Patents

Literature

69results about How to "Small pressure resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of biomass-base polyurethane foam material

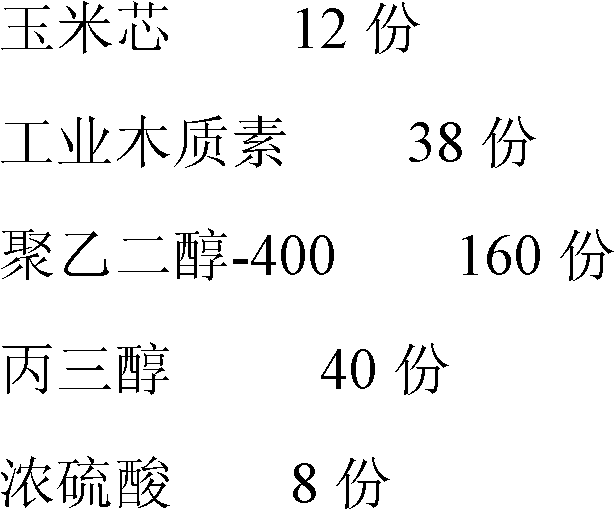

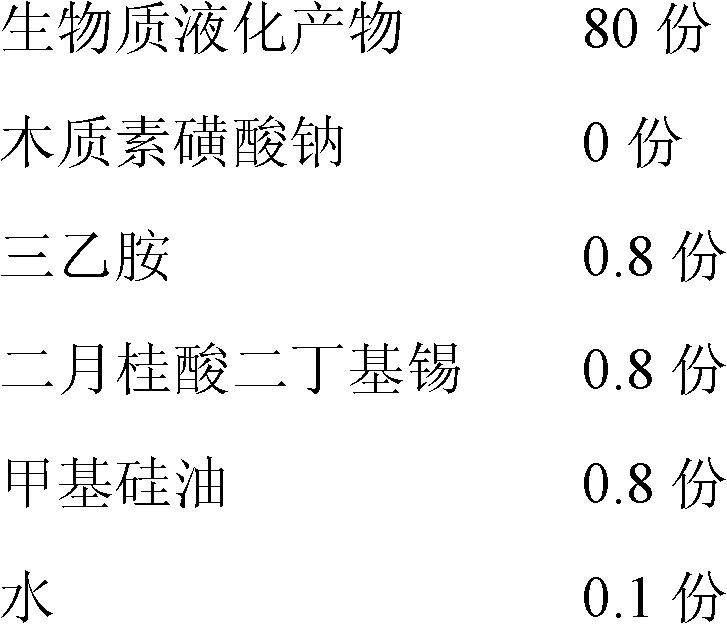

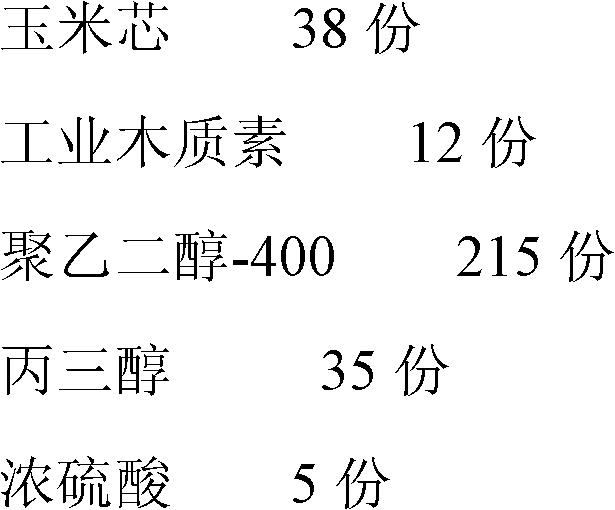

The invention discloses a preparation method of a biomass-base polyurethane foam material, belonging to the technical field of chemical industry. The method mainly comprises the following steps: mixing polybasic alcohol liquefier and liquefying catalyst, putting the mixture in a container, heating to 150-200 DEG C, adding biomass waste and industrial lignin, liquefying, and cooling to room temperature to obtain a biomass liquefied product; and mixing the prepared biomass liquefied product, foaming catalyst, foam stabilizer, foaming agent and lignosulphonate into a component A, using isocyanate as a component B, mixing the component A and component B in a mixing vessel, stirring at 20-40 DEG C at 8000-14000 rpm for 5-30 seconds, pouring the mixture into a die, naturally foaming for 5-60 seconds, standing at 80-120 DEG C for 8-24 hours, and storing at room temperature for 8-24 hours until the mixture is sufficiently aged and formed. The invention can obviously improve the properties of the biomass-base polyurethane foam.

Owner:CHINA AGRI UNIV

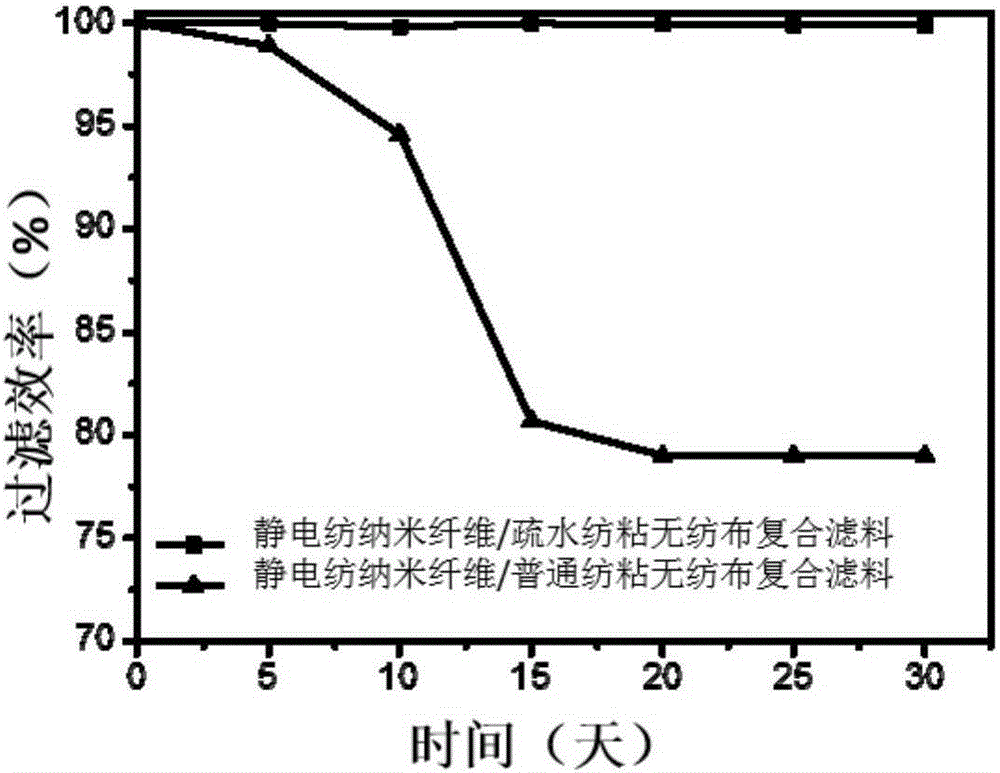

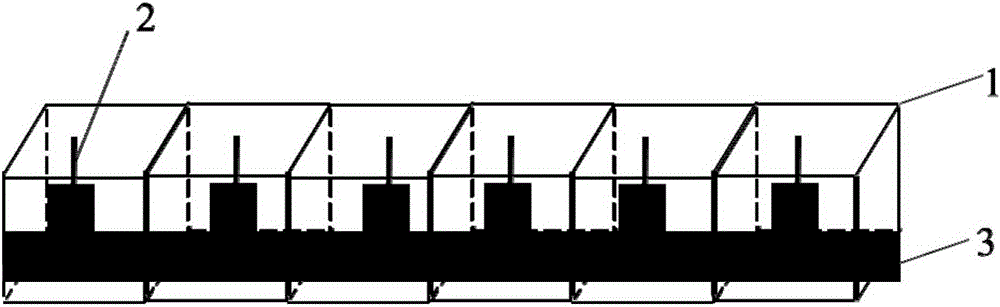

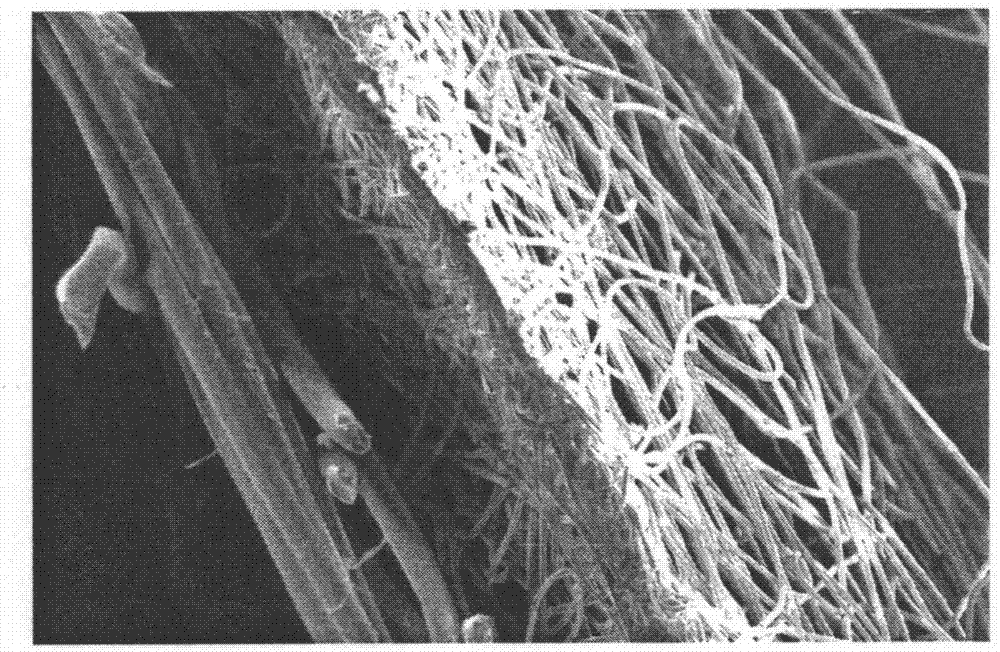

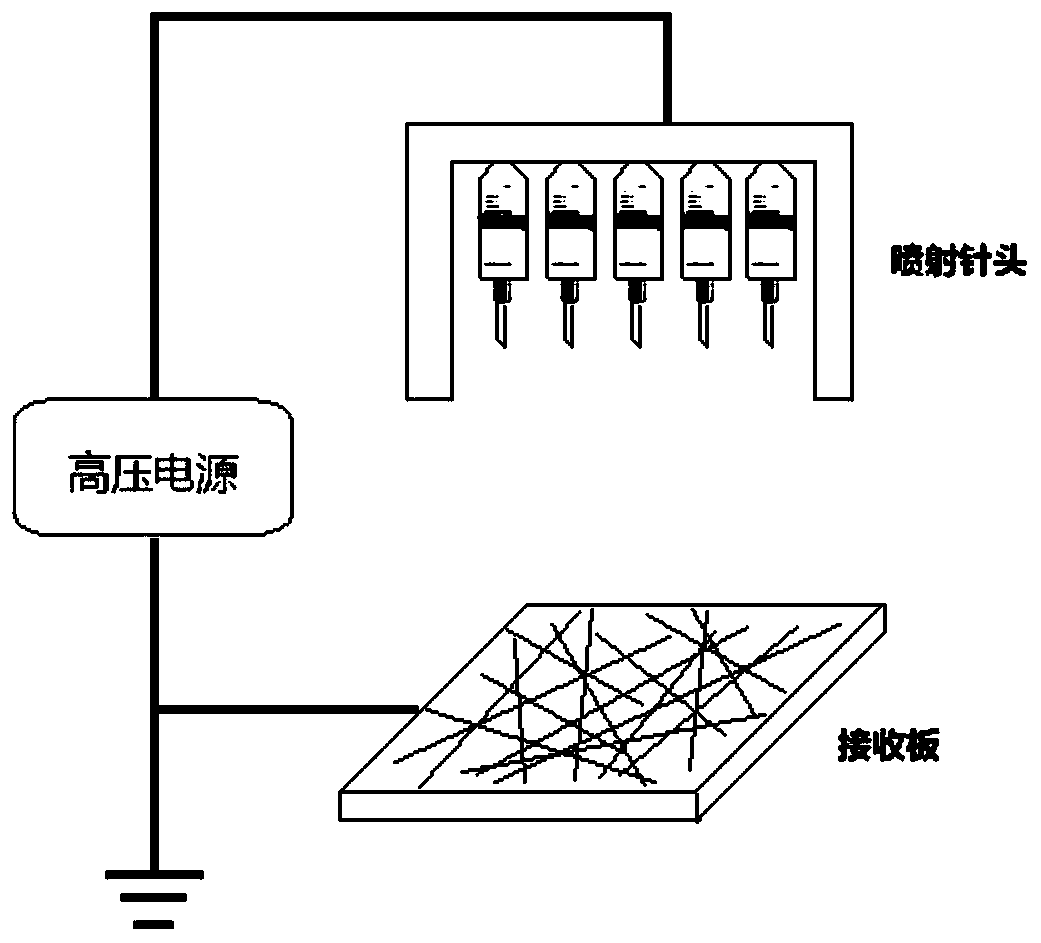

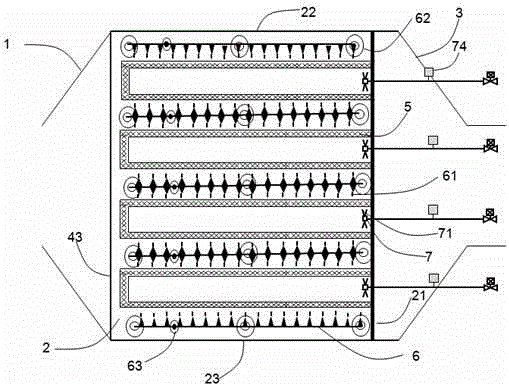

Electrostatic spinning method and nanometer fiber/anti-sticking non-woven fabric composite filter material prepared through electrostatic spinning method

ActiveCN105200539AImprove uniformityElectric field interference weakenedFilament/thread formingFiltration separationWoven fabric compositeElectrospinning

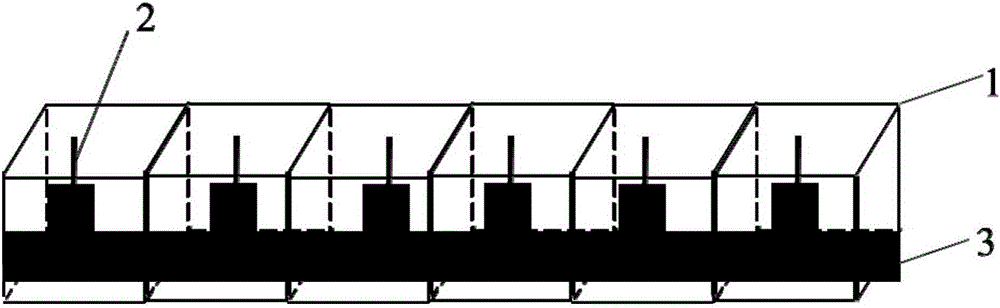

The invention relates to an electrostatic spinning method and a nanometer fiber / anti-sticking non-woven fabric composite filter material prepared through the electrostatic spinning method. Multi-needle electrostatic spinning is adopted in the electrostatic spinning method, and needles of multi-needle electrostatic spinning are insulated from one another. The prepared nanometer fiber / anti-sticking non-woven fabric composite filter material is formed by overlapping and compositing materials for overlapping from bottom to top according to the low-to-high sequence of filtering efficiency of a filtering material, the face, with electrostatic spinning fiber, of each layer of material for overlapping faces upwards, the uppermost layer of material for overlapping is covered with anti-sticking non-woven fabric, and therefore it is ensured that the top layer and the bottommost layer are both anti-sticking non-woven fabric layers; of every two adjacent layers of materials for overlapping, the filtering efficiency value for particles with grain size of 0.02 micron to 10 microns of the upper layer is 1.03-1.3 times that of the lower layer, the number of overlapping layers of the materials for overlapping ranges from 2 to 6, the anti-sticking non-woven fabric and the interlayer structure with electret effect nanometer fibers arrayed at intervals are formed, and the nanometer fiber / anti-sticking non-woven fabric composite filter material is formed; the filtering efficiency of the nanometer fiber / anti-sticking non-woven fabric composite filter material for particles with grain size of 0.02 micron to 10 microns reaches 99.999% or higher, and the pressure resistance is kept between 10 Pa and 30 Pa.

Owner:DONGHUA UNIV

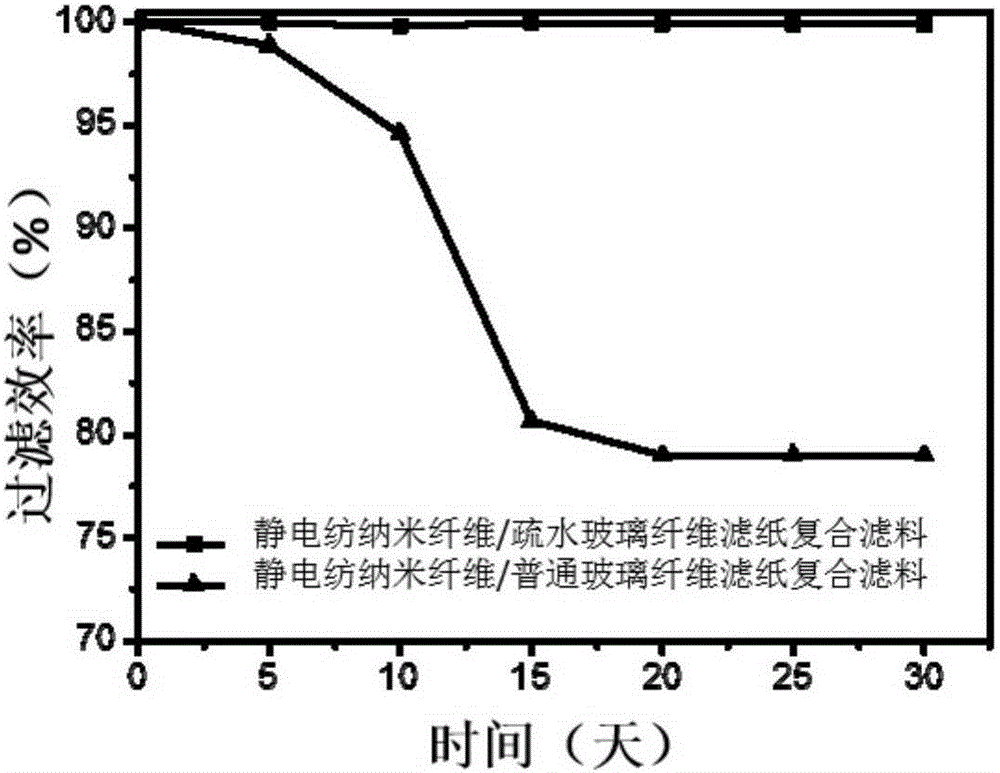

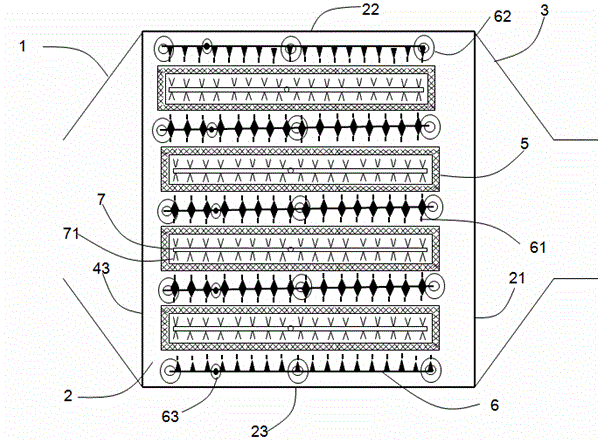

Static spinning method and nano fiber/glass fiber composite filter material prepared by same

ActiveCN105233568AImprove uniformityElectric field interference weakenedFilament/thread formingFiltration separationGlass fiberFiber

The invention relates to a static spinning method and a nano fiber / glass fiber composite filter material prepared by the same. According to the static spinning method, multiple needles are used to carry out static spinning, and the needles are insulated to each other. The nano fiber / glass fiber composite filter material is prepared by laminating and combining different filter materials together from bottom to top, wherein the filter efficiency of filter materials increases from bottom to top; the side, which is provided with static spun fibers, of each filter material layer is upward, the surface of the top layer is covered by glass fiber filter paper to ensure that the top layer and bottom layer of the filter material are both made of glass fiber filter paper. For two neighbored filter material layers, the filter efficiency of the upper layer on particles with a size of 0.02 to 10 [mu]m is 1.03 to 1.3 times higher than that of the lower layer. The composite filter material comprises two to six filter material layers, and has an sandwich structure, wherein in the sandwich structure, glass fiber filter paper and nano fiber with an electret effect are arranged alternately. The nano fiber / glass fiber composite filter material has a filter efficiency of 99.999% or more on particles with a size of 0.02 to 10 [mu]m, and the pressure resistance is maintained at 10 to 30 Pa.

Owner:上海迅江科技有限公司

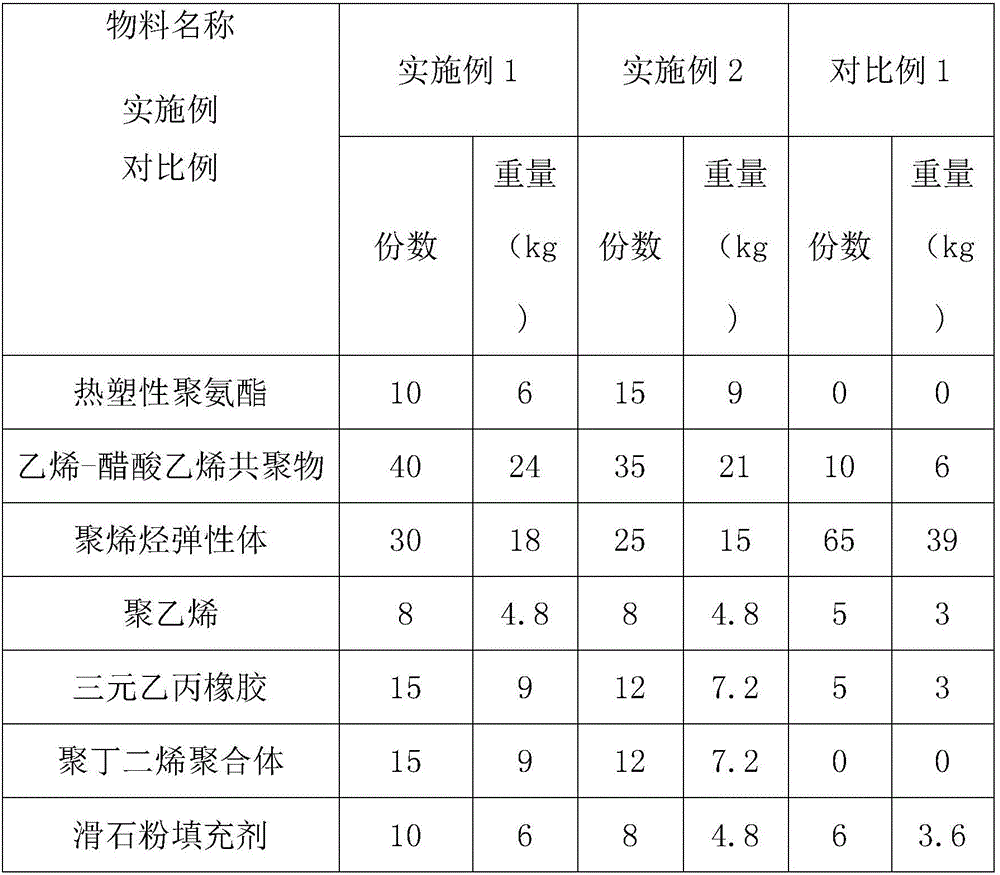

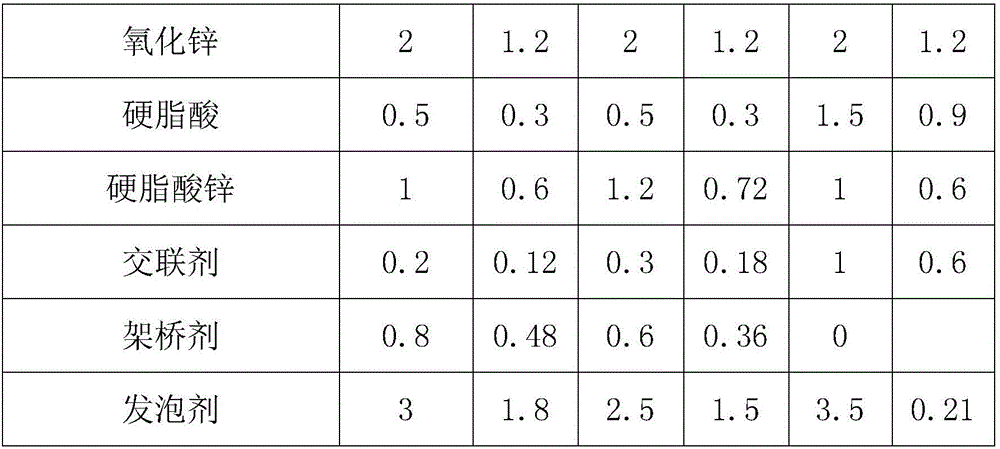

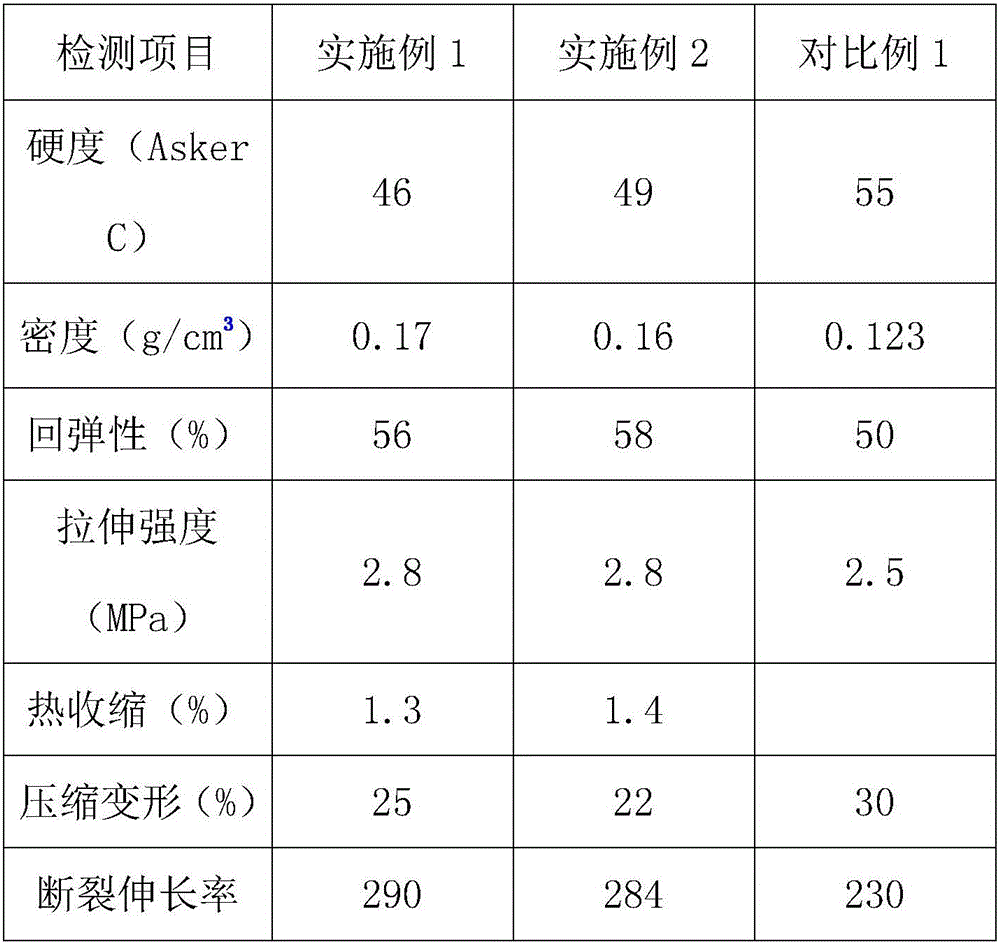

Thermoplastic polyurethane composite foamed material and preparation method thereof

The invention provides a thermoplastic polyurethane composite foamed material and a preparation method thereof. The thermoplastic polyurethane composite foamed material is prepared from 10-25 parts of polyurethane, 35-45 parts of ethylene-vinyl acetate copolymers, 15-30 parts of polyolefin elastomers, 6-10 parts of polyethylene, 6-18 parts of ethylene propylene diene monomers, 6-15 parts of polybutadiene polymers, 3-5 parts of filler, 1.5-2.2 parts of zinc oxide, 0.4-0.6 parts of stearic acid, 0.8-1.4 parts of zinc stearate, 0.1-0.4 parts of a cross-linking agent, 0.7-1.0 part of a bridging agent and 2.5-3.5 parts of a foaming agent. The thermoplastic polyurethane composite foamed material is high in rebound resilience, resistant to compression and good in tear resistance. The preparation method of the thermoplastic polyurethane composite foamed material comprises steps as follows: 1) components except zinc oxide, the cross-linking agent, the bridging agent and the foaming agent are weighed; 2) all the components weighed in the step 1) are mixed; 3) the rest components are weighed; 4) the components weighed in the step 3) are added to a material obtained after mixing in the step 2) for mixing; 5) granulation is performed; 6) foaming is performed.

