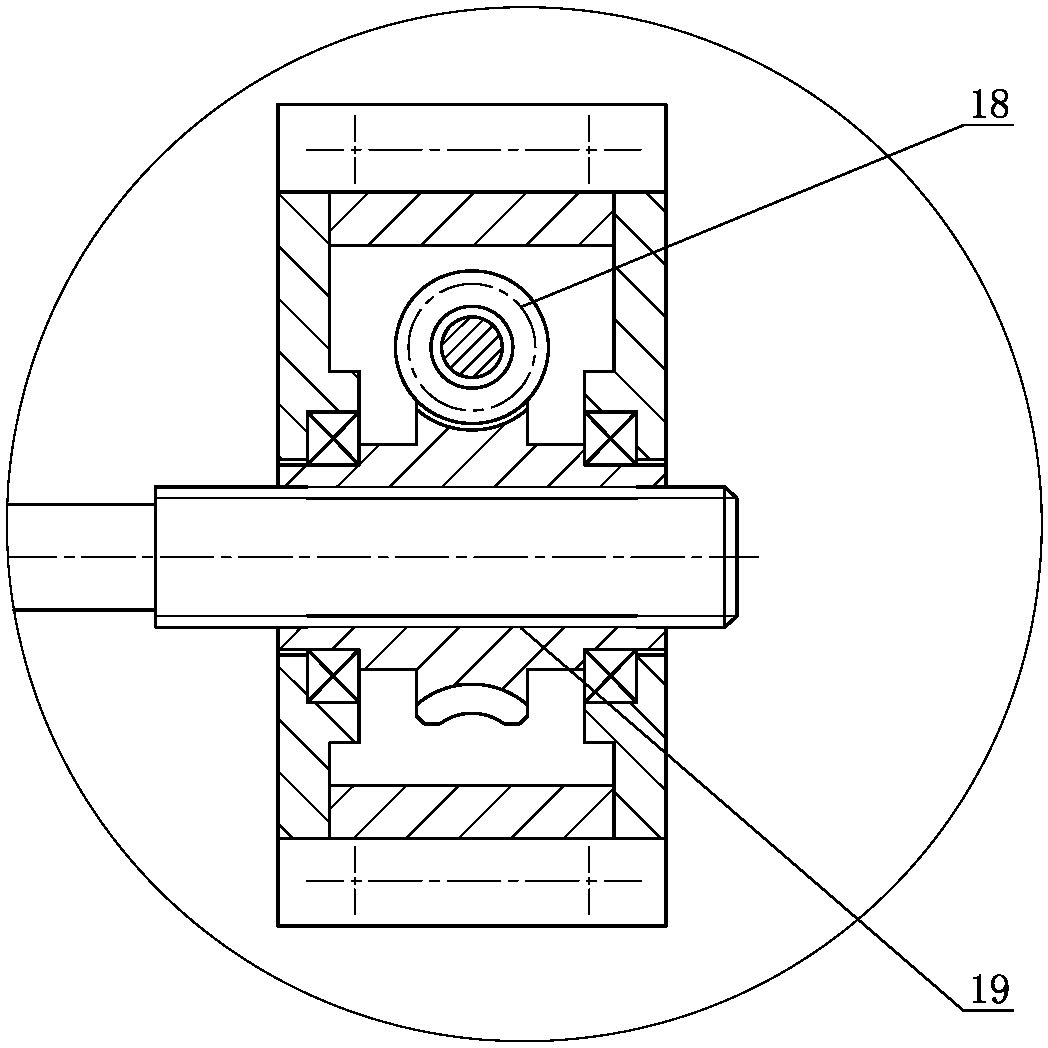

Driving mechanism of particle crusher

InactiveCN102527469ARealize the adjustment functionLarge adjustment rangeGrain treatmentsGear driveDrive shaft

The invention relates to a driving mechanism of a particle crusher. The driving mechanism of the particle crusher comprises a quick roller, a slow roller, an idle gear I and an idle gear II, wherein a driving gear is arranged on an axial end on one side of the quick roller; a slow roller driving gear is arranged on the axial end on the same side of the slow roller; two pair of supporting plates are respectively arranged on the axial ends on the two sides of the slow roller; the two pairs of supporting plates synchronously swing through the driving of a synchronous adjusting mechanism, so the distance between the quick roller and the slow roller is synchronously and uniformly adjusted; the synchronous adjusting mechanism comprises two groups of turbine worm pairs and screw rod nut pairs; the nuts of each group of screw rod nut pairs are turbines of the turbine worm pairs; each group of screw rods is axially and fixedly connected with an adjusting rod; the adjusting rod is connected with a supporting plate; a spring which elastically resets the supporting plate is arranged between the adjusting rod and the supporting plate; and the two groups of worms are coaxially connected througha driving shaft to realize synchronous rotation. Due to the adoption of the driving mechanism of the particle crusher, when the distance between the rollers is adjusted, a gear driving system is always in an optimal meshing state, the distance between the quick roller and the slow roller is synchronously adjusted precisely, the frequency of replacing the rollers is reduced, and the application range of the particle crusher is widened.

Owner:JIANGSU MUYANG GRP CO LTD

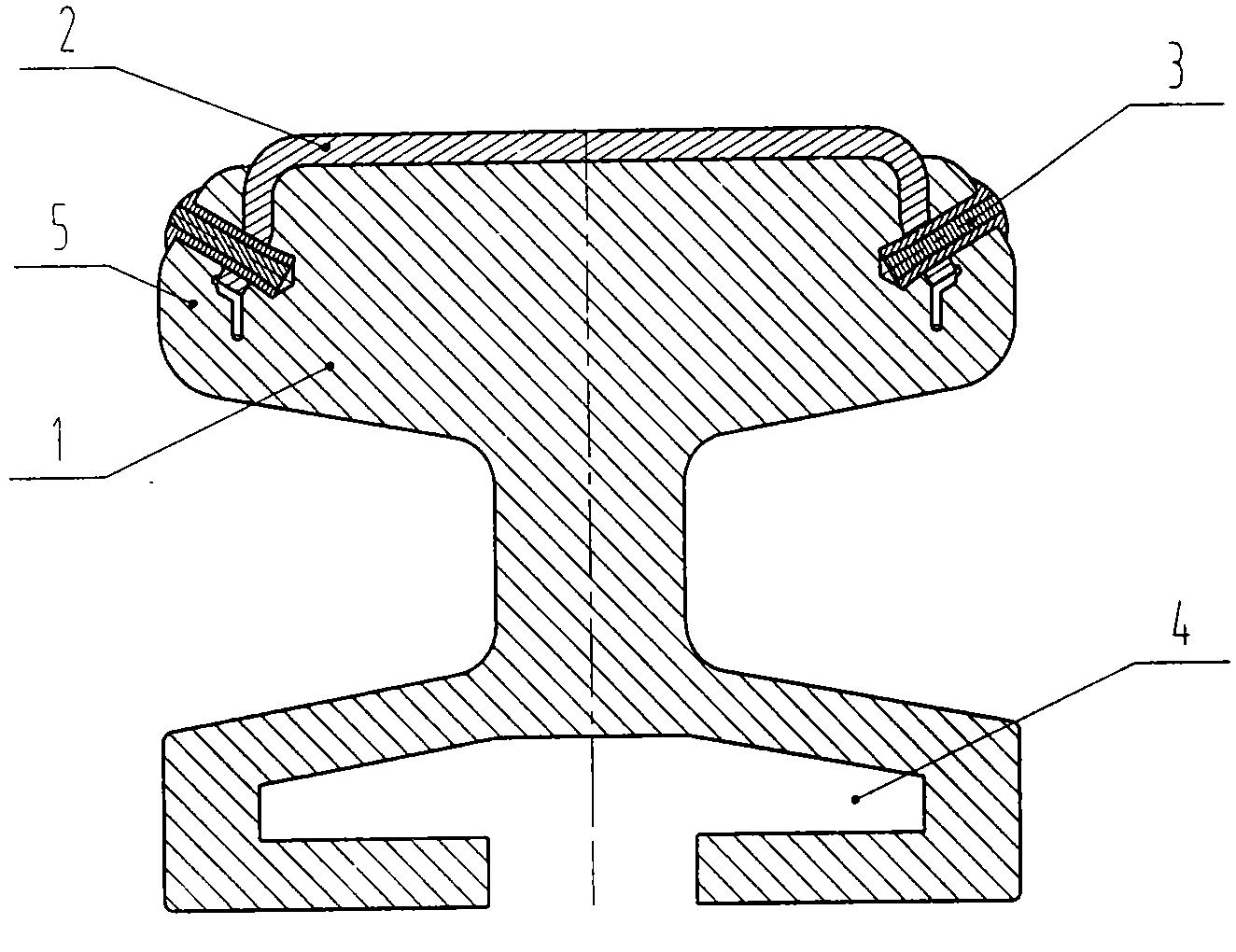

Hydraulic coal mine support for low-position roof blasting-down

InactiveCN1526914AReduce the center distanceCompact structureMine roof supportsProps/chocksCoalEngineering

The hydraulic coal mine support for low-position roof blasting-down consists of single row double uprights with top beam and pedestal hinged to ends, securing beam hinged to back of the top beam, coal blasting mechanism behind the securing beam, front link rod and back link rod hinged to between the pedestal and the securing beam, pedestal pushing mechanism, top beam protecting unit, balancing jack hinged to between the top beam and the securing beam, etc. The coal blasting mechanism consists of tail beam, board inserting jack, inserted board and tail beam jack. The hydraulic coal mine support is developed by synthesizing available supports, and has the advantages of homogeneous upright stress, compact structure, high support strength, high safety, etc.

Owner:YANKUANG GRP CO LTD

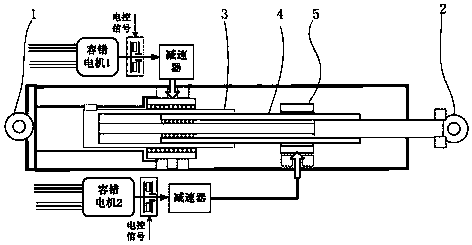

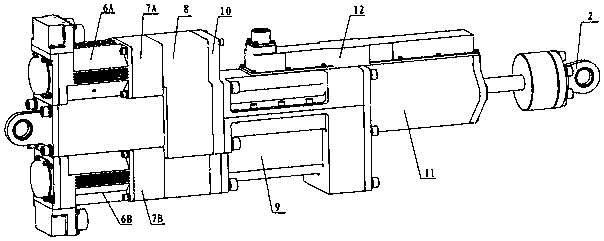

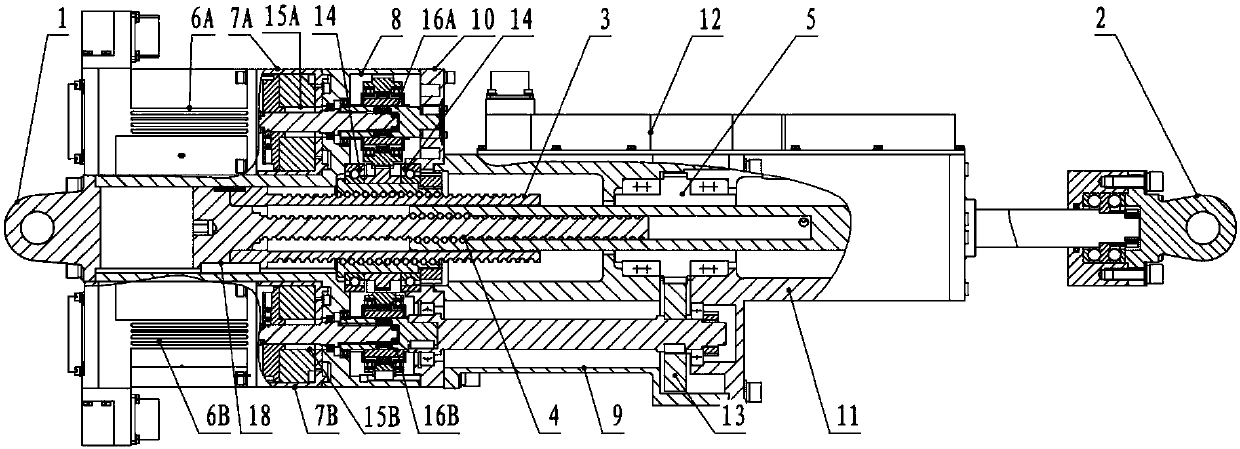

Straight-line type anti-jamming double-redundancy electromechanical actuator

ActiveCN107725705AHigh specific powerReduce radial footprintGearingMechanical energy handlingAnti jammingBall screw

The invention discloses a straight-line type anti-jamming double-redundancy electromechanical actuator, and the electromechanical actuator has the characteristics of the anti-jamming and the double redundancy, namely a main working mode and a backup working mode which are mainly realized through a straight-line transmission mechanism. A main function component of the straight-line transmission mechanism is a nested roll-ball screw-rod pair which comprises an outer screw rod and an inner screw rod, wherein the outer screw rod mainly works, and the inner screw rod serves as the backup. Accordingto the straight-line type anti-jamming double-redundancy electromechanical actuator, the radial-direction occupation space is reduced by means of the nested layout, an axial-direction zero position length is shortened at the same time, and the specific power of the actuator is increased.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

