Self-locating high-sealing large-flow three-way valve

A high-sealing, high-flow technology, applied in the direction of multi-way valves, shaft seals, valve details, etc., can solve the problem that the bathroom outlet channel and bathroom inlet channel cannot be directly connected, the overall height of the three-way valve cannot be made higher, and the screw connection Insufficient reliability and other problems, to achieve the effects of reducing hidden dangers of leakage, small pressure resistance, and small water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

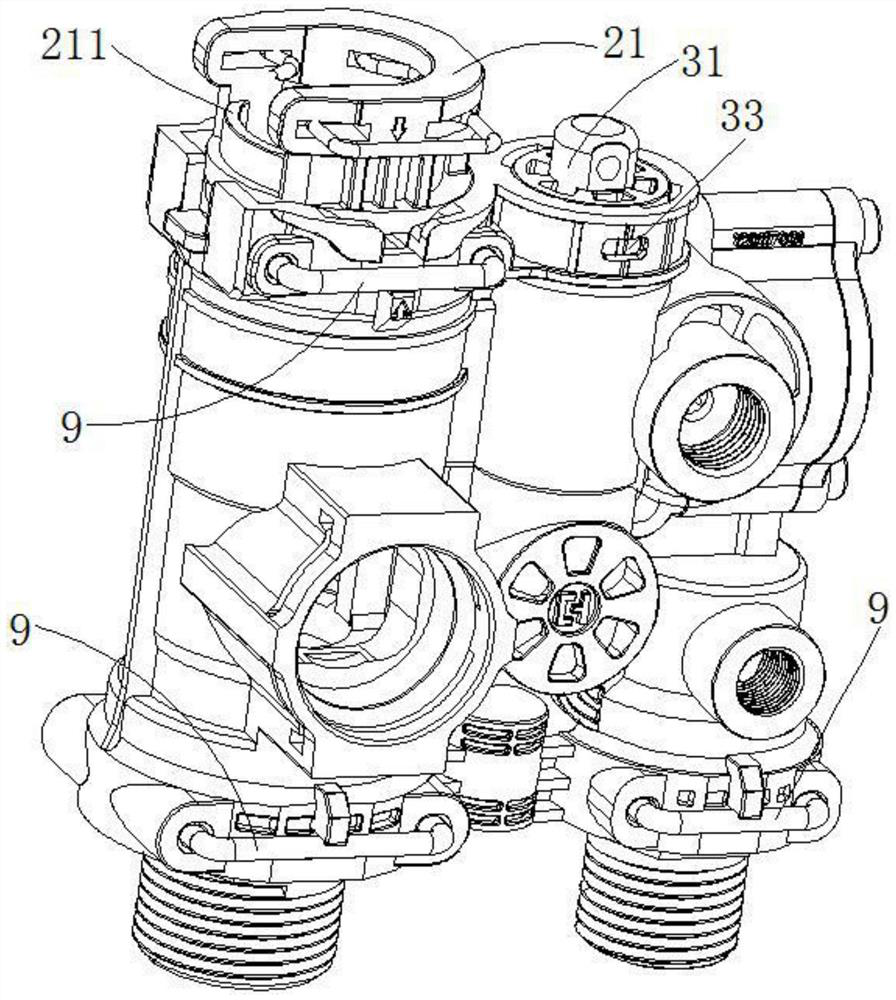

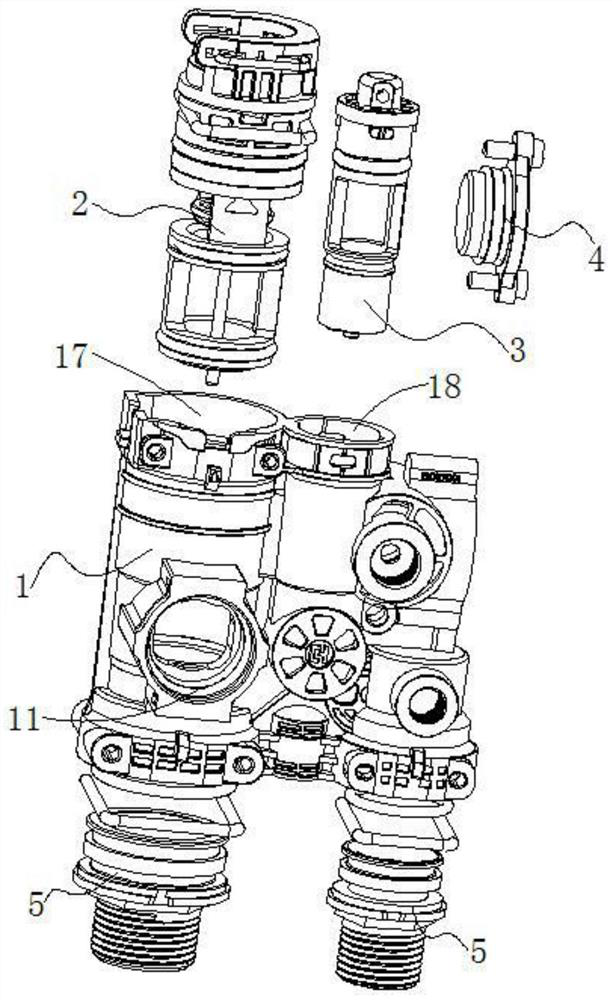

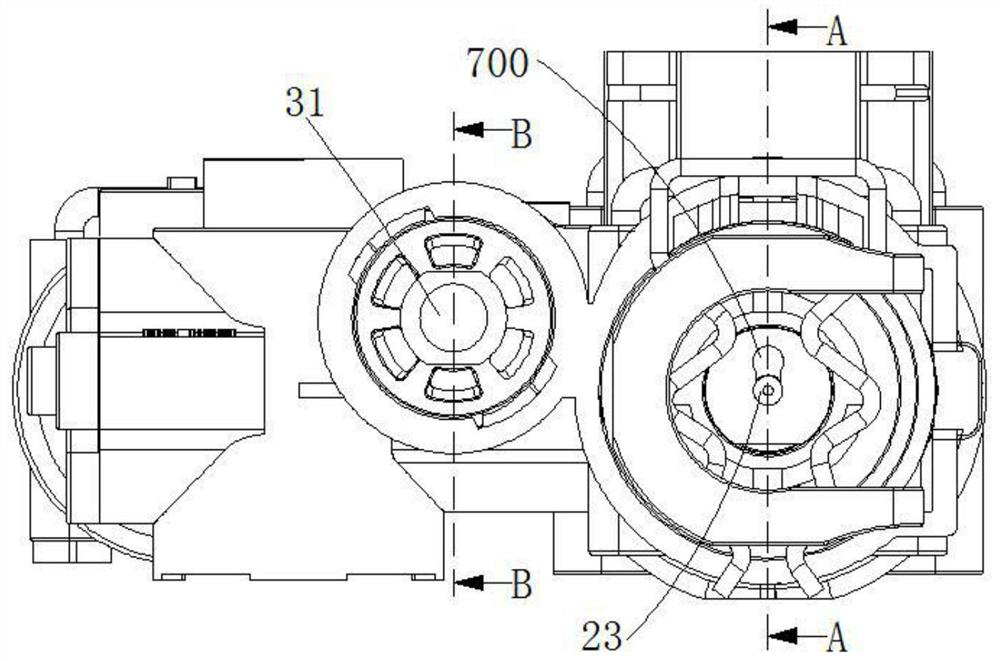

[0050] Such as Figure 1 to Figure 16 As shown, a self-positioning, high-sealing, high-flow three-way valve includes a housing 1, and the housing 1 includes a water inlet channel 11, a first water outlet channel 12, a second water outlet channel 13, and a valve cavity 17. The first water outlet channel 12, the second water outlet channel 13 are switched and communicated with the water inlet channel 11. The housing 1 includes a connected bathroom water outlet channel 14 and a bathroom water inlet channel 15. When the water inlet channel 11 is connected to the first water outlet channel 12 At this time, the water inlet channel 11 is not connected with the second water outlet channel 13, which is to supply hot water to the floor heating system at this time; when the water inlet channel 11 is connected with the second water outlet channel 13, the water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com