Owner:ANTA CHINA

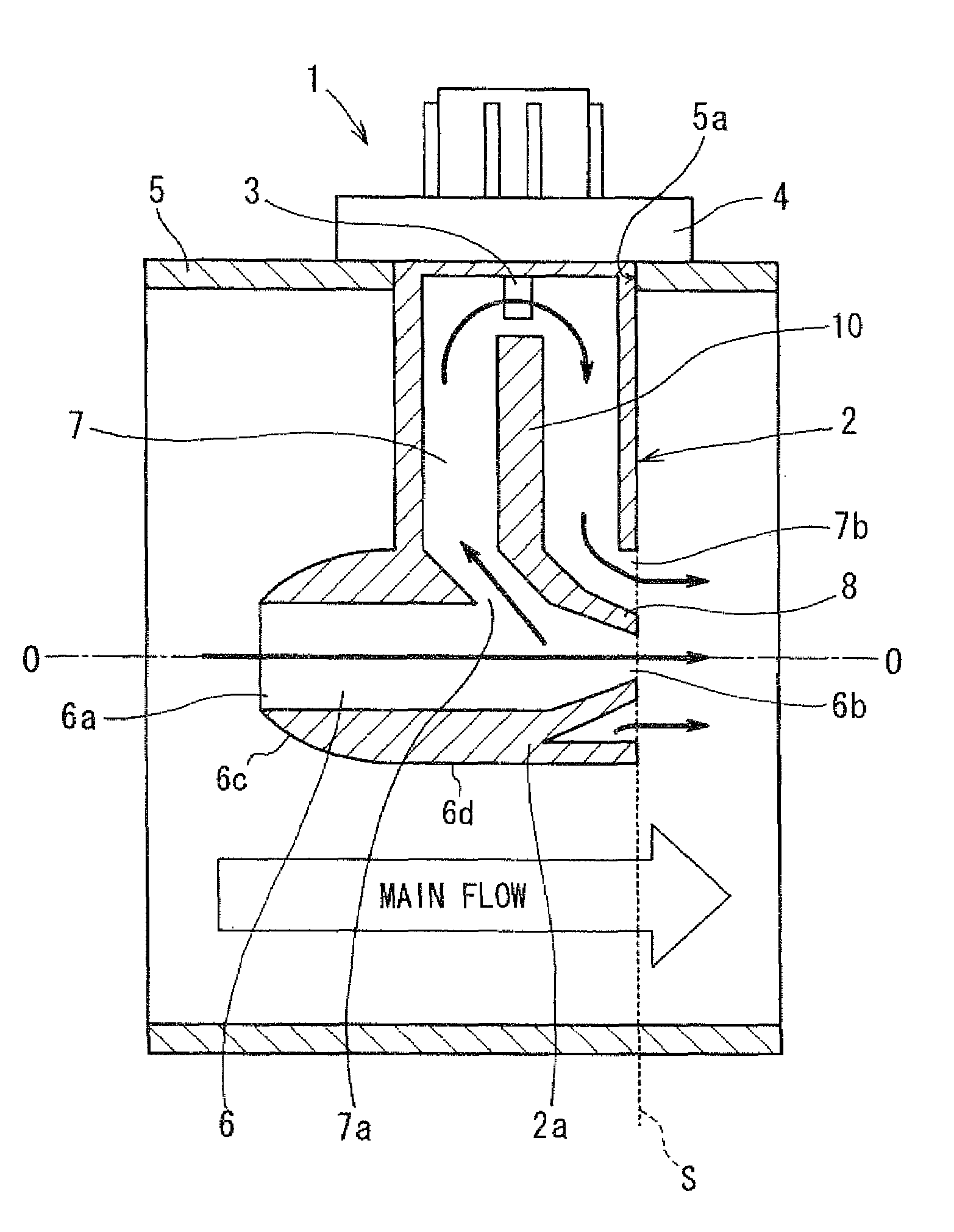

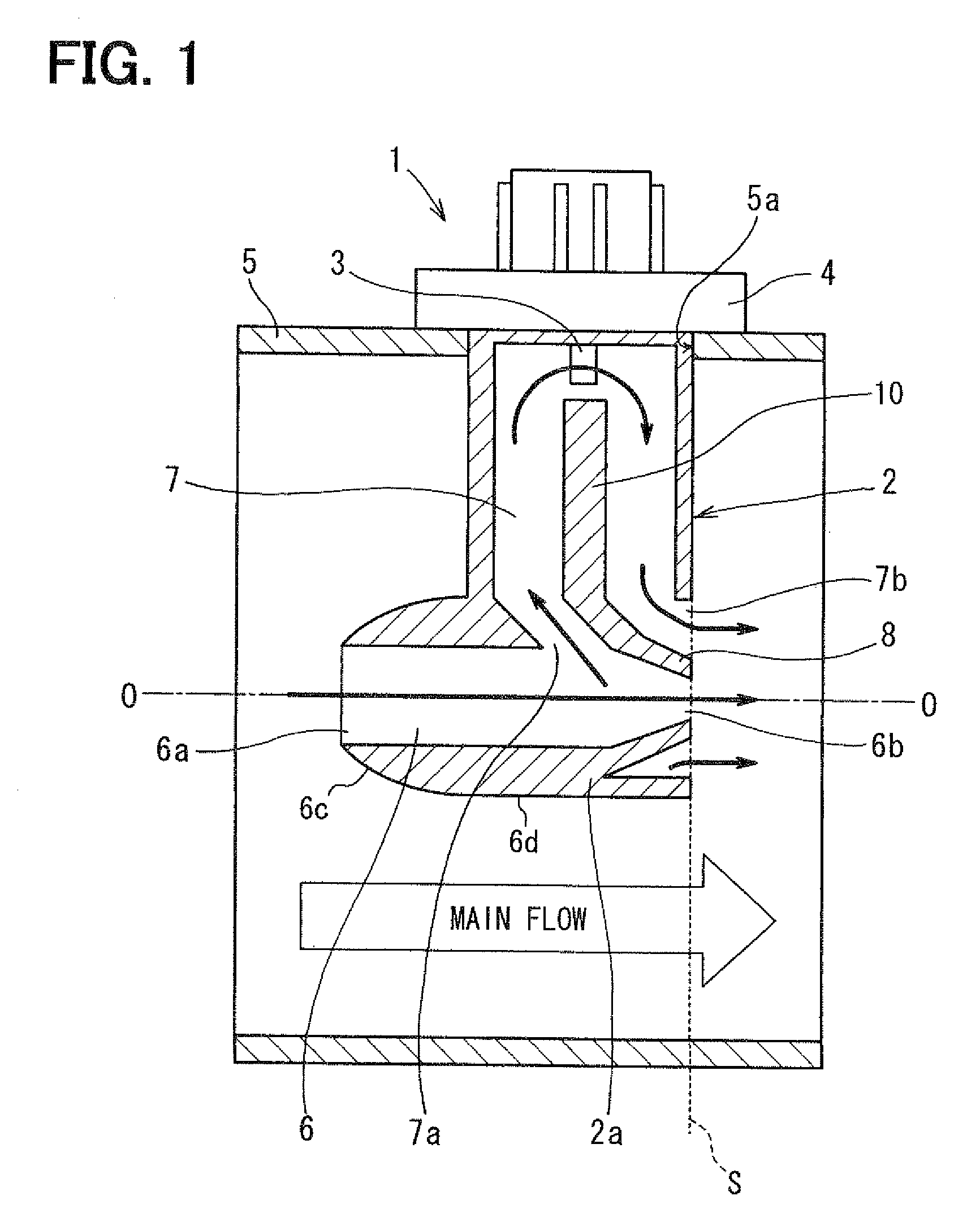

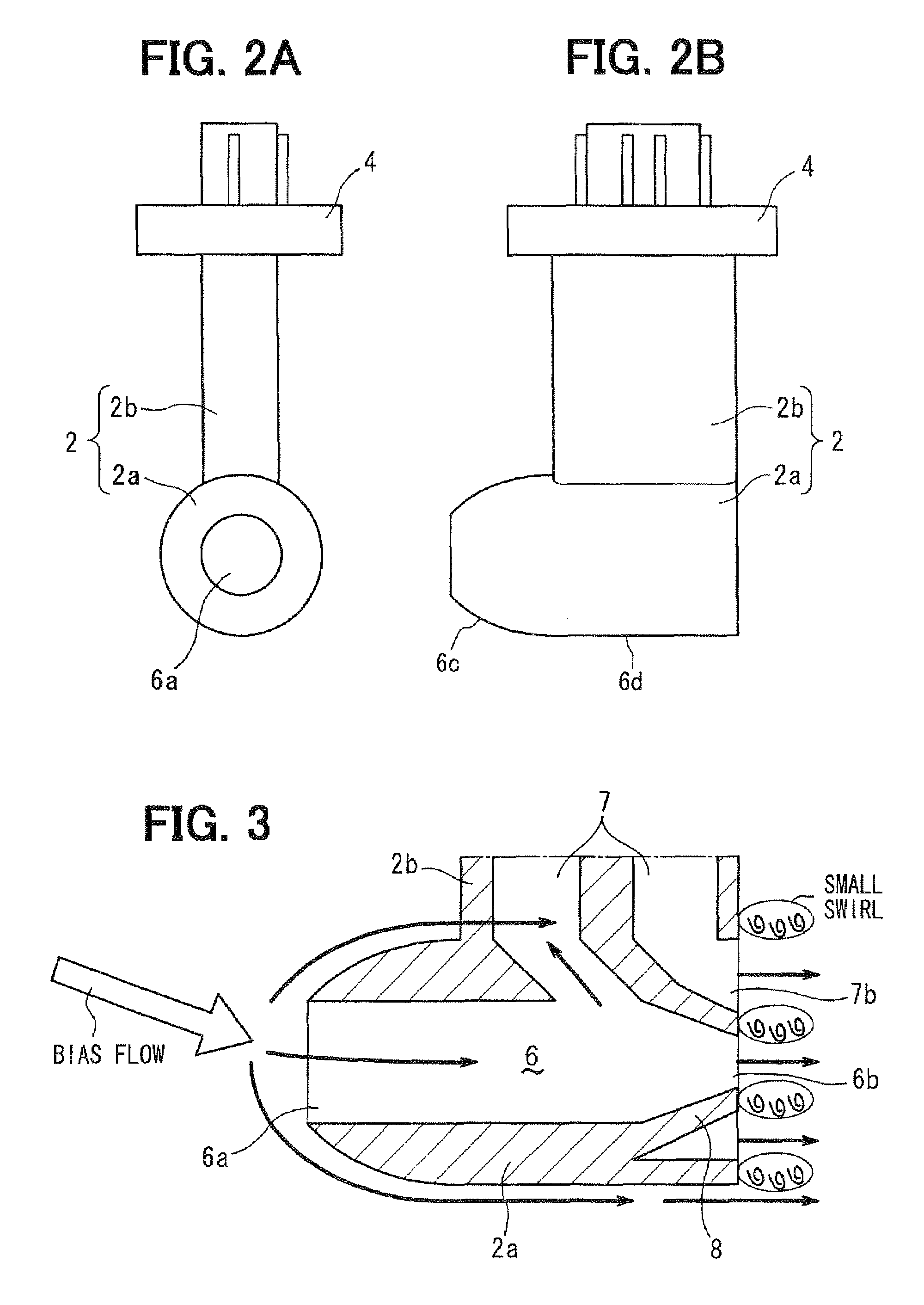

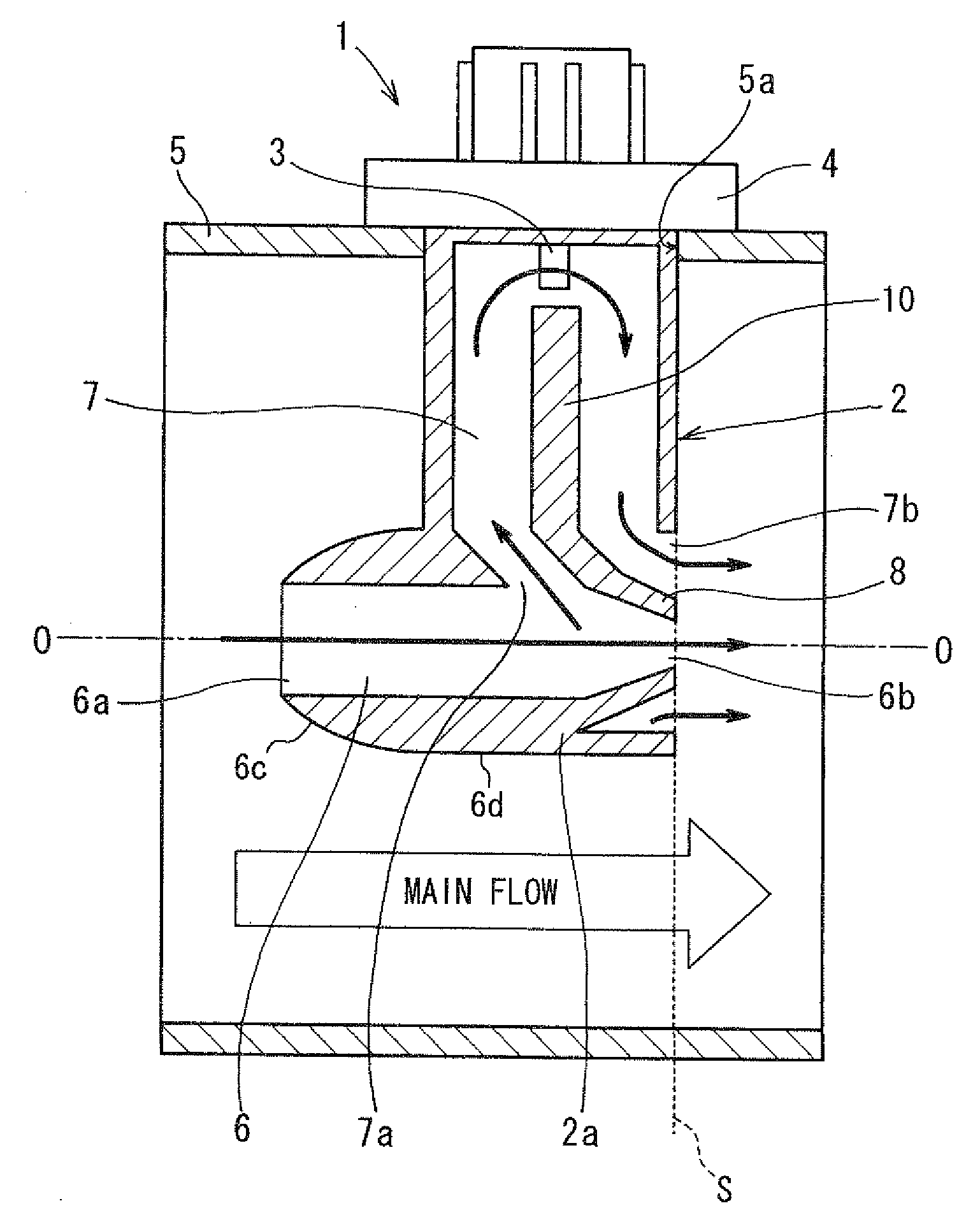

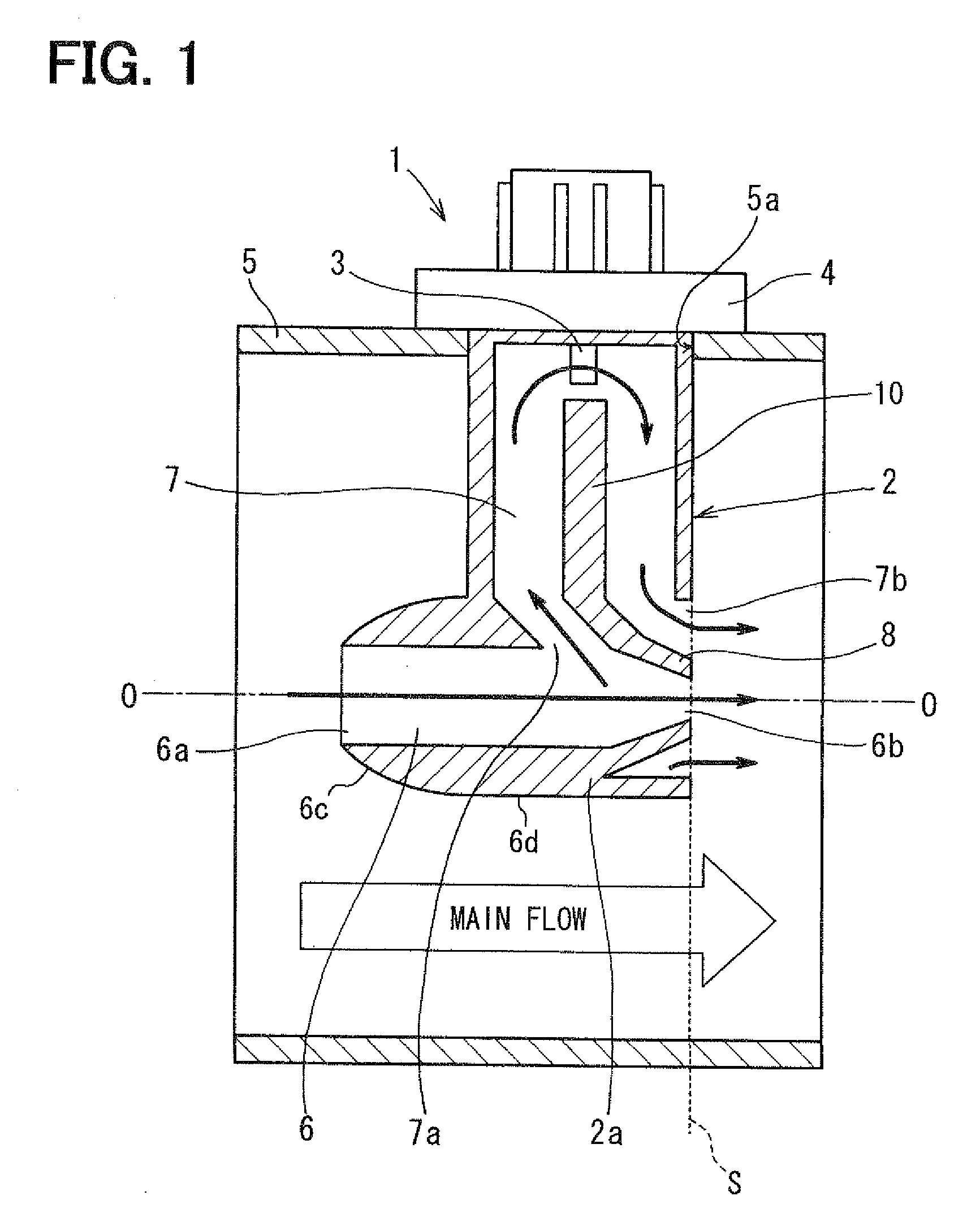

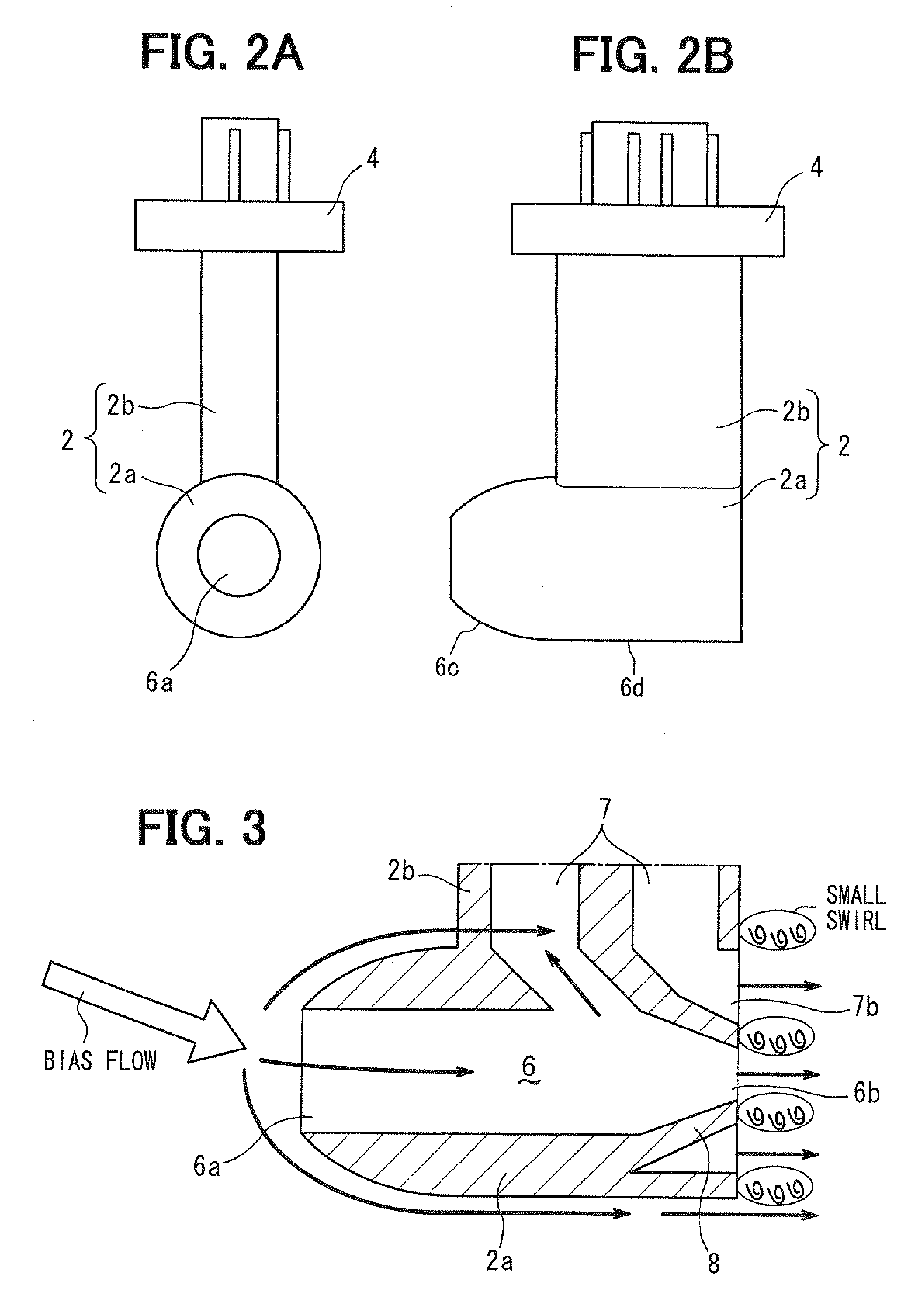

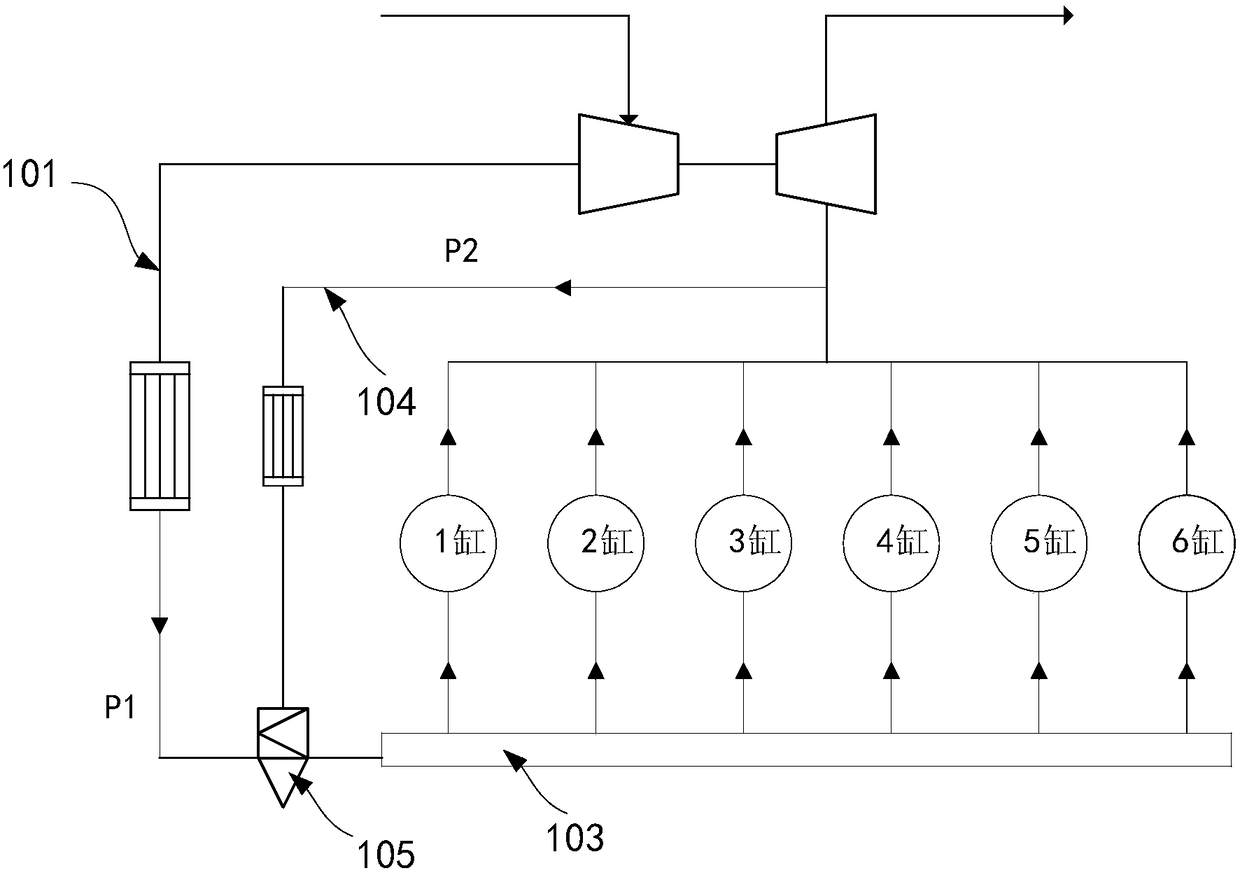

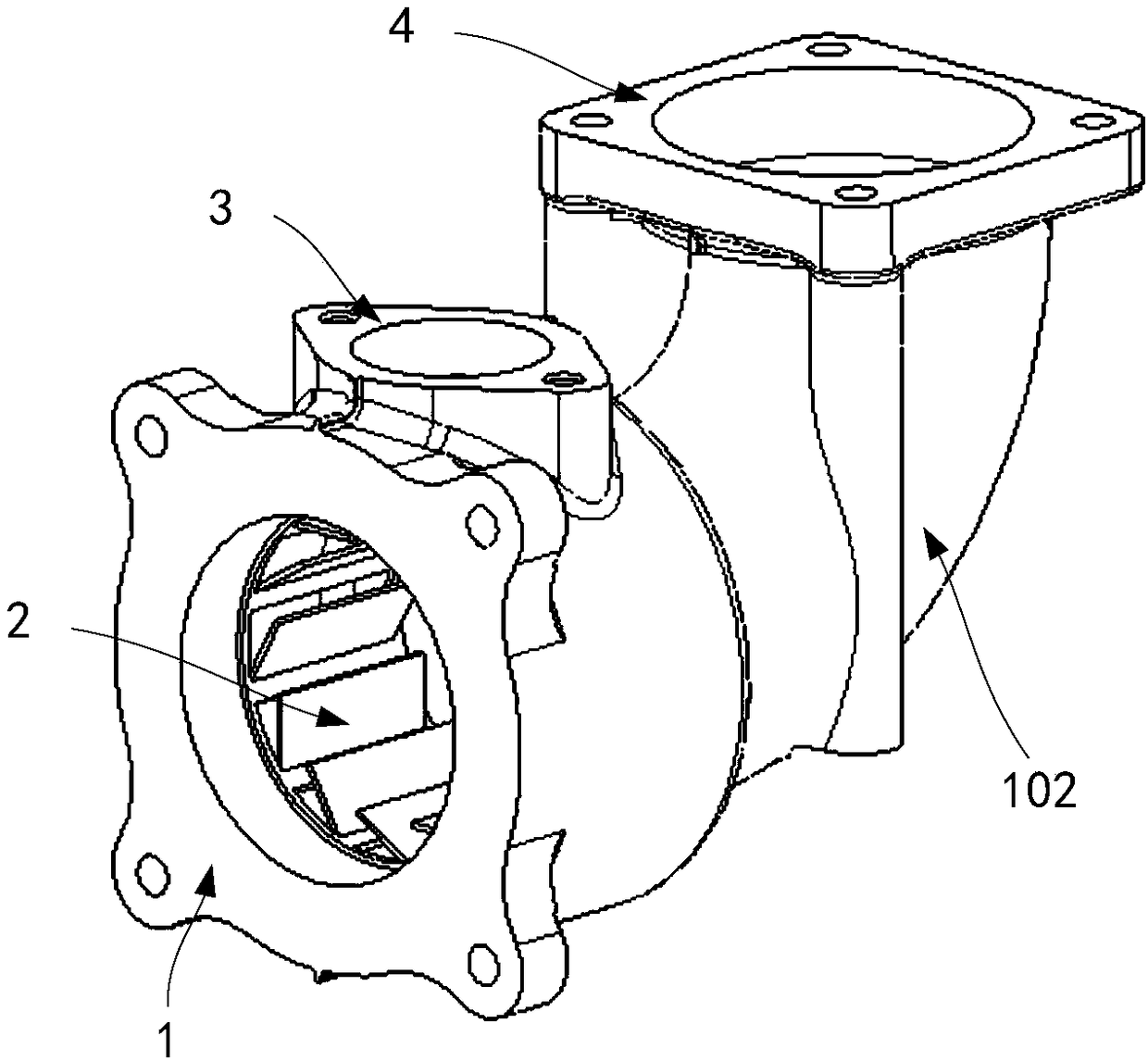

Air flow measuring device

ActiveUS7665351B2Improve detection accuracyAvoid separationEngine testingVolume/mass flow measurementMeasurement deviceMechanical engineering

An air flow measuring device includes a flow amount sensor for measuring a flow amount of air in a duct, and a tube body for defining a bypass passage in the duct. An upstream end surface of the tube body has an inlet of the bypass passage, and a downstream end surface thereof has an outlet of the bypass passage. An outer diameter of an outer peripheral surface of the tube body has a smallest dimension at the upstream end surface, and a largest dimension at the downstream end surface. Furthermore, the outer peripheral surface of the tube body has an upstream portion extending downstream from the upstream end surface in a predetermined range, and the upstream portion of the outer peripheral surface is a convex curve surface in which the outer diameter is increased by a ratio from the upstream end surface toward downstream.

Owner:DENSO CORP

Air flow measuring device

ActiveUS20080307869A1Improve accuracyImprove detection accuracyEngine testingVolume/mass flow measurementMeasurement deviceEngineering

An air flow measuring device includes a flow amount sensor for measuring a flow amount of air in a duct, and a tube body for defining a bypass passage in the duct. An upstream end surface of the tube body has an inlet of the bypass passage, and a downstream end surface thereof has an outlet of the bypass passage. An outer diameter of an outer peripheral surface of the tube body has a smallest dimension at the upstream end surface, and a largest dimension at the downstream end surface. Furthermore, the outer peripheral surface of the tube body has an upstream portion extending downstream from the upstream end surface in a predetermined range, and the upstream portion of the outer peripheral surface is a convex curve surface in which the outer diameter is increased by a ratio from the upstream end surface toward downstream.

Owner:DENSO CORP

Micron fiber/nano fiber composited electret filter material and preparation method thereof

ActiveCN107469466AEasy to prepareStrong process controllabilityArtificial thread manufacturing machinesElectro-spinningElectrospinningFiber layer

The invention relates to a micron fiber / nano fiber composited electret filter material and a preparation method thereof. The preparation method is as follows: a micron fiber and nano fiber three dimensional structure composited electret filter material is obtained by forming on a receiving base material in one step by using an annular gradient solvent vapor rapid removing device and a double-area isolation spinning control technique in the electrostatic spinning process. An electret material is evenly distributed in a micron fiber and nano fiber layer of the composited electret filter material, the charge storage capability and the charge stability of the electret material are strengthened under the action of a high voltage electric field, and the electrostatic effect of the composited electret filter material is utilized to effectively improve the filtering efficiency of the filter material. The charge stability of an electret of the micron fiber / nano fiber composited electret filter material is very high, the surface electrostatic potential is 300-8000 V, the filtering efficiency of particles of 0.02-20 [mu]m is greater than or equal to 99.97%, the resistance is less than or equal to 30 Pa, the service life is long, and the prospect of development and application is broad.