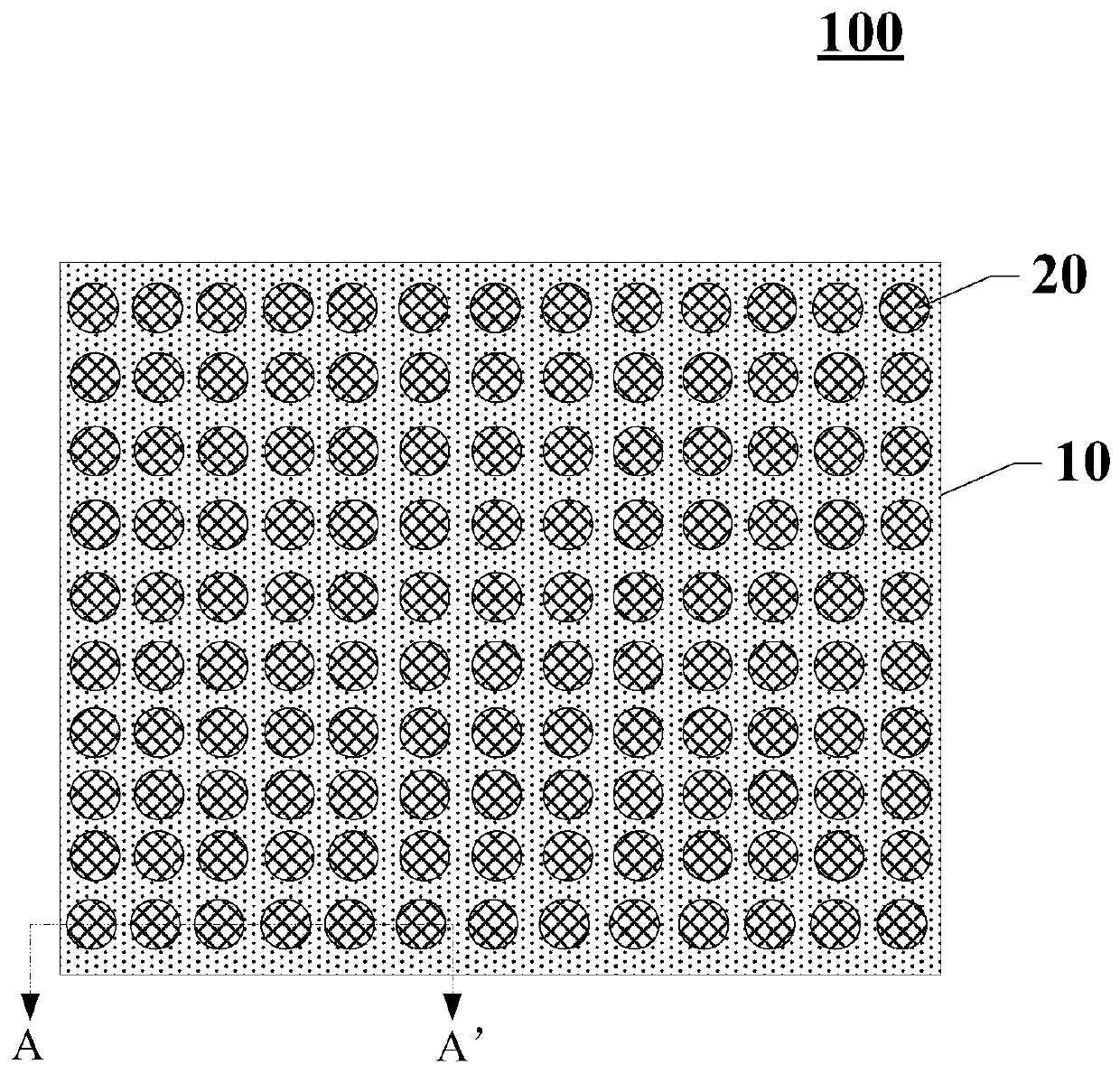

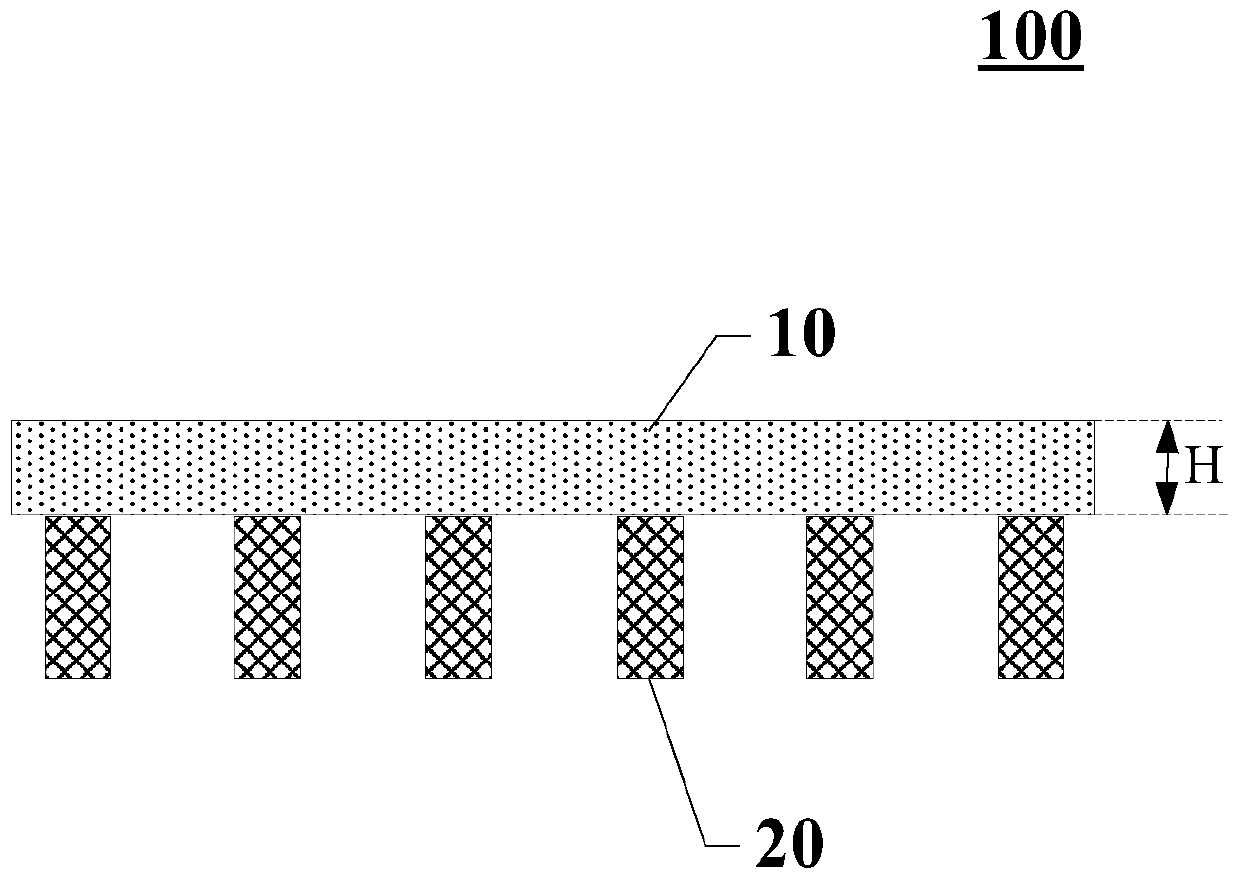

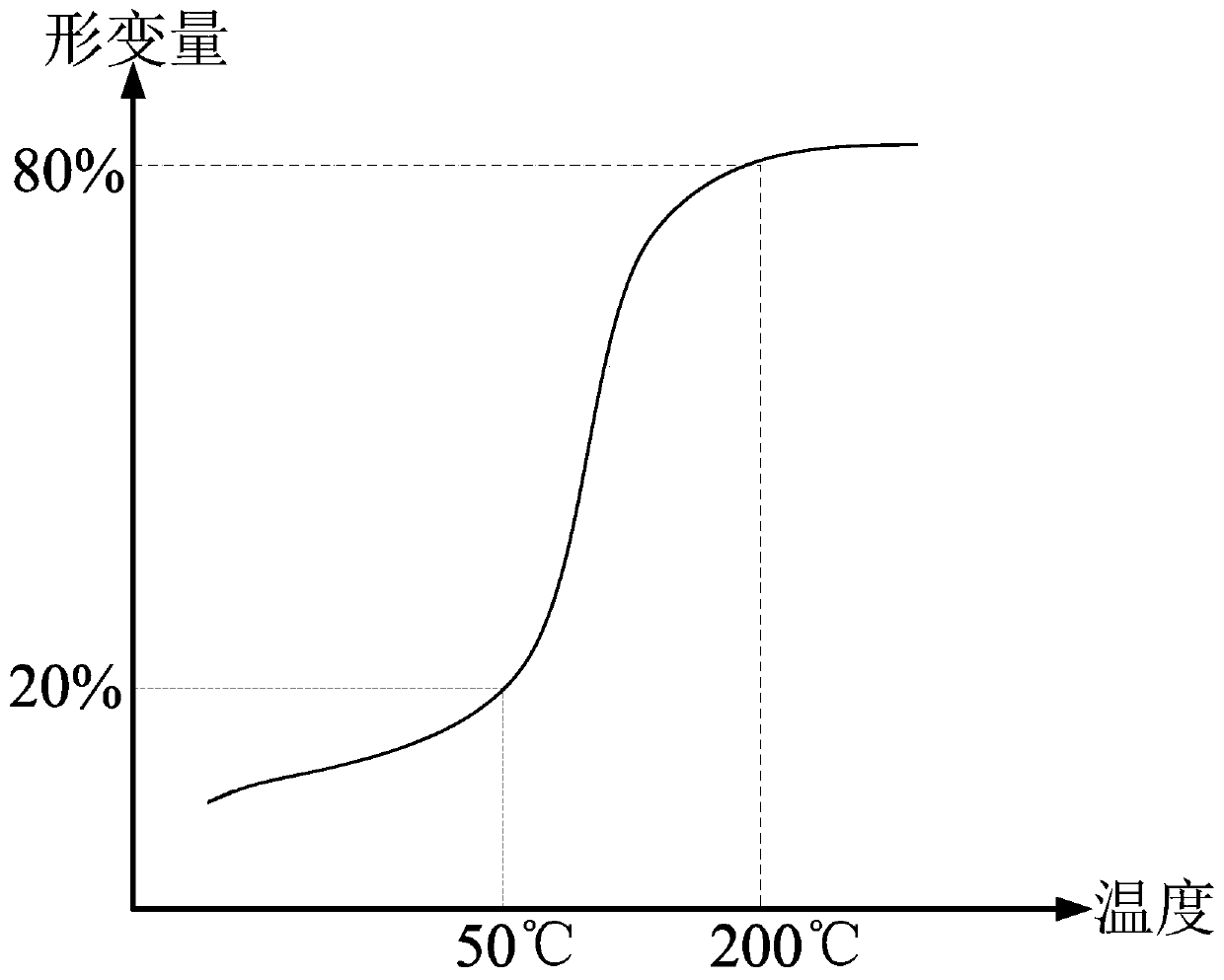

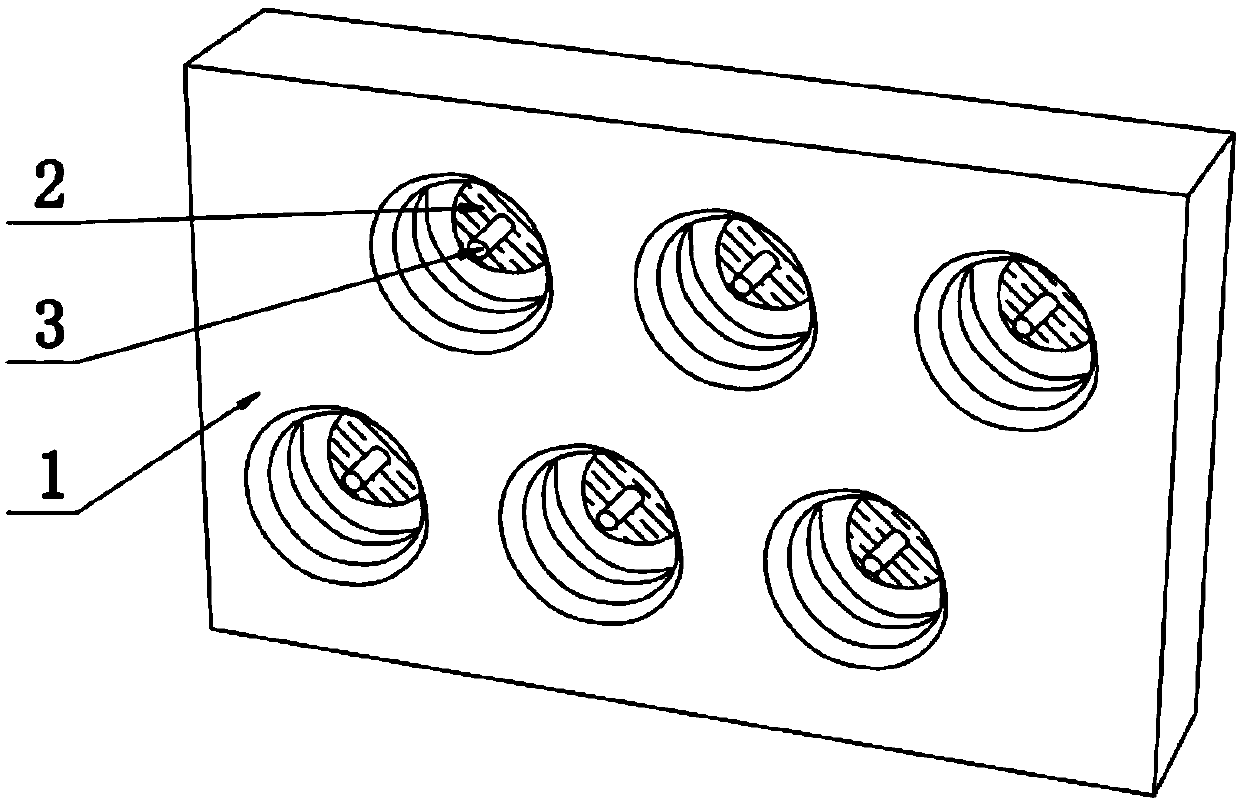

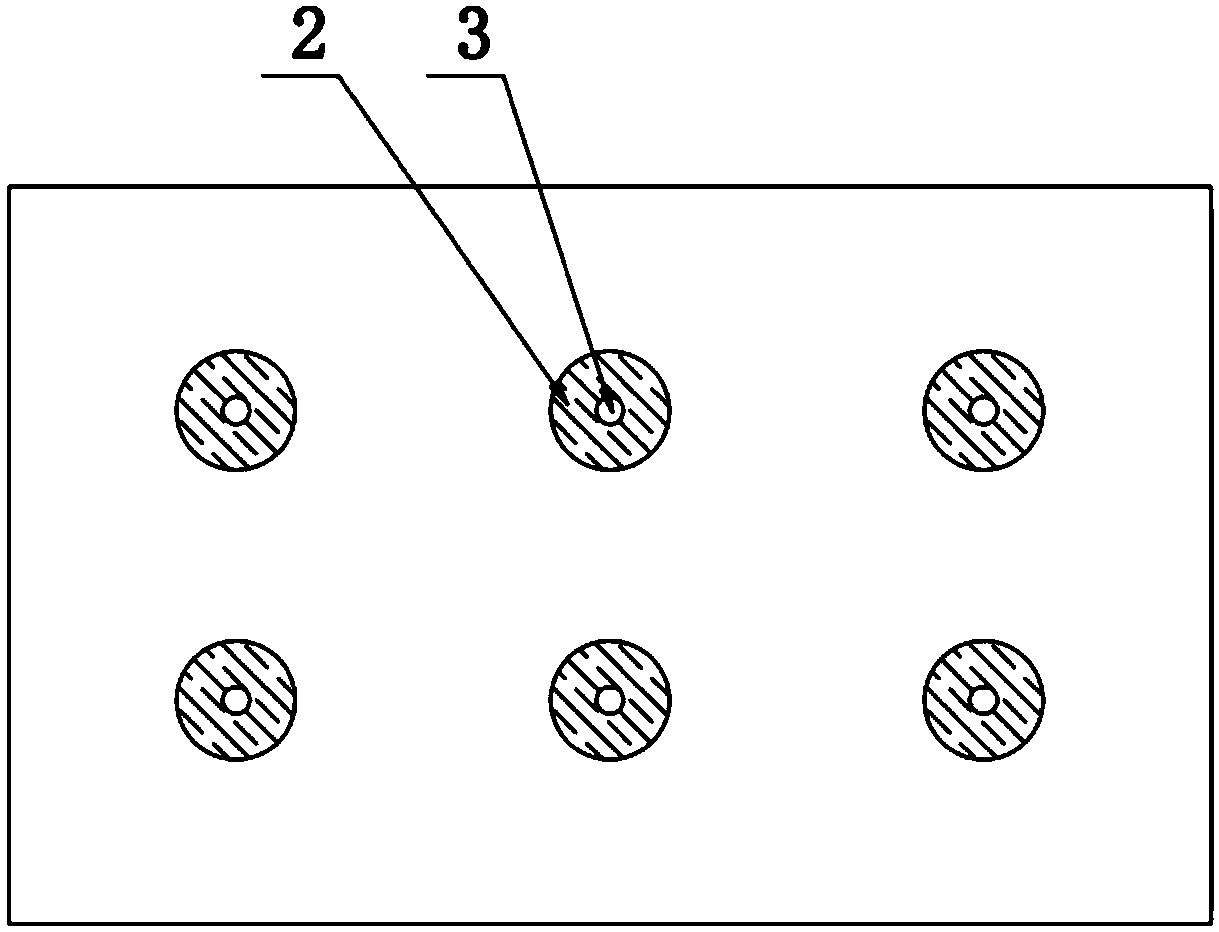

Mass transfer head and method for an electronic element

InactiveCN110289240AIncrease the center distanceReduce the center distanceSemiconductor/solid-state device manufacturingSemiconductor devicesAlloy substrateMass transfer

The invention discloses a mass transfer head and method for an electronic element, and relates to the technical field of electronic element production. The transfer head comprises a memory alloy substrate and a plurality of electronic element pick-up heads fixed on the first surface of the memory alloy substrate. At the same temperature, the center distances between any two adjacent electronic element pick-up heads are equal; the memory alloy substrate deforms along with the change of temperature; when the temperature rises, the memory alloy substrate stretches, and the center distance between any two adjacent electronic element pick-up heads is increased; when the temperature decreases, the memory alloy substrate is shrunk, and the center distance between any two adjacent electronic element pick-up heads is reduced. The distance between the electronic element pick-up heads fixed on the memory alloy substrate can be adjusted by the adjustment of the temperature. The mass transfer head is flexibly suitable for different Micro-LED pitches and pixel pitches, thereby avoiding the consumption of the Micro-LED resources.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

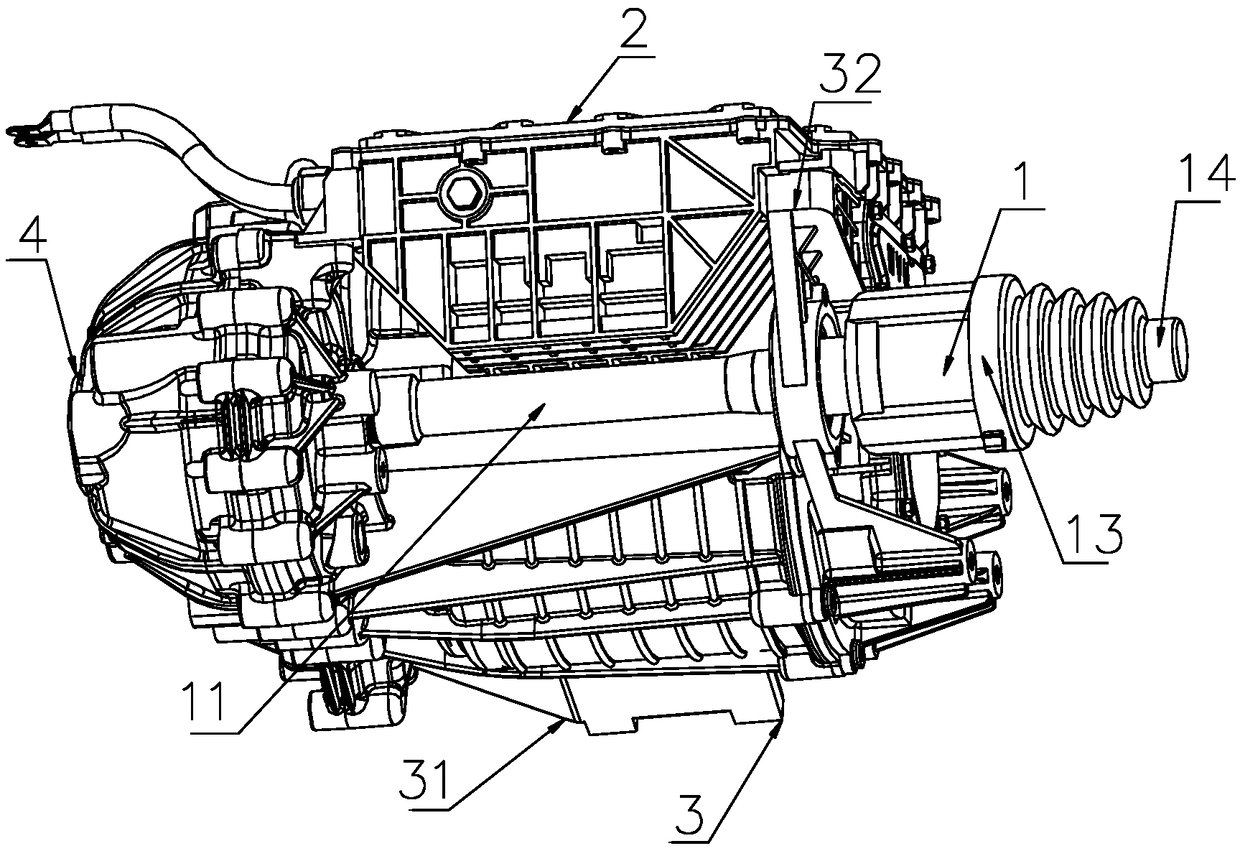

Four-stage driving combined type speed reducer and speed reduction method thereof

InactiveCN101761633AImprove machining accuracyReduce the center distanceToothed gearingsGear wheelControl theory

The invention relates to a four-stage driving combined type speed reducer and a speed reduction method thereof. The four-stage driving combined type speed reducer with small teeth difference is a bevel gear-planetary-parallel shaft-four-stage drive with small teeth difference and structurally comprises an input gear pair, a middle planetary gear pair, a parallel shaft gear pair, an output gear pair with small teeth difference, a box body and an end cover. The principle of the speed reduction method of the four-stage driving combined type speed reducer with small teeth difference is that the speed reduction of the speed reducer is realized through a first-stage driving bevel gear drive, a second-stage planetary gear drive, a third-stage driving parallel shaft drive and a fourth-stage driving drive with small teeth difference. The invention has the advantages that the transmission speed ratio and the output torque of the vertical speed reducer are greatly improved, and the bearing capacity and the overload capacity are strong; and the vibration noise is low, the heat dissipation is rapid, the gear machining precision is improved, the machining precision can be ensured easily, the volume and the weight of the entire speed reducer are reduced, the manufacturing cost of the large-power vertical speed reducer is greatly reduced and the production cycle is shortened.

Owner:TIANJIN GENERAL PRINCIPLE MACHINERY NEW TECH

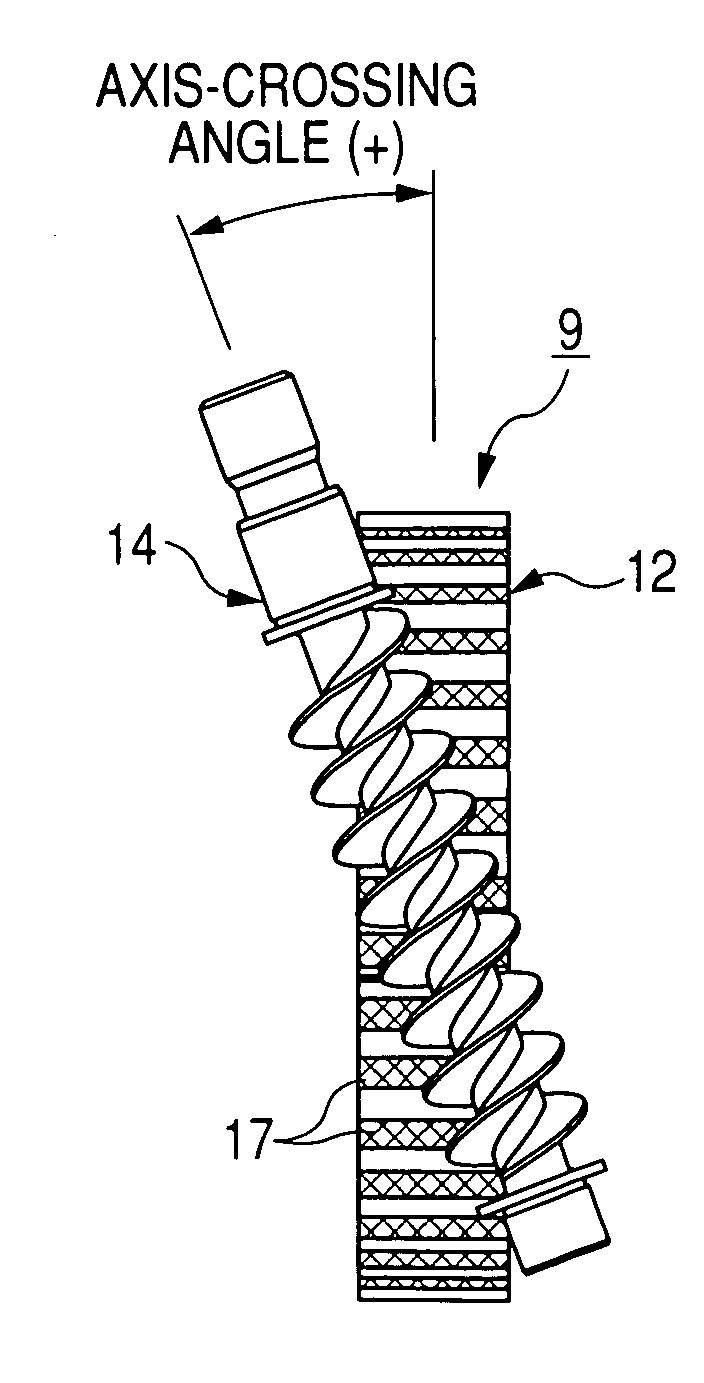

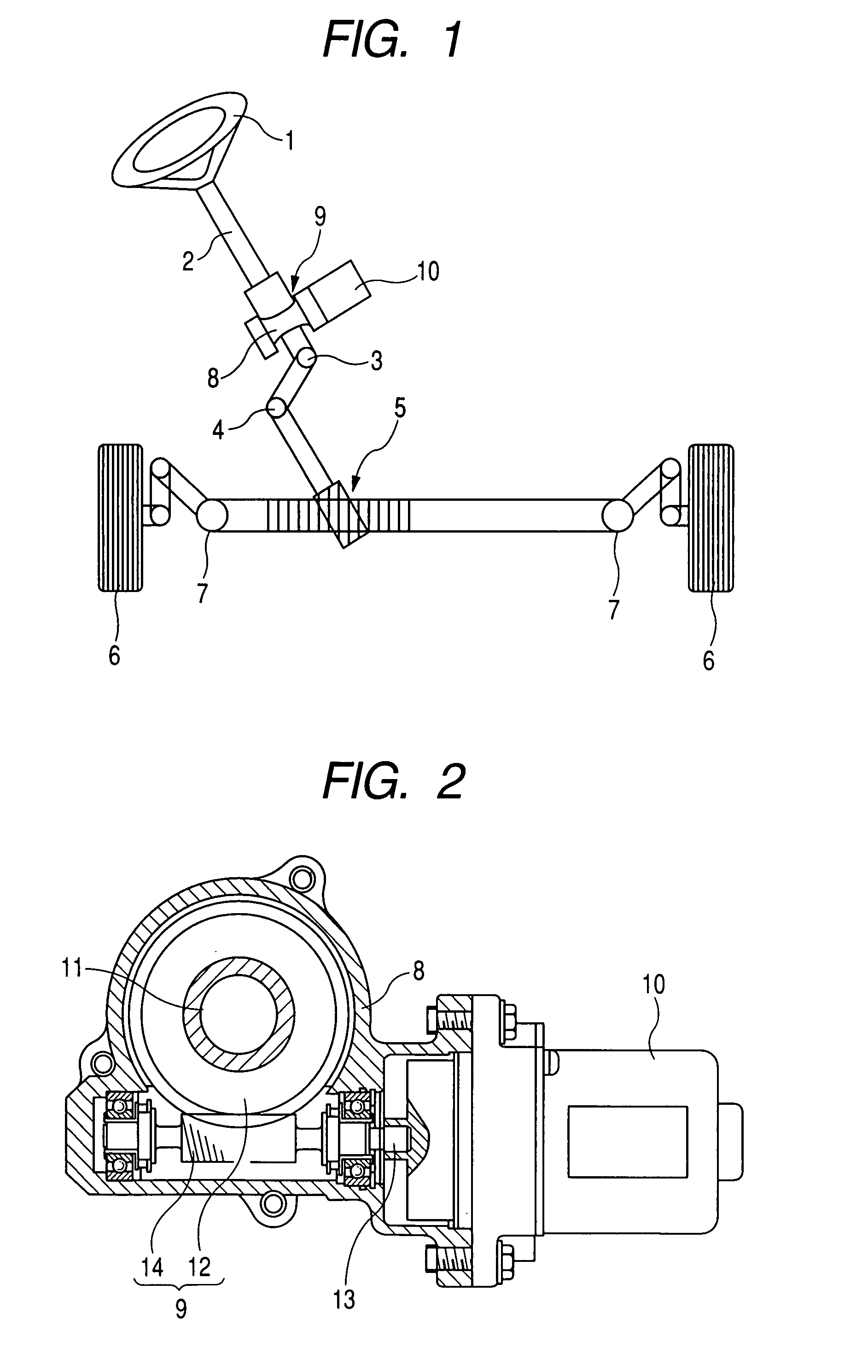

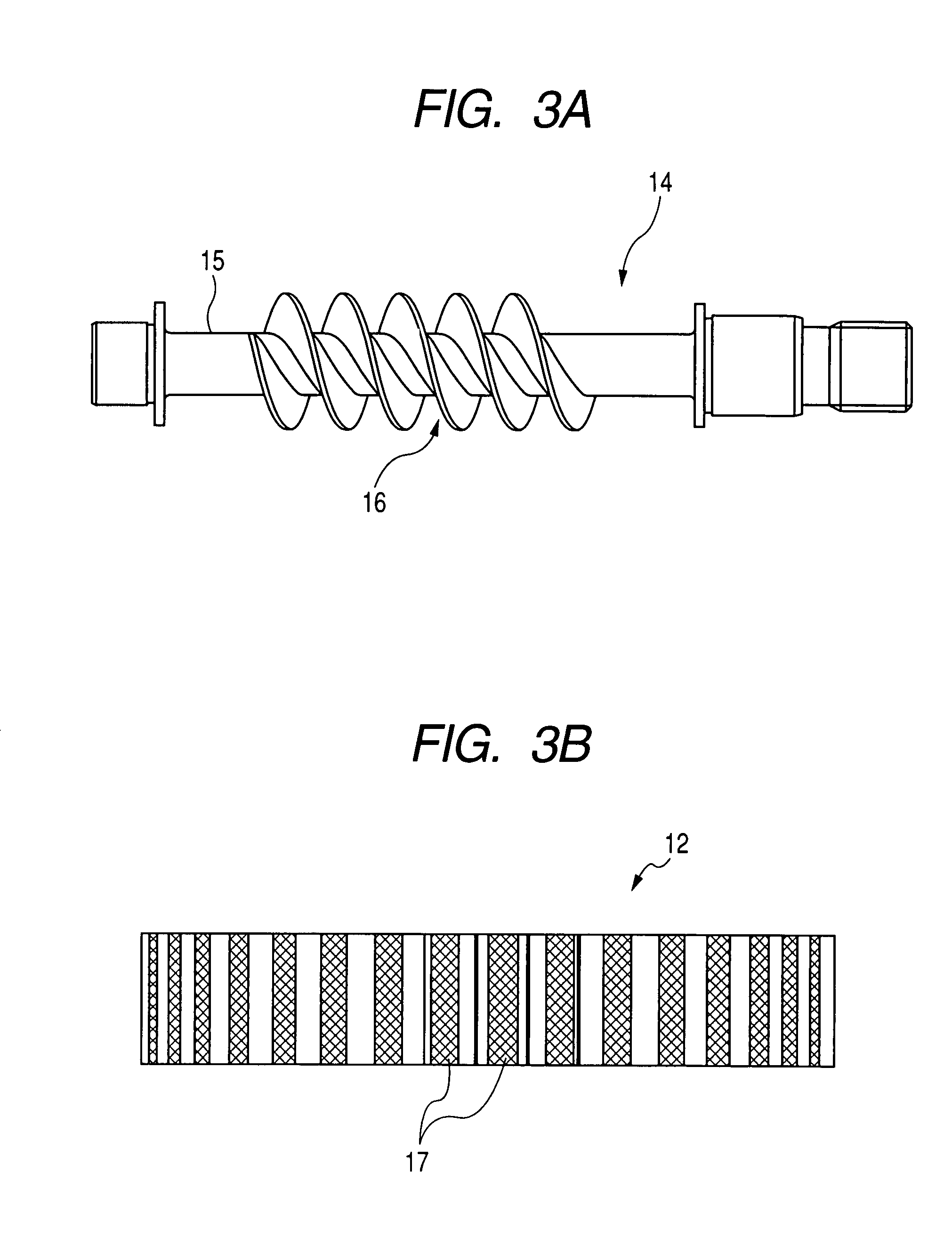

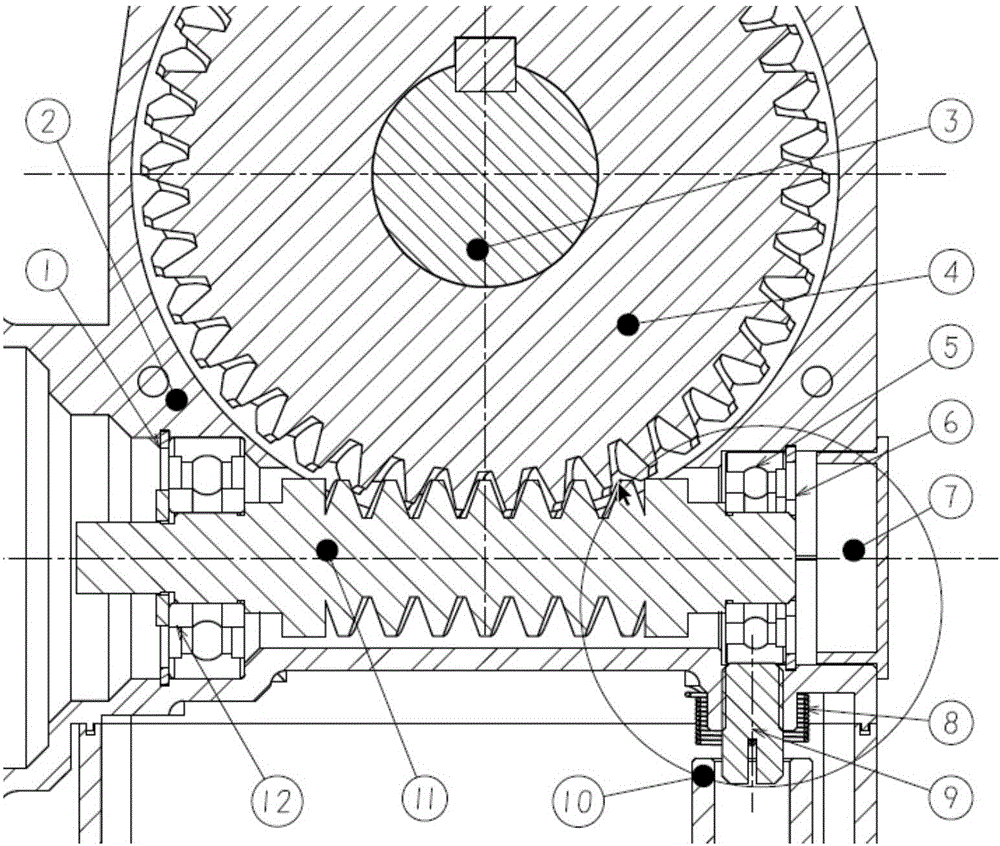

Worm reducer and electric power steering apparatus

ActiveUS7661332B2Life reduction can be preventedReduce MechanismsToothed gearingsPower driven steeringElectric power steeringReducer

In a worm reducer for reducing the rotation transmitted to a worm and transmitting the reduced rotation to a worm wheel, the worm reducer being composed of the worm with screw faces formed on its outer periphery and the worm wheel with worm wheel teeth formed on its peripheral surface, the worm wheel teeth being in mesh with the screw faces of the worm, the worm wheel teeth are formed so that the lead angle of the worm wheel is smaller than that of the worm.