Owner:DONGHUA UNIV

Two-component polyurethane cement plugging glue, and preparation and application thereof

InactiveCN107201208AEasy to useFast curingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEnvironmental resistanceNon toxicity

The invention relates to two-component polyurethane cement plugging glue, and preparation and application thereof. The two-component polyurethane cement plugging glue comprises a polyurethane polymer and a sodium silicate curing agent, wherein the polyurethane polymer and the curing agent are in the mass ratio of 3:1 to 5:1. The two-component polyurethane cement plugging glue is prepared by mixing the polyurethane polymer and the sodium silicate curing agent. The two-component polyurethane cement plugging glue is used for quickly plugging cement fissures, cracks, splitting seams and the like, and can also be compounded and used with glass fibre cloth for sewage pipeline and treatment pond hole repairing and water seepage plugging. The two-component polyurethane cement plugging glue has the characteristics of easiness in use, high curing speed, low viscosity, capacity of directly performing crack treatment and the like, and further has the characteristics of high hydrolysis resistance, pressure resistance, high cement adhering strength, environment friendliness, non-toxicity and the like.

Owner:SHANGHAI HECHENG POLYMER TECH CO LTD

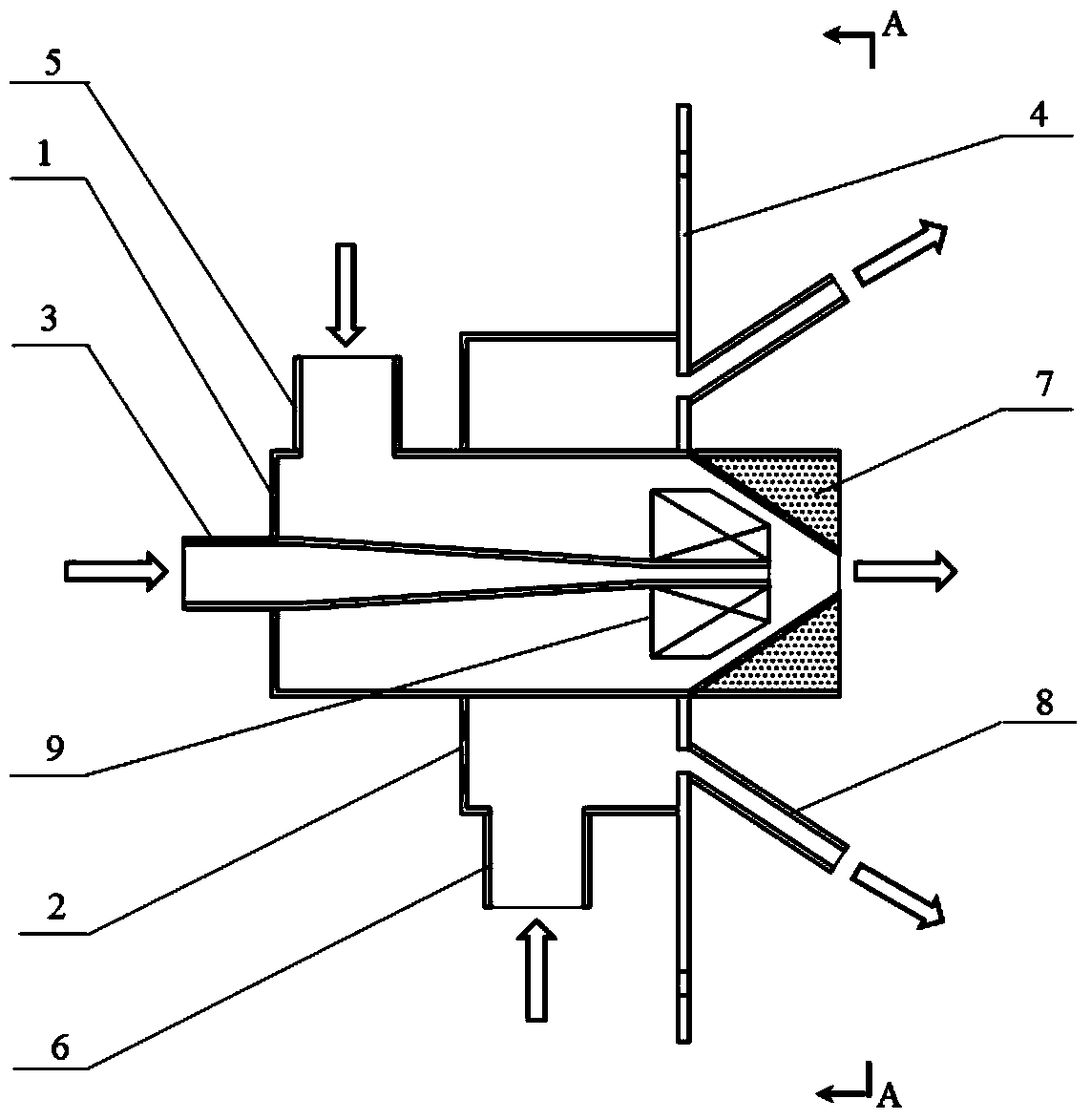

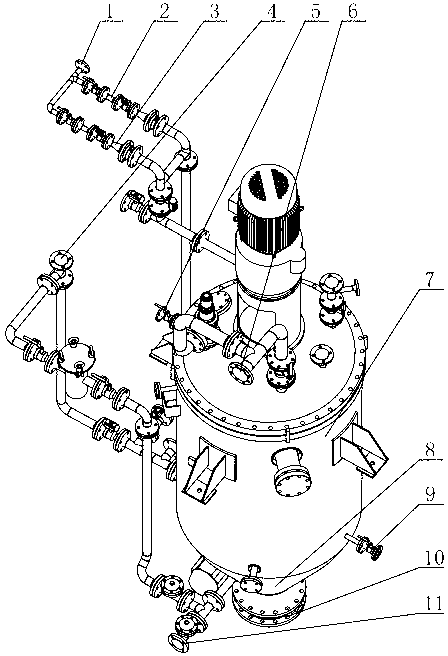

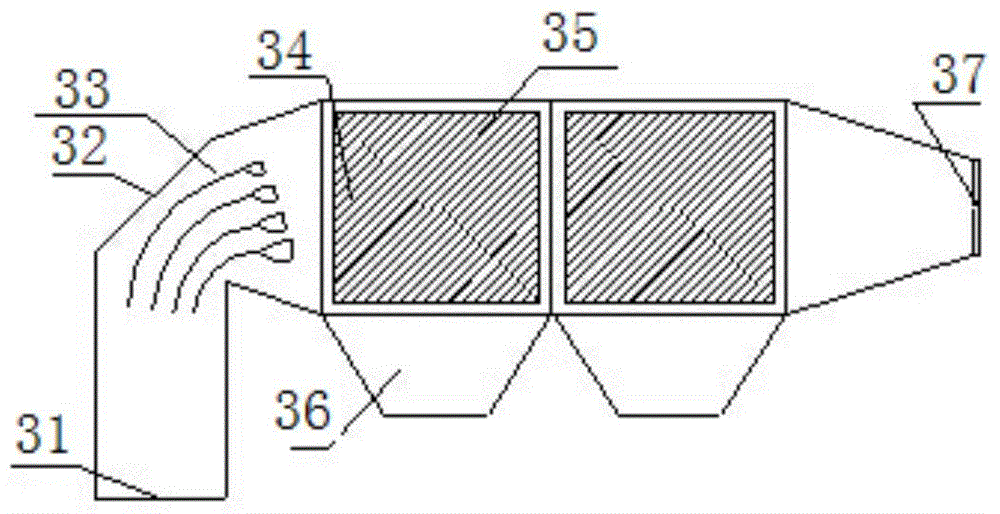

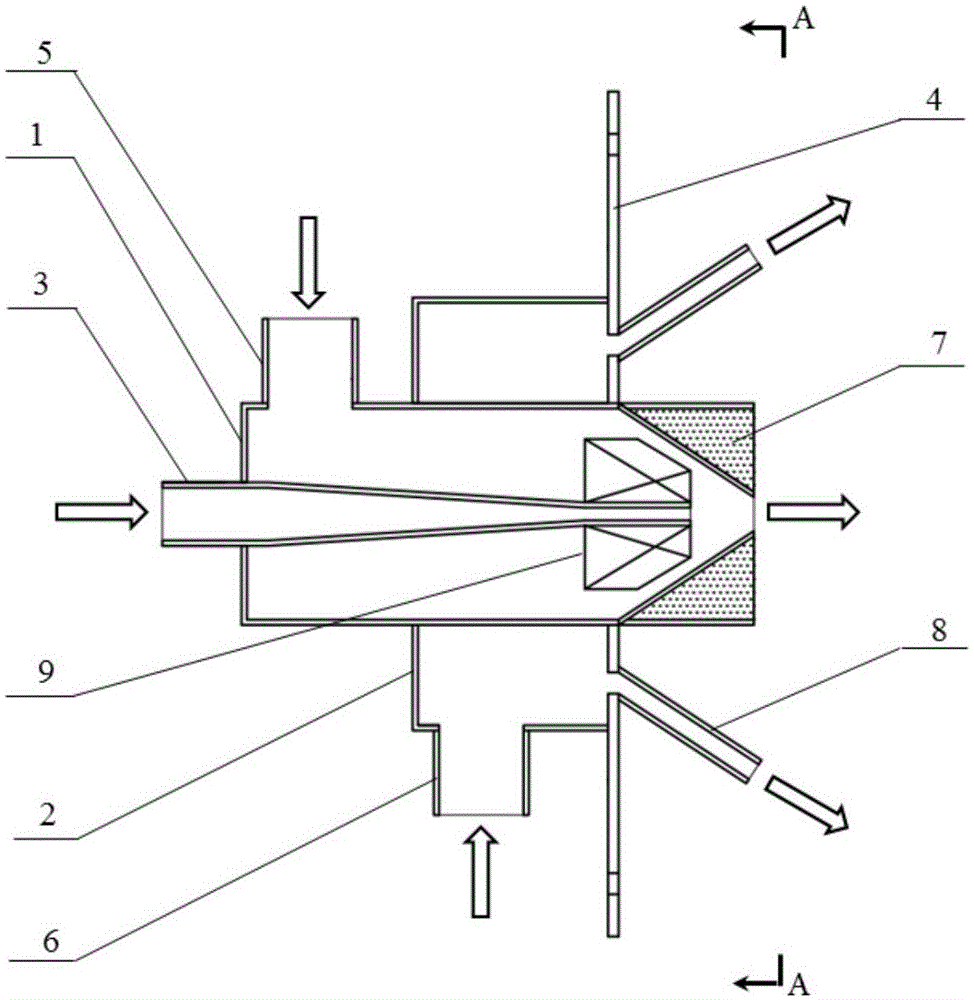

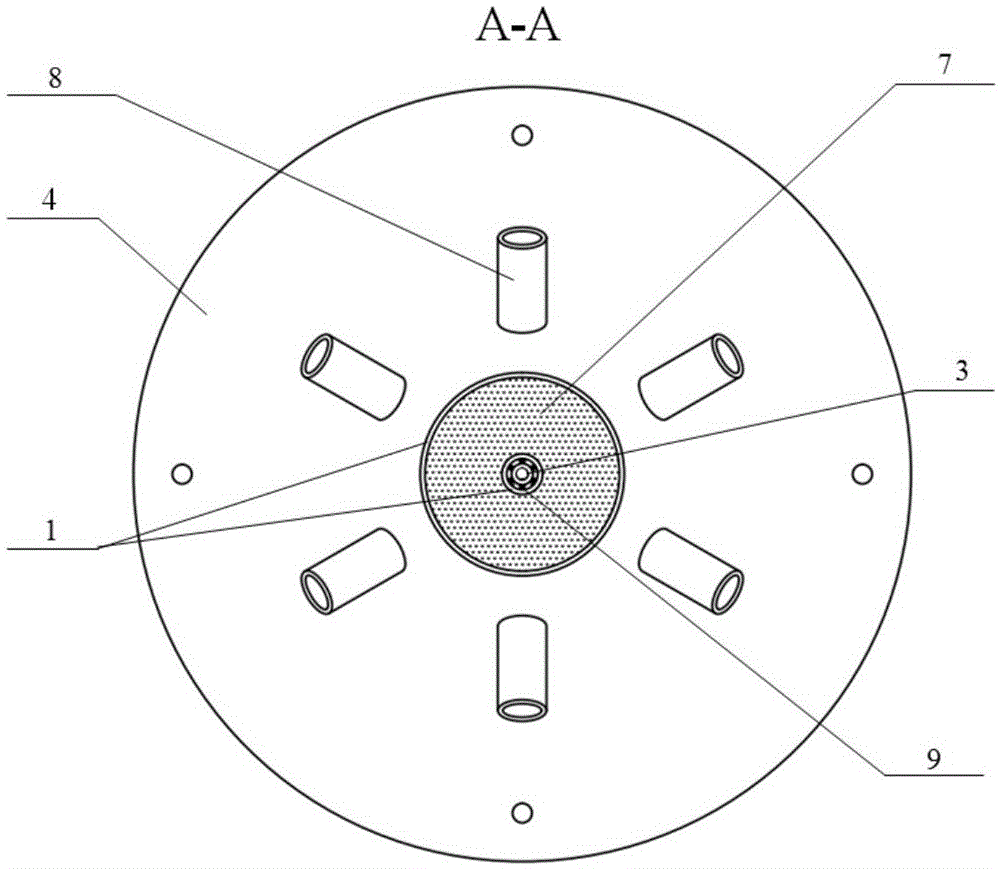

Diagonal-flow constant-temperature flameless burner

The invention relates to a diagonal-flow constant-temperature flameless burner comprising an inner barrel, an outer barrel, a center tube and an annular baffle plate, wherein the inner barrel is horizontally arranged; one end of the inner barrel is communicated with an inlet pipe of the inner barrel; the other end of the inner barrel extends into a combustion furnace; the part of the inner barrel, inside the combustion furnace, is of an inner and outer dual-layer structure; a groove formed by the inner layer and the outer layer is filled with a refractory matter; the center tube is composed of an inlet section, a transition section and an outlet section; the diameter of the inlet section is greater than that of the outlet section; the transition section is of a tapered structure; the center tube horizontally penetrates through the center of the inner barrel; a certain axial distance is kept between the end face of the outlet section and the end face of an air outlet of the inner barrel; the outer sleeve is arranged outside the inner barrel; one end of the outer sleeve is open and tightly connected with one side of the annular baffle plate; one side surface of the outer barrel is communicated with an inlet pipe of the outer barrel; a plurality of diagonal-flow nozzles are uniformly arranged at the other side of the annular baffle plate at the periphery of the inner barrel along the circumference; one end of each diagonal-flow nozzle is fixed on a round baffle plate and communicated with the outer barrel; the outflow direction of the other end deviates from the outflow direction of the center tube. The diagonal-flow constant-temperature flameless burner works in a constant temperature state without cold and heat exchange.

Owner:PEKING UNIV

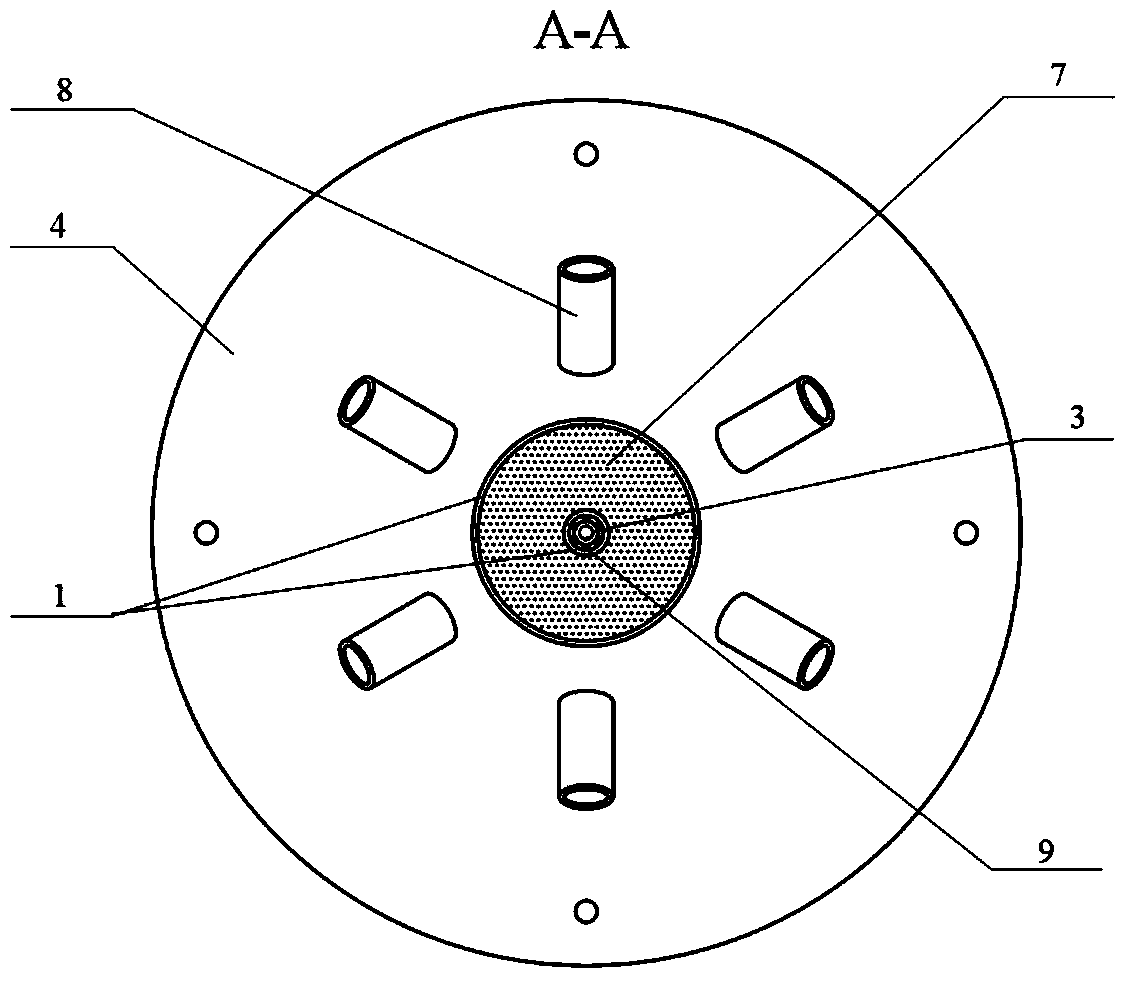

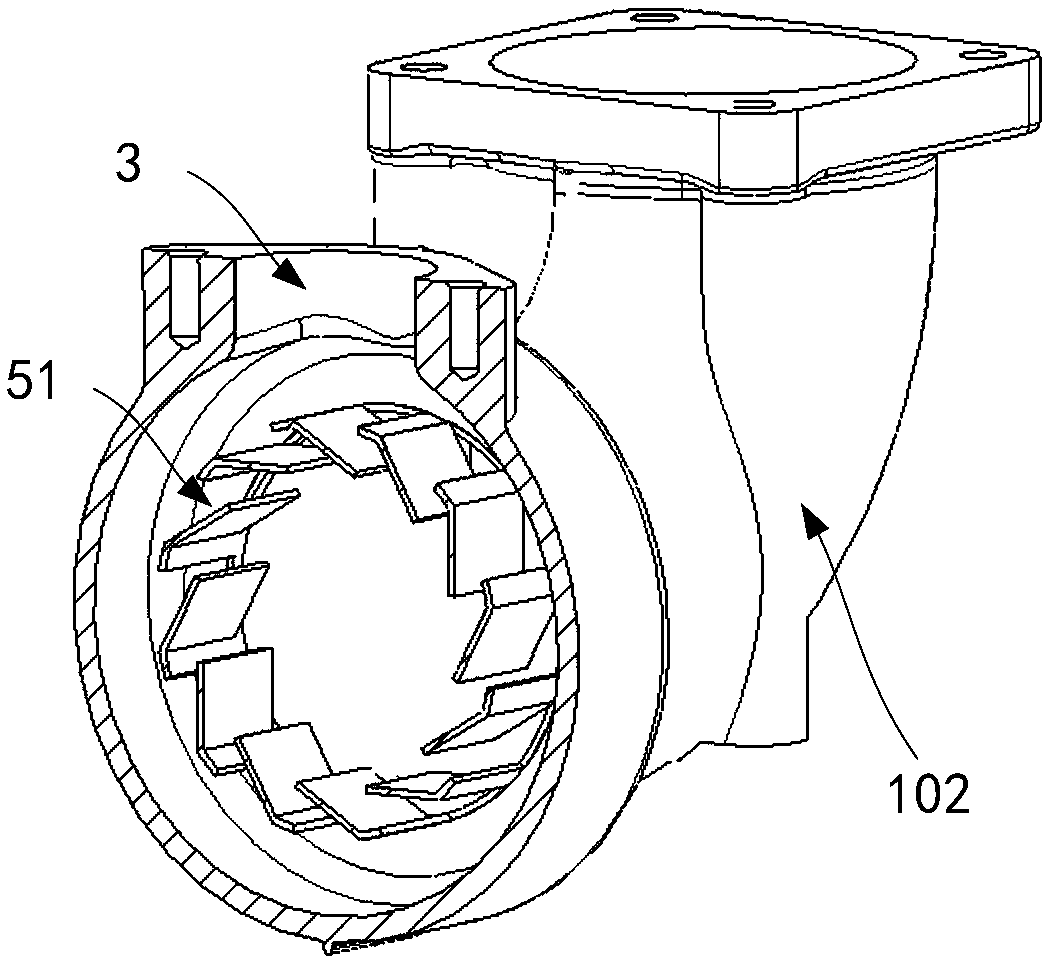

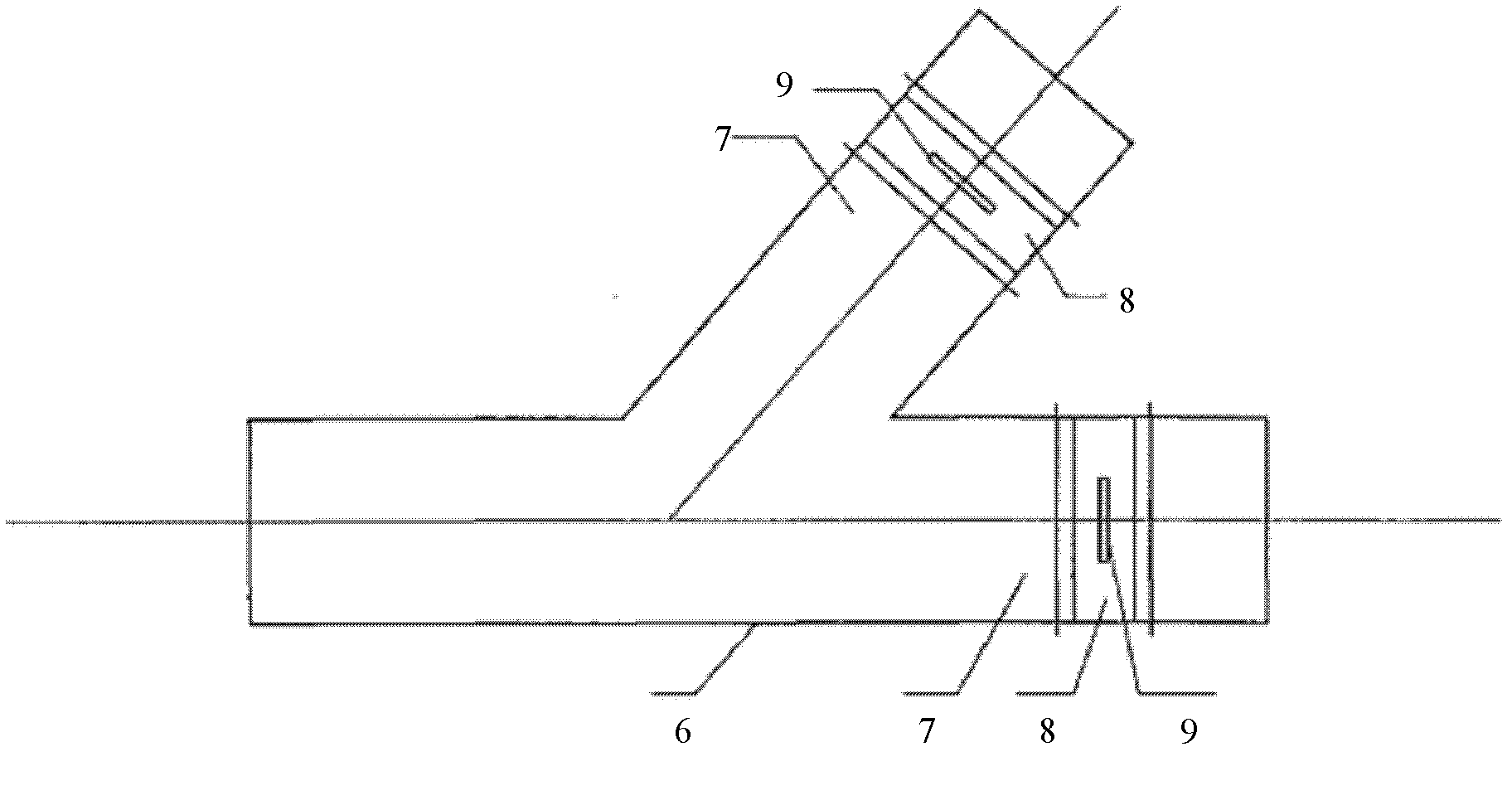

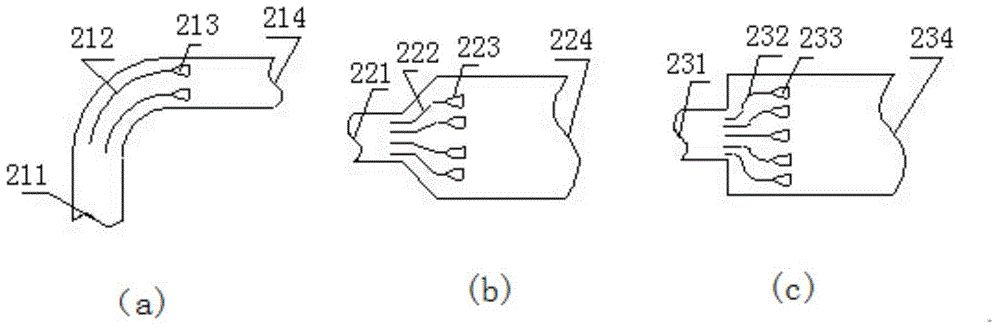

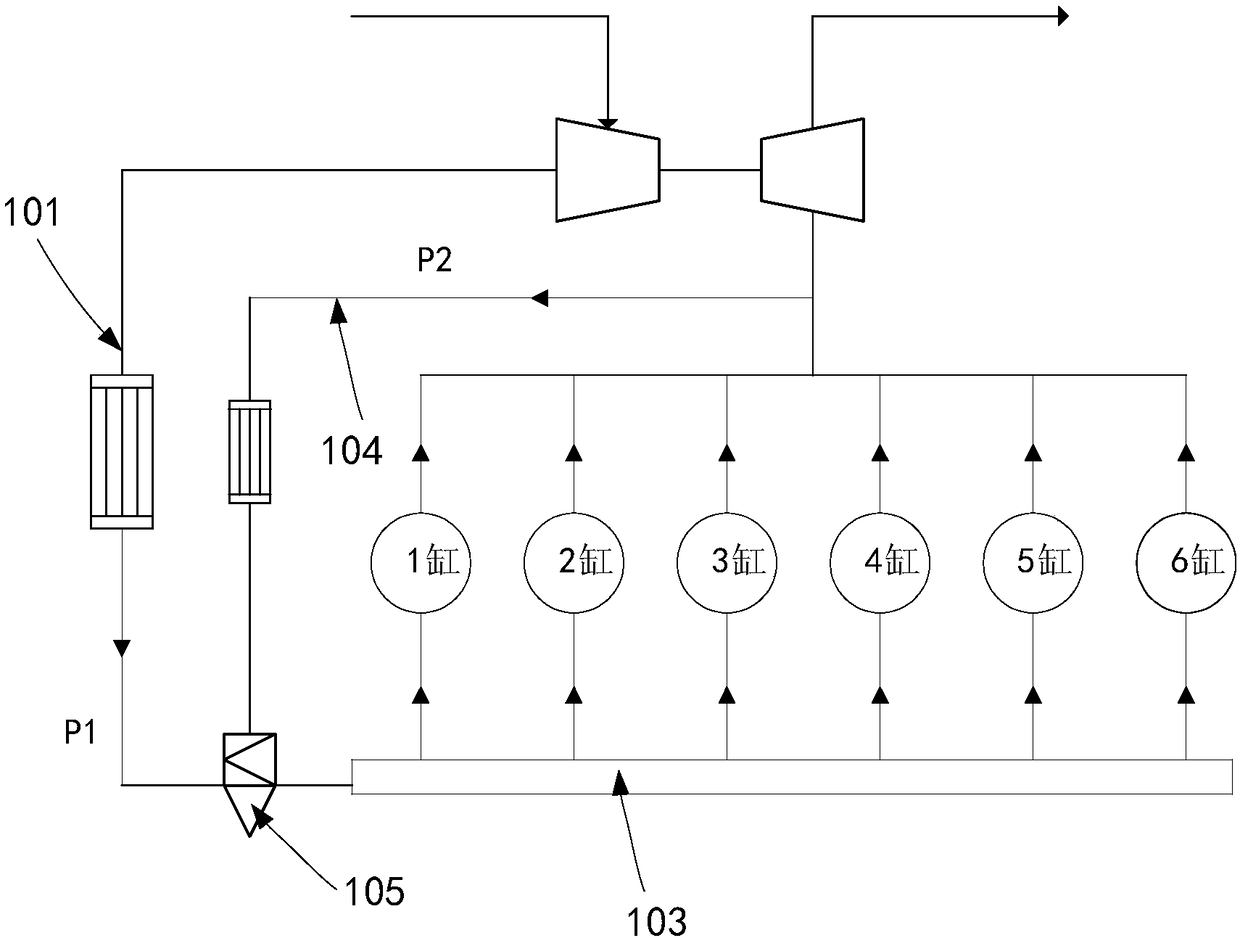

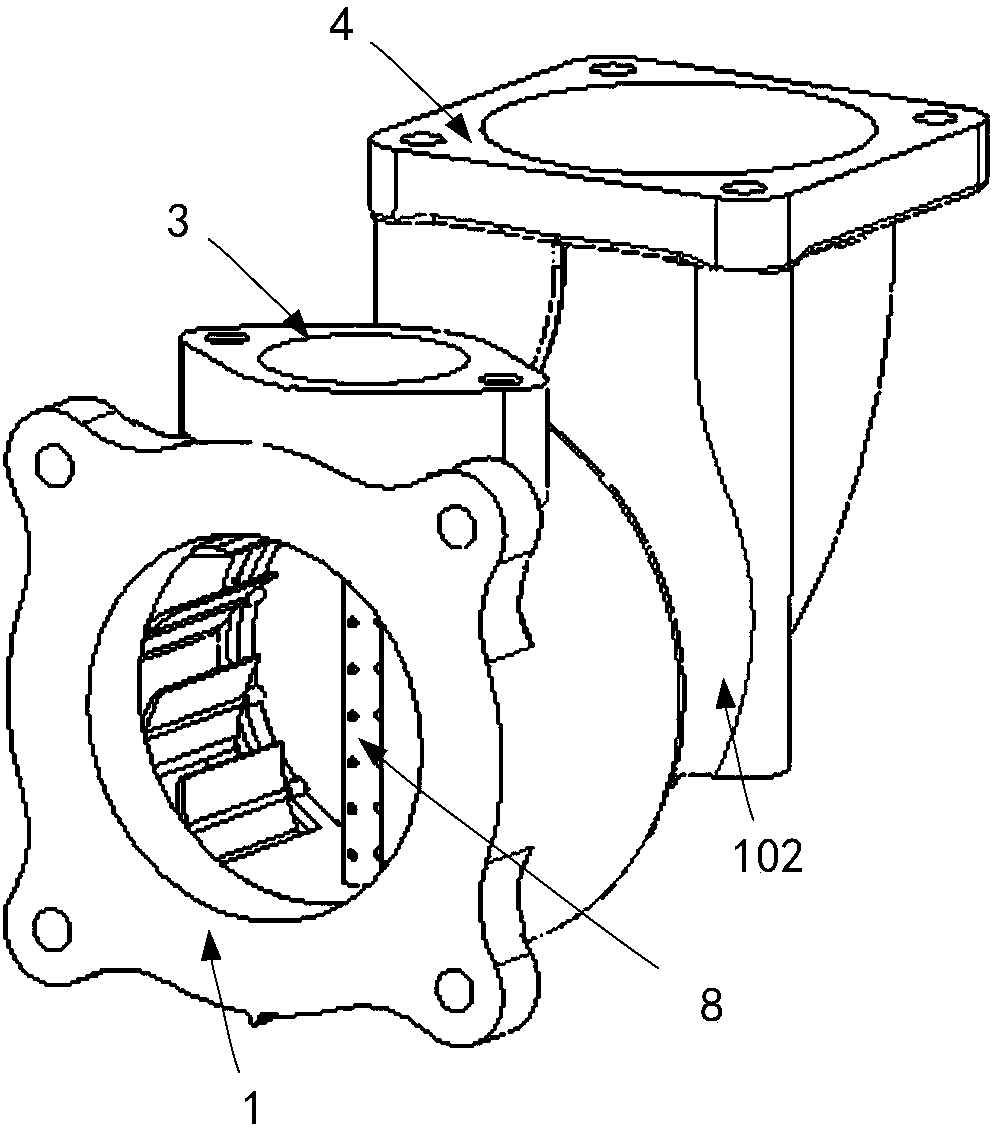

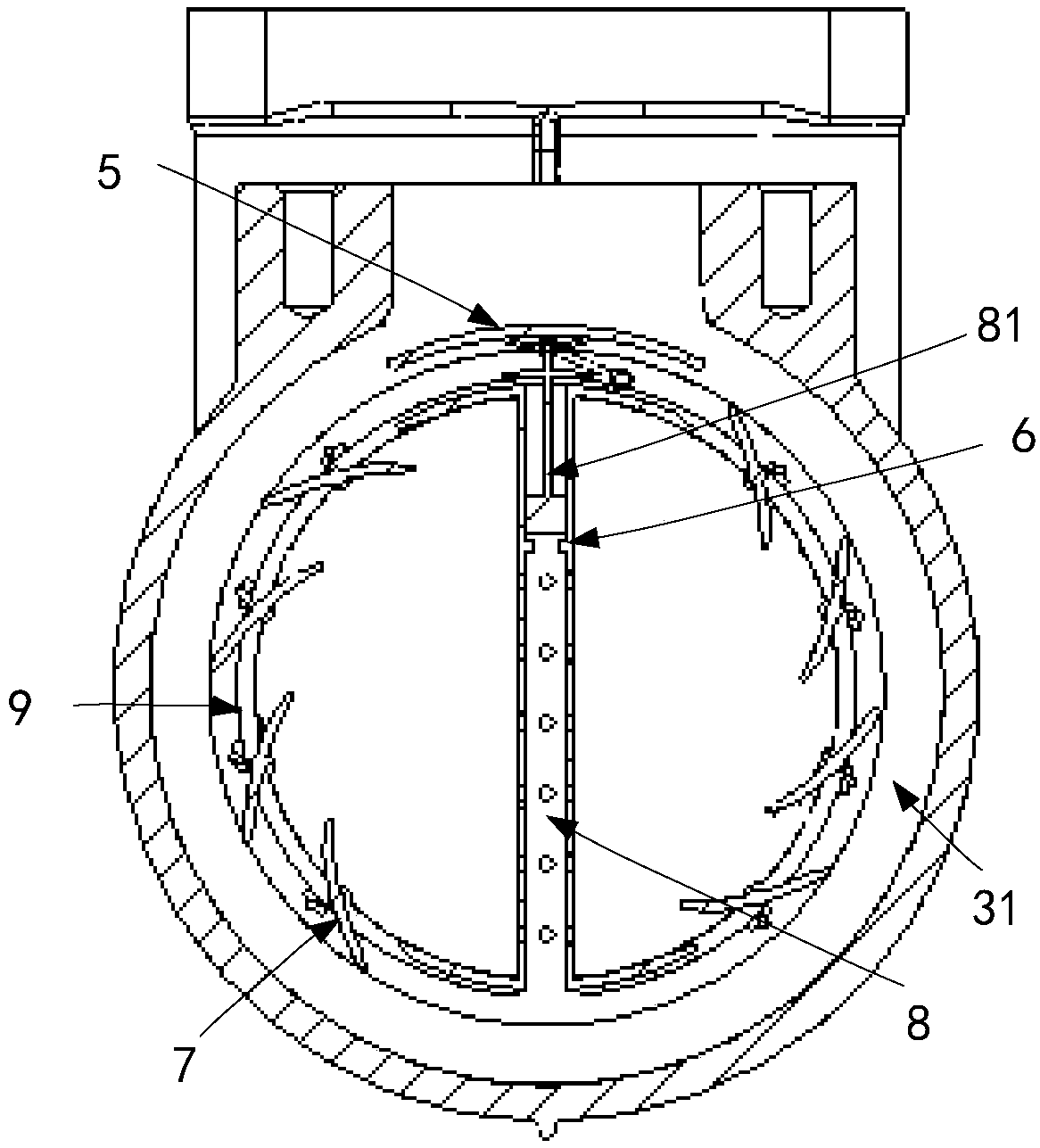

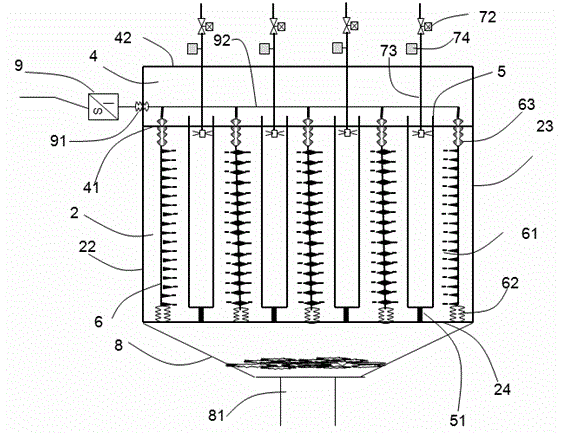

EGR mixing device and internal combustion machine

ActiveCN108150316ASimplify the intake structureSmall pressure resistanceExhaust gas recirculationMachines/enginesCombustion chamberDifferential pressure

The invention provides an EGR mixing device. The device comprises an EGR mixing pipe communicating with an air inlet pipe and a combustion chamber, an EGR mixing cavity is formed in the inlet segmentof the air inlet pipe of the EGR mixing pipe, a waste air inlet communicating with the EGR mixing cavity is formed in the side wall of the EGR mixing pipe, a mixing cavity support is supported and erected in the EGR mixing cavity, an air inlet valve plate for blocking the waste air inlet is supported and erected on the mixing cavity support, the air inlet valve plate comprises a first closing sidepushed by input air in the air inlet pipe to be closed and a second opening side pushed by input air of the waste air inlet to be opened. Fresh air and waste air are mixed in the EGR mixing cavity, the waste air inlet is blocked or opened through the air inlet valve plate on the mixing cavity support, when the waste air inlet is blocked, backflow caused by the fact that air pressure in the air inlet pipe is larger than that of the waste air inlet is avoided, the air inlet structure of an EGR pipeline is simplified, the pressure difference between the fresh air and the waste air is used for blocking the waste air inlet, the pressure resistance of the EGR pipeline is small, and the EGR rate is improved. The invention further provides an internal combustion machine.

Owner:WEICHAI POWER CO LTD

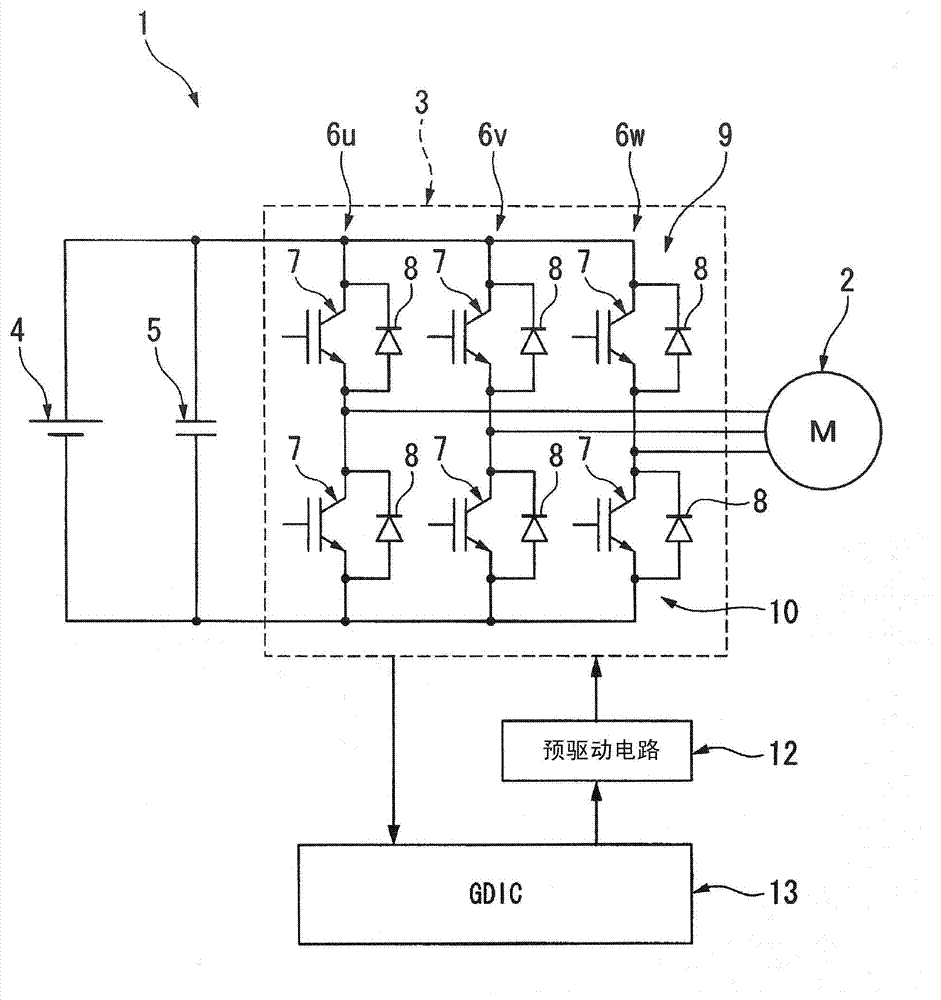

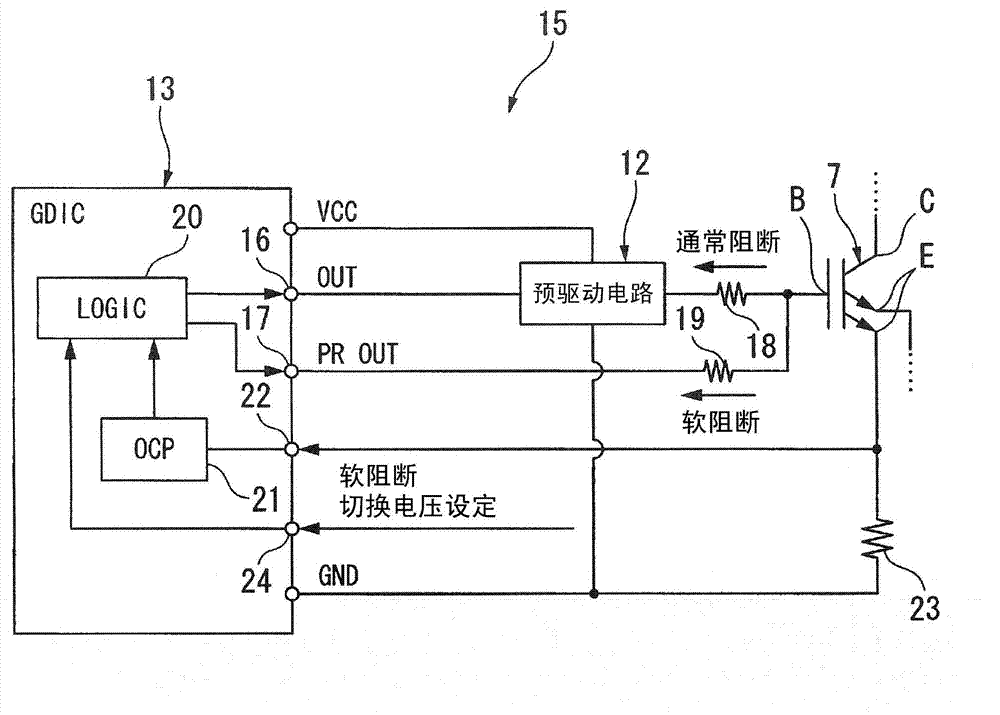

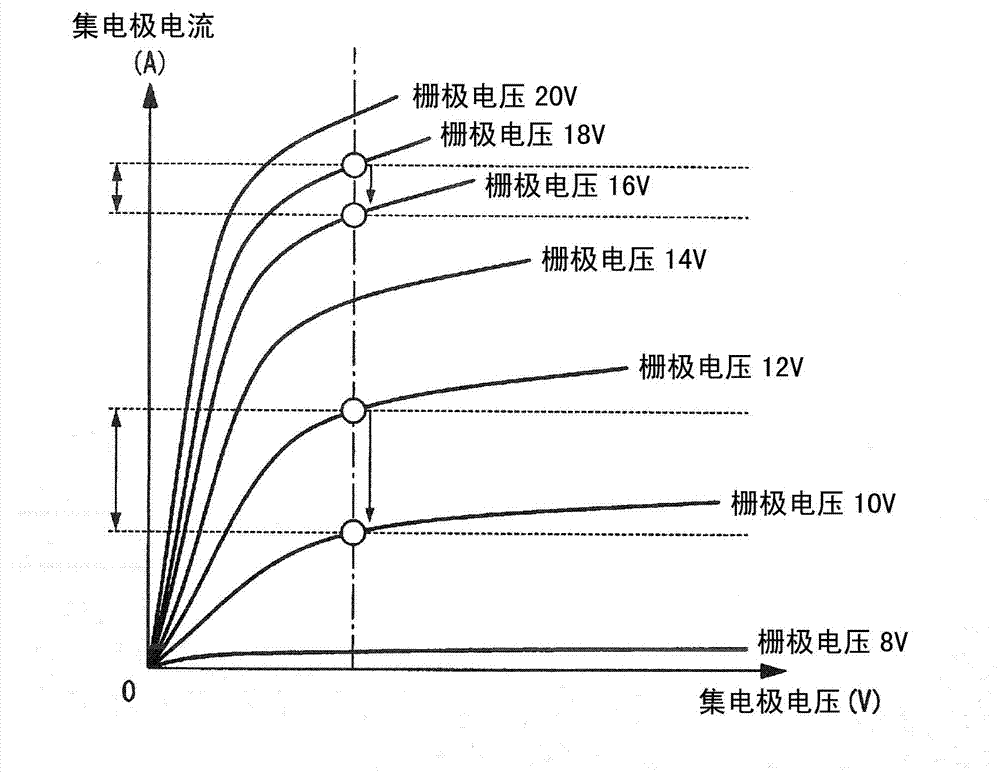

Short-circuit protection method

InactiveCN102893524ASuppress feverAvoid feverElectronic switchingEmergency protective arrangements for automatic disconnectionElectrical resistance and conductancePower switching

Disclosed is short-circuit protection method for circuits equipped with a plurality of power switching elements, wherein, in cases in which a short circuit has been detected in one power switching element by means of a detection means for detecting short circuits in the aforementioned power switching elements, a shutdown process is executed that shuts down the gates of the other power switching elements through which the short circuit current from the short circuit in the aforementioned one power switching element is passed; and moreover, while the shutdown process is being executed, the value of the gate resistance of the aforementioned other power switching elements is changed.