Owner:NSK LTD

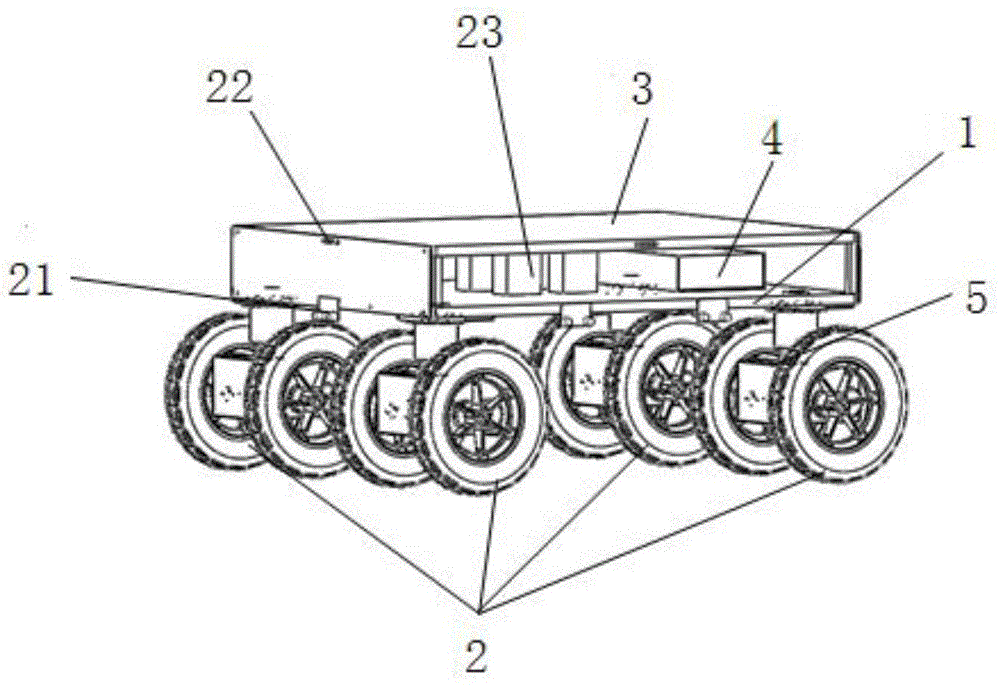

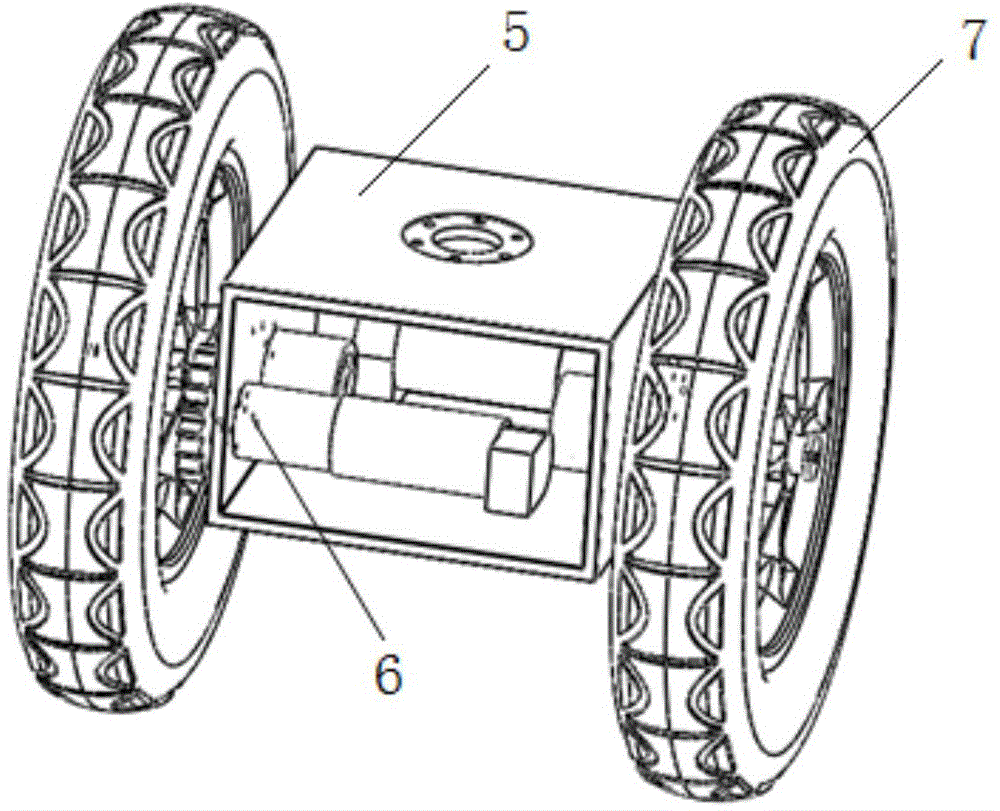

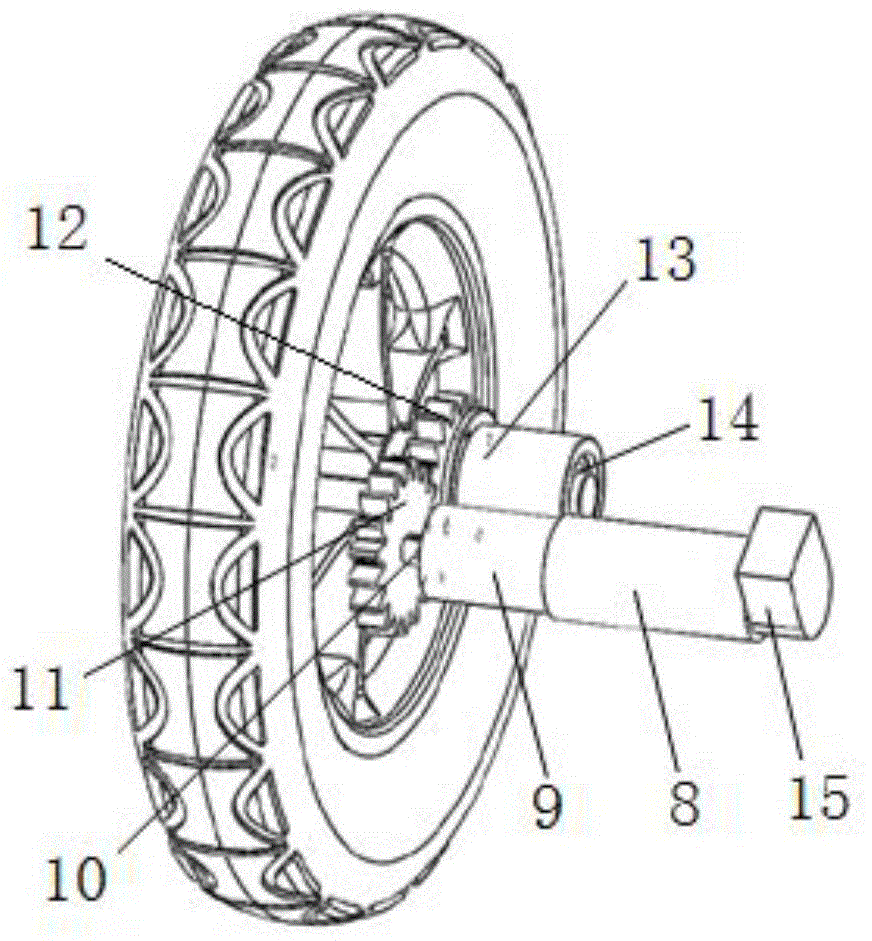

Transport cart with omnibearing movement function

InactiveCN104973123AEasy to controlImprove transport efficiencySteering linkagesUltrasonic sensorEmbedded controller

The invention discloses a transport cart with an omnibearing movement function. The transport cart with the omnibearing movement function comprises a cart body platform, dual differential driving units, a goods platform, a control cabinet, an acceleration sensor, a battery power set and a wireless communication module. An embedded controller and a servo motor driver are arranged in the control cabinet. The four dual differential driving units are movably connected with the cart body platform. Both the control cabinet and the battery power set are fixedly connected into the cart body platform. An ultrasonic sensor, the acceleration sensor and the wireless communication module are fixed to the cart body platform. Numerical values measured by the acceleration sensor are transmitted to the embedded controller through the wireless communication module, and the servo motor driver drives the dual differential driving units according to the control quantity worked out by the embedded controller so as to achieve omnibearing movement of the cart body platform. According to the transport cart with the omnibearing movement function, through the coordinated control of the four dual differential driving units, the control performance of the system is improved, and the moving speed of the cart body platform is made more stable.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

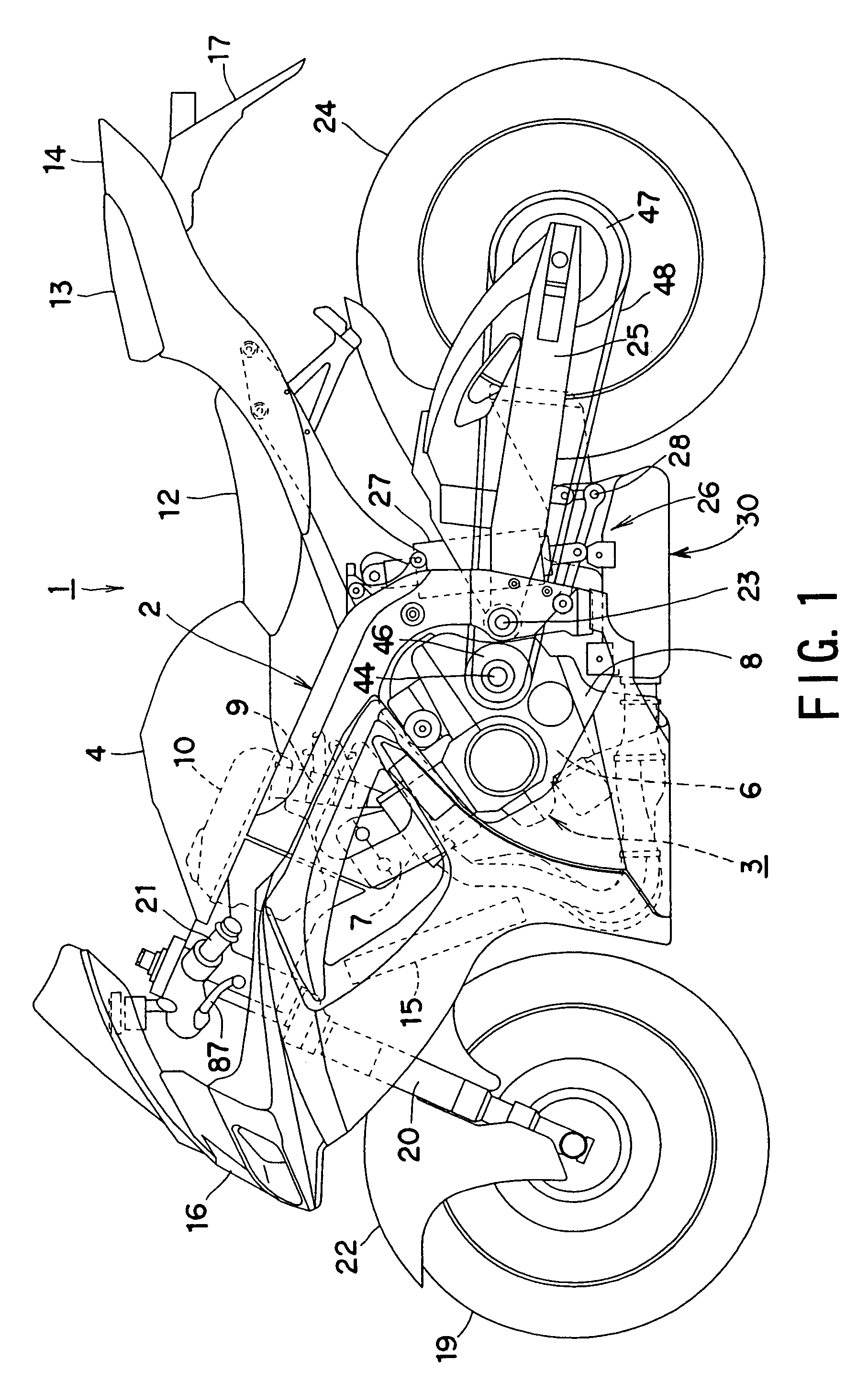

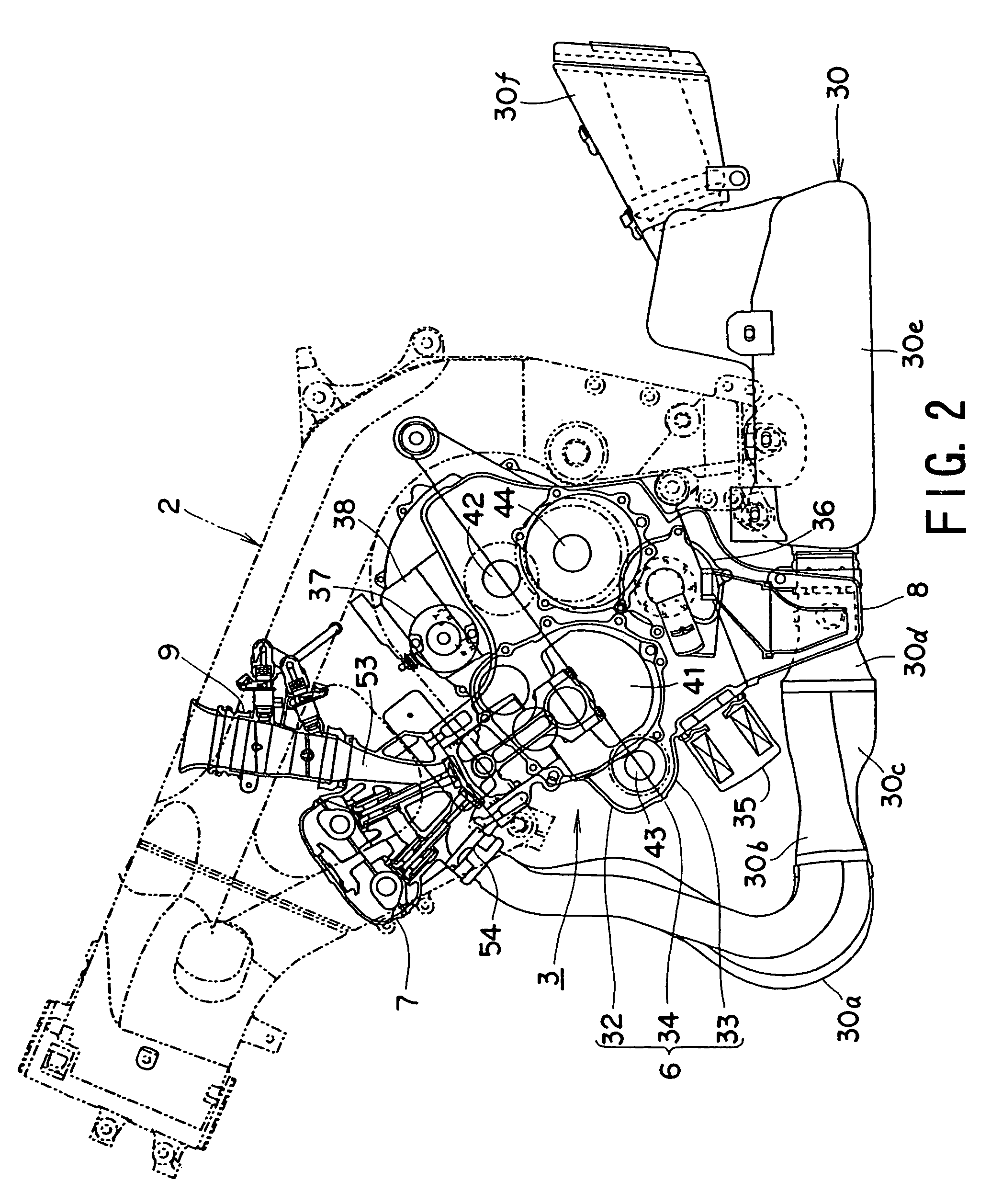

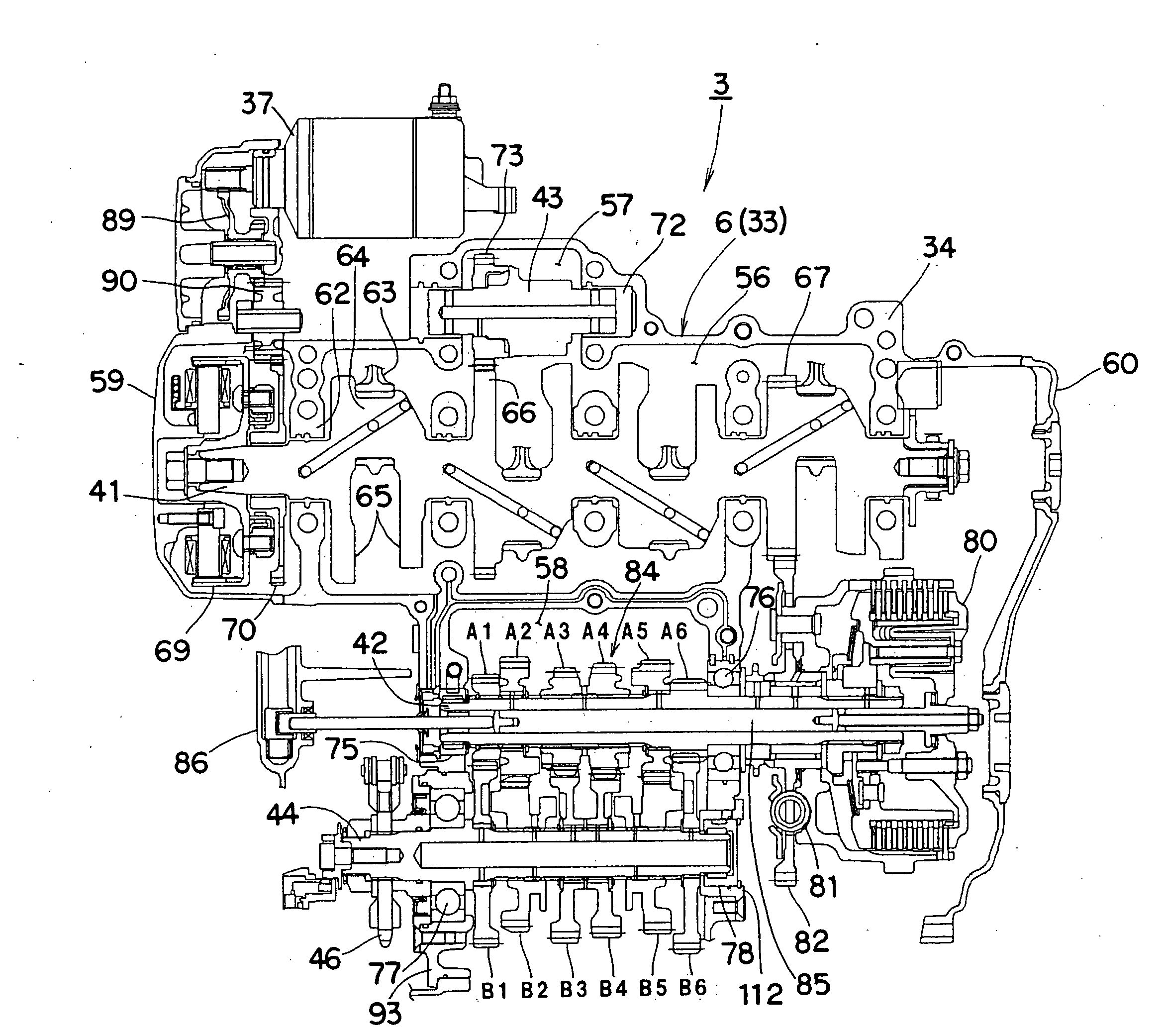

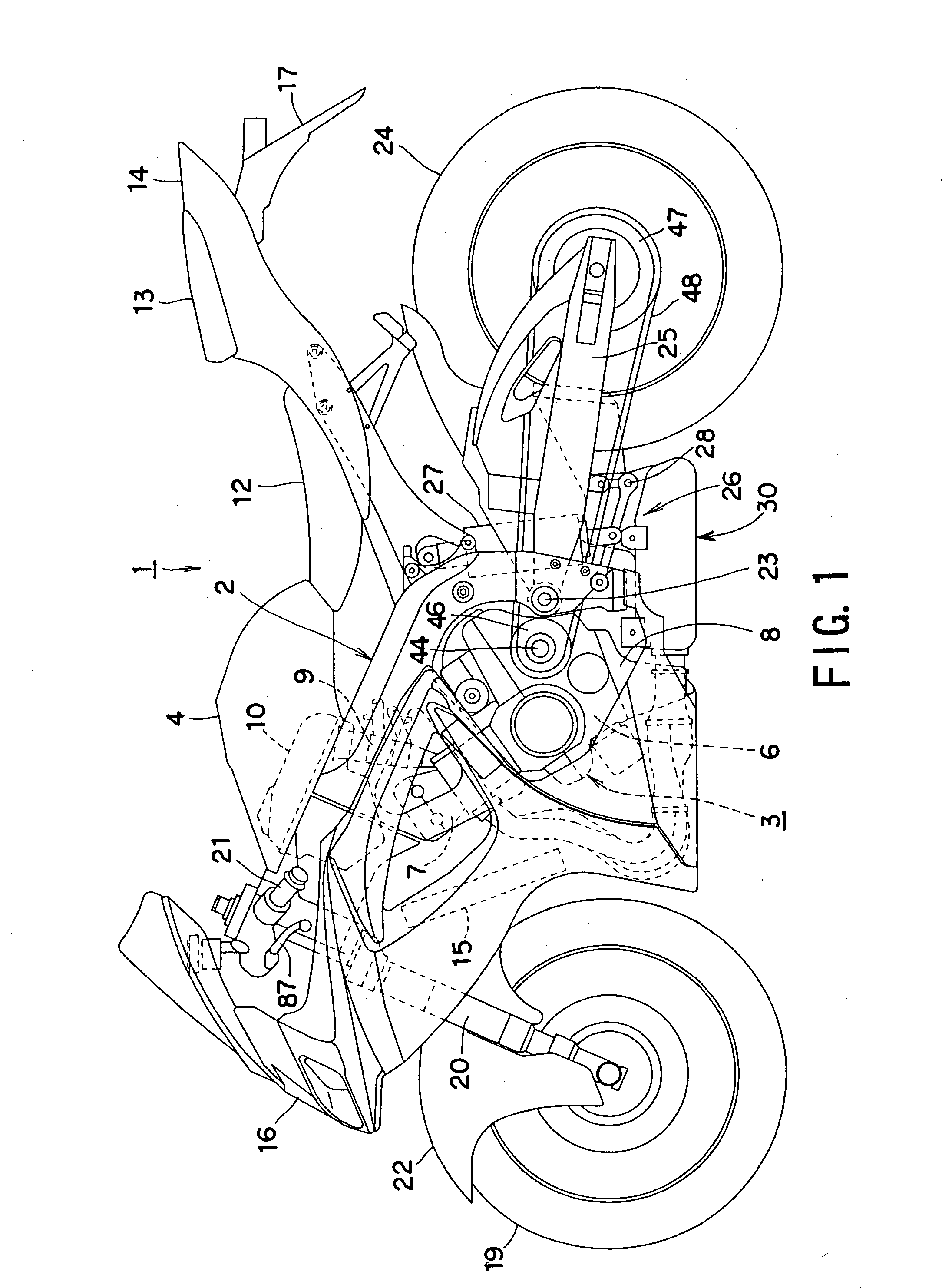

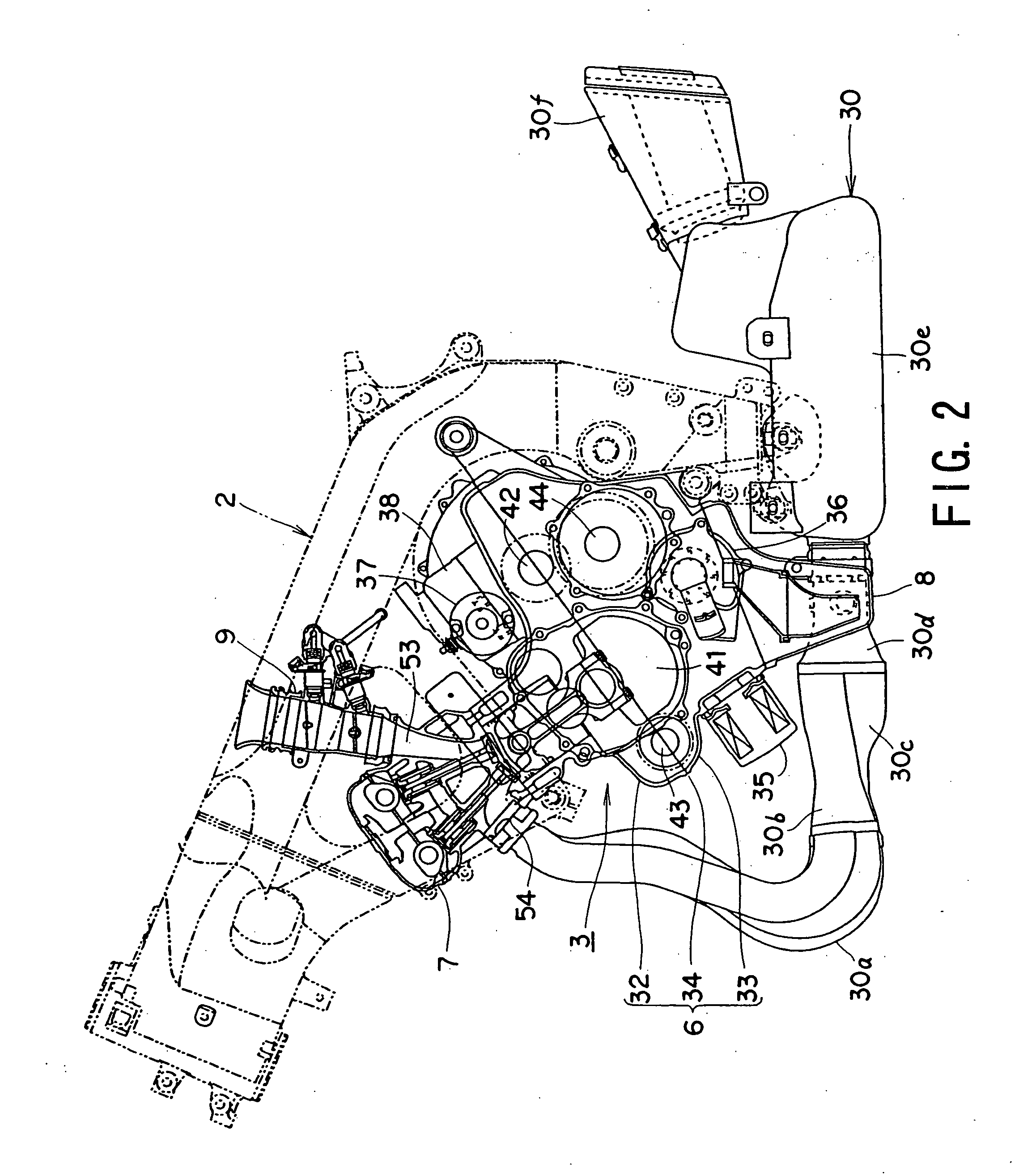

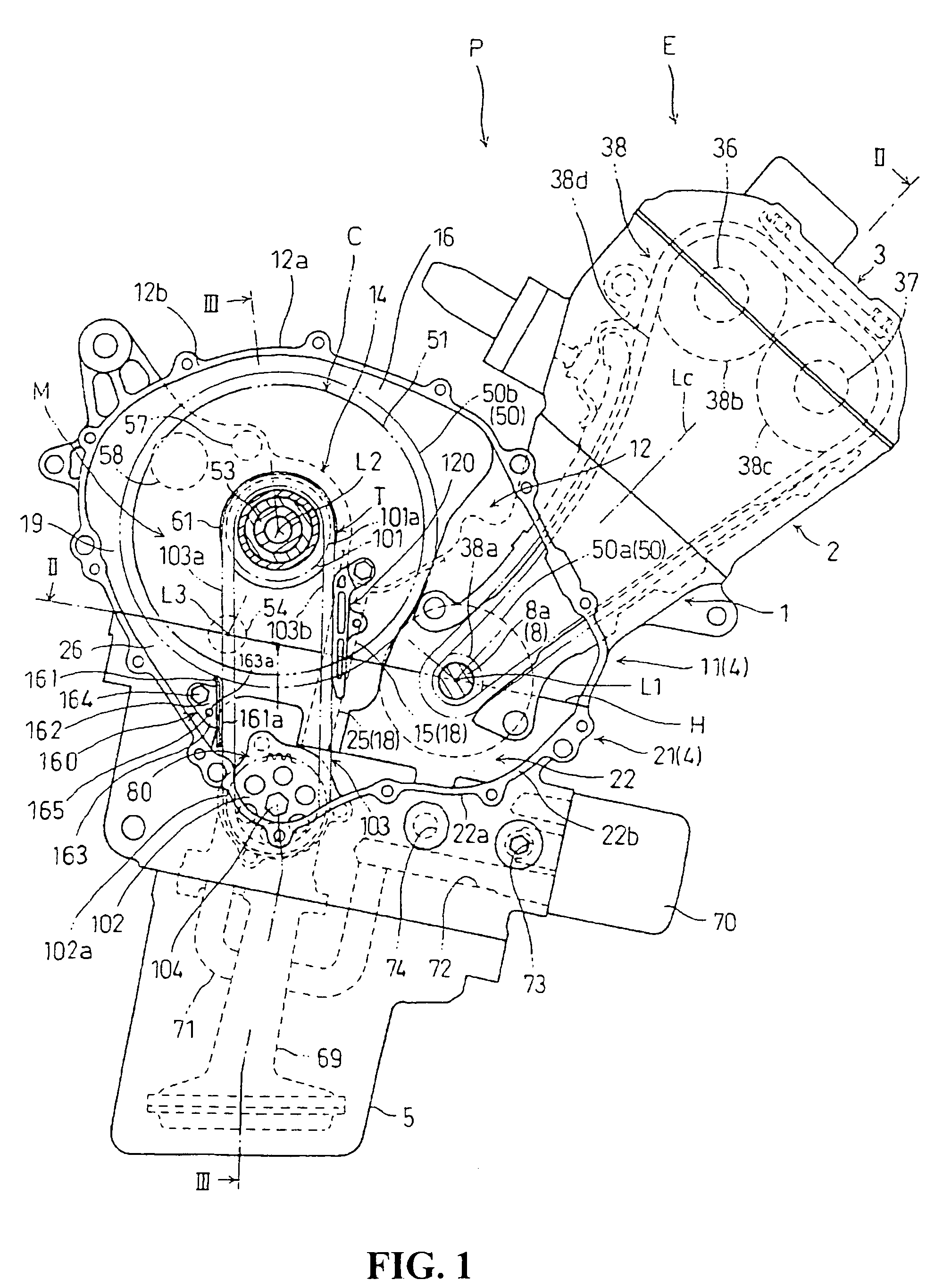

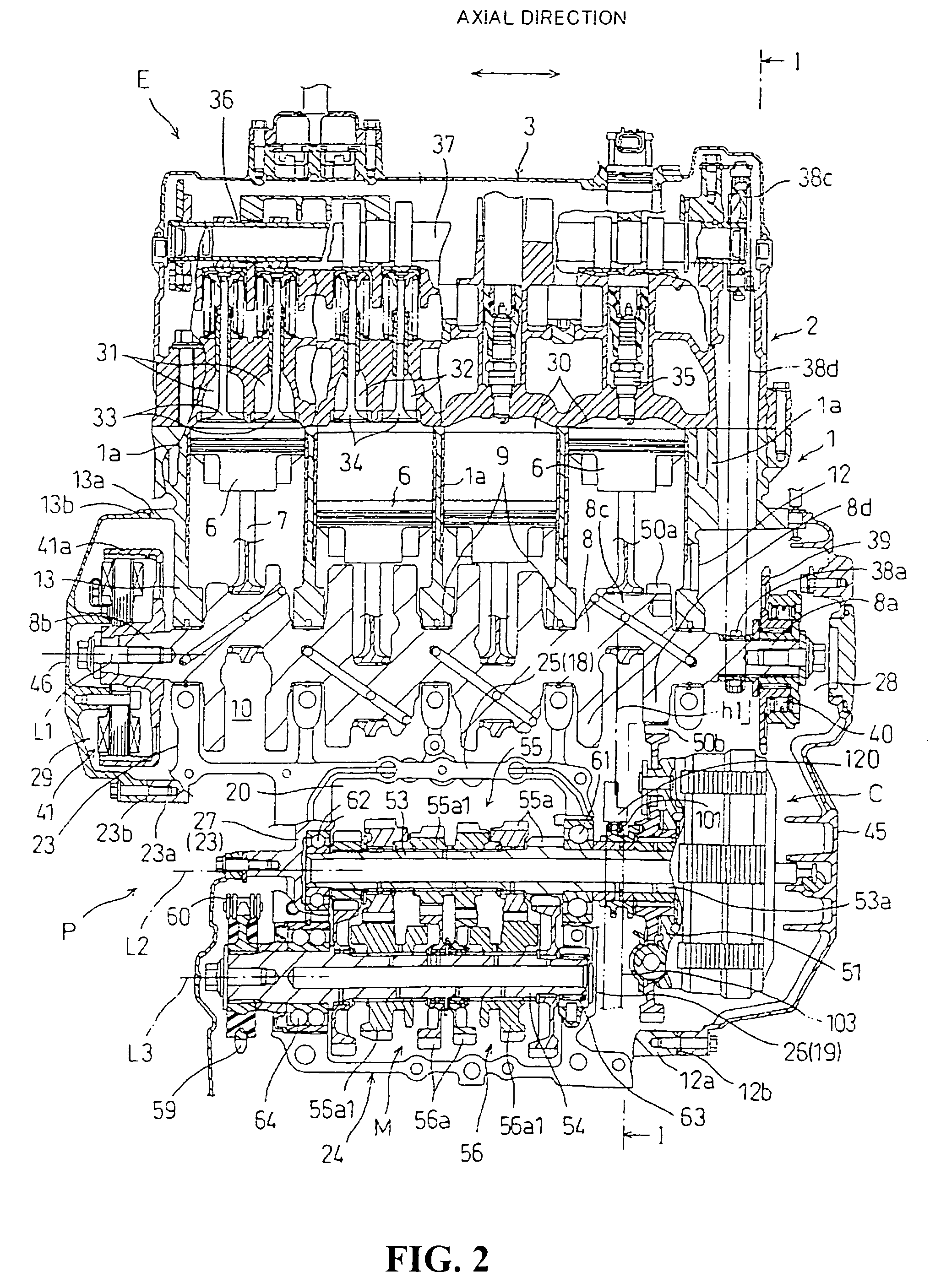

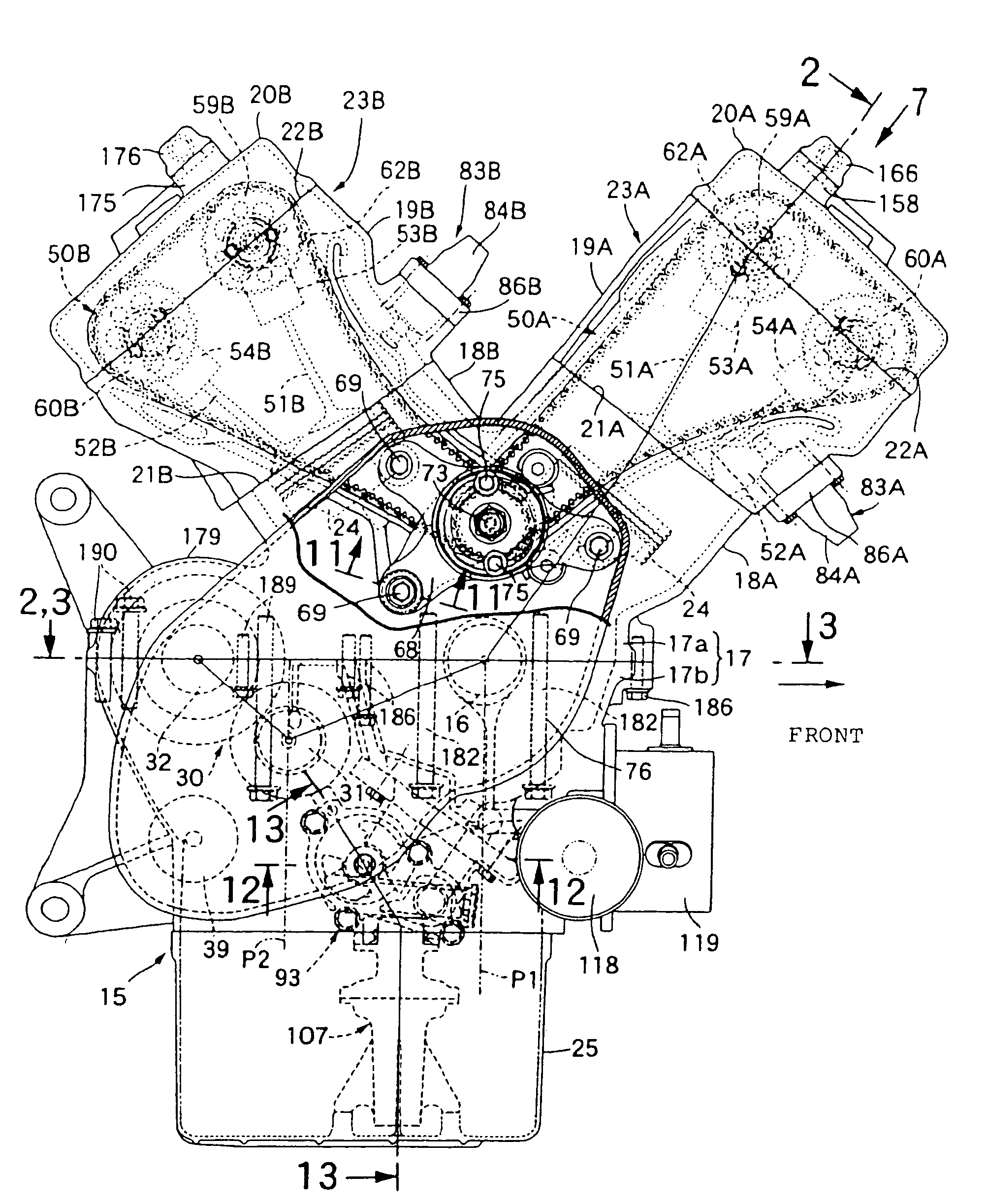

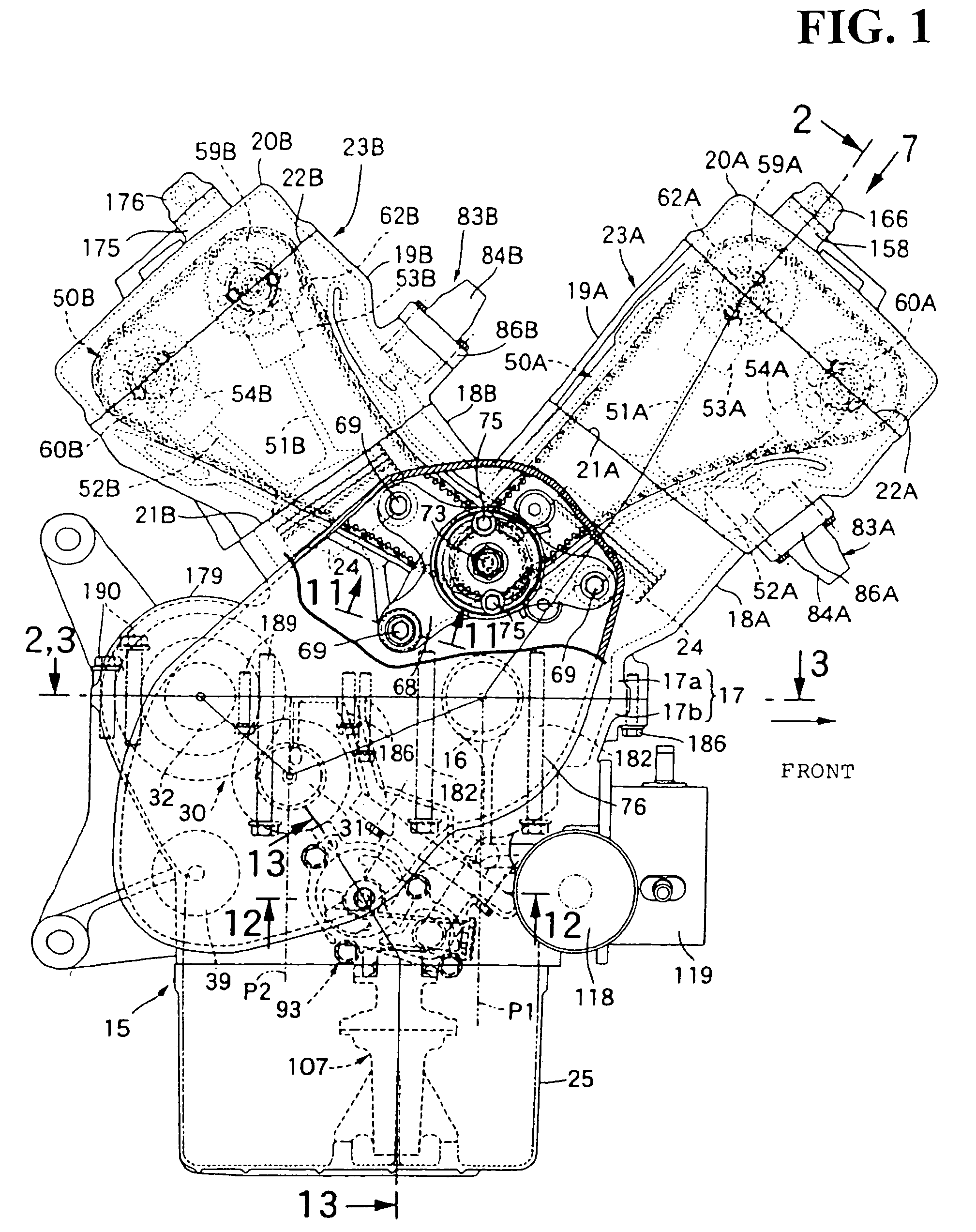

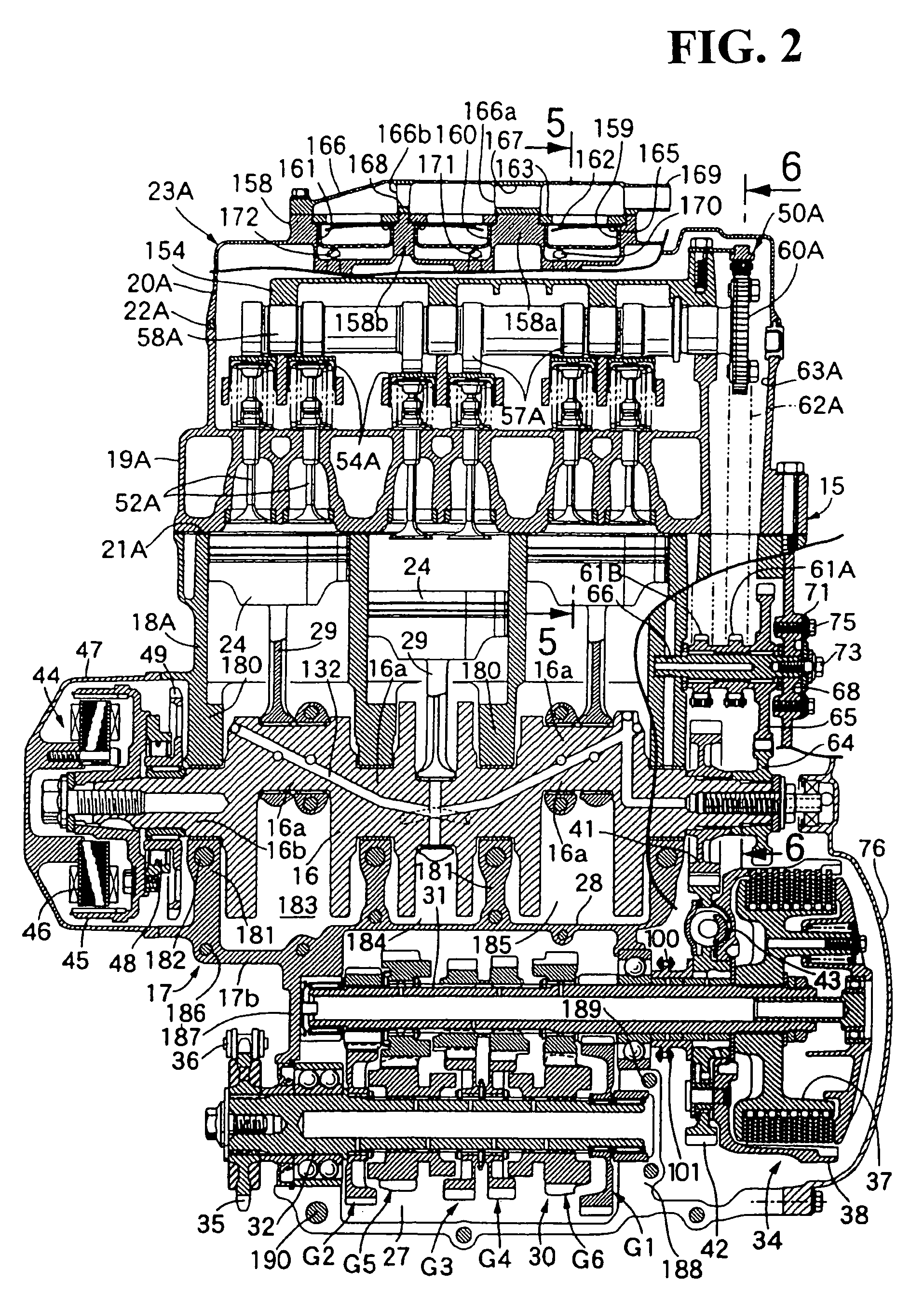

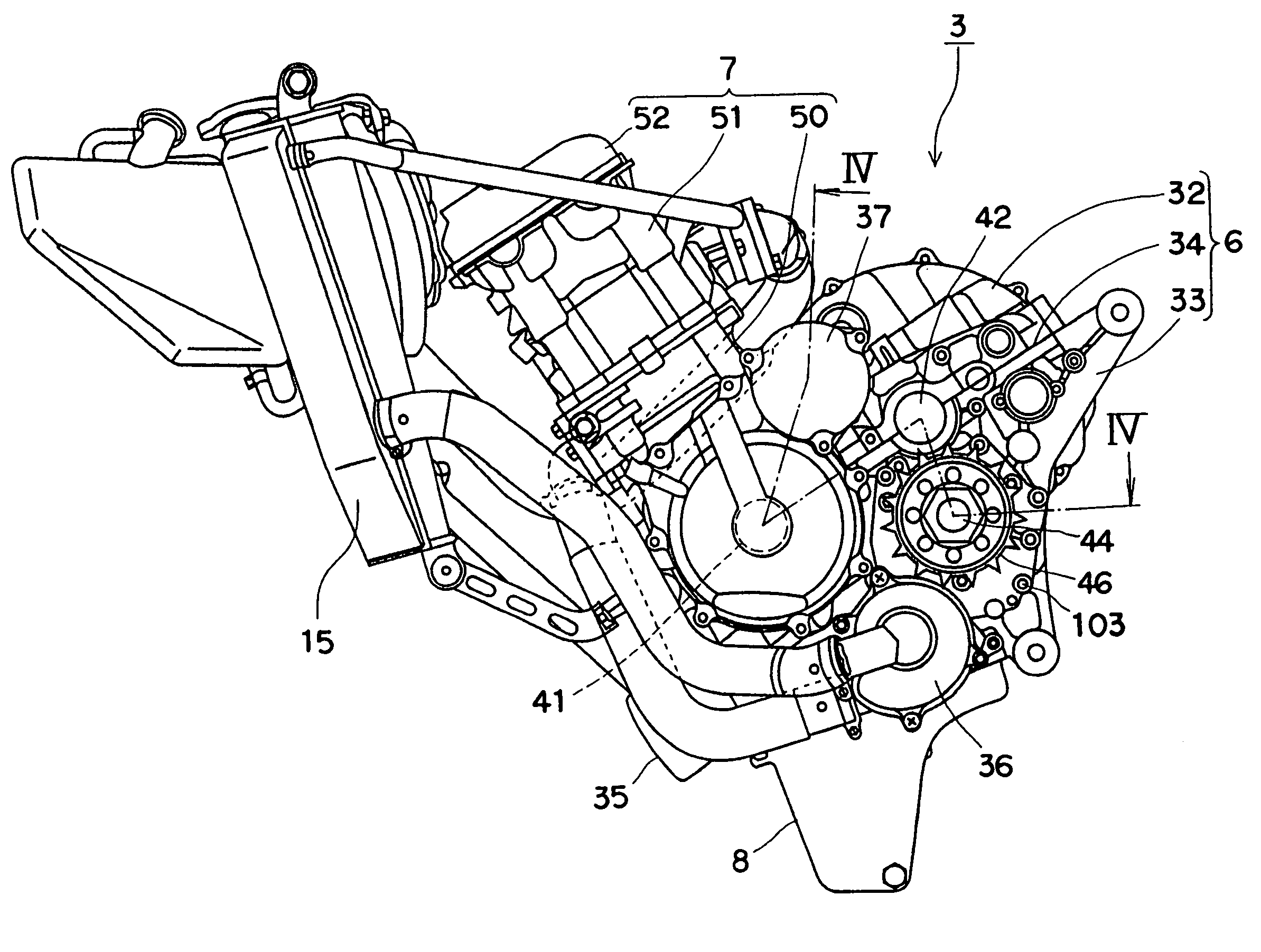

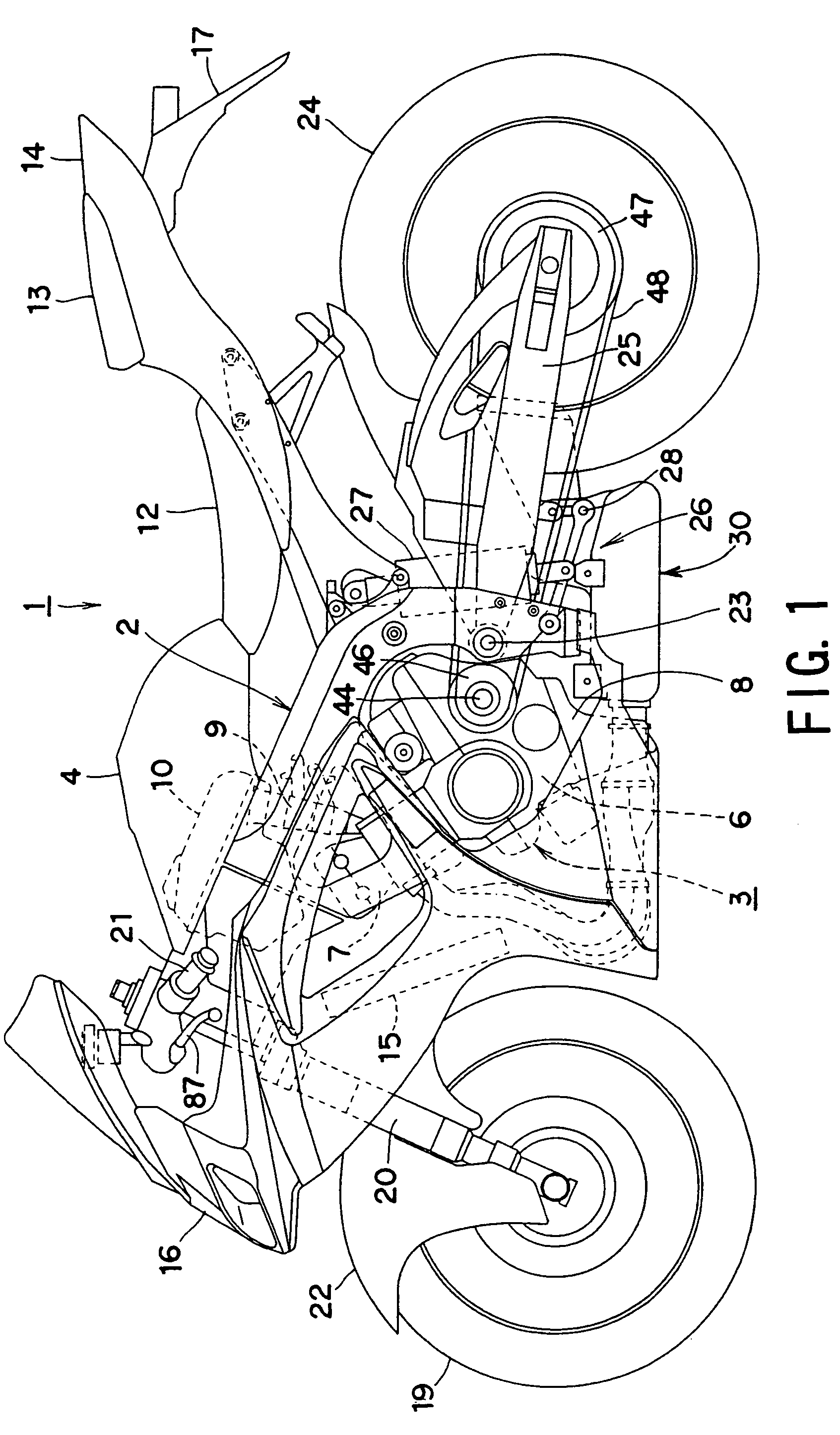

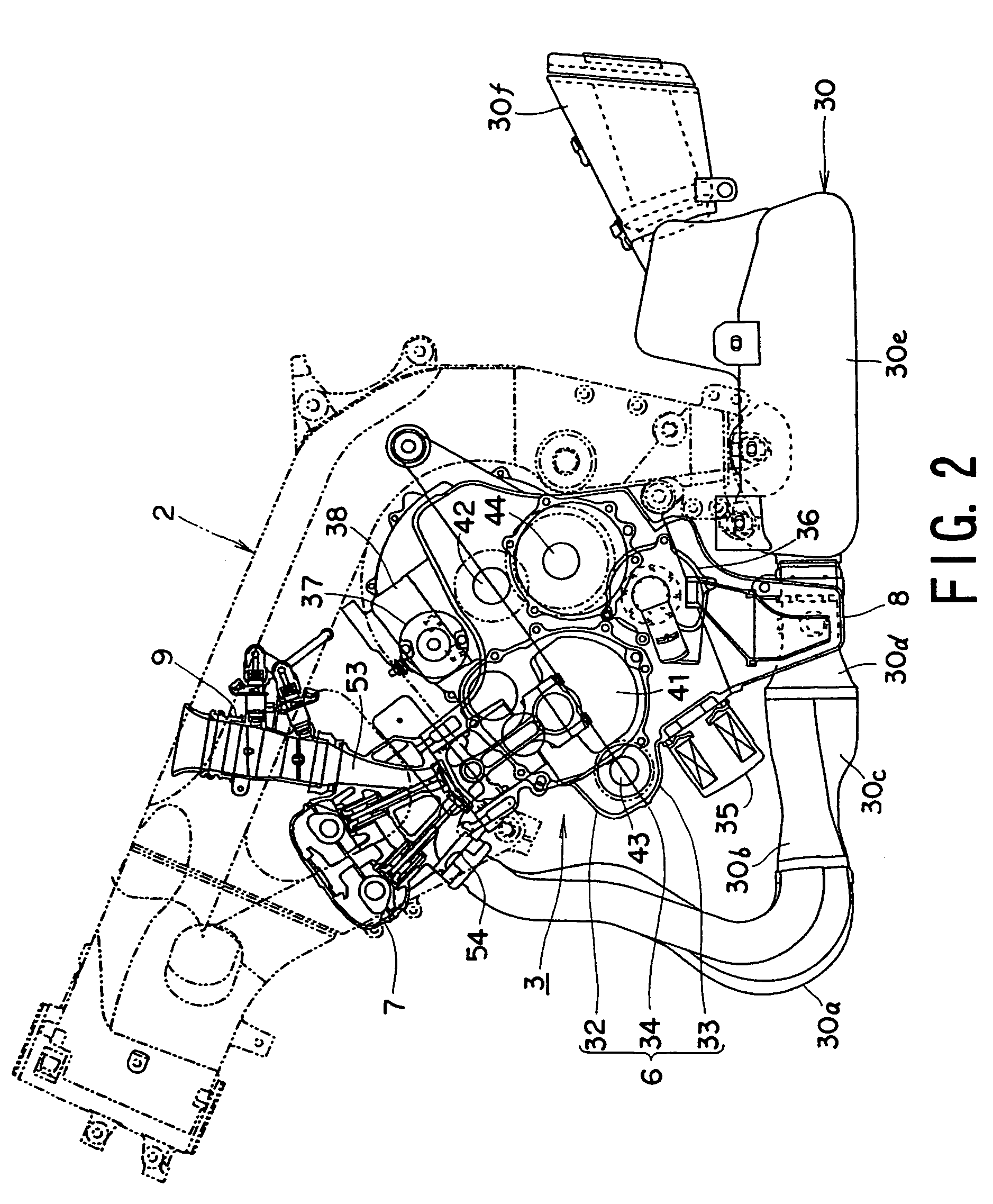

Engine for motorcycle

ActiveUS7353792B2Improving and enhancing workabilityCompact structureCasingsInertia force compensationMechanical engineeringCrankshaft

An engine for a motorcycle includes an engine case split in an upper case section and a lower case section. A mating surface between the upper case section and the lower case section extends linearly and inclines forward downward in a side view of the motorcycle. A crankshaft, a transmission input shaft, and a balancer shaft extending in the width direction of the motorcycle are rotatably supported at the mating surface, and a transmission output shaft rotated by the transmission input shaft is supported in the lower case section. The balancer shaft, the crankshaft, and the transmission input shaft are arranged in that order from the front side in the running direction of the motorcycle. The transmission output shaft is disposed below the transmission input shaft.