Owner:HONDA MOTOR CO LTD

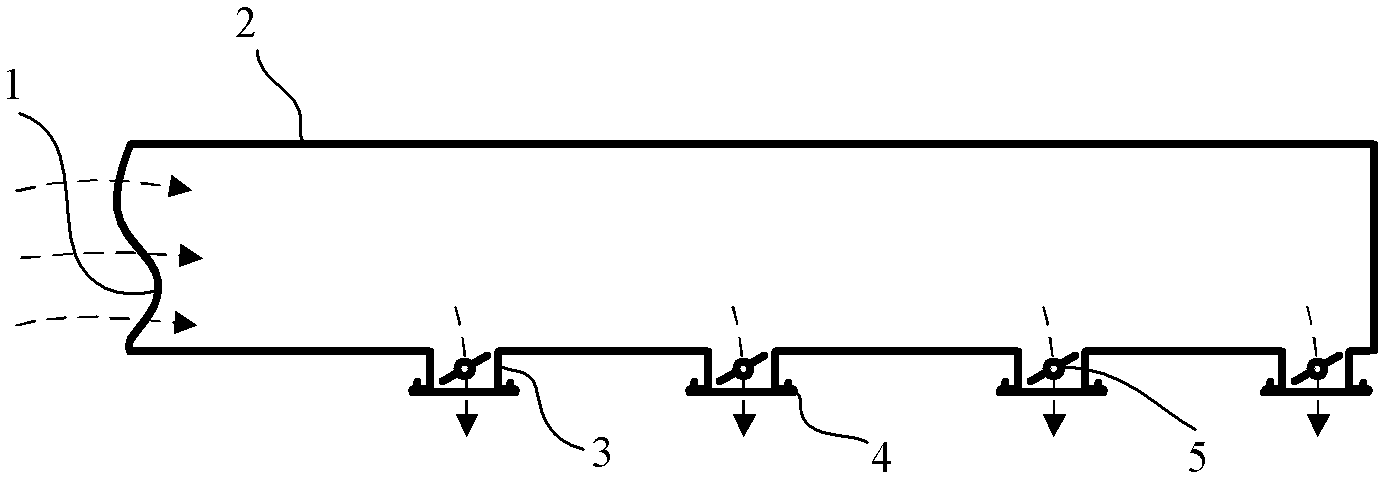

Shunt type air bath duct

ActiveCN102841508ASolve the problem of mediating mutual interferenceSmall pressure resistancePhotomechanical exposure apparatusMicrolithography exposure apparatusShunt typesEngineering

The present invention discloses a shunt type air bath duct, which comprises a body and at least a shunt unit. The body is provided with at least one branch air outlet. The shunt unit and the branch air outlet are correspondingly arranged one-to-one. The height of the body is sequentially reduced along with the shunt unit. The shunt unit comprises a regulation member and a shunt piece, wherein the regulation member can be movably arranged on the body and connected with the shunt piece, and the shunt piece is parallel to the body. With the shunt type air bath duct of the present invention, flows of various branches can be regulated, the problem of mutual interference of branch flow regulation is solved, piezoresistance of the air bath system is reduced, and energy consumption is saved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

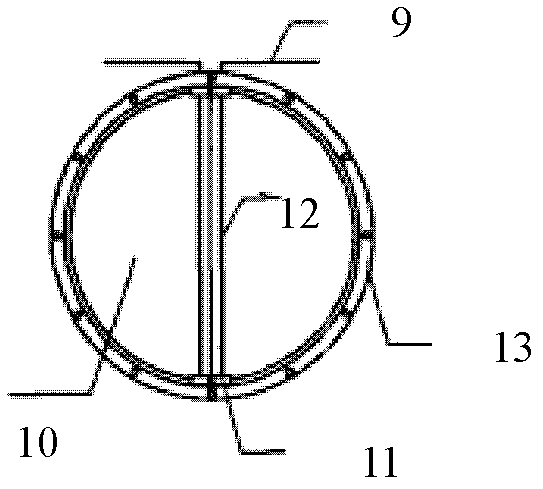

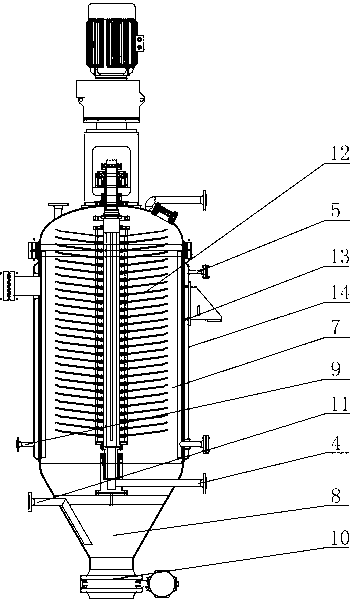

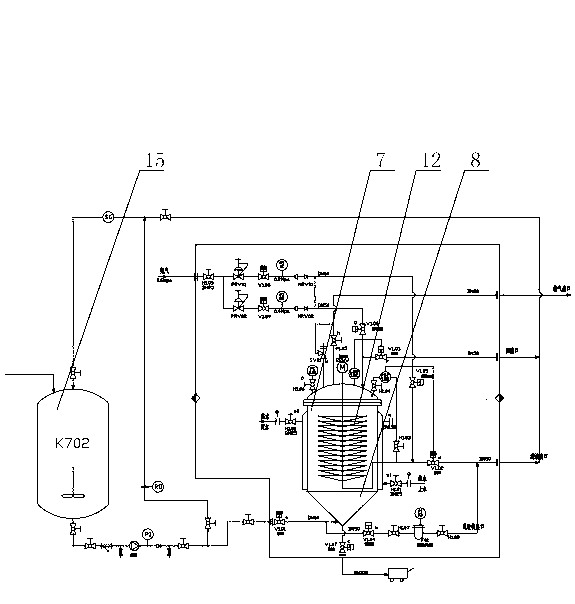

Rotating disk filter

The invention relates to a rotating disk filter. The rotating disk filter comprises a filter barrel, wherein the bottom of the filter barrel is of the shape of an inverted cone, the lower part of the inverted-cone-shaped bottom is provided with a deslagging port, the inverted-cone-shaped bottom is connected with a material inlet by a pipeline, the filter barrel comprises an inner barrel and an outer barrel, a heat source cavity is formed between the outer wall surface of the inner barrel and the inner wall surface of the outer barrel, for the heat source cavity, a heat source inlet is formed in one side of the outer barrel, and a heat source outlet is formed in the other side of the heat source chamber; and the filter barrel is provided with a material outlet by the pipeline, the top of the filter barrel is provided with a filter cover, the upper part of the filter cover is provided with an air outlet, and the top of the filter cover is also provided with a back blowing device by the pipeline. The rotating disk filter has the advantages of reasonable structure and convenience in operation. The bottom of the filter barrel adopts an inverted-cone-shaped structure, and the rotating disk filter can efficiently solve the problems that filter cake piles and remains during the deslagging so as to cause the incomplete deslagging.

Owner:FEATURE-TEC (WUXI) FILTRATION TECH CO LTD

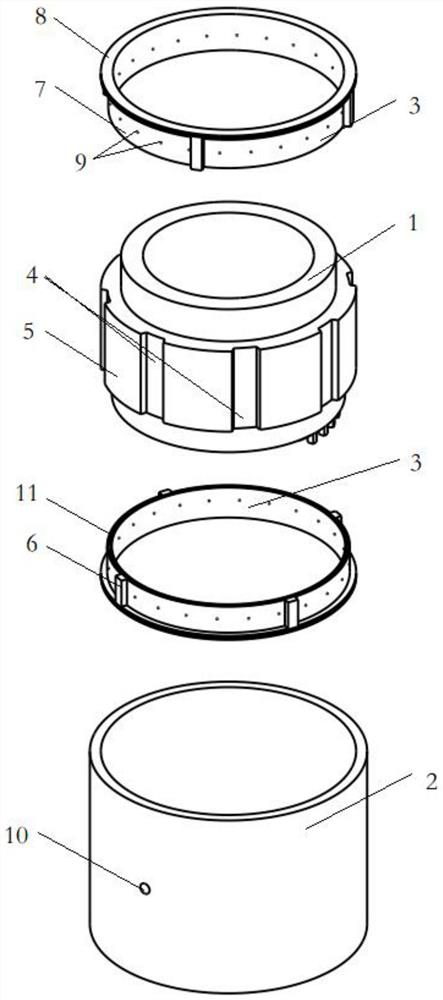

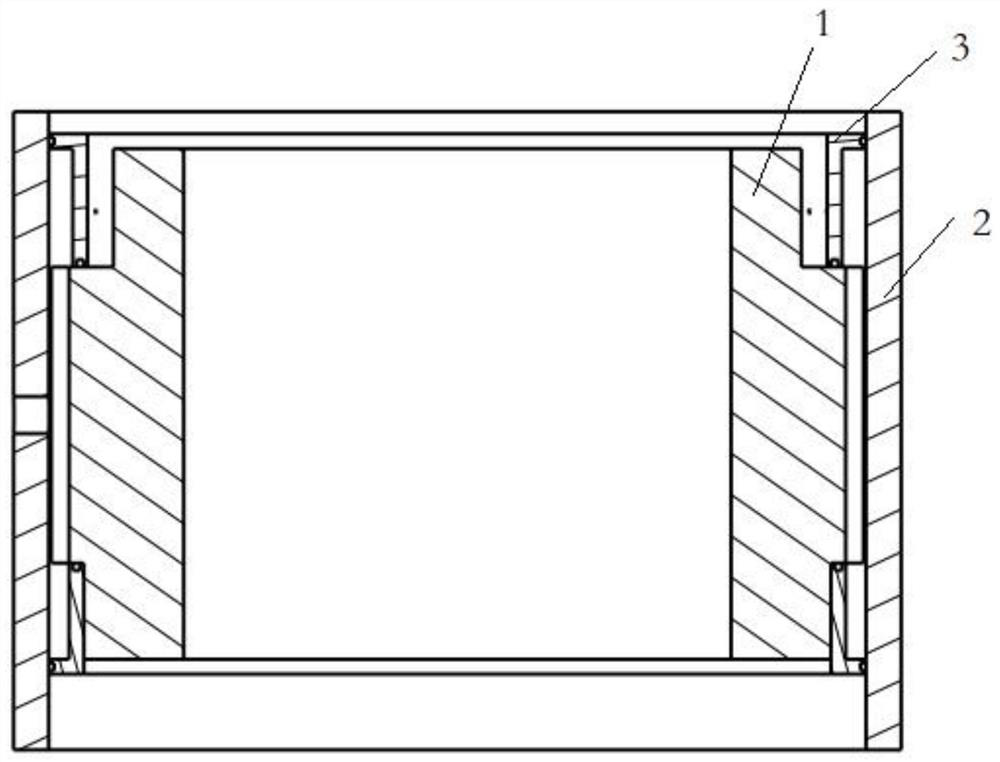

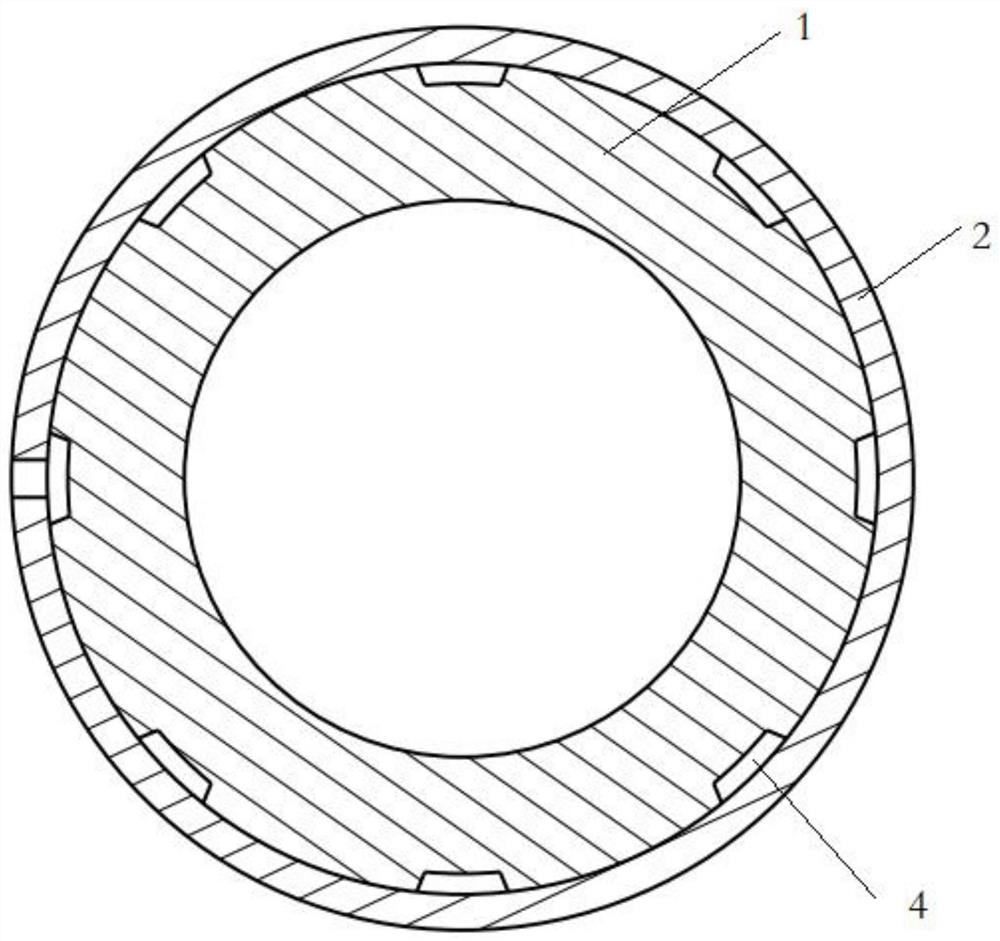

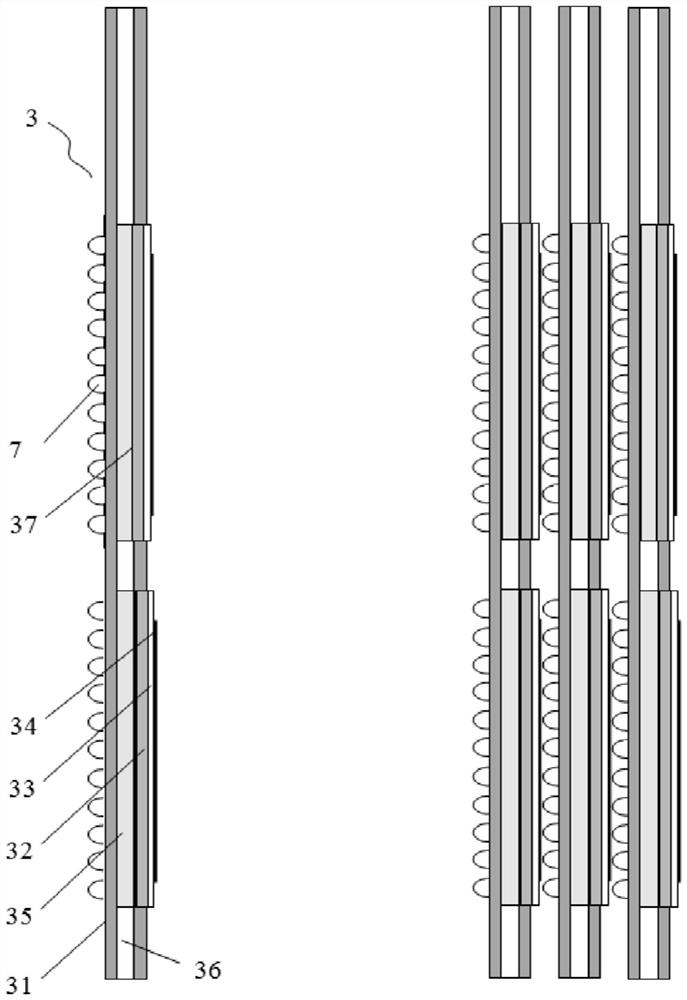

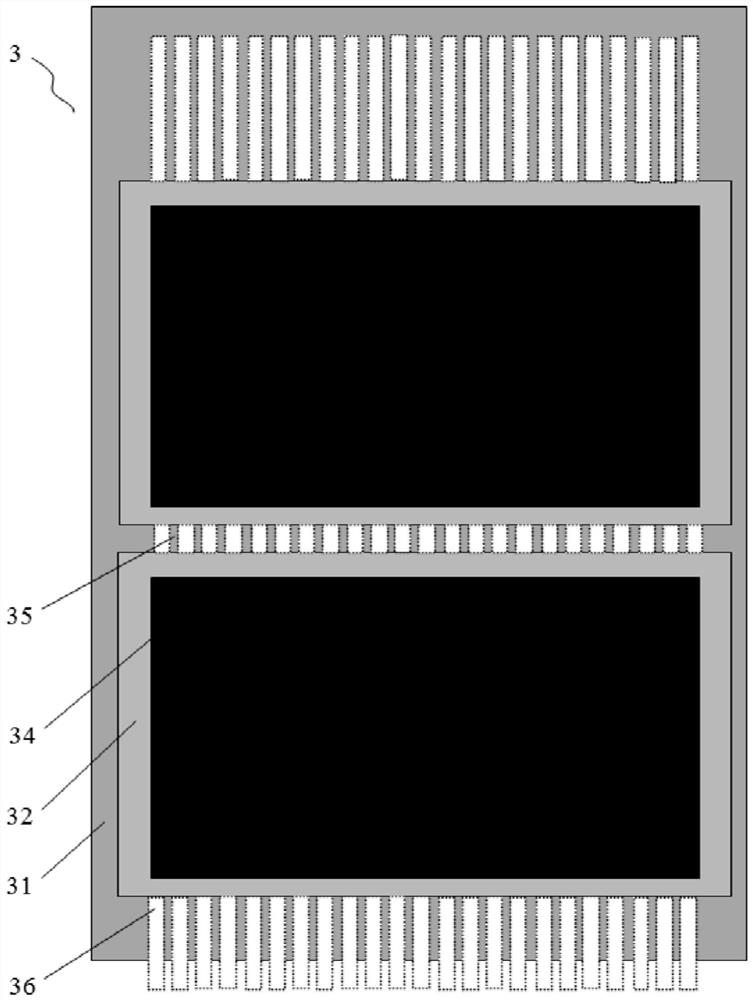

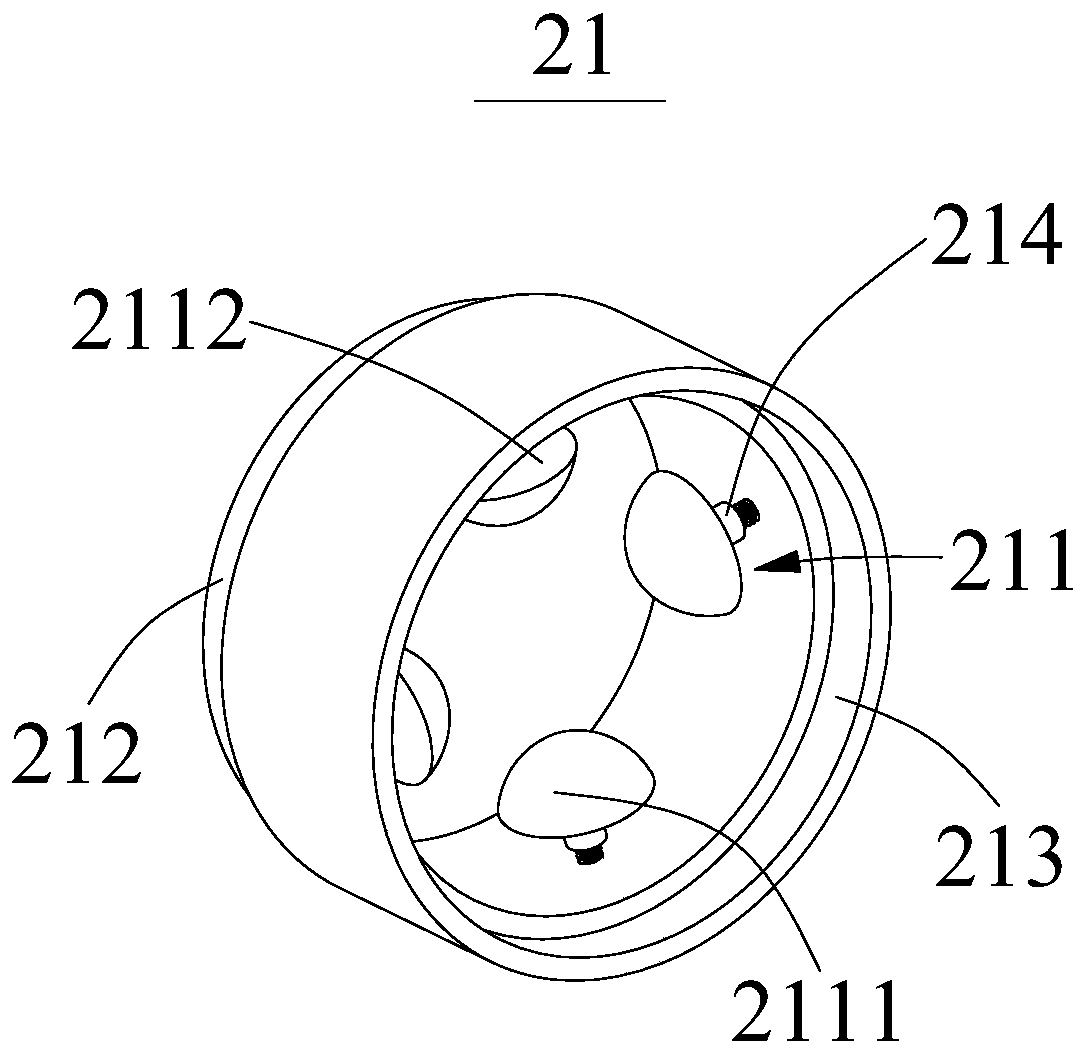

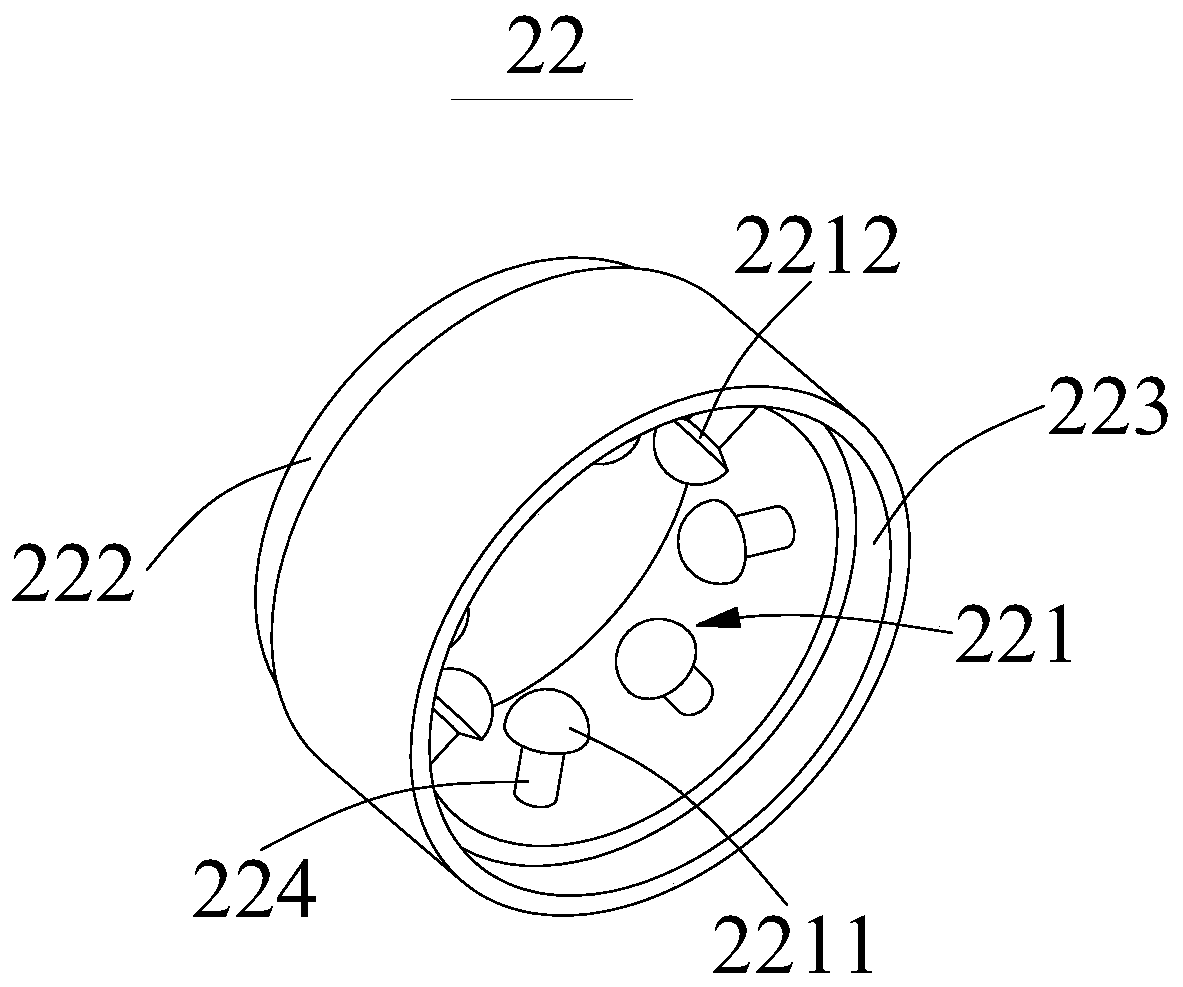

Stator cooling structure and motor provided with stator cooling structure

PendingCN113381531ARealize heat exchange and coolingSimple structureMagnetic circuit stationary partsCooling/ventillation arrangementPhysicsMechanical engineering

The invention provides a stator cooling structure and a motor provided with the stator cooling structure. A stator is coated with a shell, and the inner surface of the shell and the outer surface of the stator are arranged in a gapless manner; a plurality of axial slots are formed in the inner surface of the shell or the outer surface of the stator, and a first oil way blocking structure is arranged between every two adjacent axial slots; the two ends of the stator are provided with the two oil rings respectively, a plurality of radial oil injection channels are formed in the oil rings in the circumferential direction, and the oil injection channels face the windings at the two ends of the stator; at least one second oil way blocking structure is axially arranged on the second heat dissipation part and abuts against a first oil way blocking structure; and cooling oil axially circulates in the axial slots so as to make contact with the first heat dissipation part of the stator, flow to the connecting part, circulate in the circumferential direction and enter the gap through the multiple oil spraying channels so as to make contact with the second heat dissipation part, and efficient heat exchange between the stator iron core and the winding is achieved.