Owner:SUZUKI MOTOR CORP

Engine for motorcycle

ActiveUS20070068296A1Improving and enhancing workabilityCompact structureInertia force compensationToothed gearingsEngineeringMechanical engineering

An engine for a motorcycle includes an engine case split in an upper case section and a lower case section. A mating surface between the upper case section and the lower case section extends linearly and inclines forward downward in a side view of the motorcycle. A crankshaft, a transmission input shaft, and a balancer shaft extending in the width direction of the motorcycle are rotatably supported at the mating surface, and a transmission output shaft rotated by the transmission input shaft is supported in the lower case section. The balancer shaft, the crankshaft, and the transmission input shaft are arranged in that order from the front side in the running direction of the motorcycle. The transmission output shaft is disposed below the transmission input shaft.

Owner:SUZUKI MOTOR CORP

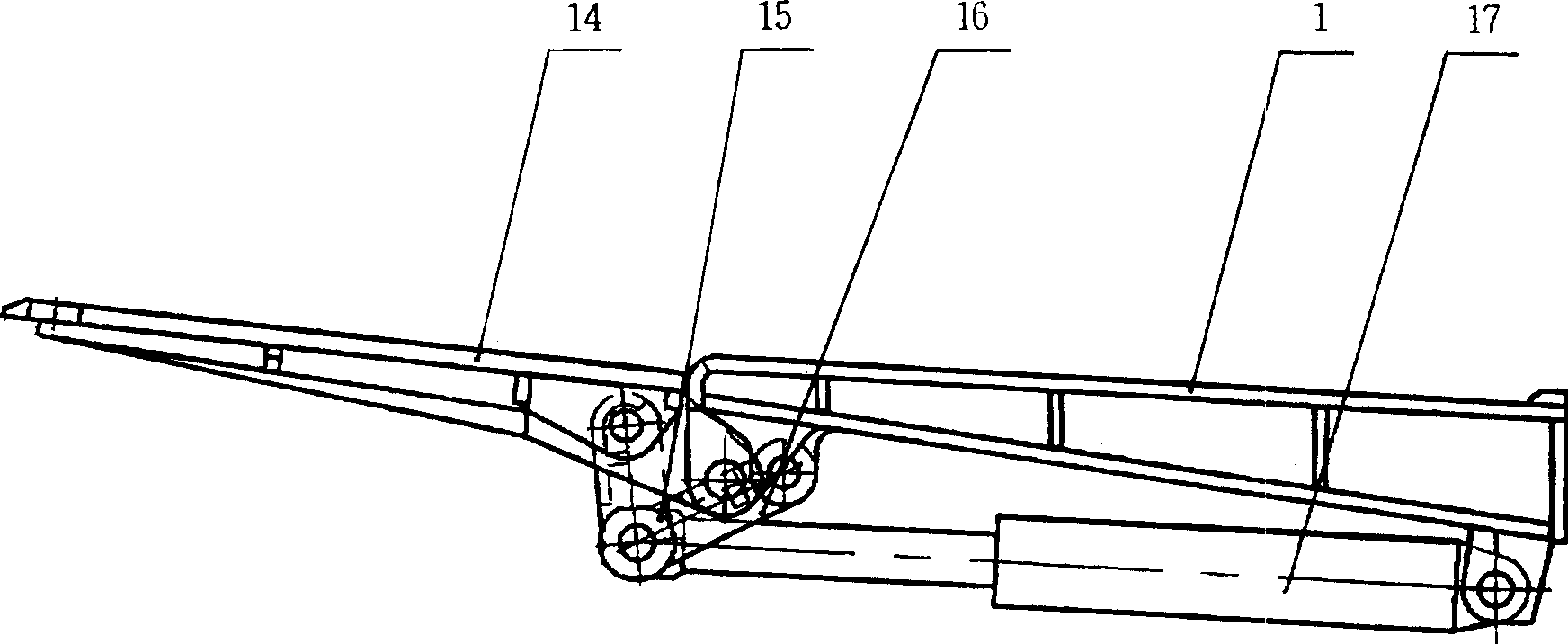

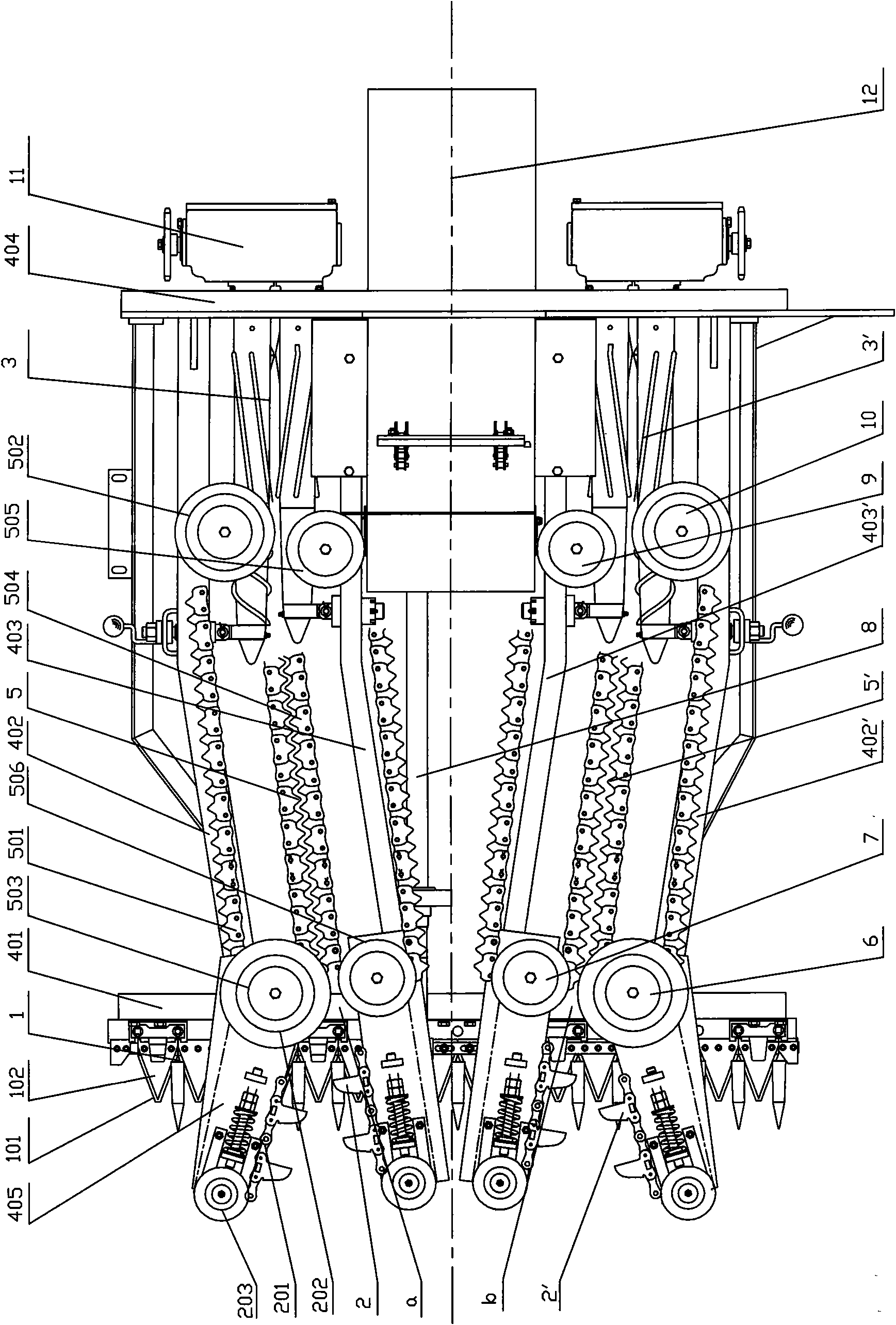

Harvesting unit body of small row spacing corn harvesting machine

The invention relates to a harvesting unit body of a small row spacing corn harvesting machine, which comprises a plurality of groups of harvesting bodies and a straw cutter arranged on a header mounting bracket, wherein each group of the harvesting bodies comprises a pair of picking rolls, a pair of reeling devices arranged at the front end of the header mounting bracket, and a straw gripping conveyer arranged on the header mounting bracket between reeling outputs of each pair of the reeling devices and guide ends of the picking rolls. The harvesting unit body is characterized in that a bracket body of the header mounting bracket which is between the reeling outputs of each pair of the reeling devices of two adjacent groups of the harvesting bodies and the guide ends of the picking rollsand is provided with the straw gripping conveyer takes a symmetrical central line of the picking rolls of the two adjacent harvesting bodies as a reference to symmetrically tilt towards the central line, the center distance of two gripping input ends of adjacent straw gripping conveyers is kept between 350 and 450 millimeters, and two gripping output ends of the adjacent straw gripping conveyers correspond to the guide ends of the picking rolls respectively. The harvesting unit body of the small row spacing corn harvesting machine has the advantages of compact structure, low cost, reliable useand strong adaptability, and is suitable for harvesting small raw spacing corns.

Owner:山东威泰重工科技有限公司

Power unit with auxiliary machine driving transmission mechanism

InactiveUS20070082774A1Reduce vibrationWithout deterioration in working efficiencyValve drivesGearingDrive shaftCrankcase

In a power unit, a counter shaft of a transmission and a crank shaft of an internal combustion engine, both located below a main shaft of the transmission, are arranged parallel to each other on a separating plane H of a crankcase. In a transmission mechanism T which drives an oil pump located below the separating plane H, a drive sprocket is placed on the main shaft of the transmission and a driven sprocket is placed on a drive shaft of the oil pump. An endless chain slidably touches a slender long chain guide along the running direction of the endless chain. The chain guide is fitted only to an end wall of an upper crankcase at its fitting part. The chain guide stretches across the end wall of the upper crankcase and an end wall of a lower crankcase, and effectively suppresses vibration of the endless chain.

Owner:HONDA MOTOR CO LTD

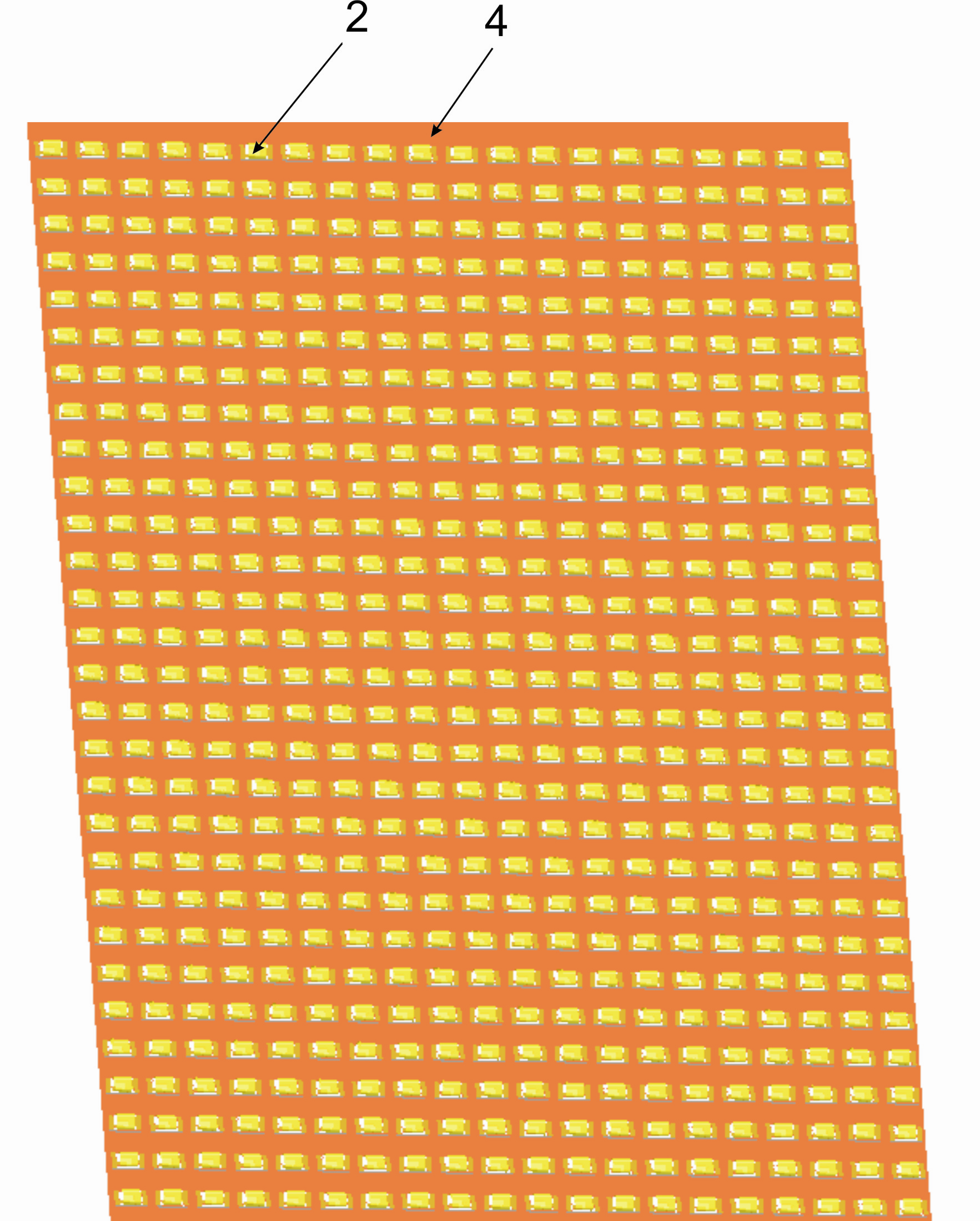

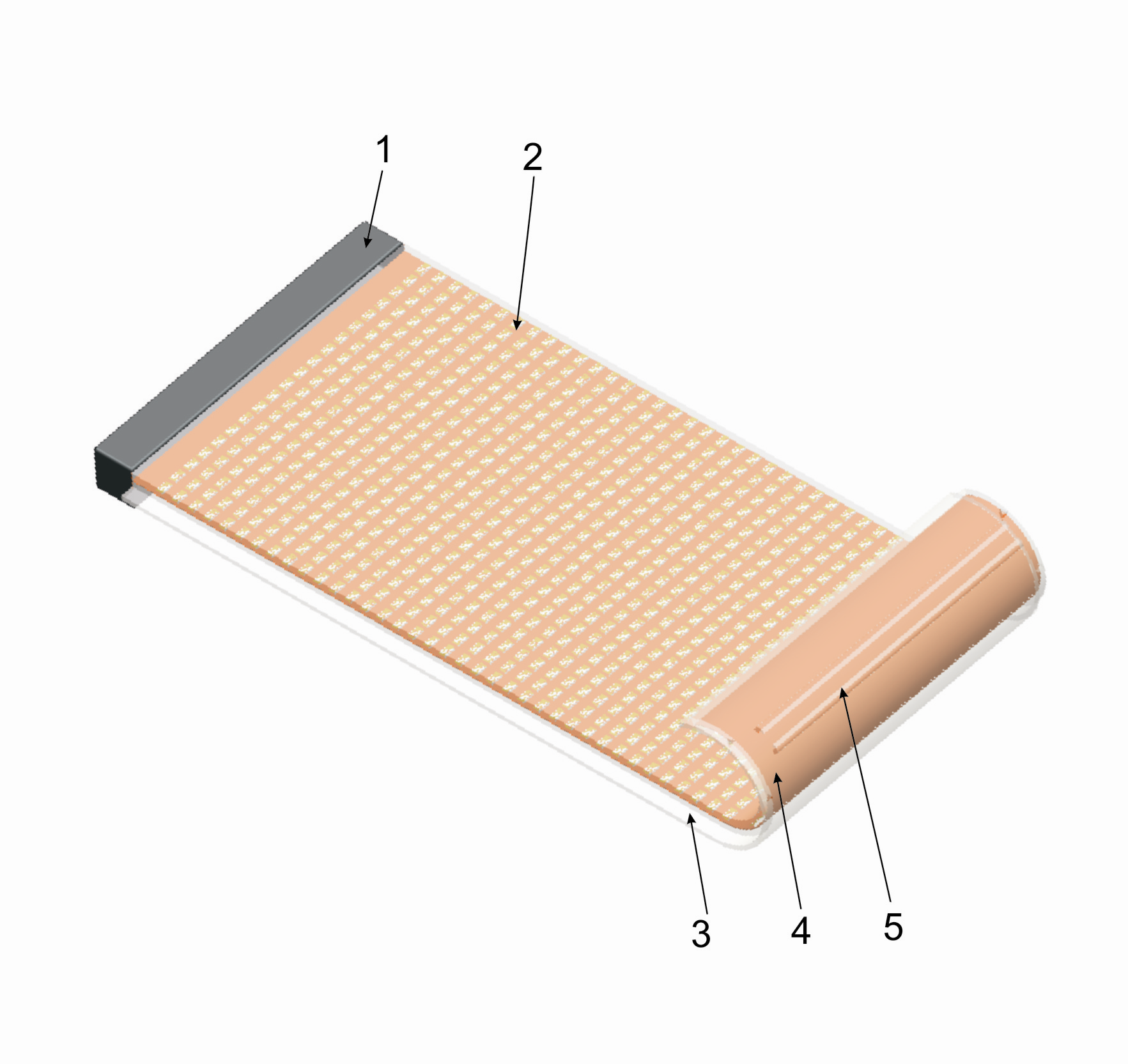

Lift-type soft light emitting diode (LED) display screen

InactiveCN102194383AReduce the center distanceIncrease display pixelsIdentification meansEngineeringLight-emitting diode

The invention relates to a lift-type soft light emitting diode (LED) display screen, which is provided with a fixed mechanism, a lift mechanism and a package mechanism; at the two sides of an LED soft lamp belt, one side is shaped like a male buckle (2), the other side is shaped like a female buckle (3), and the male buckle (2) corresponds to the female buckle (3). When two or more LED soft lamp belts are connected in parallel, the female buckle (3) of one of the lamp belts is locked with the male buckle (2) of another lamp belt to form the quadrate soft screen (5).

Owner:王伟

Silicon wafer wire cutting machine

ActiveCN106863630AImprove pass rateReduce the center distanceWorking accessoriesFine working devicesWire cuttingElectric machinery

The invention discloses a silicon wafer wire cutting machine which comprises a cutting head, a feeding table, a feeding table fixing frame, a wire winding and unwinding tool, a wire drum chamber and a main motor. The feeding table is fixed to the feeding table fixing frame. The cutting head is located below the feeding table. The wire winding and unwinding tool is arranged on one side of the cutting head, and a wire drum chamber is arranged on the other side of the feeding table fixing frame. Mortar nozzles are arranged on the two sides of a cutting guiding wheel, after boxes are fully filled with mortar, the mortar flows out at a constant speed, impact force on the silicon wafer is small, and the mortar on the two sides can be evenly distributed on a wire net. According to the cutting head of the silicon wafer wire cutting machine, the central distance between mounting holes is smaller, the wire net is smaller, stability is higher, wires are not prone to breaking, cutting quality is higher, and production efficiency and the silicon wafer percent of pass are increased.

Owner:无锡展照精密机械科技有限公司

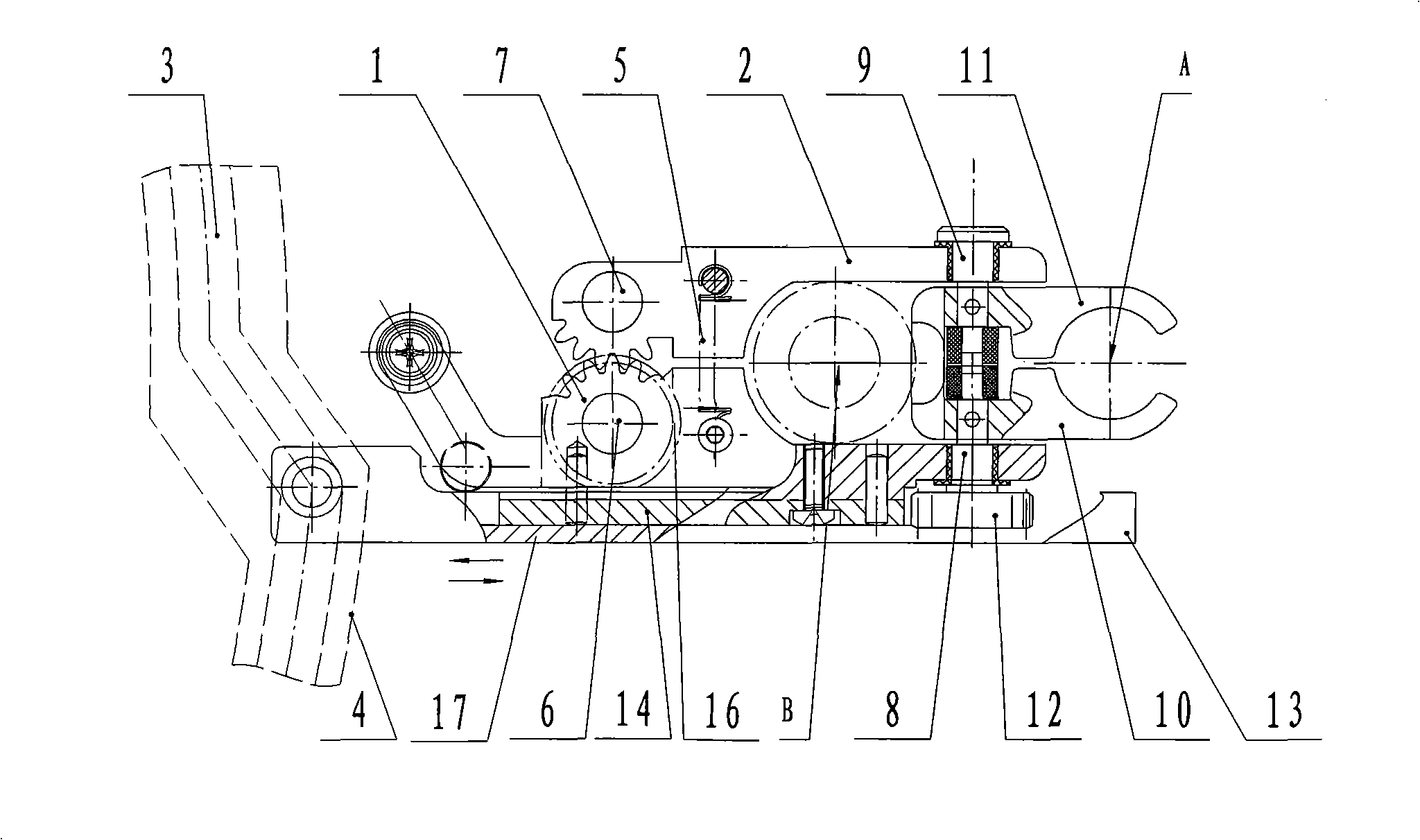

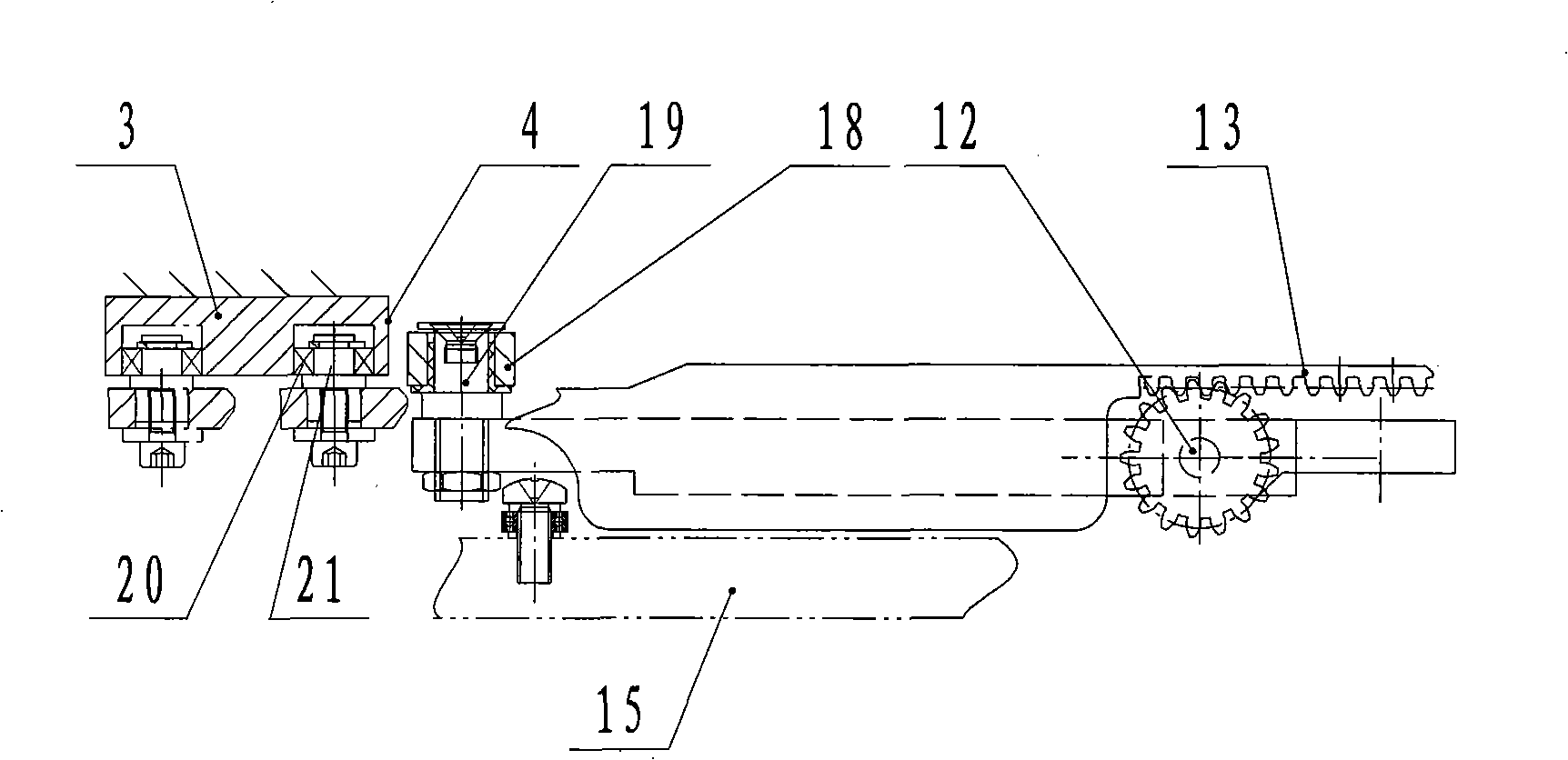

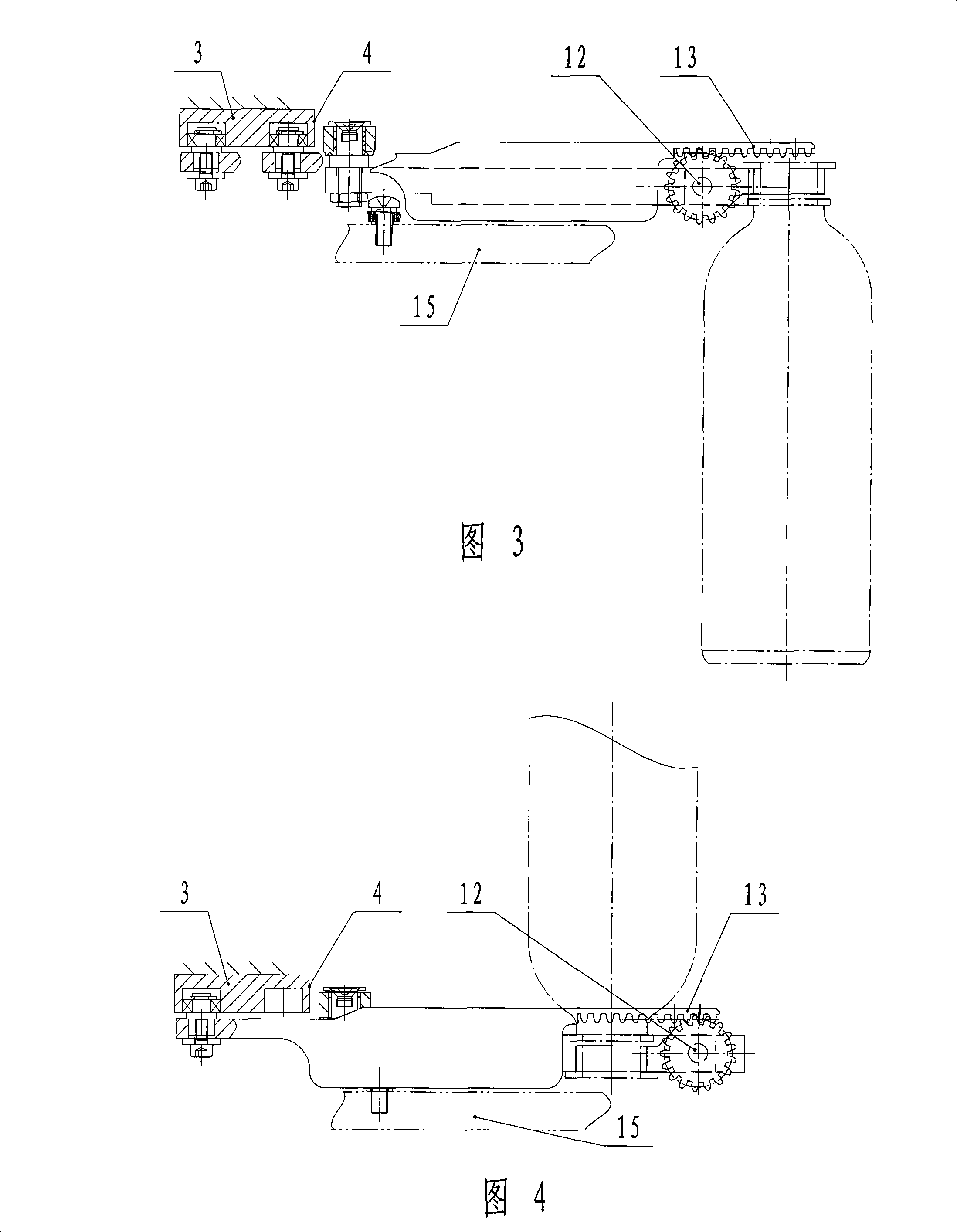

Roll-over type mechanical arm

InactiveCN101342698ACompact structureReasonable structureProgramme-controlled manipulatorGear wheelEngineering

The present invention relates to an overturn type manipulator which comprises a driving arm, a driven arm, an overturn control cam, a clamp control cam, a clamp spring, a left jaw and a right jaw. The driving arm is fixed at a turnplate by a driving arm shaft. The driven arm is fixed at the turnplate by a driven arm shaft. One end of the driving arm is equipped with the left jaw by a left jaw rotating shaft. The other end of the driving arm is connected with one end of the driven arm by a gear pair. The other end of the driven arm is equipped with the right jaw by a right jaw rotating shaft. The left jaw rotating shaft is connected with an overturn transmission mechanism which is used for controlling the left jaw rotating shaft to rotate. The overturn transmission mechanism is contacted and matched with the overturn control cam. The present invention provides an overturn type manipulator which has simple and compact structure and low manufacturing cost, occupies small space and works stably and reliably.

Owner:TRUKING TECH LTD

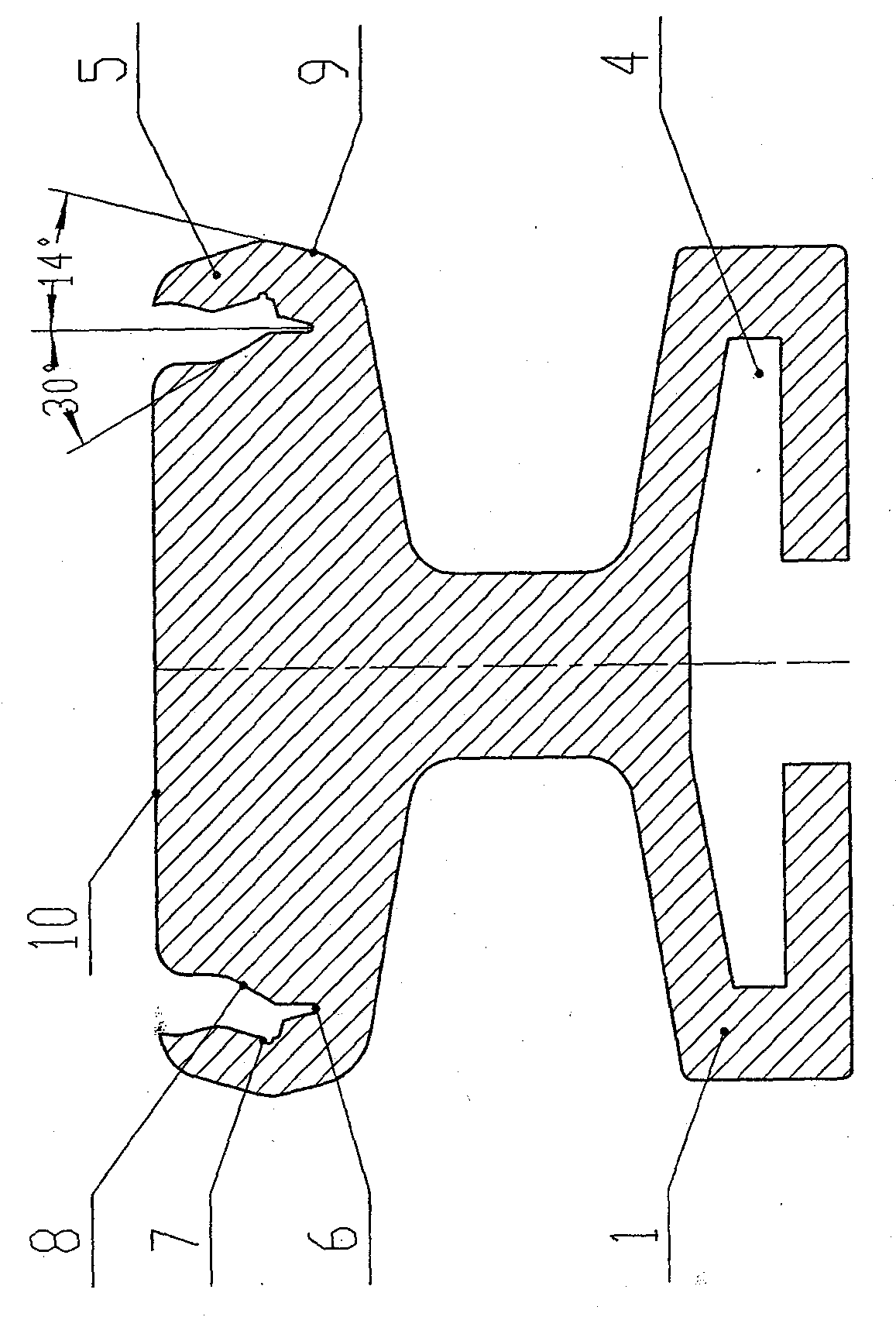

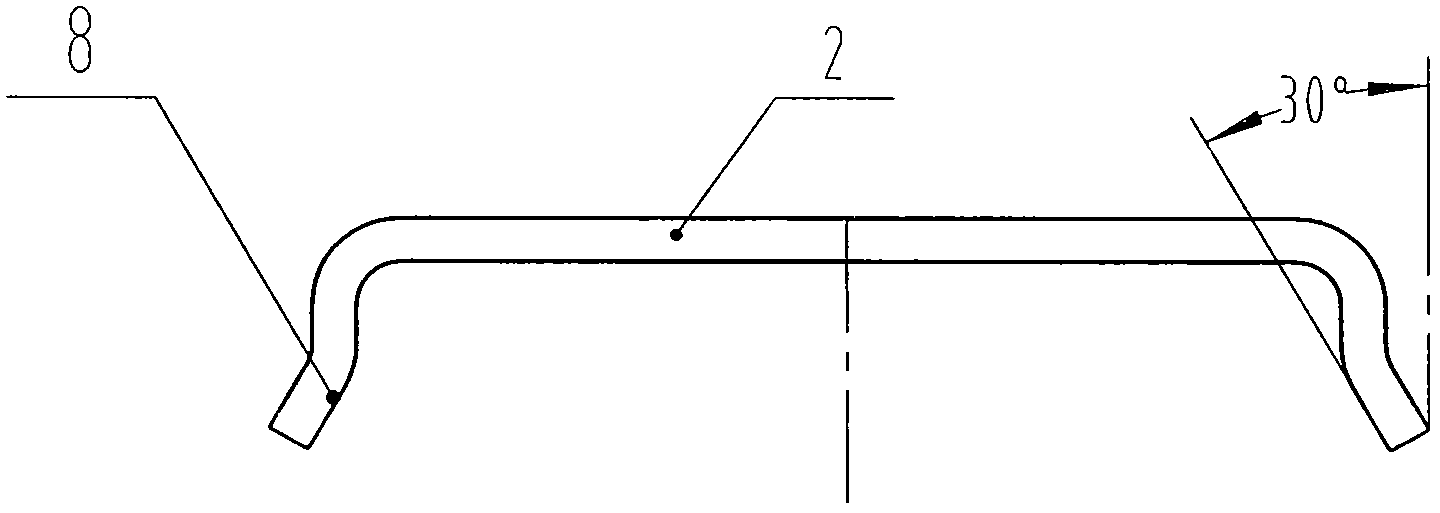

Steel and aluminum composite conductor rail with dovetail groove

The invention relates to a steel and aluminum composite conductor rail with a dovetail groove and belongs to equipment for urban mass transit. The steel and aluminum composite conductor rail with the dovetail groove is characterized in that the dovetail groove (4) is formed in the left side of an aluminum rail body (1), inward inclined faces (8) of 30 degrees are arranged on the upper side and the lower side of the top face (10) of the right side of the aluminum rail body (1), and two supporting lugs (5) on the outer side of the top of the aluminum rail body (1) are provided with groove bottoms (6) and middle ditches (7). A connecting plate (11) of a middle connector is provided with a dovetail-shaped top (12) which can be embedded in the dovetail groove (4). Two dovetail-shaped tops (19) of an insulation support (17) can be arranged on a straight flow positive electricity composite rail body (15) and a back flow negative electricity composite rail body (16) in a sleeved mode, and thus stainless steel contact faces of two steel and aluminum composite conductor rails are made to be located in the same vertical plane.

Owner:李雷

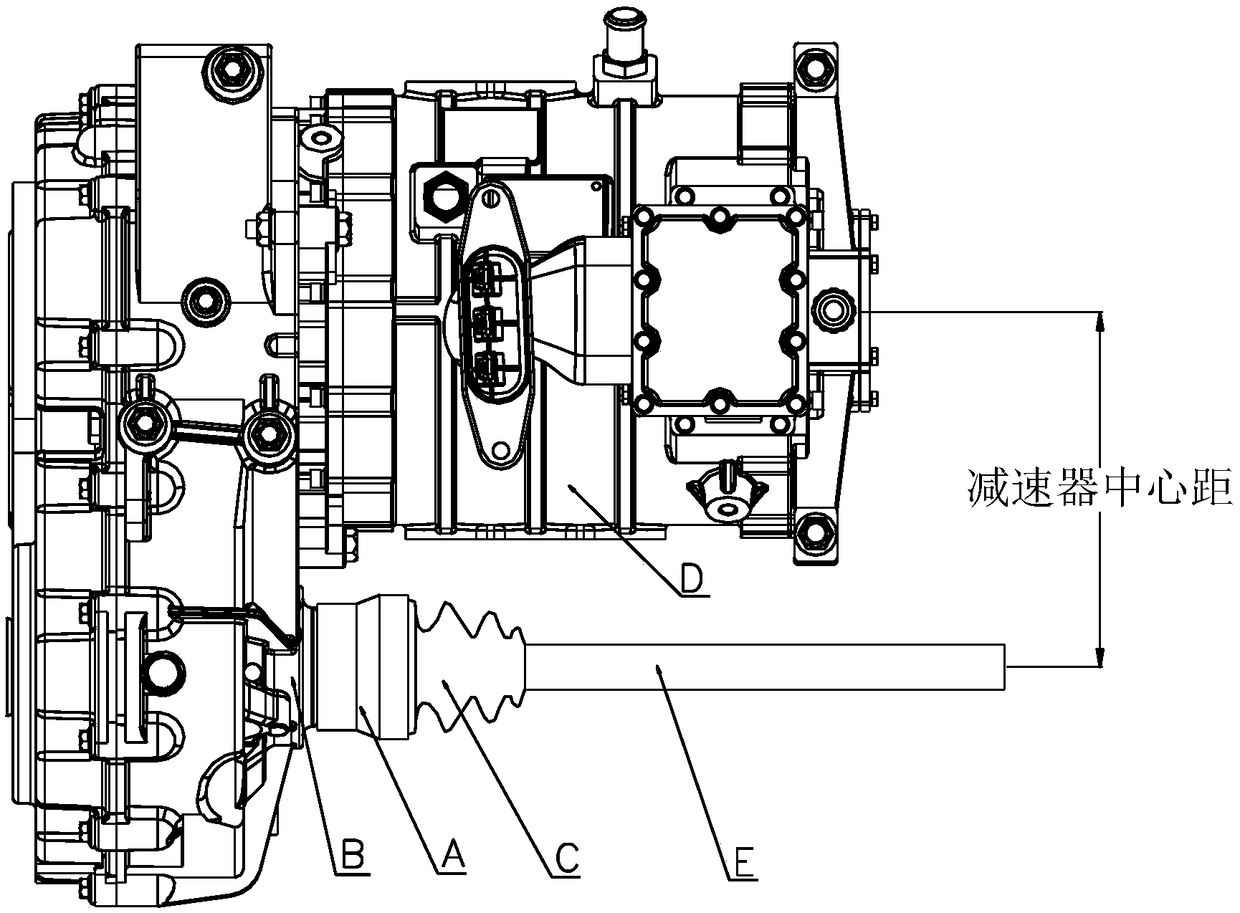

Three-in-one electric driving integrated system of new energy vehicle

InactiveCN109501564AReduce the center distanceReduce headroomElectric propulsion mountingControl devicesElectricityNew energy

The invention discloses a three-in-one electric driving integrated system of a new energy vehicle. The system comprises a half-shaft mechanism, a controller, a motor and a transmission box, wherein the motor is provided with an integrated housing and an integrated end cover; the two ends of the half-shaft mechanism are fixedly connected with the integrated housing and the integrated end cover; thetransmission box is connected with the integrated housing of the motor; the integrated housing, the integrated end cover and the half-shaft cooperatively surround to form an odd space; the controlleris installed in the odd zero space and fixed to the housing of the motor. The motor housing and the right end cover of the transmission box are designed into an integrated structure, the output half-shaft supporting frame and the motor housing rear end cover are designed into an integrated structure, a half-shaft cage is moved back to the outer side of the rear end cover of the motor, so that previous space which is preserved for preventing the moving interfering of the output half-shaft and the motor and the controller is omitted, and therefore the central spacing between the output half-shaft of the input half-shaft of the transmission box is reduced to the minimum through the designing.

Owner:HEFEI JUYI POWER SYST CO LTD

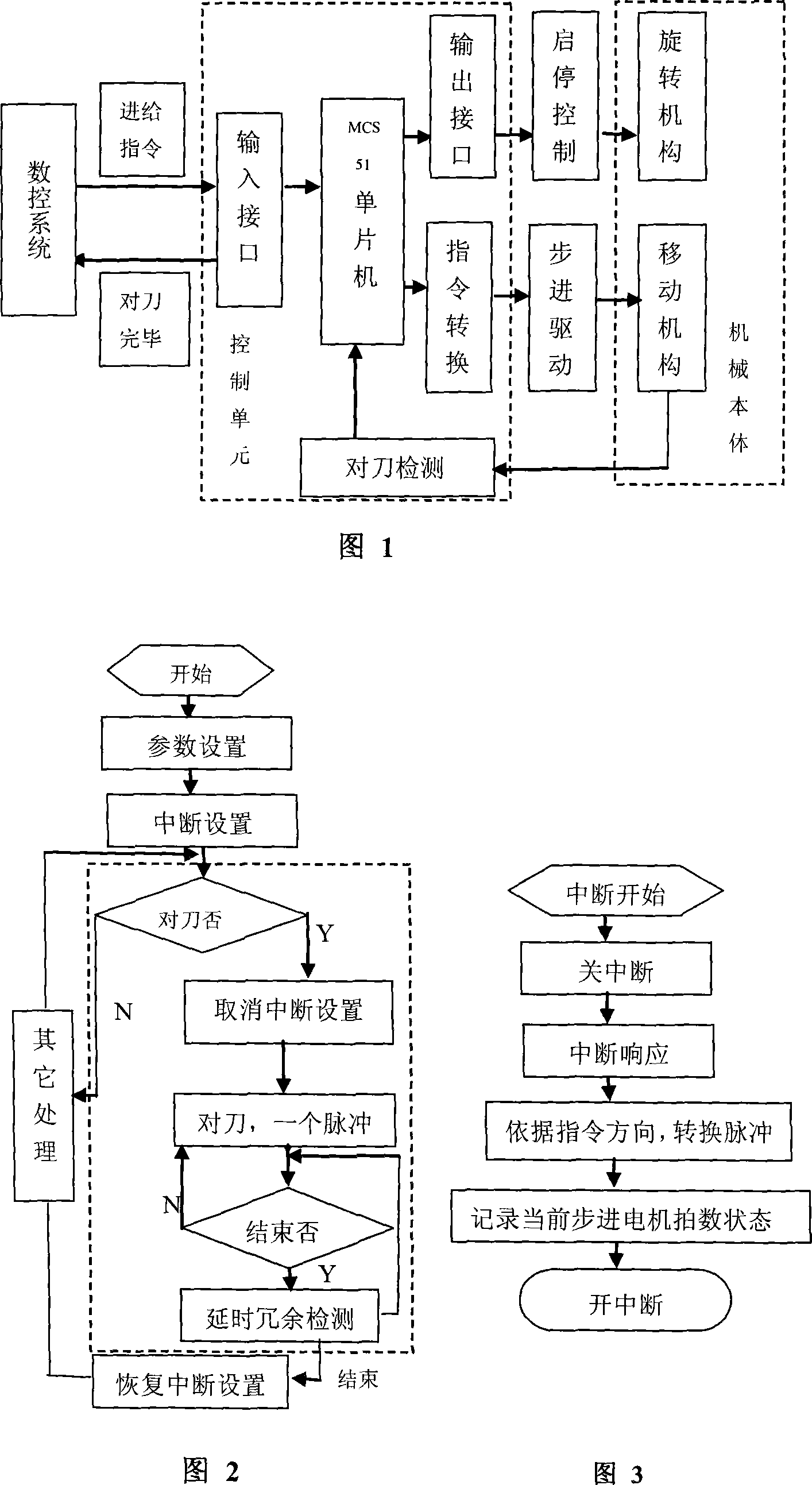

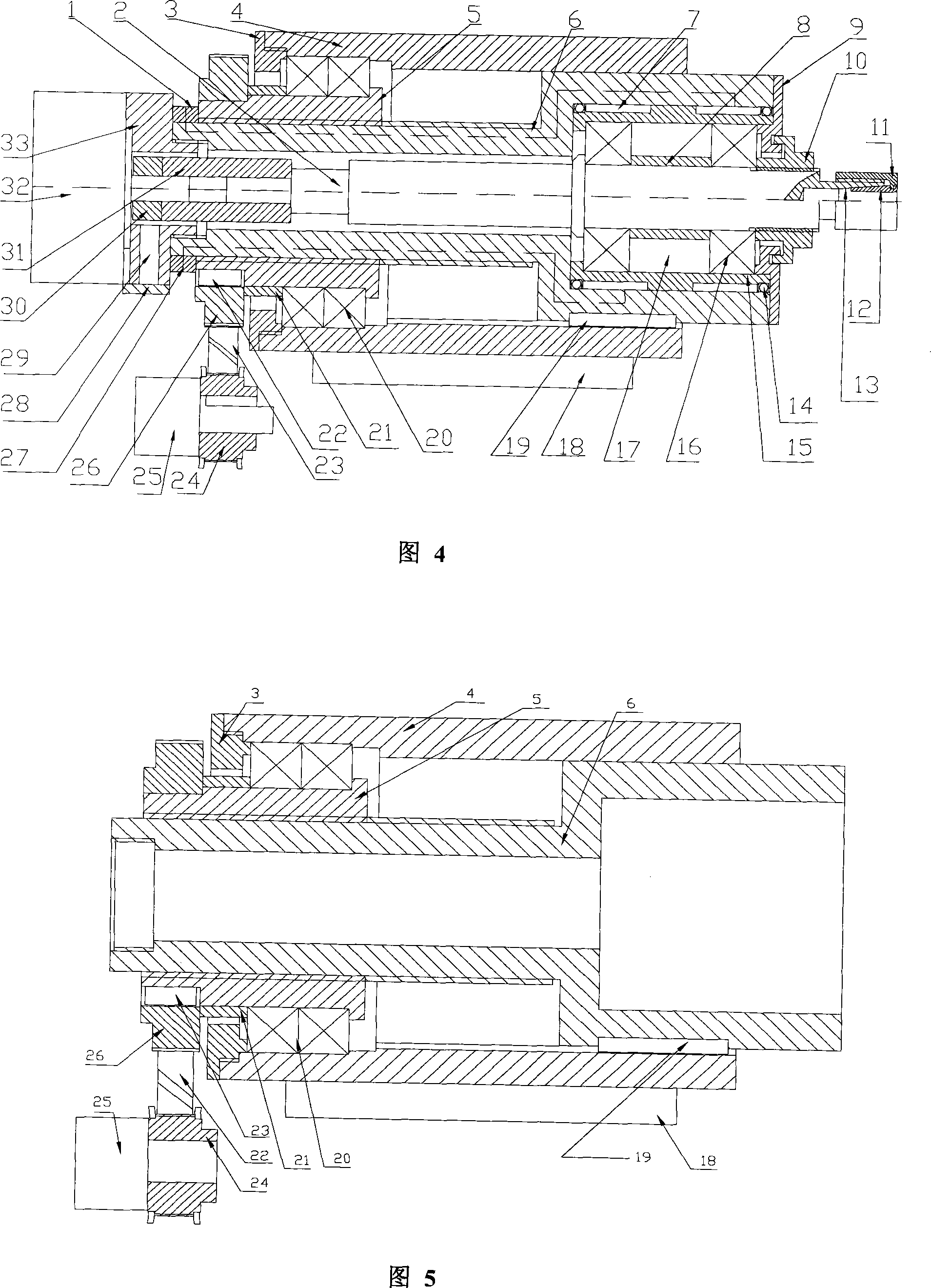

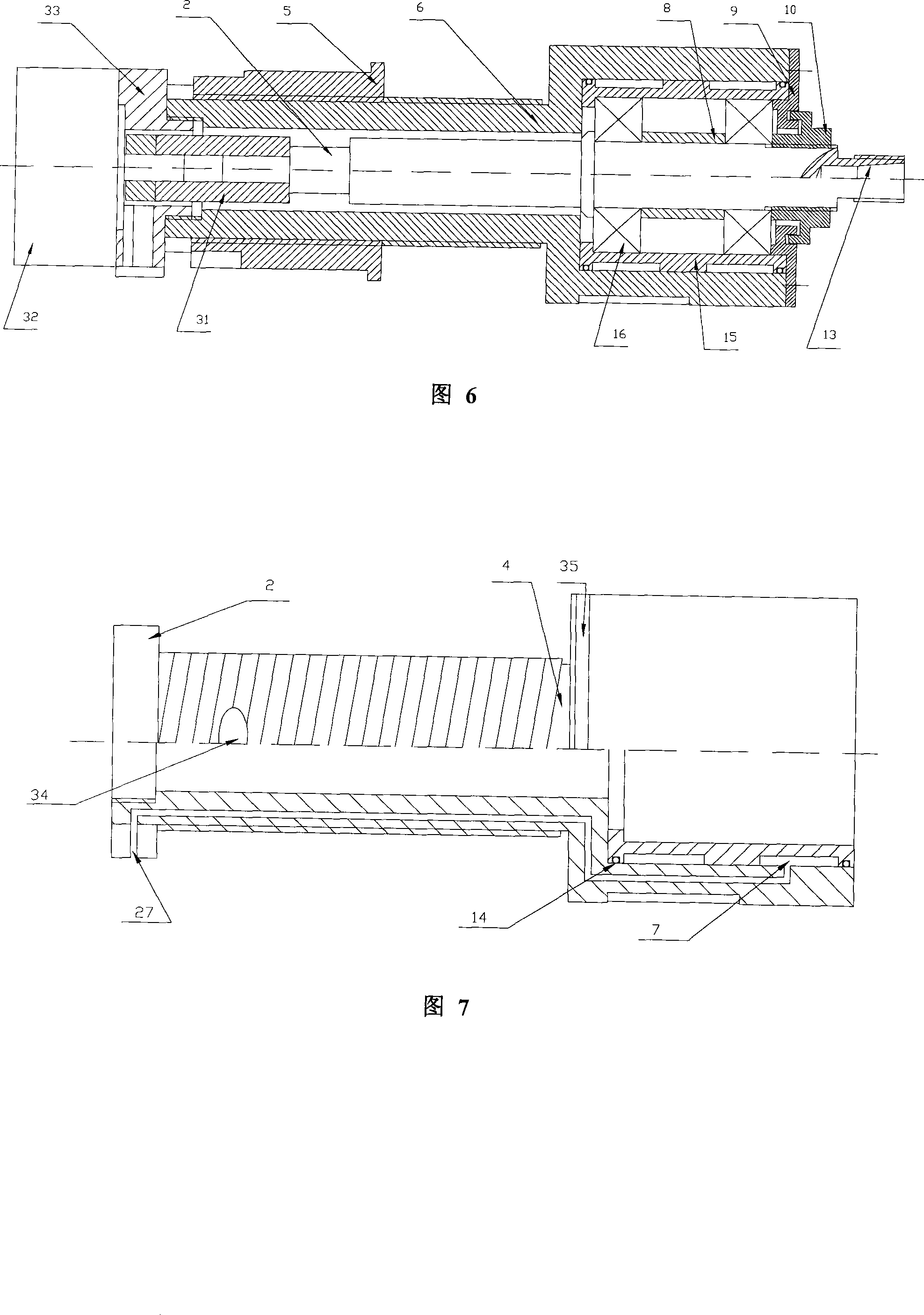

Carving head with feed motion

InactiveCN101234576AReduce the center distanceReduce difficultyAutomatic control devicesFeeding apparatusControl signalEngineering