Owner:LEADRIVE TECH (SHANGHAI) CO LTD

Gas deduster

InactiveCN103933821APrevent escapeAvoid secondary pollutionCombination devicesProduct gasEngineering

Owner:任利萍

Three-phase vortex street current sharing method and device

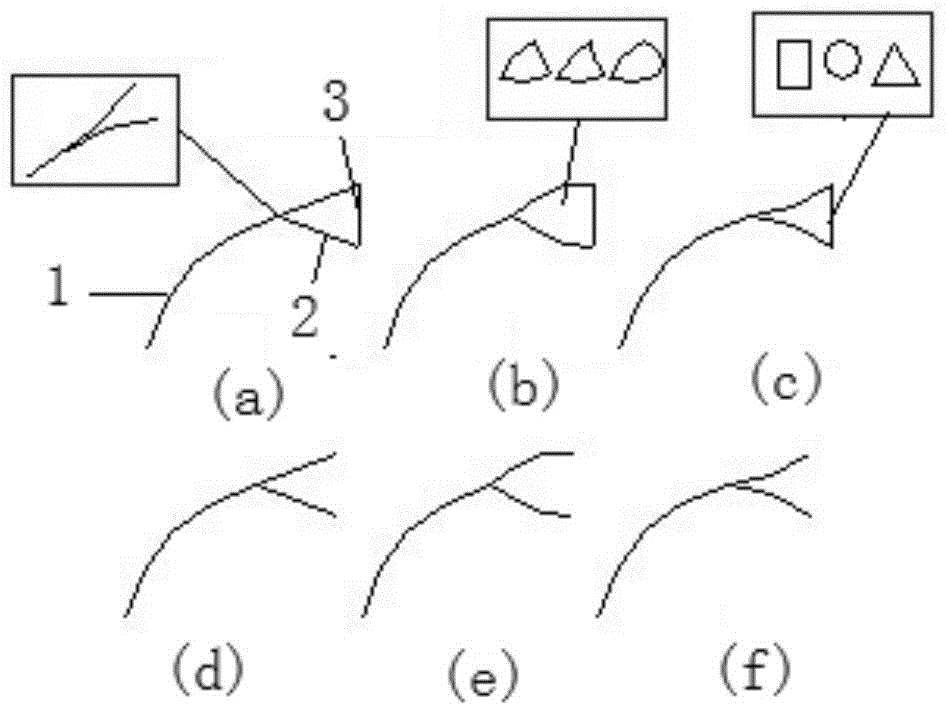

ActiveCN104455897AReduce resistanceAchieve three-phase current sharing effectElectrostatic separationFluid dynamicsParticle flowEngineering

The invention discloses a three-phase vortex street current sharing device which comprises front-end flow guide boards and three-phase vortex street current sharing baffles. The windward faces of the three-phase vortex street current sharing baffles are each of a streamline body structure. The leeward faces of the three-phase vortex street current sharing baffles are each of a bluff body structure. The front-end flow guide boards are connected with the streamline body structure ends of the three-phase vortex street current sharing baffles which can be used for achieving the increased vortex street current sharing effect in a corner or a gradually-expanding pipeline or a suddenly-expanding pipeline. The windward faces of the three-phase vortex street current sharing device are each of the streamline body structure, resistance in the gas, liquid and solid three-phase movement processes is fully reduced, the pressure drop and the energy consumption of a system are reduced, and operation cost is reduced; the leeward faces are each of the bluff body structure, so that when gas, liquid drops and particles flow through bluff bodies, two-way vortex streets are generated behind the bluff bodies, the flow field turbulence behind the current sharing baffles is improved, and the three phases are more evenly mixed through transverse conveyance of the vortex streets.

Owner:SHANDONG UNIV

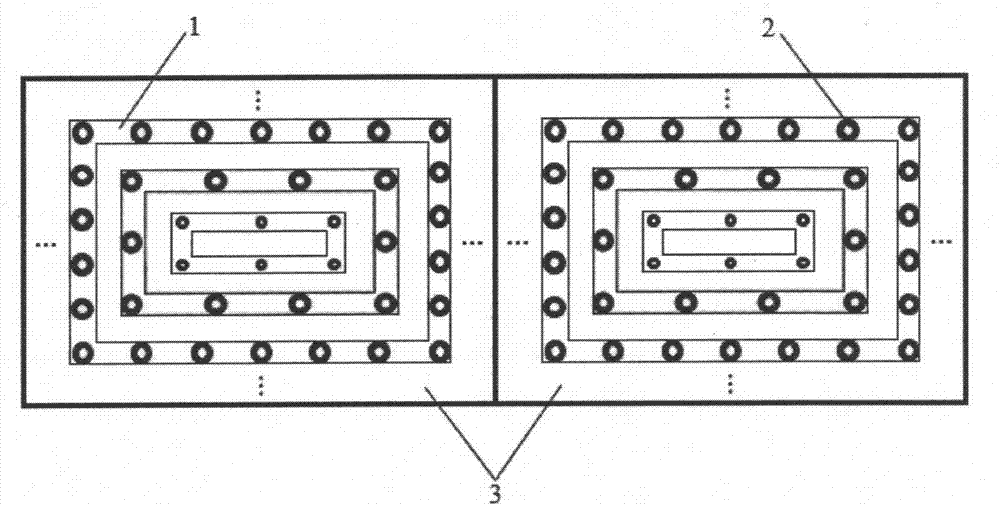

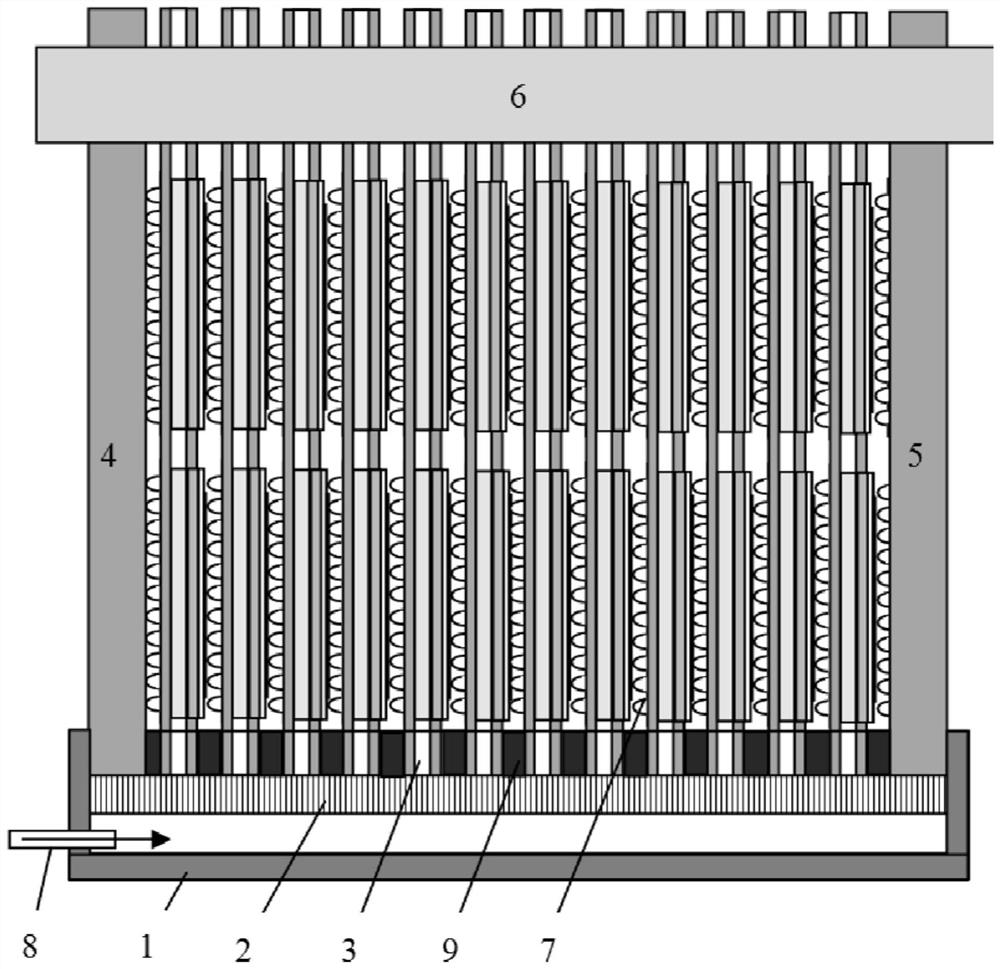

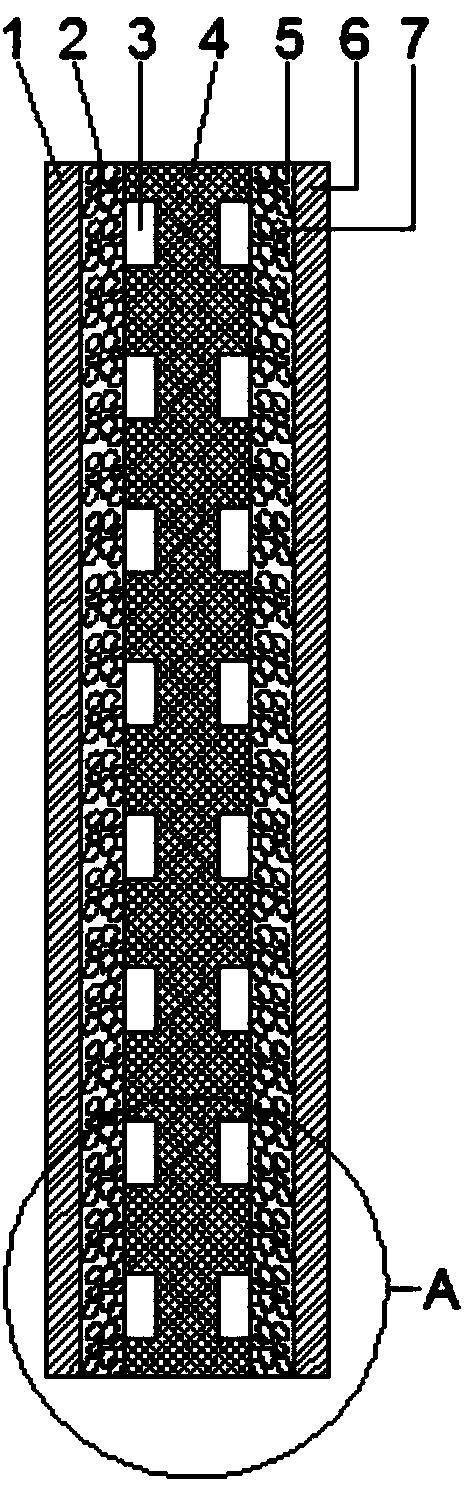

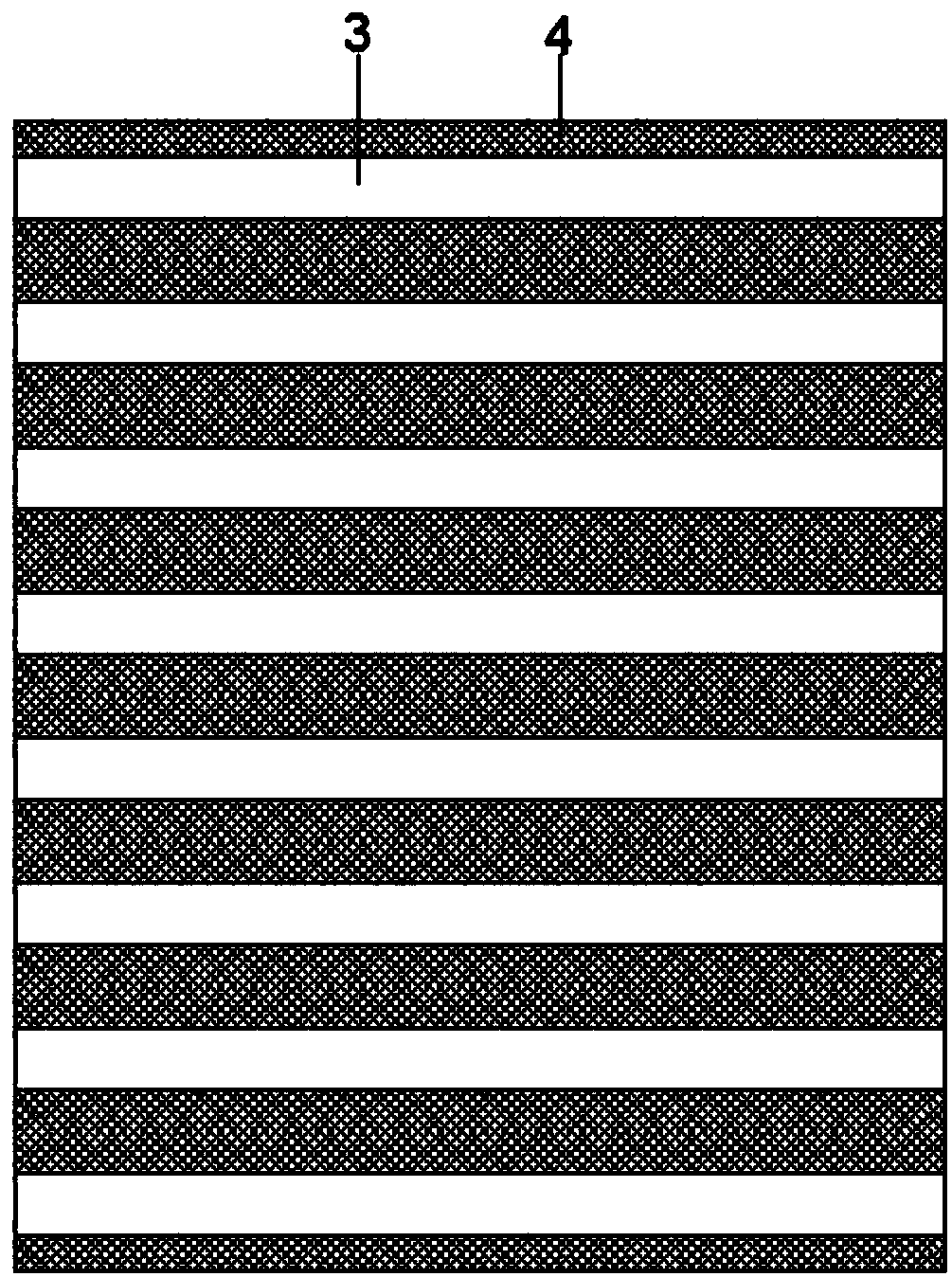

Solid oxide fuel cell stack

PendingCN111613825AReduce scrap rateExtend your lifeSealing/support meansFuel cellsElectrical battery

The invention discloses a solid oxide fuel cell stack. The solid oxide fuel cell stack comprises a cell base, a gas distribution plate, cell repeating units, a negative end plate and a positive end plate, the gas distribution plate is fixed in the battery base, and a fuel cavity is formed between the gas distribution plate and a bottom plate of the battery base; the bottom ends of the negative endplate and the positive end plate are fixed in the cell base; the number of the cell repeating units is more than two, the cell repeating units are sequentially arranged between the negative end plateand the positive end plate side by side, and a gap is reserved between every two adjacent cell repeating units and used for air to penetrate through. The bottom ends of the cell repeating units are fixed on the upper surface of the gas distribution plate through a first sealing piece; the cell repeating units, the negative end plates and the positive end plates are connected through connectors toform electric series connection between two adjacent cell repeating units; a fuel inlet is formed in one side of the battery base, fuel is introduced into a fuel cavity in the battery base through the fuel inlet, and then the fuel is distributed into each cell repeating unit for reaction power generation.

Owner:徐州普罗顿氢能储能产业研究院有限公司

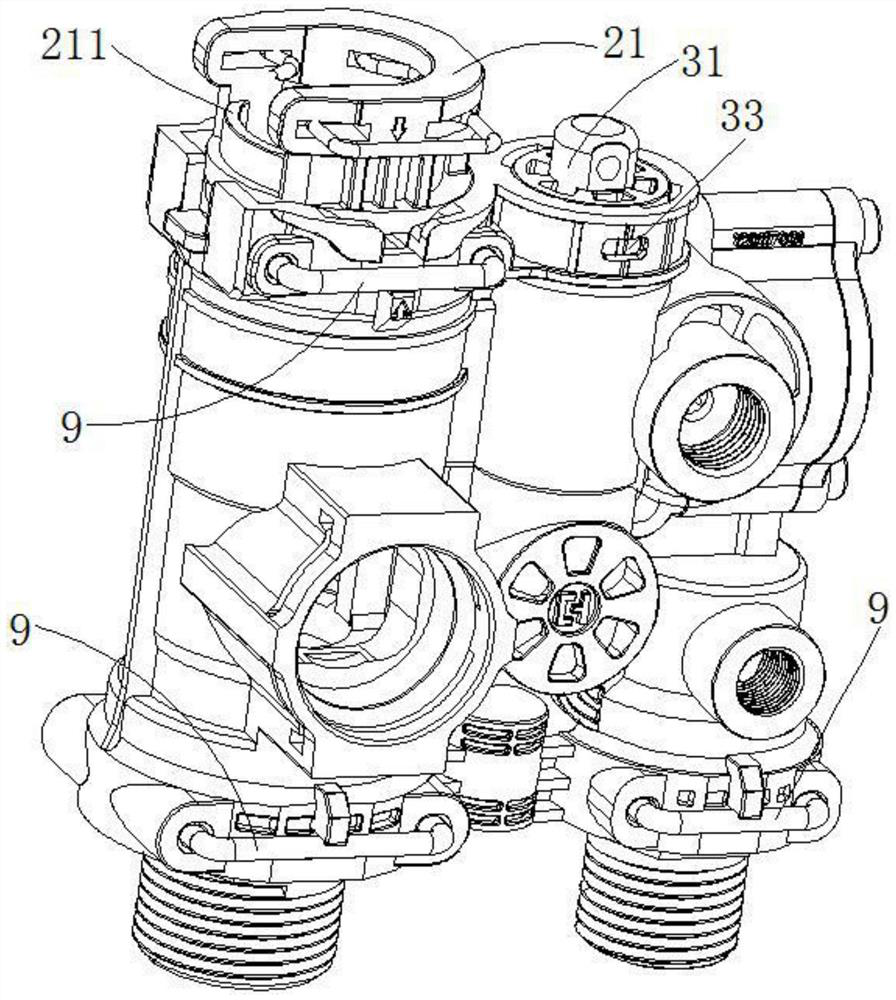

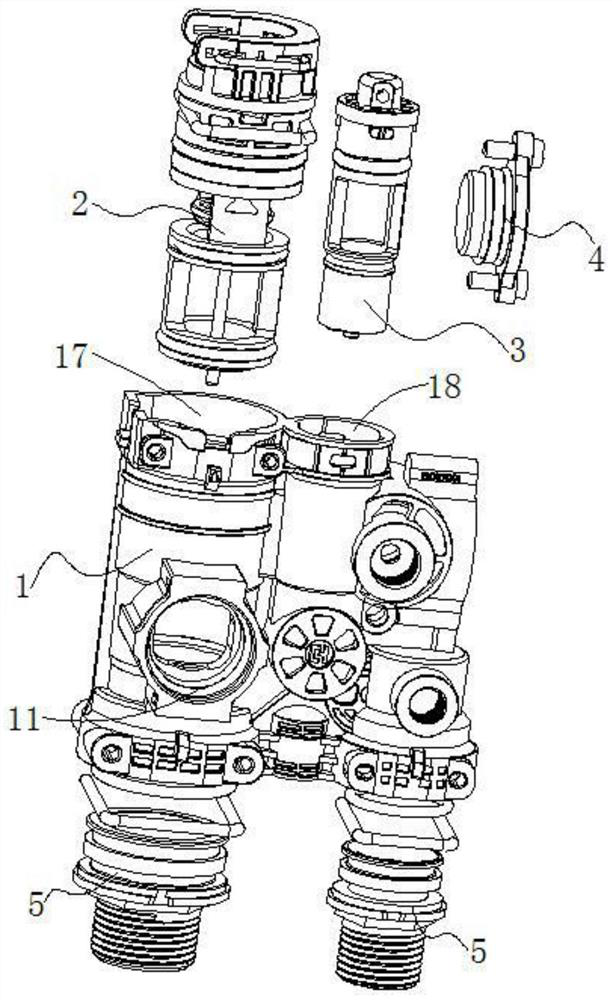

Self-locating high-sealing large-flow three-way valve

ActiveCN112483695ALower the altitudeFew partsSpindle sealingsOperating means/releasing devices for valvesPlastic materialsElectric machinery

The invention discloses a self-locating high-sealing large-flow three-way valve. The three-way valve comprises a shell, wherein the shell comprises a water inlet channel, a first water outlet channel,a second water outlet channel and a valve cavity, the first water outlet channel and the second water outlet channel communicates with the water inlet channel in a switching mode, a valve element ismounted in the valve cavity and comprises a motor base and a three-way framework, the shell, the motor base and the three-way framework are made of plastic materials, the lower end of the motor base extends downwards to form a motor base clamping head, a three-way framework clamping groove allowing the motor base clamping head to be mounted from the side face is formed in the upper end of the three-way framework, the motor base and the three-way framework are connected by inserting the motor base clamping head into the three-way framework clamping groove in a matched mode, and the motor base is connected with the shell through clamping screws. According to the three-way valve, self-locating during mounting can be conveniently realized through the motor base and the three-way framework.

Owner:ZHEJIANG CHUNHUI INTELLIGENT CONTROL

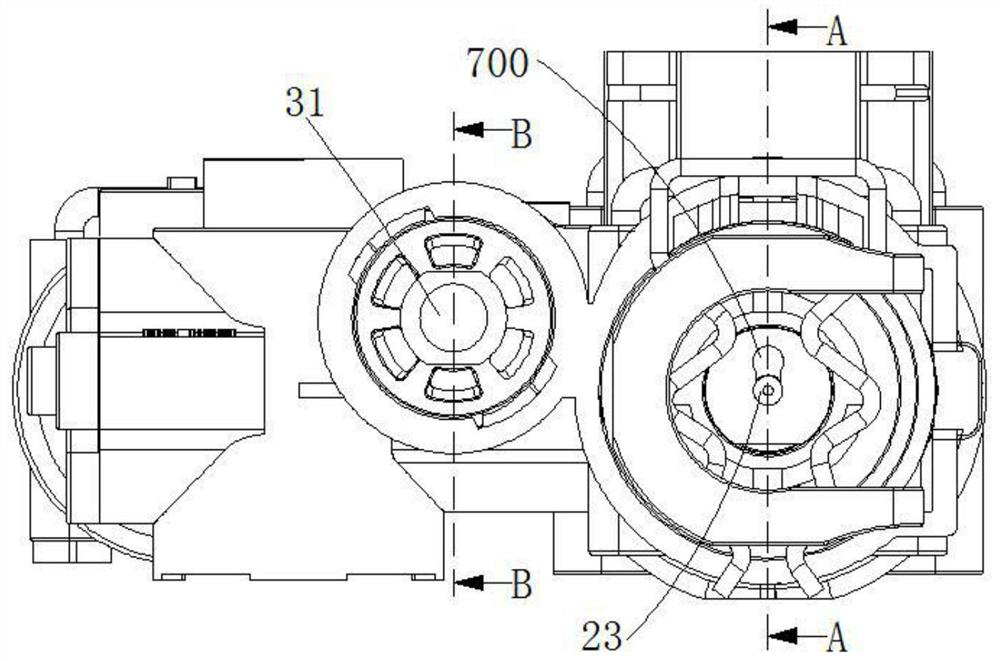

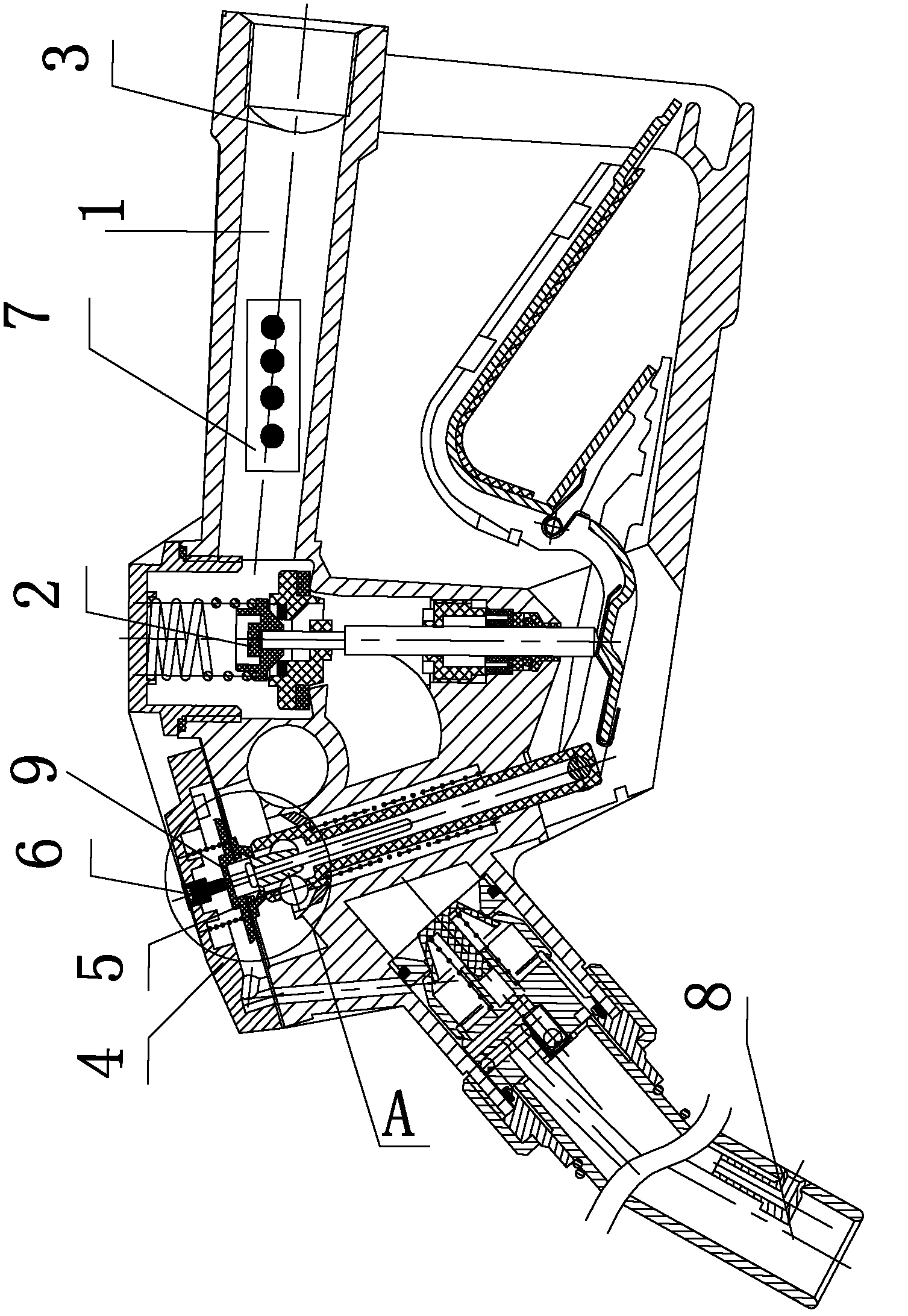

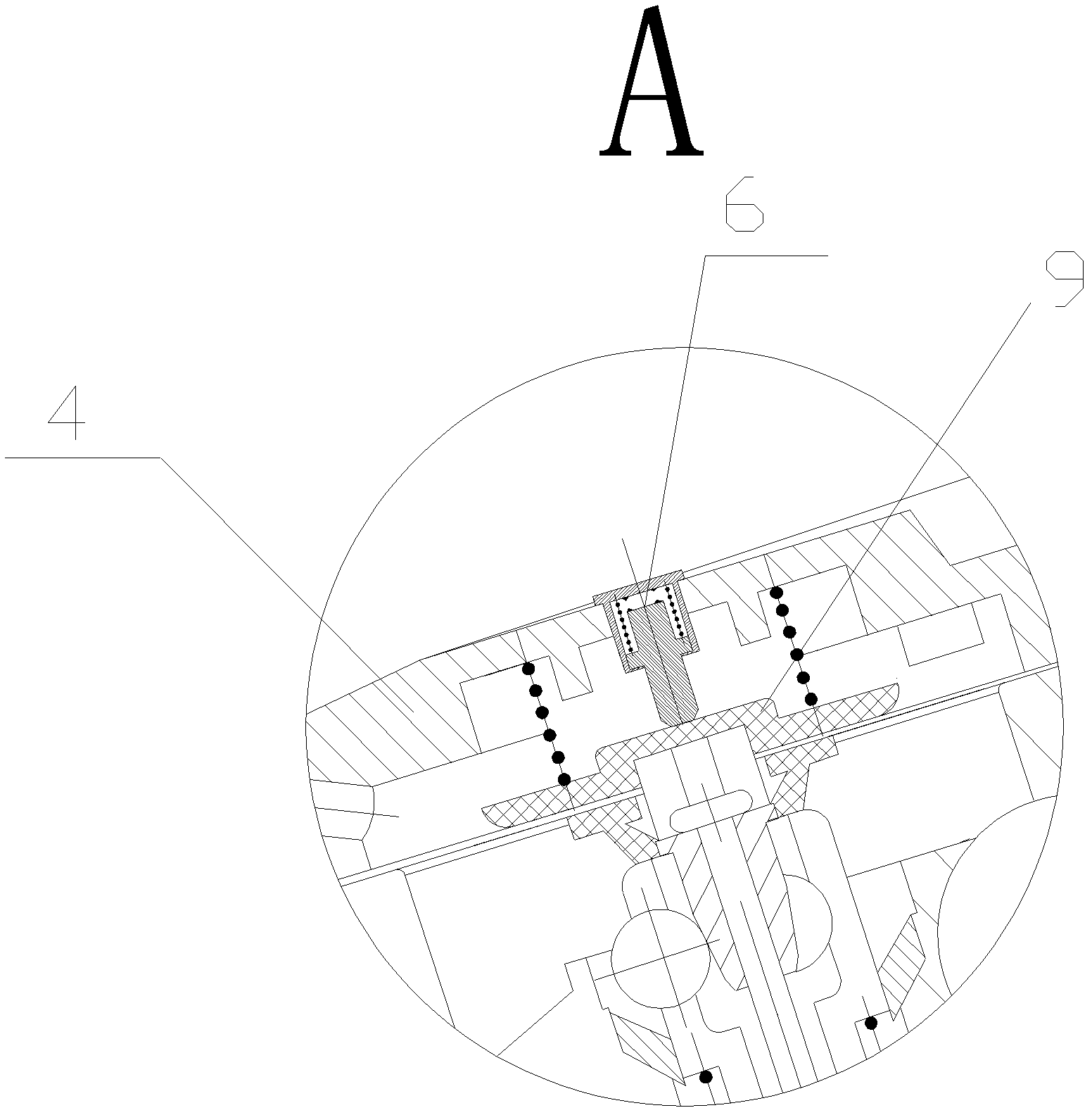

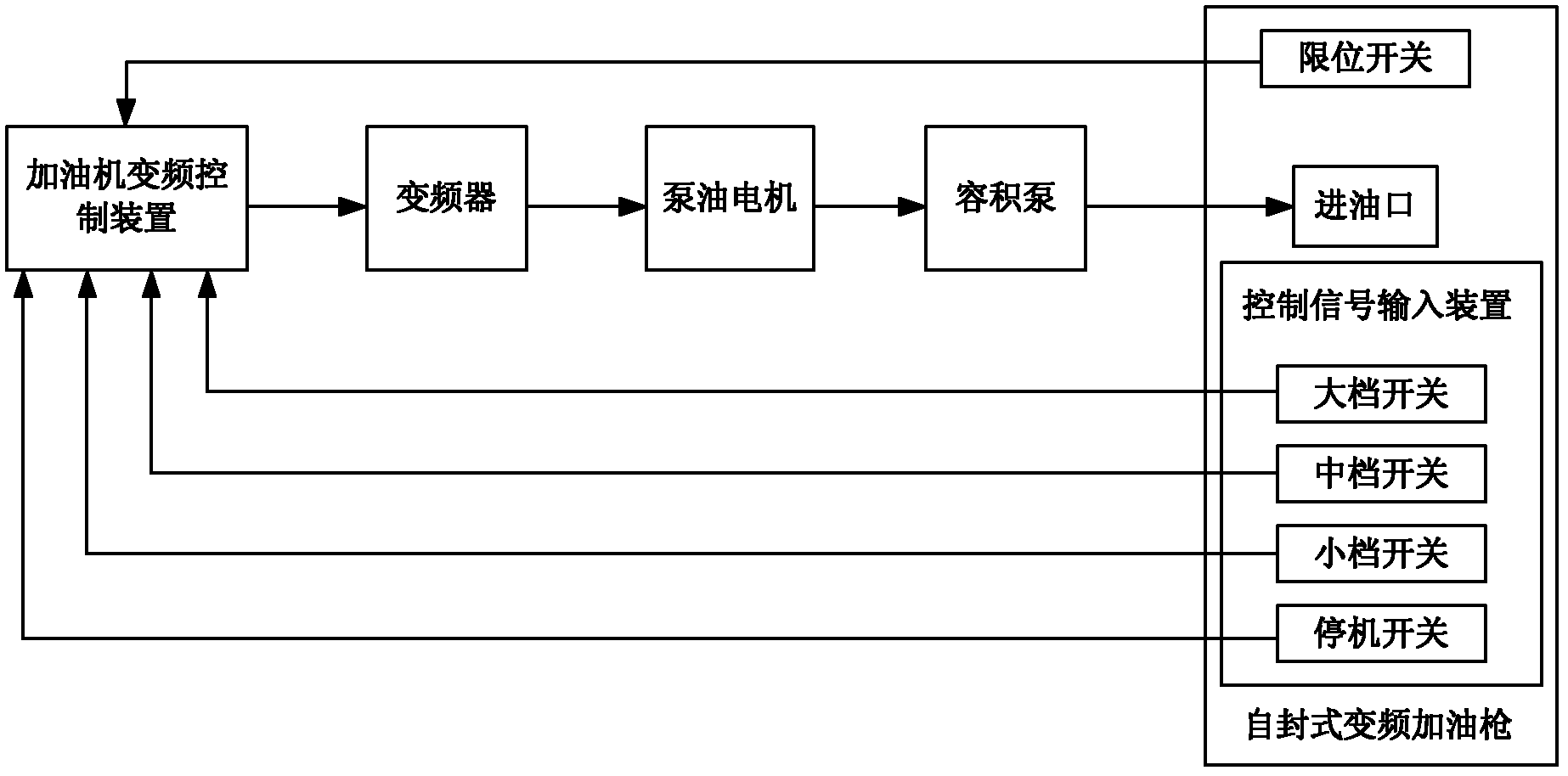

Self-sealing variable-frequency oil gun and control method thereof

ActiveCN102424352ASpeed real-time controlImprove pumping efficiencyLiquid transferring devicesElectricityControl signal

The invention discloses a self-sealing variable-frequency oil gun, which comprises an oil inlet and a self-sealing structure, wherein the self-sealing structure comprises a gating membrane; a self-sealing top cover is arranged above the self-sealing structure; a volume pump in an oiling machine hydraulic system is connected with the oil inlet of the oil gun; and an oiling machine variable-frequency control device in the oiling machine hydraulic system, a frequency converter, an oil pumping motor and the volume pump are connected in sequence. The self-sealing variable-frequency oil gun is characterized in that: the oil gun is provided with a control signal input device; the control signal input device is electrically connected with the oiling machine variable-frequency control device; a limiting switch is arranged from the self-sealing top cover to the inside of the oil gun; the top of the limiting switch is positioned on the self-sealing top cover; the bottom of the limiting switch ispressed against the top of the gating membrane; and the limiting switch is electrically connected with the variable-frequency control device. A control method of the oil gun comprises the following steps of: controlling the magnitude of the oil output of the oil gun through an input signal; and judging whether the self-sealing structure is in self-sealing state to control whether to stop the oil pumping motor. The oil gun has a good energy-saving effect and high safety performance.

Owner:SOUTH CHINA UNIV OF TECH

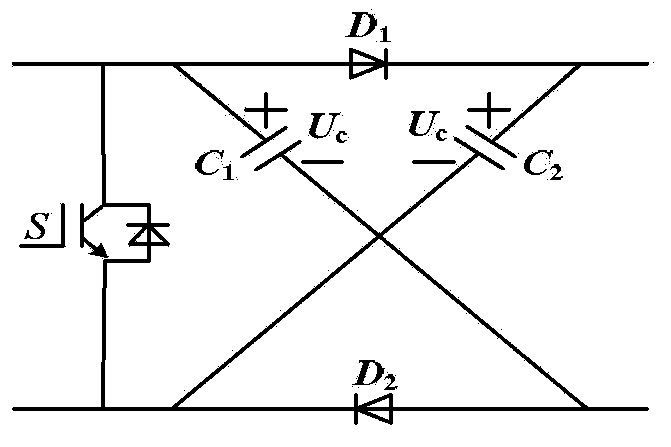

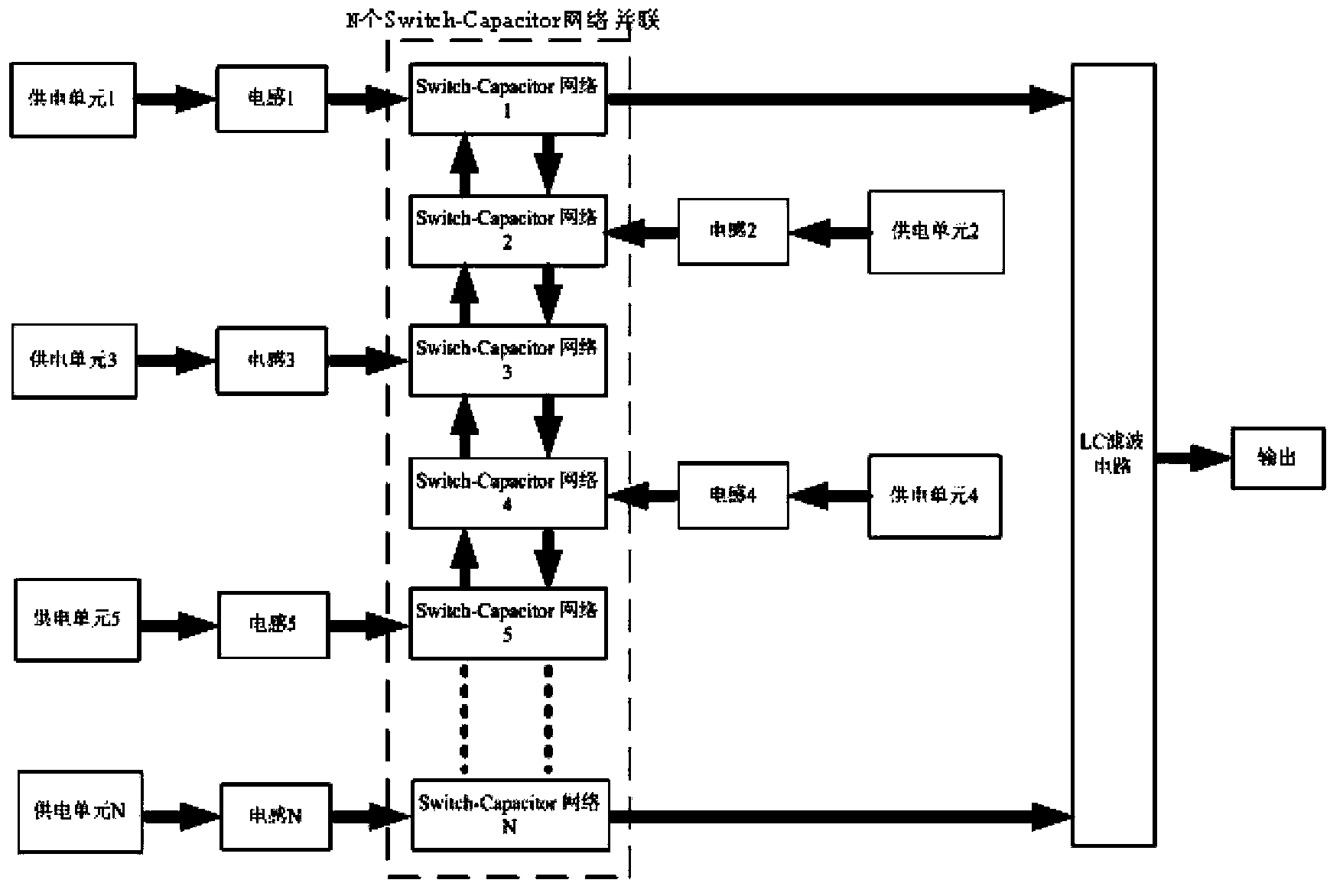

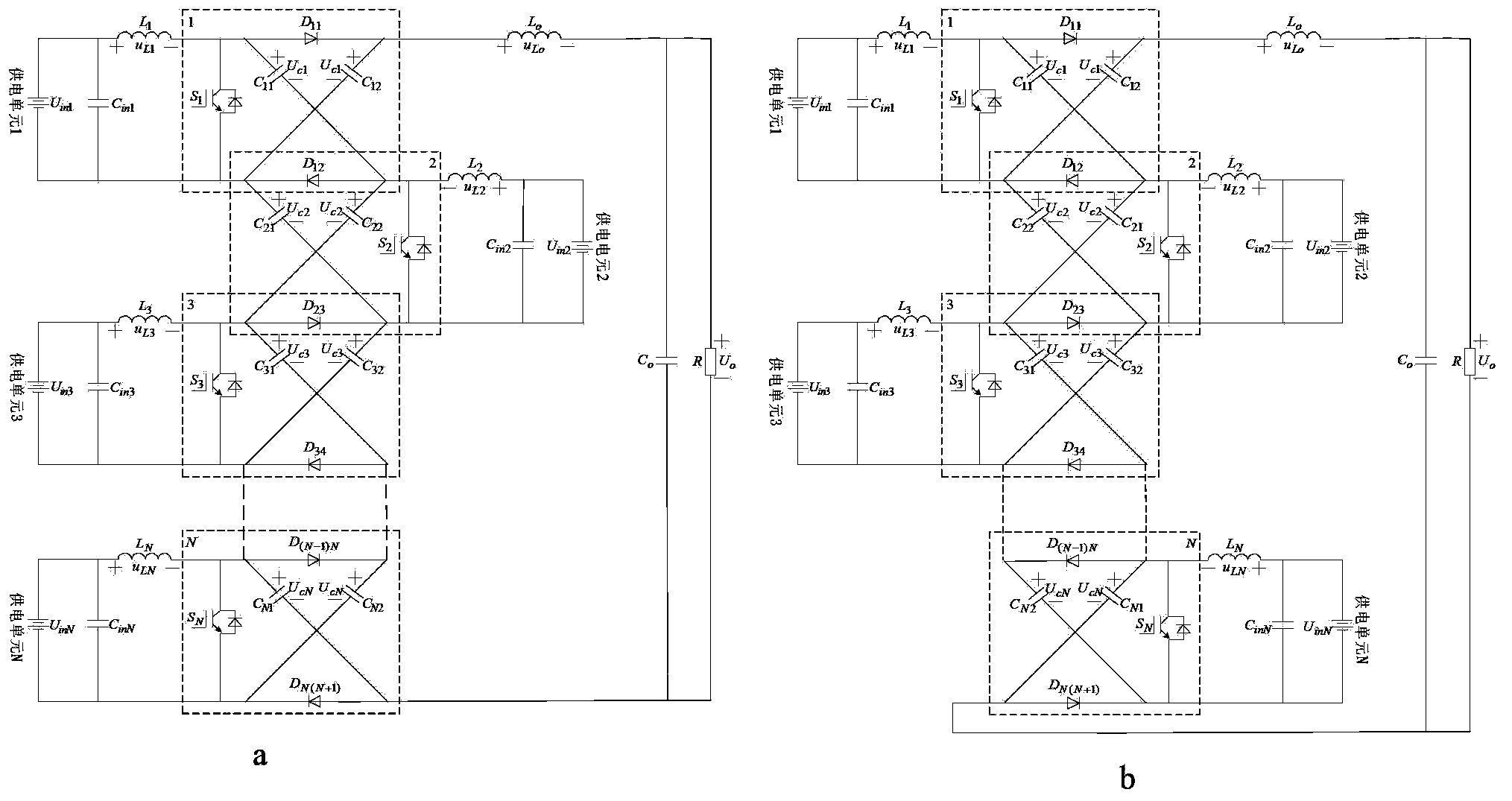

Multi-input boost converter based on Switch-Capacitor networks

InactiveCN103414339AIncrease profitIncrease boost capacityApparatus without intermediate ac conversionMulti inputCapacitor voltage

The invention discloses a multi-input boost converter based on Switch-Capacitor networks. The multi-input boost converter is mainly formed by connecting multiple Switch-Capacitor networks in parallel, the capacitor voltages in all the Switch-Capacitor networks are equal, and a larger output voltage is achieved through the mode of accumulating multiple network capacitor voltages. The multi-input boost converter is used for replacing multiple single-input boost converters. The multi-input boost converter allows the input of multiple energy sources, the properties, the amplitude values and the characters of input sources can be identical and can also be very different, the input sources can supply power to loads respectively or simultaneously, and therefore the stability and the flexibility of a system are improved, the preferential utilization of the energy sources is achieved, and system cost is lowered.

Owner:CHONGQING UNIV

A diagonal flow normal temperature flameless burner

The invention relates to a diagonal-flow constant-temperature flameless burner comprising an inner barrel, an outer barrel, a center tube and an annular baffle plate, wherein the inner barrel is horizontally arranged; one end of the inner barrel is communicated with an inlet pipe of the inner barrel; the other end of the inner barrel extends into a combustion furnace; the part of the inner barrel, inside the combustion furnace, is of an inner and outer dual-layer structure; a groove formed by the inner layer and the outer layer is filled with a refractory matter; the center tube is composed of an inlet section, a transition section and an outlet section; the diameter of the inlet section is greater than that of the outlet section; the transition section is of a tapered structure; the center tube horizontally penetrates through the center of the inner barrel; a certain axial distance is kept between the end face of the outlet section and the end face of an air outlet of the inner barrel; the outer sleeve is arranged outside the inner barrel; one end of the outer sleeve is open and tightly connected with one side of the annular baffle plate; one side surface of the outer barrel is communicated with an inlet pipe of the outer barrel; a plurality of diagonal-flow nozzles are uniformly arranged at the other side of the annular baffle plate at the periphery of the inner barrel along the circumference; one end of each diagonal-flow nozzle is fixed on a round baffle plate and communicated with the outer barrel; the outflow direction of the other end deviates from the outflow direction of the center tube. The diagonal-flow constant-temperature flameless burner works in a constant temperature state without cold and heat exchange.

Owner:PEKING UNIV

PVDF/ionic liquid/PSU high-efficiency low-resistance filtering membrane and preparation method thereof

The invention provides a PVDF / ionic liquid / PSU high-efficiency low-resistance filtering membrane and a preparation method thereof. The preparation method comprises the following steps: step S1, respectively preparing a PVDF solution and a PSU solution, adding an ionic liquid AmimCl into the PVDF solution, and carrying out mixing so as to obtain a PVDF mixed spinning solution; and step S2, placinga layer of a filtering cloth onto a receiving plate as a supporting material, respectively injecting the PVDF mixed spinning solution and the PSU solution into an electrospinning needle, and separately or simultaneously carrying out spinning so as to obtain the PVDF / ionic liquid / PSU high-efficiency low-resistance filtering membrane. By adoption of a technical scheme of the invention, the filteringmembrane obtained by using the preparation method provided by the invention has multiple filtering effects of electret filtration, interception filtration and the like; meanwhile, due to large diameter of PSU fiber and small diameter of PVDF fiber, the resistance of filtration is reduced, and the efficiency of filtration is increased at the same time.

Owner:SHENZHEN ZHONGJIAN NANFANG ENVIRONMENT CO LTD

Double-sided groove type surface solidification layer foam structure

InactiveCN107825770AImprove sealingHigh external release performanceLayered productsGas releaseComposite material