The invention provides a carving head with feed movement, which consists of a carving head control system and an execution mechanical system, wherein, the carving head control system consists of a single chip system which depends on an electrical contact for tool setting; the execution mechanical system comprises the feed movement and a mechanism of high-speed rotating and cutting movement, which are integrated and realized in the manner of nesting. An input port of the single chip system receives signals of standard numerical control commands from a numerical control system; the signals are transformed into special control signals of a stepping motor after processed inside the single chip and then are outputted to the stepping motor through a command transforming interface, thereby realizing the separate control of feed movement of the carving head. Simultaneously, the tool setting process is realized by cycled detection of the signals of the electrical contact by the single chip system, and the numerical control system can be monitored in the whole process and can be removed at any time. The carving head with feed movement combines a movable feed mechanism and a principal axis with high-speed rotation in the manner of nesting, thereby decreasing the carving head size, overcoming the problem of limited space after the conventional principal axis is provided with a feed device, increasing the complete performance and production efficiency and guaranteeing the product quality.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

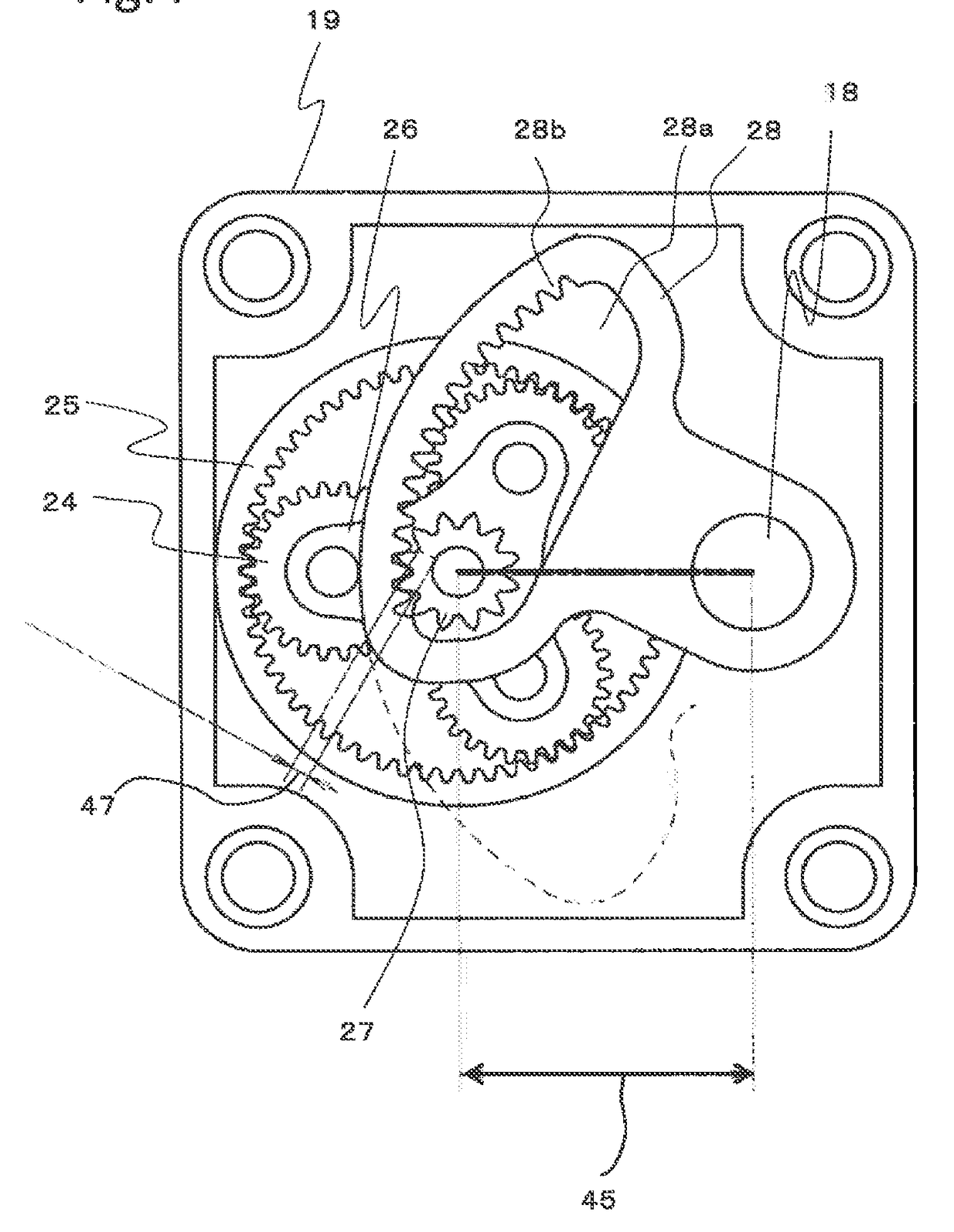

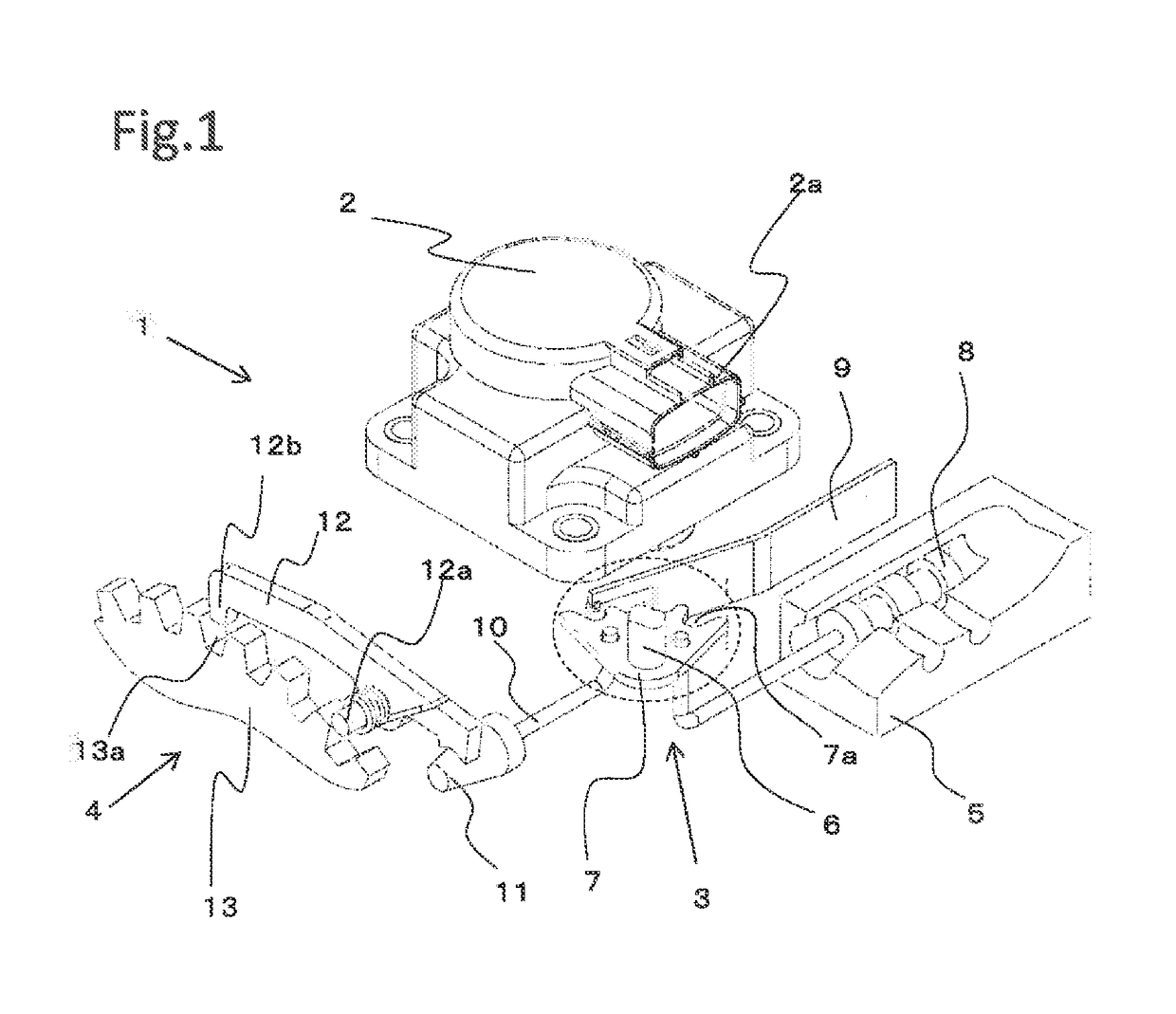

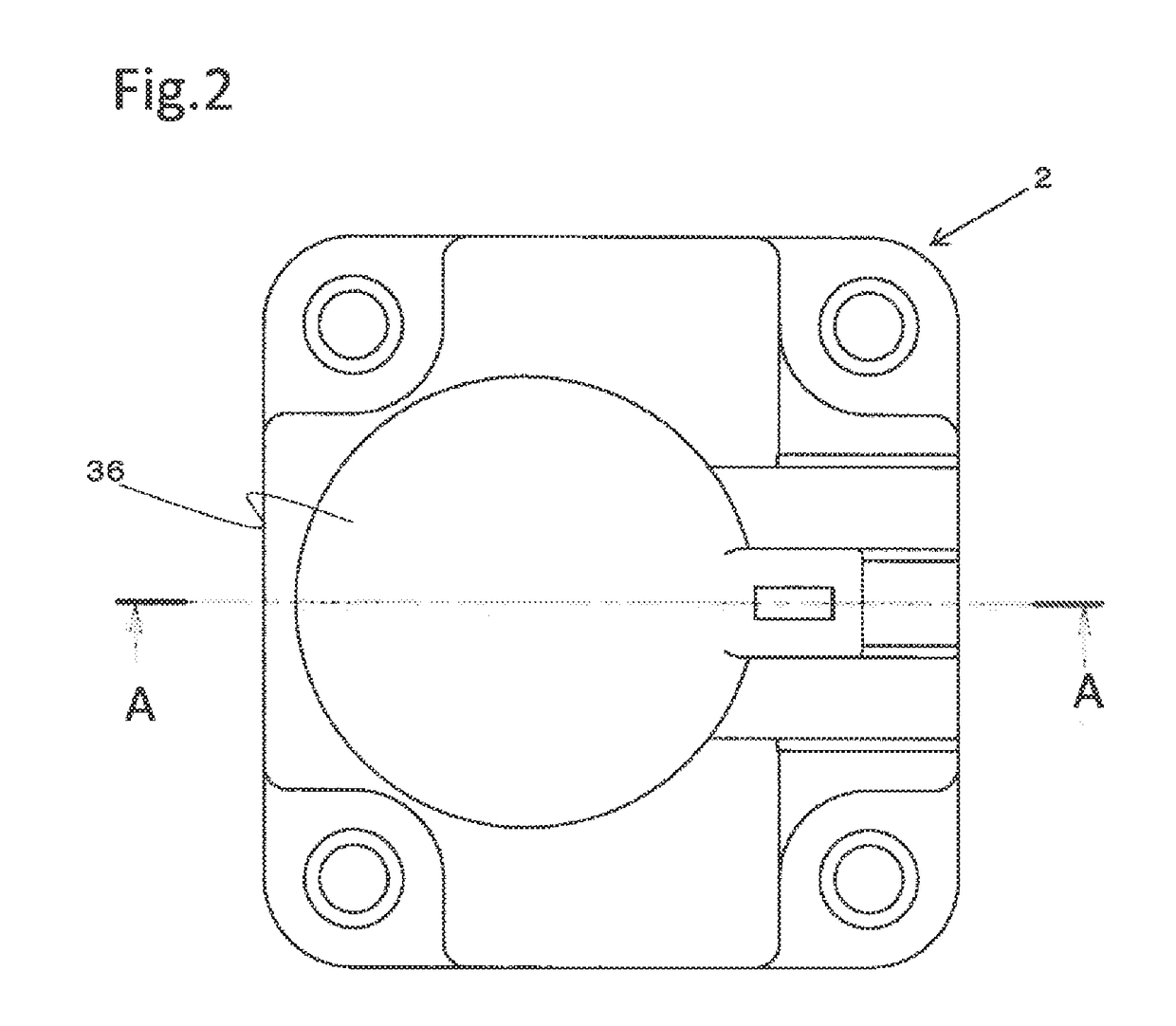

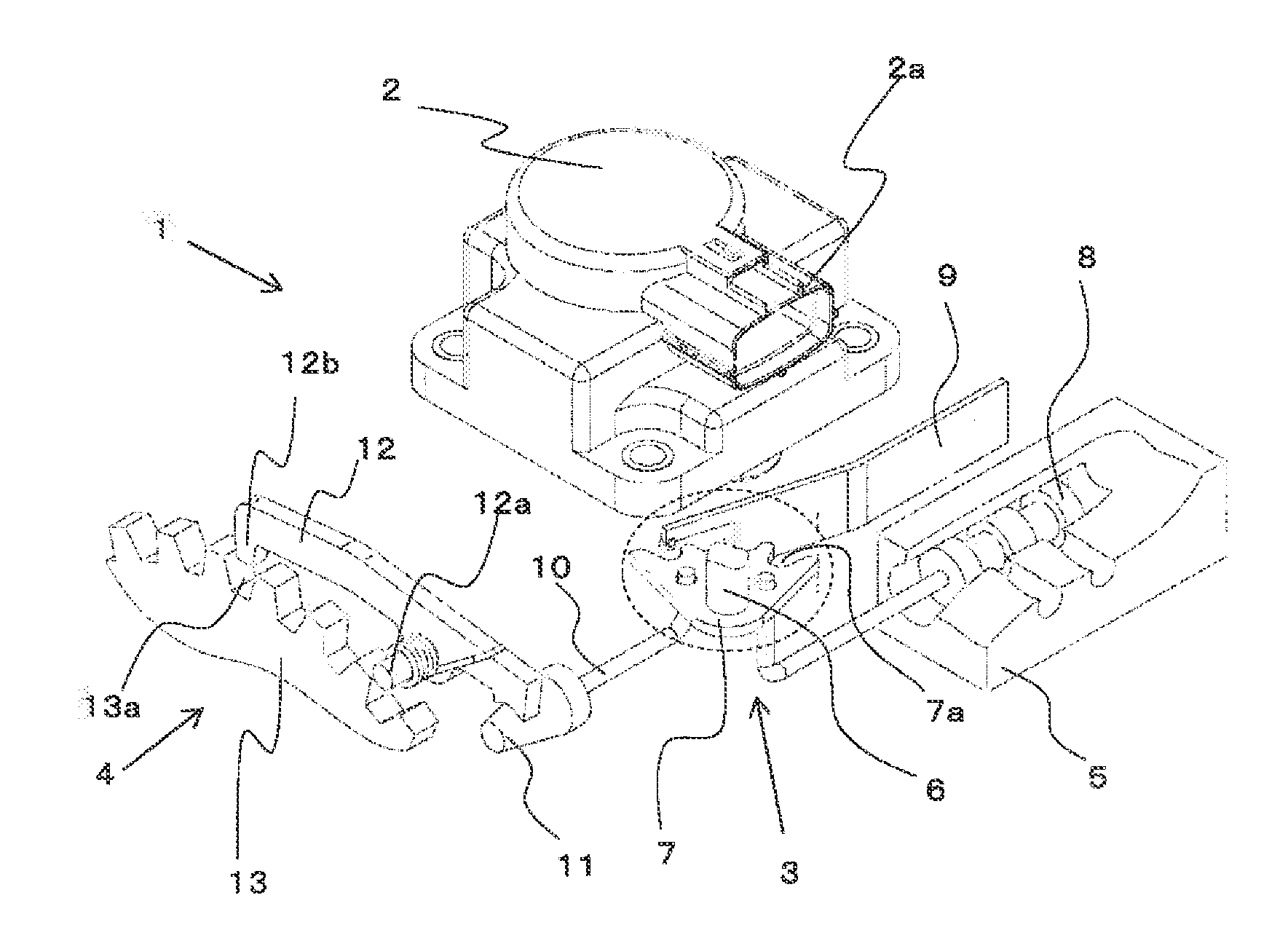

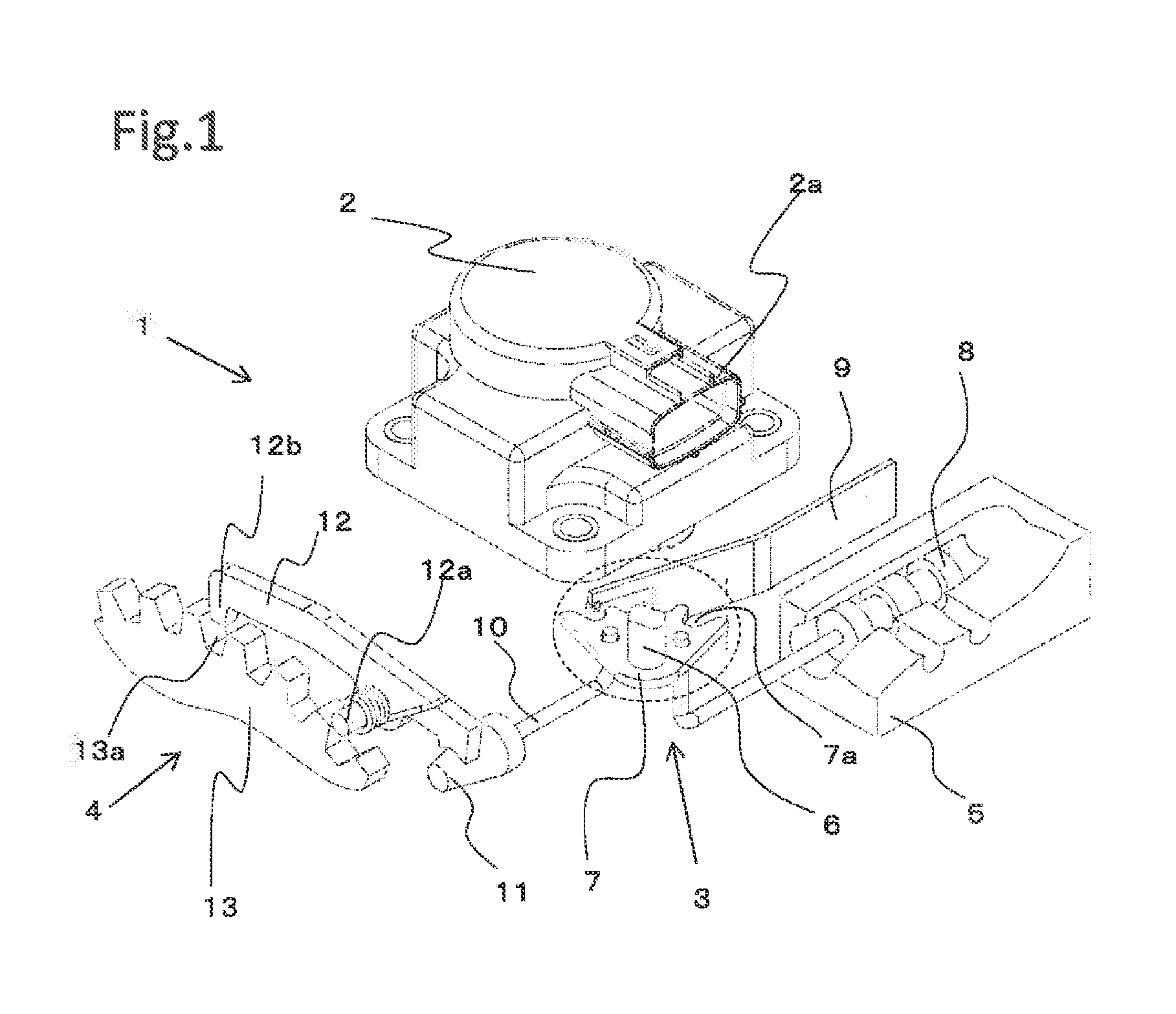

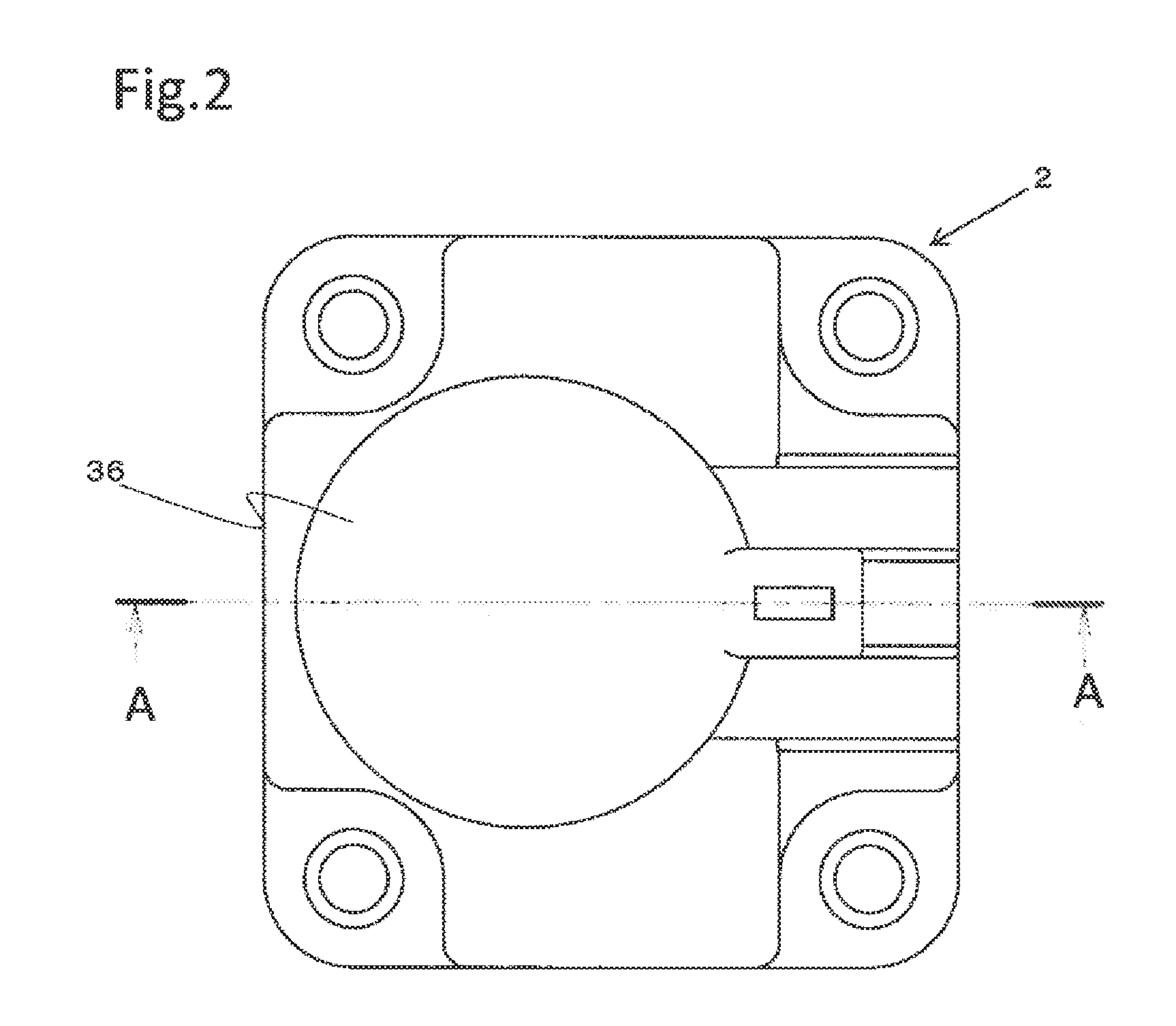

Range switching apparatus

InactiveUS9726281B2Suppressing increase in size of componentReduce component countGear lubrication/coolingToothed gearingsGear wheelEngineering

A compact and lightweight range switching apparatus is provided by suppressing the increase in the size of components in the range switching apparatus. The range switching apparatus includes: a motor mounted in a housing; a pinion placed on a shaft of the motor; a sector-shaped gear wheel having an opening inside which a gear engaging the pinion is formed; and an output shaft rotatably supporting the gear wheel in the housing.

Owner:MITSUBISHI ELECTRIC CORP

Worm gear and worm set with center distance adjustment and clearance elimination, brake and steering system

ActiveCN106838129AEliminate backlashSmooth transmissionToothed gearingsPhotovoltaic energy generationBrakeControl engineering

The invention relates to a worm gear and worm set with a center distance adjustment and a clearance elimination mechanism. The worm gear and worm set comprise a worm gear (4) and a worm(11) which are mutually engaged and also comprises a shell body (2), a first bearing (5), a second bearing (12), and a fastening bolt (9), wherein the shell body(2 covers the worm gear (4) and the worm (11); the two ends of the worm set(11) are respectively arranged inside of the shell(2) through the first bearing(5) and the second bearing(12); the fastening bolt(9) passes through the shell and the bottom of the fastening bolt is centered on the outer ring of the first bearing (5); a pressing force is applied along the radial direction of the first bearing (5) so that the worm gear (4) is attached to the worm set(11). Compared with the prior art, the worm gear and worm set can solves the problems that the transmission resistance and the transmission efficiency of the central distance machining error and the use of abrasion are not consistent. The worm gear and worm set has the advantages that the worm gear driving has stable characteristics and smooth transmission; noises are reduced and the maneuverability and comfort of the car are improved.

Owner:上海同驭汽车科技有限公司

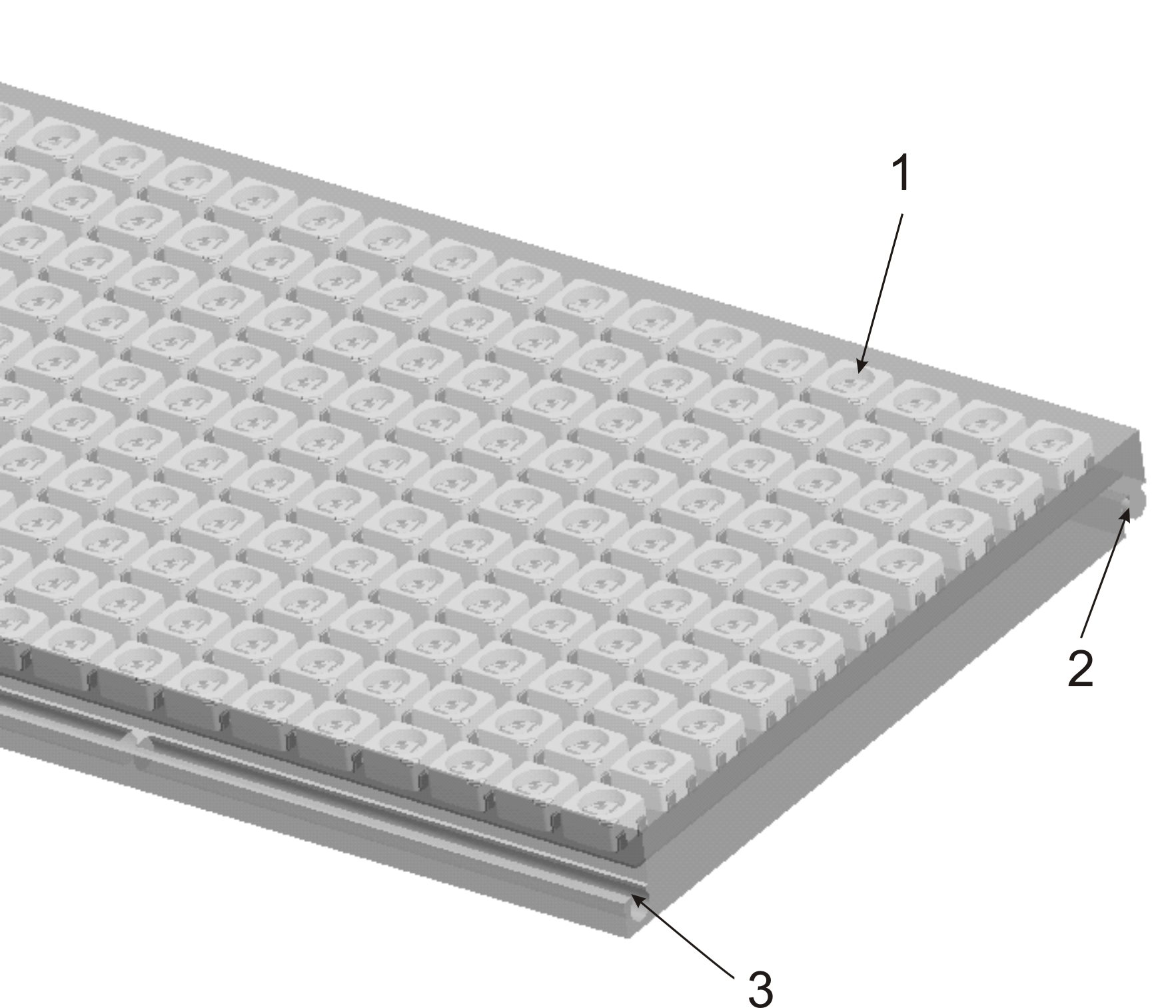

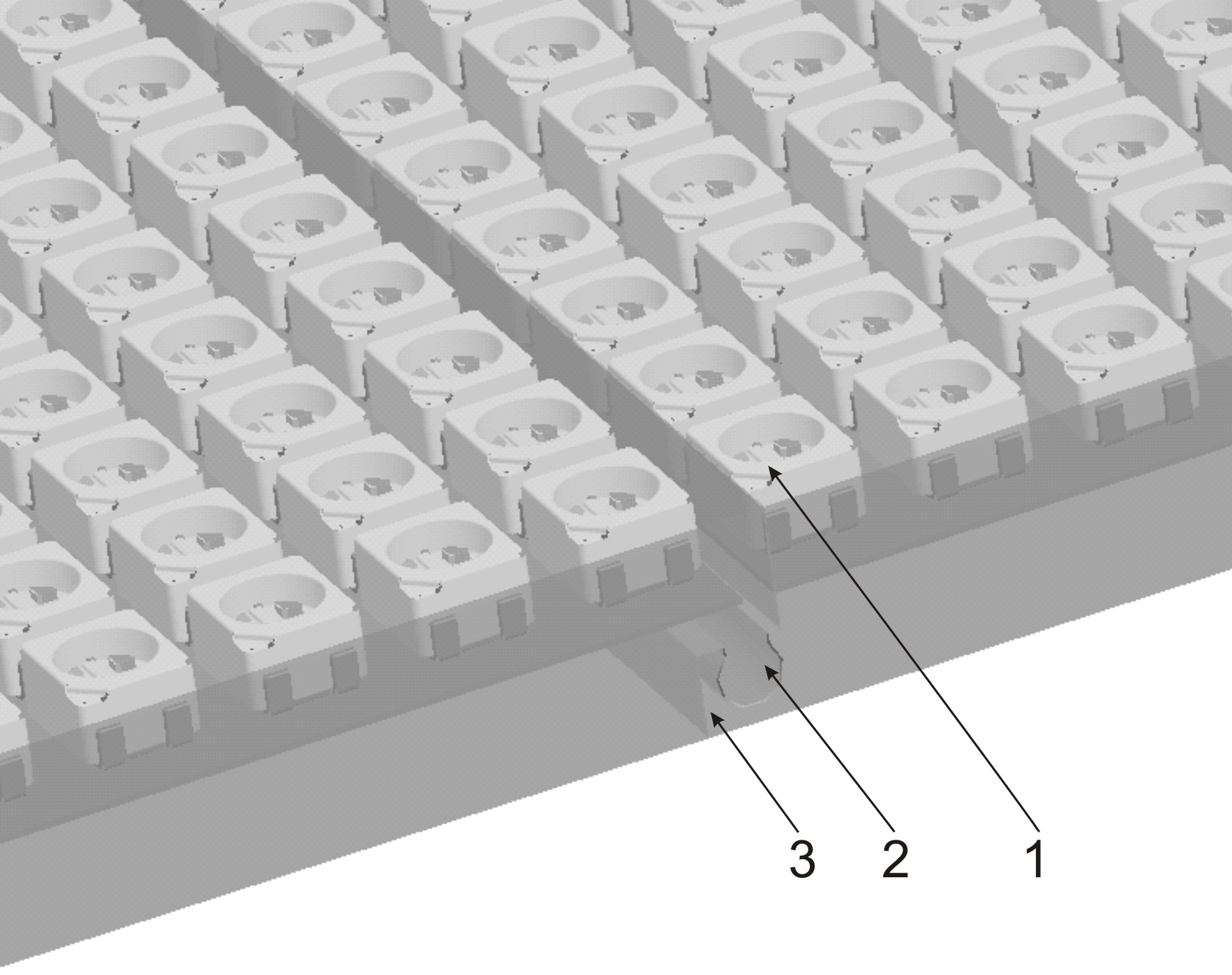

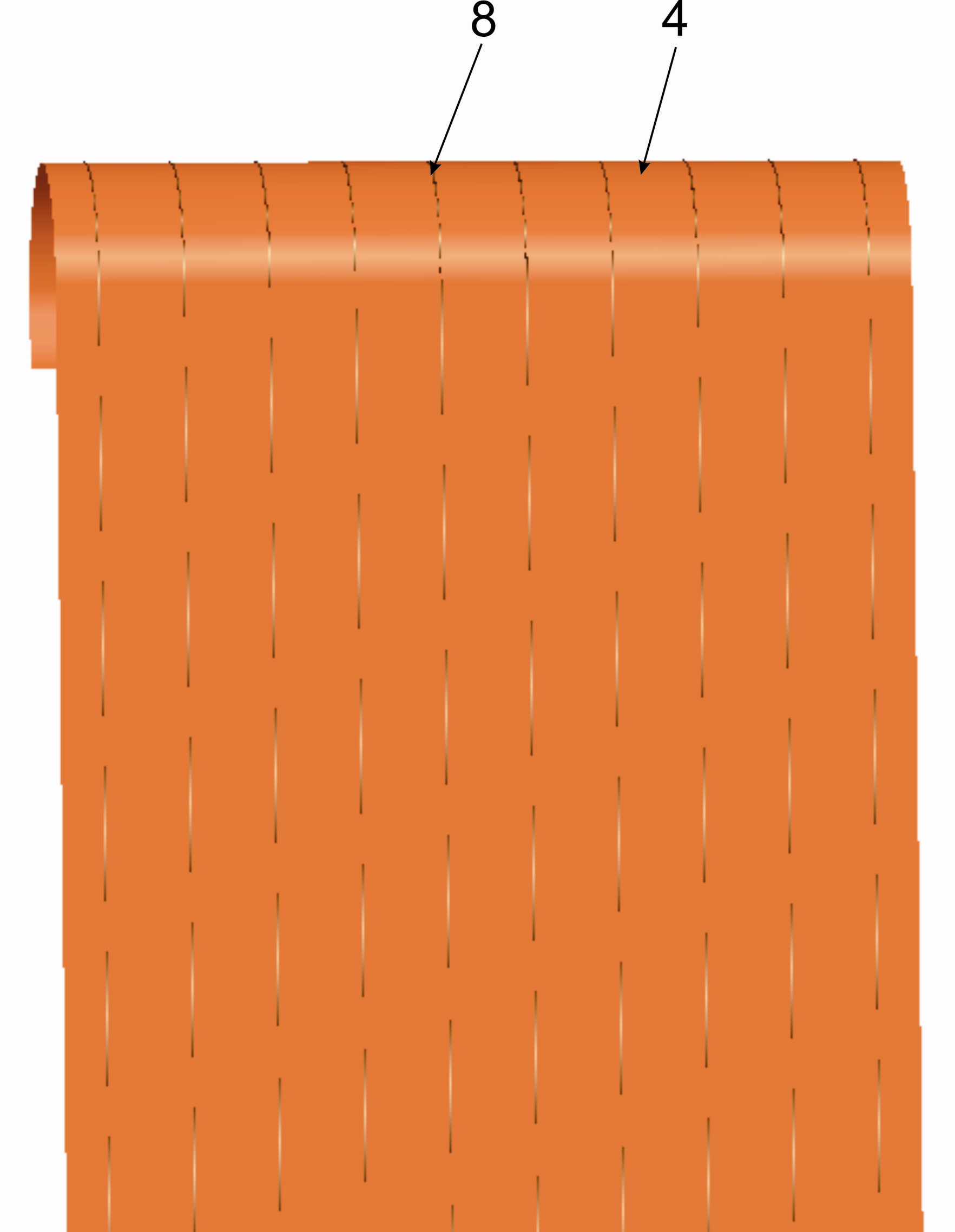

Surface mount type LED (light emitting diode) display screen

InactiveCN102074171AReduce the center distanceReduce weightPoint-like light sourceLight fasteningsLED displayHeat conducting

The utility model relates to a surface mount type LED (light emitting diode) display screen. LEDs (2) are attached to FPCs (flexible printed circuit) (4) in a surface mount manner, encapsulated with heat-conducting soft silica gel (3) and molded into unit modules. The unit modules of the surface mount type LED can be classified as independent type unit modules and combination type unit modules. Thin wires (8) are arranged on the FPCs on the backs of the independent type unit modules, and drivers (1) of the independent type unit modules are fixed at the top or bottom of the modules through bolts; and drivers of the combination type unit modules are designed to be of independent forms, the combination type unit modules are connected with the drivers through leading wires, and locking blocks (7) and locking holes (6) are arranged on the peripheries of the combination type unit modules. When two combination type unit modules are connected, the locking block (7) of one of the two unit modules is inserted into the locking hole (6) of the other unit module. T-shaped or mushroom-shaped fixing mechanisms (5) are arranged on the backs of the unit modules, so that when molding is requried, the fixing mechanisms (5) can be used for fixing the flexible LED display screen on a fixing bracket.

Owner:王伟

Range switching apparatus

InactiveUS20160131252A1Suppressing increase in size of componentReduce component countGear lubrication/coolingToothed gearingsGear wheelEngineering

A compact and lightweight range switching apparatus is provided by suppressing the increase in the size of components in the range switching apparatus. The range switching apparatus includes: a motor mounted in a housing; a pinion placed on a shaft of the motor; a sector-shaped gear wheel having an opening inside which a gear engaging the pinion is formed; and an output shaft rotatably supporting the gear wheel in the housing.

Owner:MITSUBISHI ELECTRIC CORP

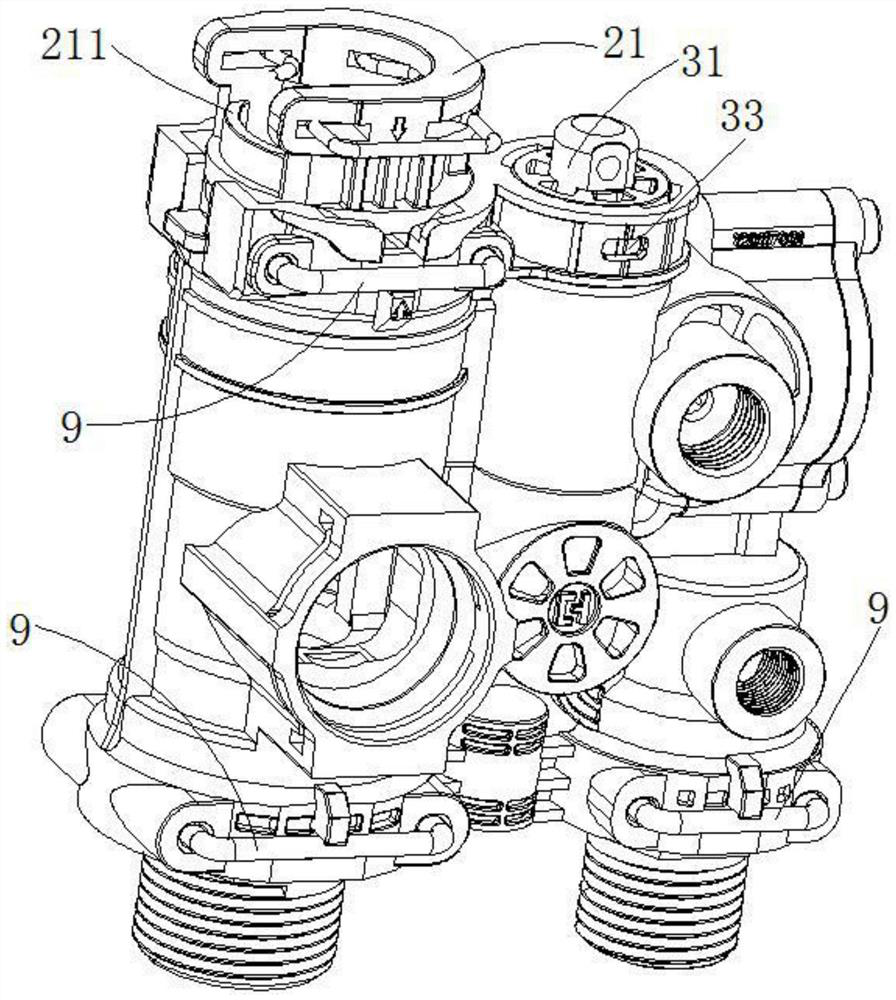

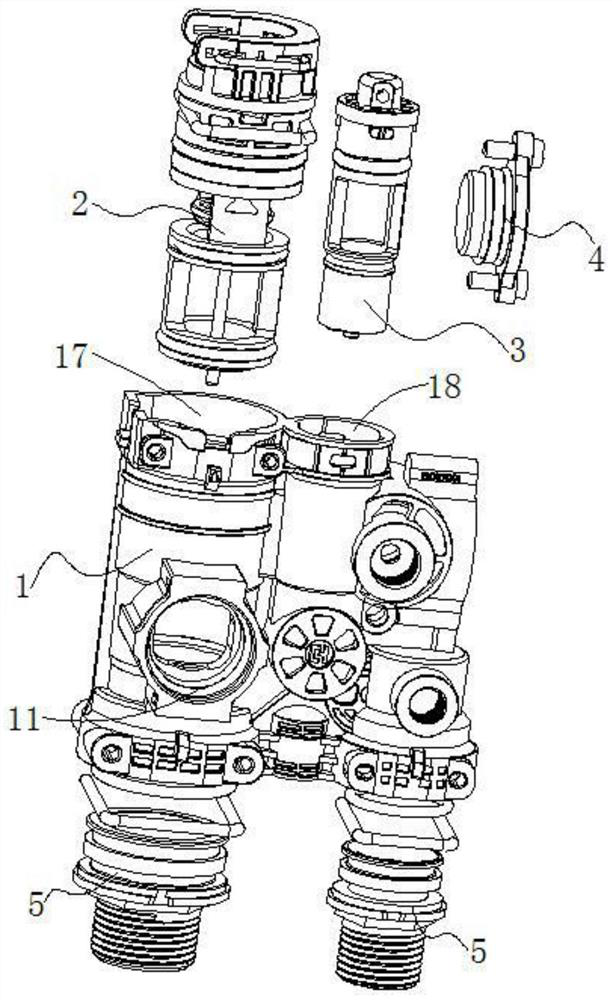

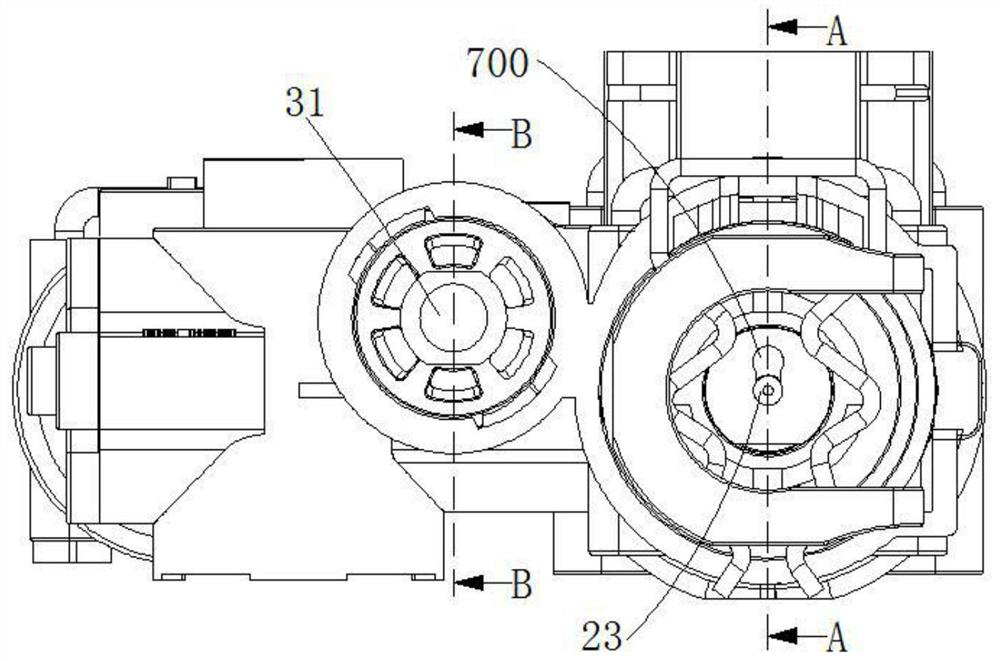

Self-locating high-sealing large-flow three-way valve

ActiveCN112483695ALower the altitudeFew partsSpindle sealingsOperating means/releasing devices for valvesPlastic materialsElectric machinery

The invention discloses a self-locating high-sealing large-flow three-way valve. The three-way valve comprises a shell, wherein the shell comprises a water inlet channel, a first water outlet channel,a second water outlet channel and a valve cavity, the first water outlet channel and the second water outlet channel communicates with the water inlet channel in a switching mode, a valve element ismounted in the valve cavity and comprises a motor base and a three-way framework, the shell, the motor base and the three-way framework are made of plastic materials, the lower end of the motor base extends downwards to form a motor base clamping head, a three-way framework clamping groove allowing the motor base clamping head to be mounted from the side face is formed in the upper end of the three-way framework, the motor base and the three-way framework are connected by inserting the motor base clamping head into the three-way framework clamping groove in a matched mode, and the motor base is connected with the shell through clamping screws. According to the three-way valve, self-locating during mounting can be conveniently realized through the motor base and the three-way framework.

Owner:ZHEJIANG CHUNHUI INTELLIGENT CONTROL

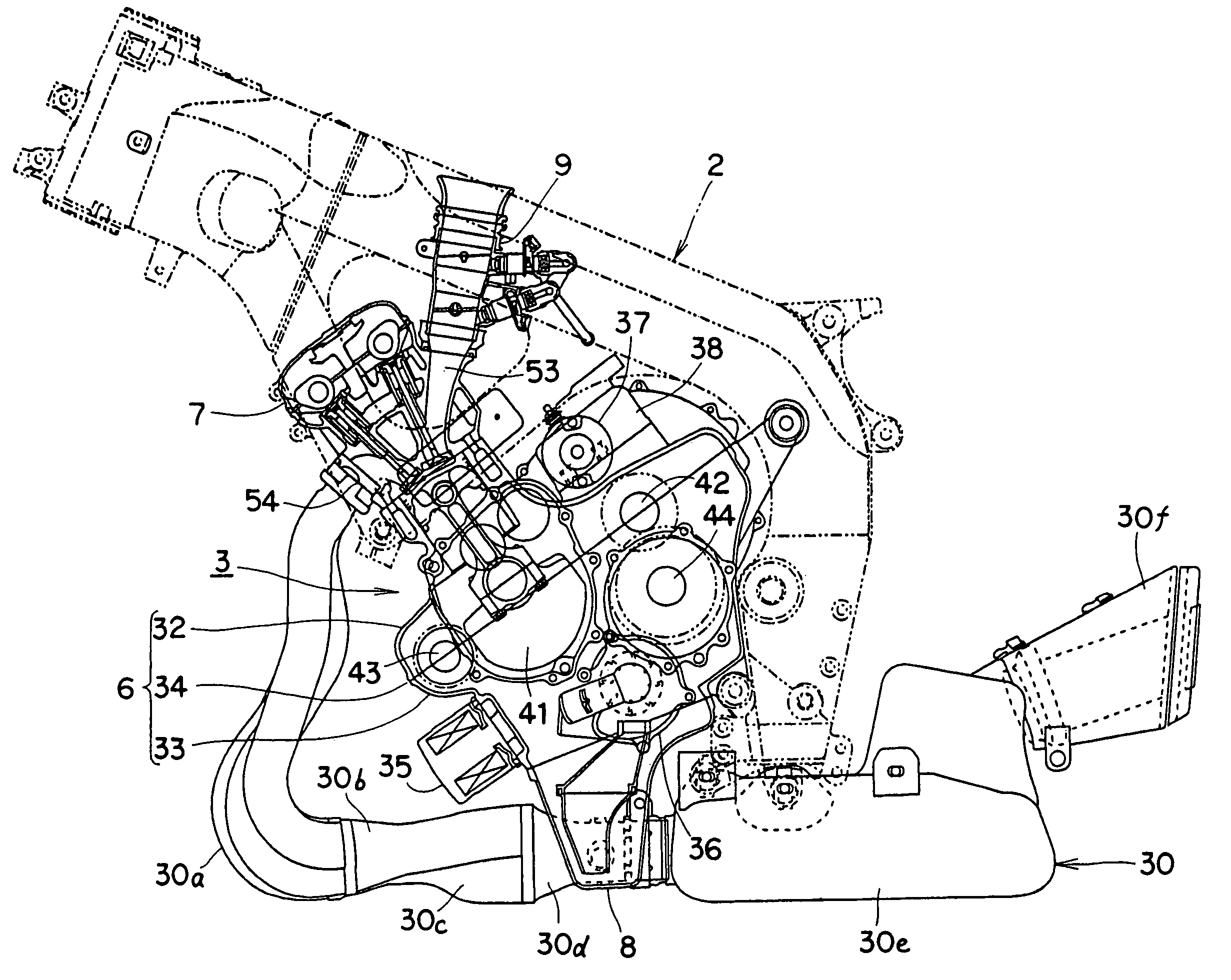

Engine for motorcycle

InactiveUS7694657B2Reduce the center distanceReduce in quantityCasingsValve arrangementsCrankcaseEngineering

In an engine for a motorcycle, a main shaft is supported rotatably by first and second support walls of a lower case which constitutes a part of a crank case. The center distance between the crank shaft and the main shaft is to be shortened while attaining a reduction in the number of parts and the number of assembling steps. A first bearing hole is formed in a first support wall for fitting therein and holding a first bearing which is mounted on one end of the main shaft. A second bearing hole is formed in a second support wall which permits the main shaft to be inserted therein from an opposite end side of the main shaft until one end of the main shaft is fitted in the first bearing. A second bearing is fitted and held in the second bearing hole so as to be fitted on the main shaft from the opposite end side of the main shaft after fitting of one end of the main shaft into the first bearing.

Owner:HONDA MOTOR CO LTD

Motorcycle engine and assembling method thereof

InactiveUS7578213B2Improve accuracyStable supportRotary bearingsGearboxesEngineeringMechanical engineering

An engine includes an engine case split into an upper case and a lower case. A crankshaft and a transmission input shaft are rotatably supported at a mating surface between the upper and lower cases, and a transmission output shaft rotated by the transmission input shaft is supported in the lower case. One side face of the lower case has a circular opening through which the transmission output shaft can be inserted from the outside. An eccentric bearing holder holding a bearing that rotatably supports one end of the transmission output shaft is mounted in the opening in a detachable manner from the outside. The axis of the transmission output shaft deviates from the center of the eccentric bearing holder toward the transmission input shaft. The inner diameter of the opening is larger than the outer diameter of the largest one of transmission driven gears of the transmission output shaft.

Owner:SUZUKI MOTOR CORP

High-frequency coaxial connector and processing method thereof

PendingCN107834319AMeet the requirements of multi-channel useReduce difficultyContact member assembly/disassemblyTwo-part coupling devicesElectrical conductorEngineering

The invention discloses a high-frequency coaxial connector and a processing method thereof. The high-frequency coaxial connector comprises a socket which comprises a C outer conductor, N C insulatorsand N C inner conductors. The C outer conductor is in the shape of a plate. The surface of the C outer conductor is provided with N mounting through holes. Each of the mounting through holes is internally provided with a coaxial C inner conductor and a C insulator is connected between them, and N is a positive integer larger than or equal to 2. According to the high-frequency coaxial connector andthe processing method thereof, the reduction of the difficulty and cost of assembly is facilitated.

Owner:苏州中航天成电子科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com