Owner:苏州海量电子材料有限公司

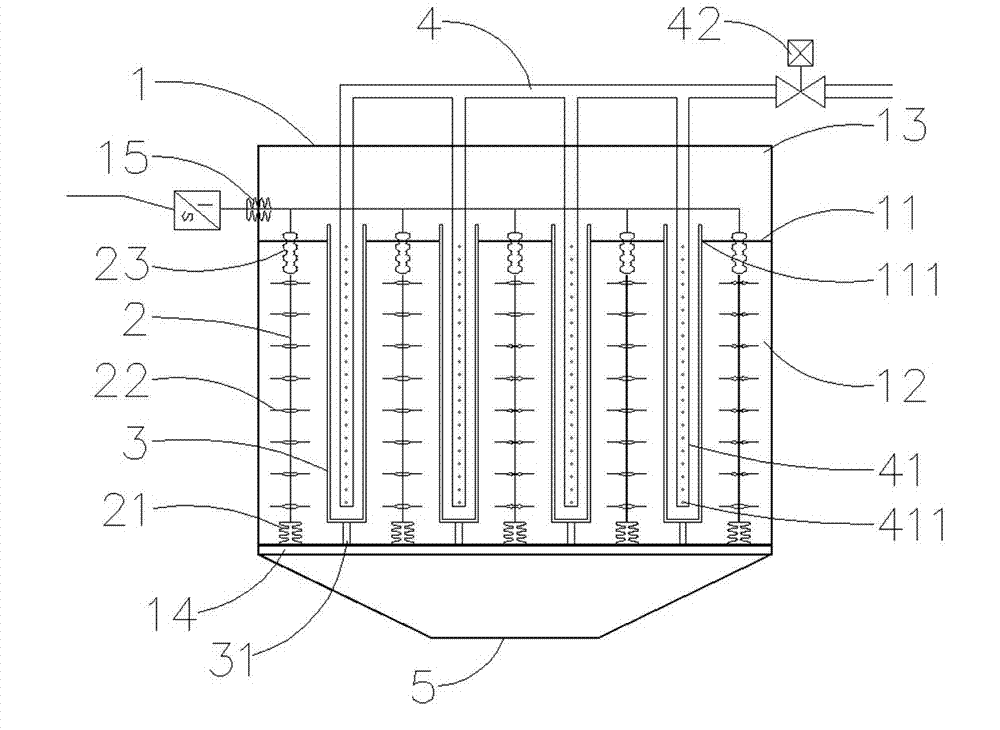

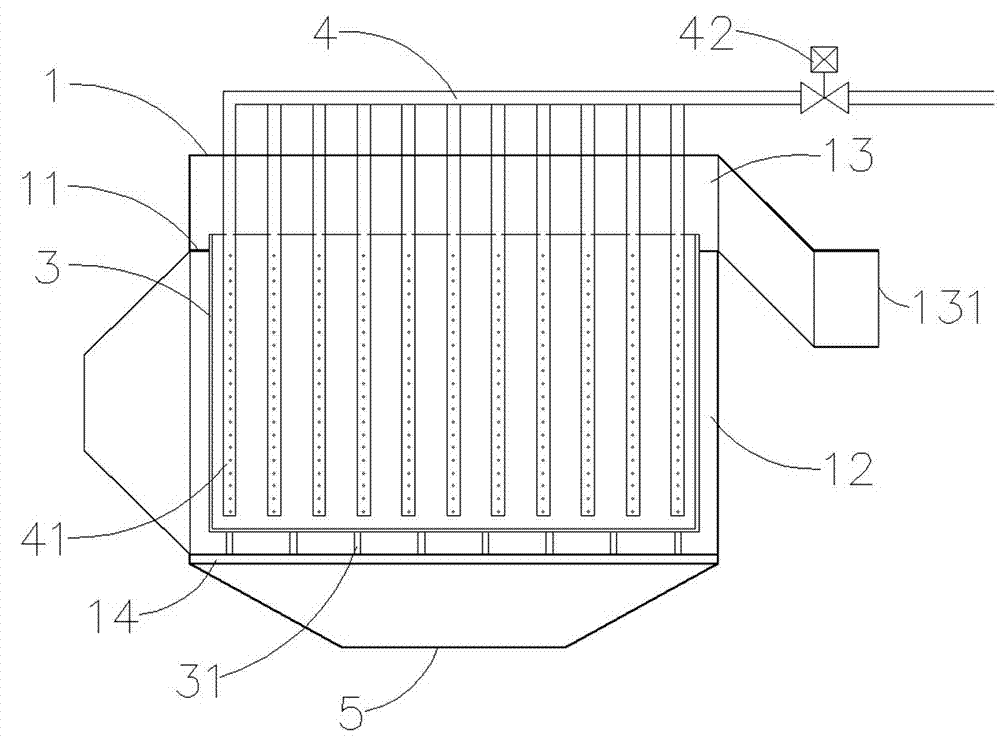

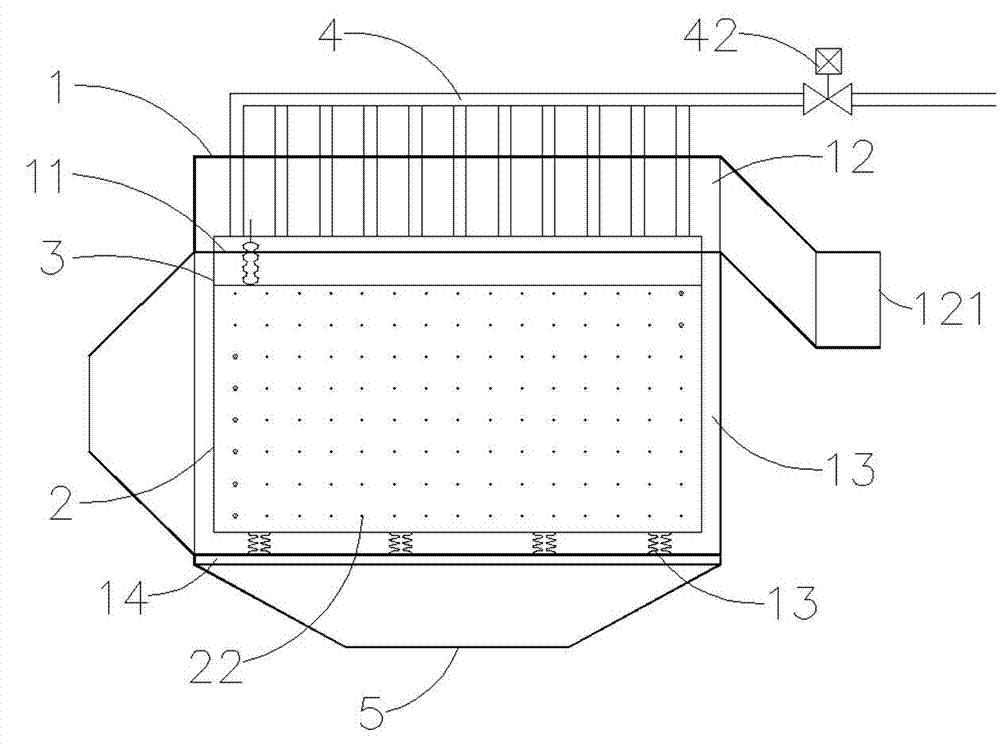

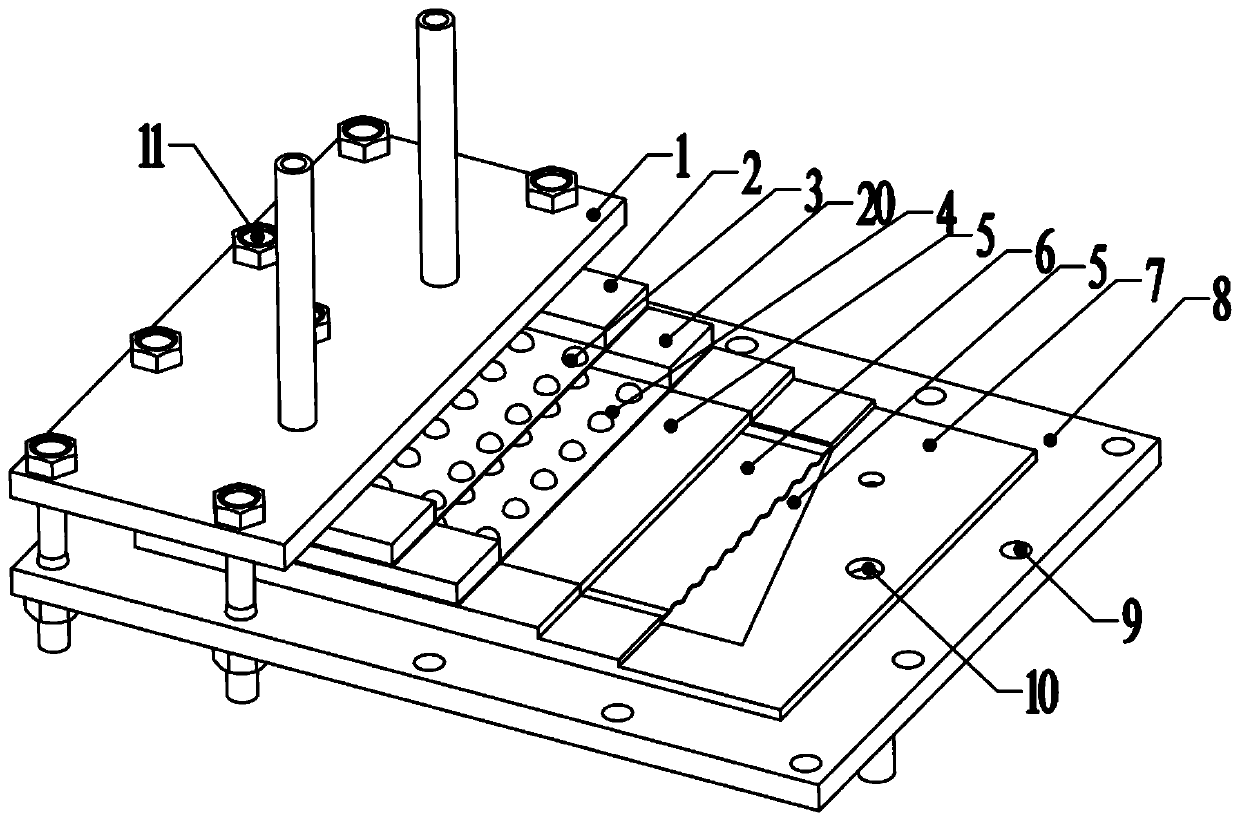

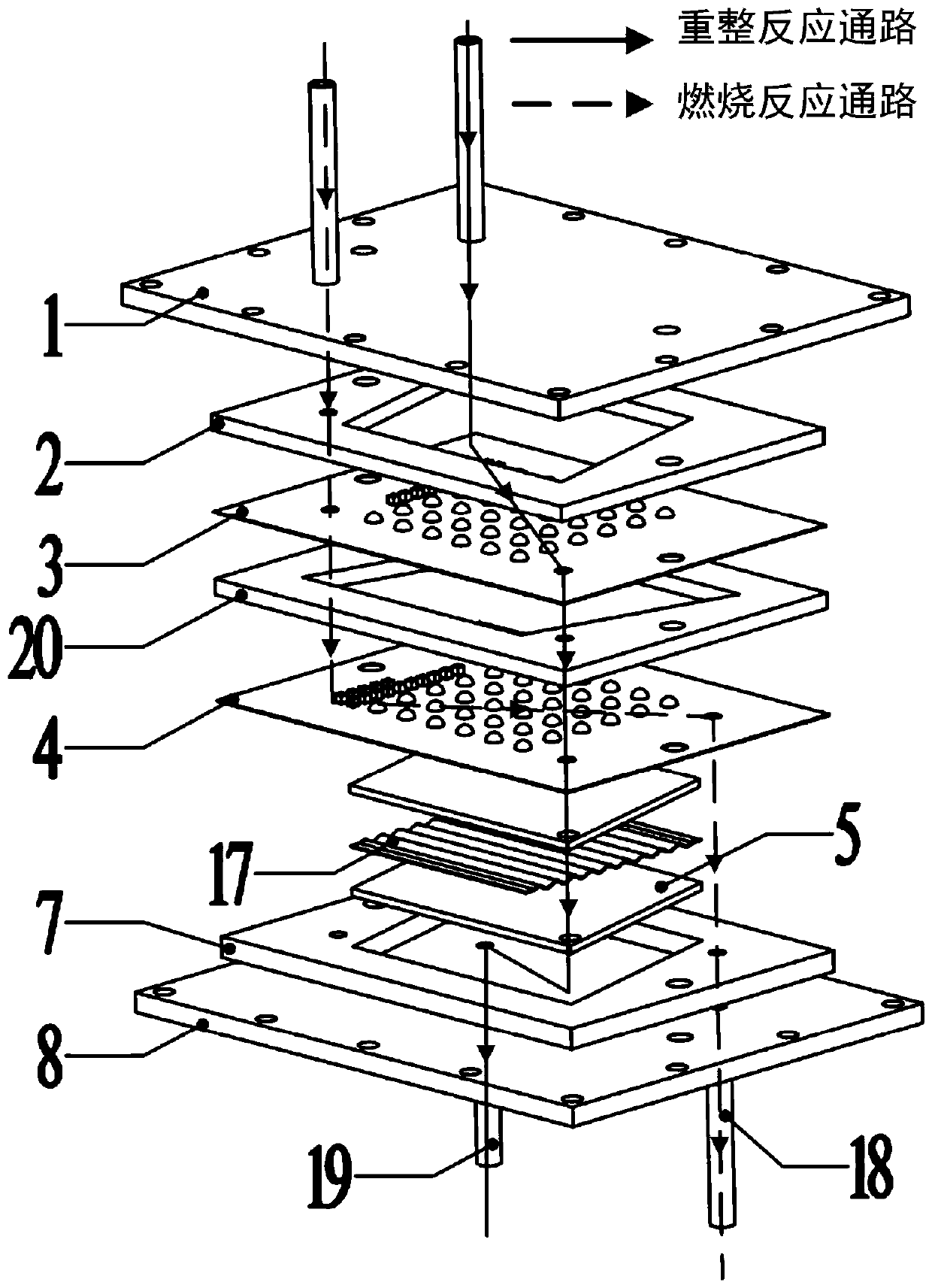

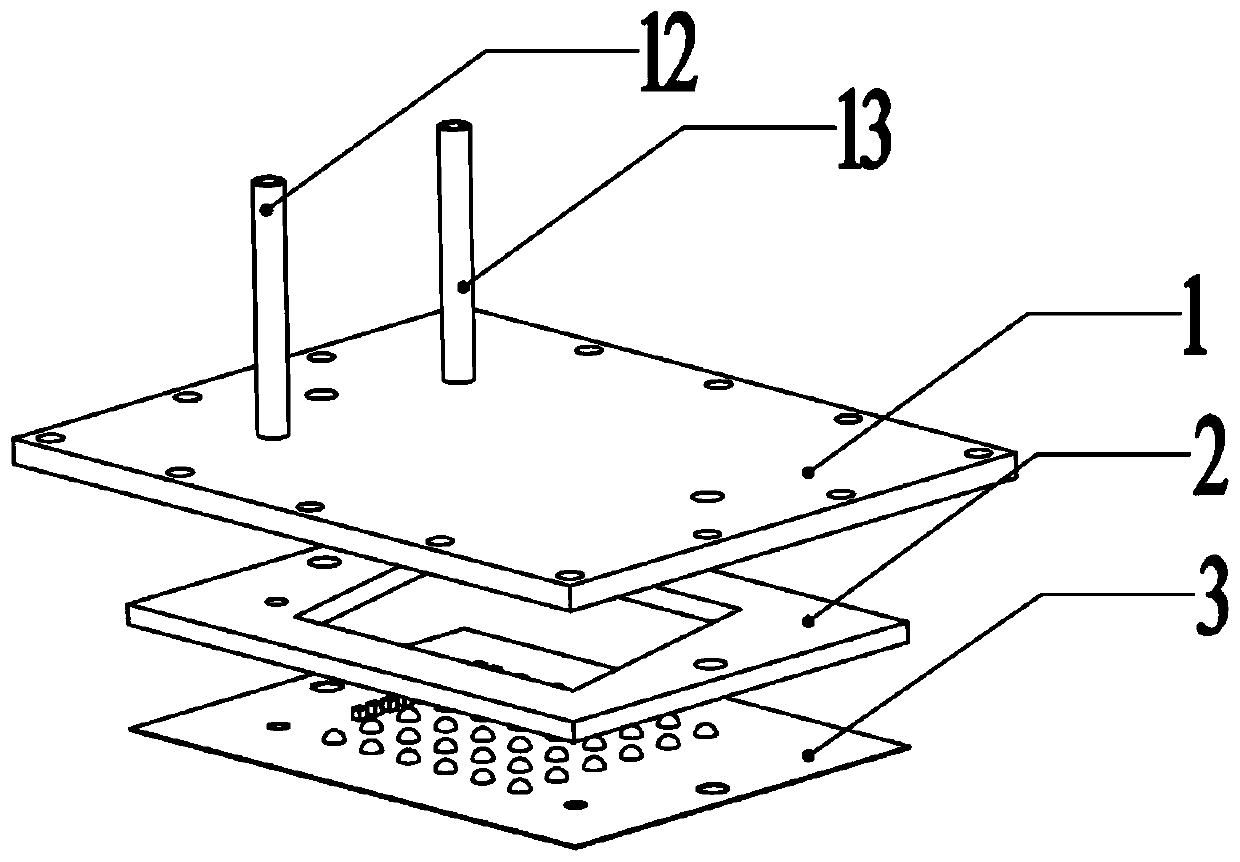

Methanol reforming hydrogen production reactor with flow velocity distribution uniformity

ActiveCN110803679AEvaporate completelyEvenly distributedHydrogenHydrogen/synthetic gas productionMethanol waterSteam reforming

The invention discloses a methanol reforming hydrogen production reactor with flow velocity distribution uniformity. The reactor comprises an upper cover plate and a lower cover plate, and further comprises the following three cavities: an evaporation cavity, wherein a through tank is arranged in the middle of a first graphite plate, an evaporation plate is arranged below the first graphite plate,and the evaporation cavity is formed in the through tank of the first graphite plate on the evaporation plate; a combustion cavity, wherein a through tank is arranged in the middle of a second graphite plate, a combustion reaction plate is arranged below the second graphite plate, and the combustion cavity is formed in the through tank of the second graphite plate on the combustion reaction plate; and a reforming reaction cavity, wherein a through tank is arranged in the middle of a third graphite plate, and two foam metal plates and a corrugated plate are arranged in the through tank. Each plate is provided with through holes, so that a methanol combustion reactant and a methanol steam reforming reactant respectively circulate through two respective paths. The reactor has the advantagesof good heat-conducting property, low density, light weight, good sealing property, uniform reactant flow velocity distribution, increase the reactant conversion rate, enhancement of the flow directionality, avoiding of turbulence and enhancement of the heat transfer and mass transfer effects.

Owner:ZHEJIANG UNIV

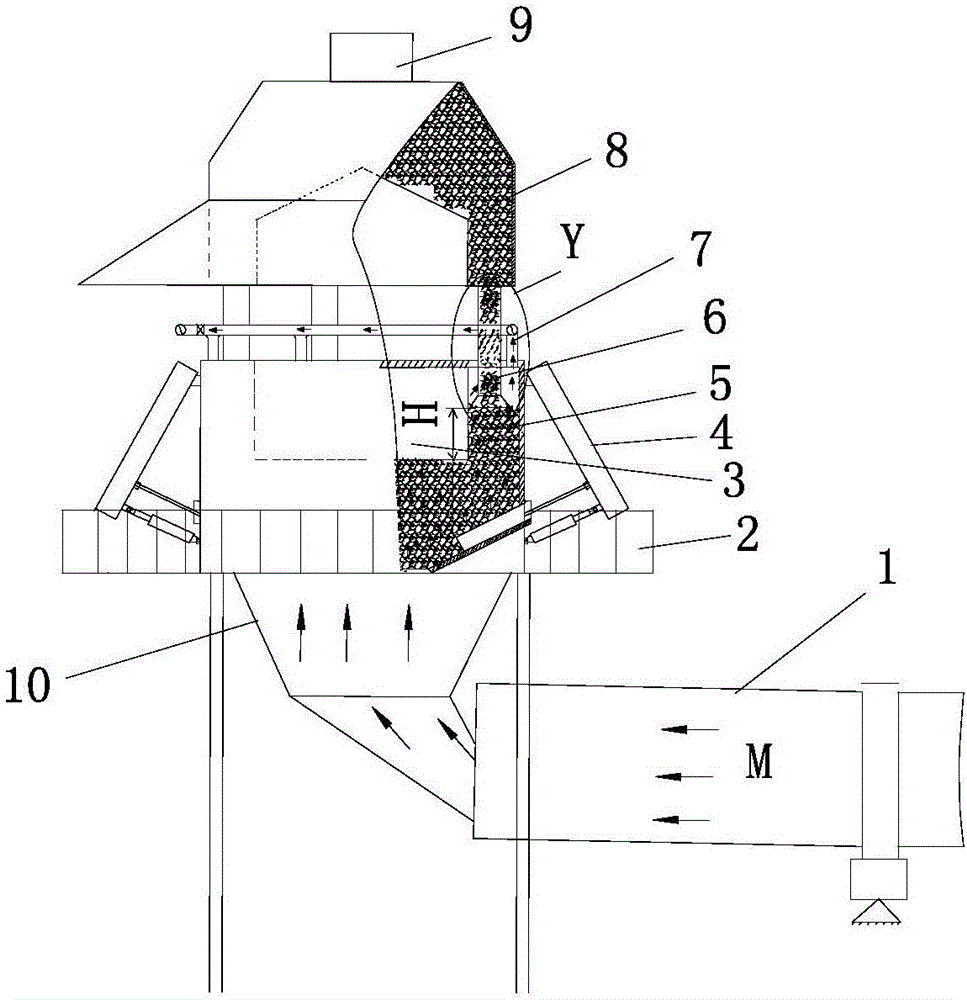

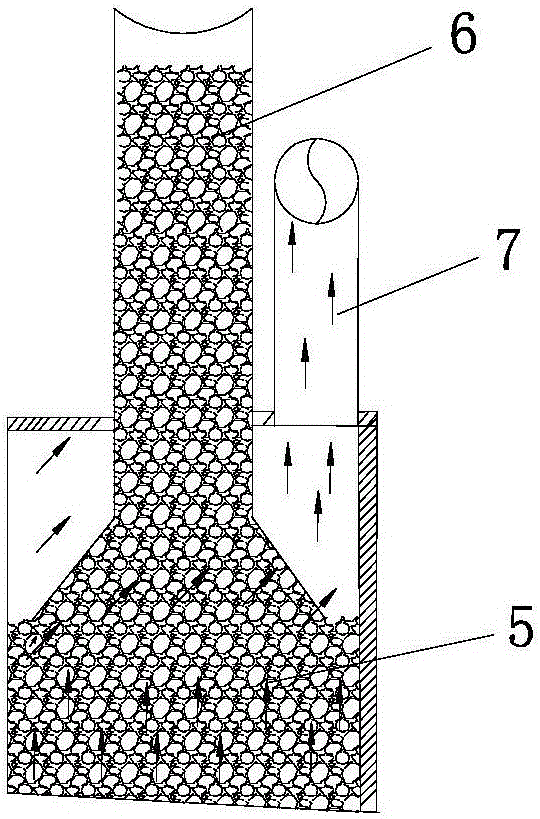

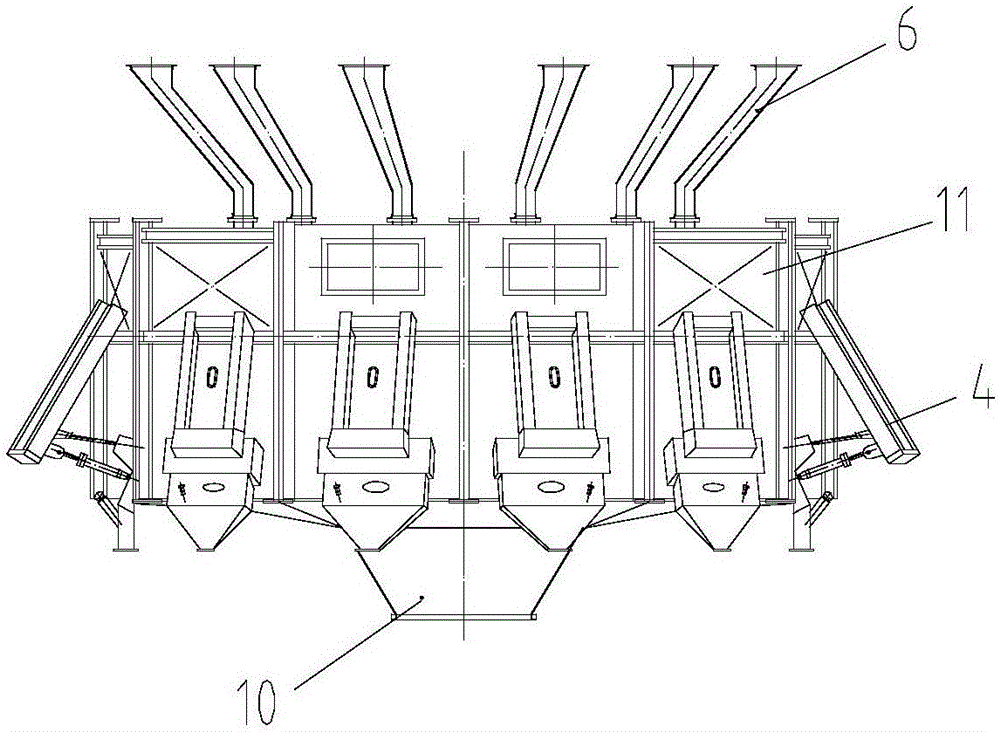

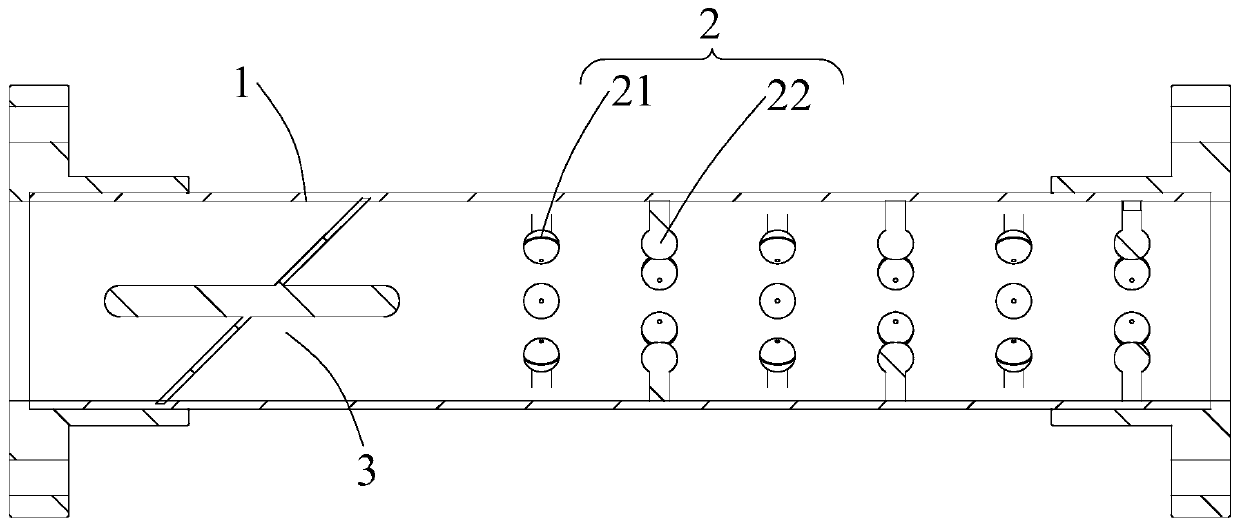

Rotary kiln vertical preheater

InactiveCN106610229AReduce the required powerSmall pressure resistanceRotary drum furnacesPreheating chargesEngineeringMechanical engineering

The invention belongs to the technical field of a rotary kiln, in particular to a rotary kiln vertical preheater. The preheater comprises a preheating chamber, material pushing devices, preheating zones, feed tubes, a bin and a feed hopper. The upper and lower ends of the preheating chamber are respectively provided with the bin and the feed hopper; the bottom of the bin is provided with a plurality of feed openings; a plurality of preheating zones are arranged in the preheating chamber along a circumferential direction; each preheating zone communicates with one feed opening of the bin through one feed tube; and the bottom of each preheating zone is provided with one material pushing device mounted on a preheater housing so as to push the material into the feed hopper. According to the preheater, the pressure resistance of the preheater is reduced, thereby reducing the actual power of a motor of a tail exhaust fan, and the energy saving effect is significant.

Owner:丹东同合高新科技有限公司

Liquid-liquid mixer and working method thereof

PendingCN110180423ASmall pressure resistanceWell mixedFlow mixersTransportation and packagingEngineeringMixing effect

Owner:JIANGSU HENGTAI NATATORIUM EQUIP

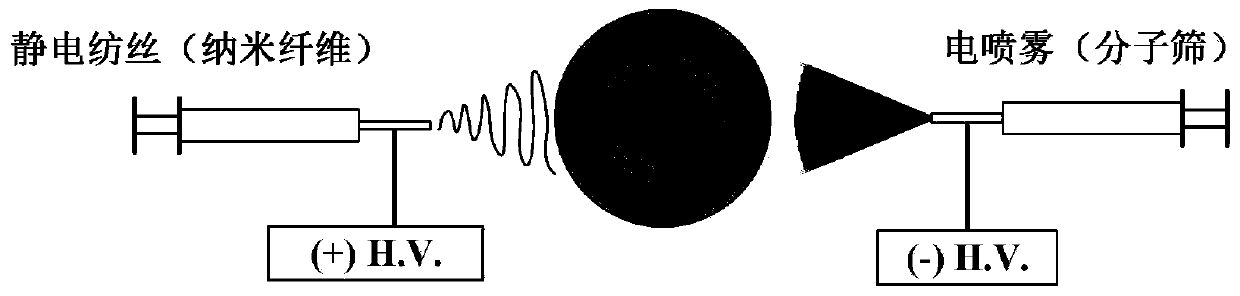

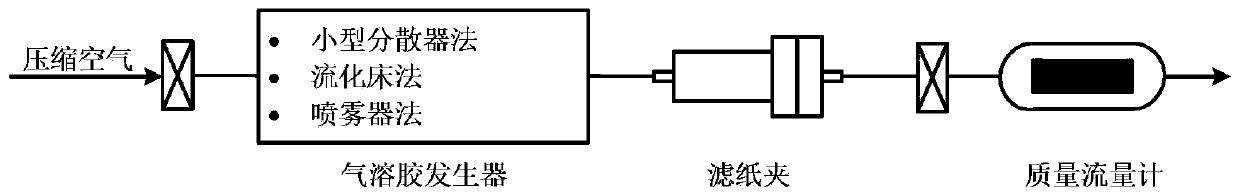

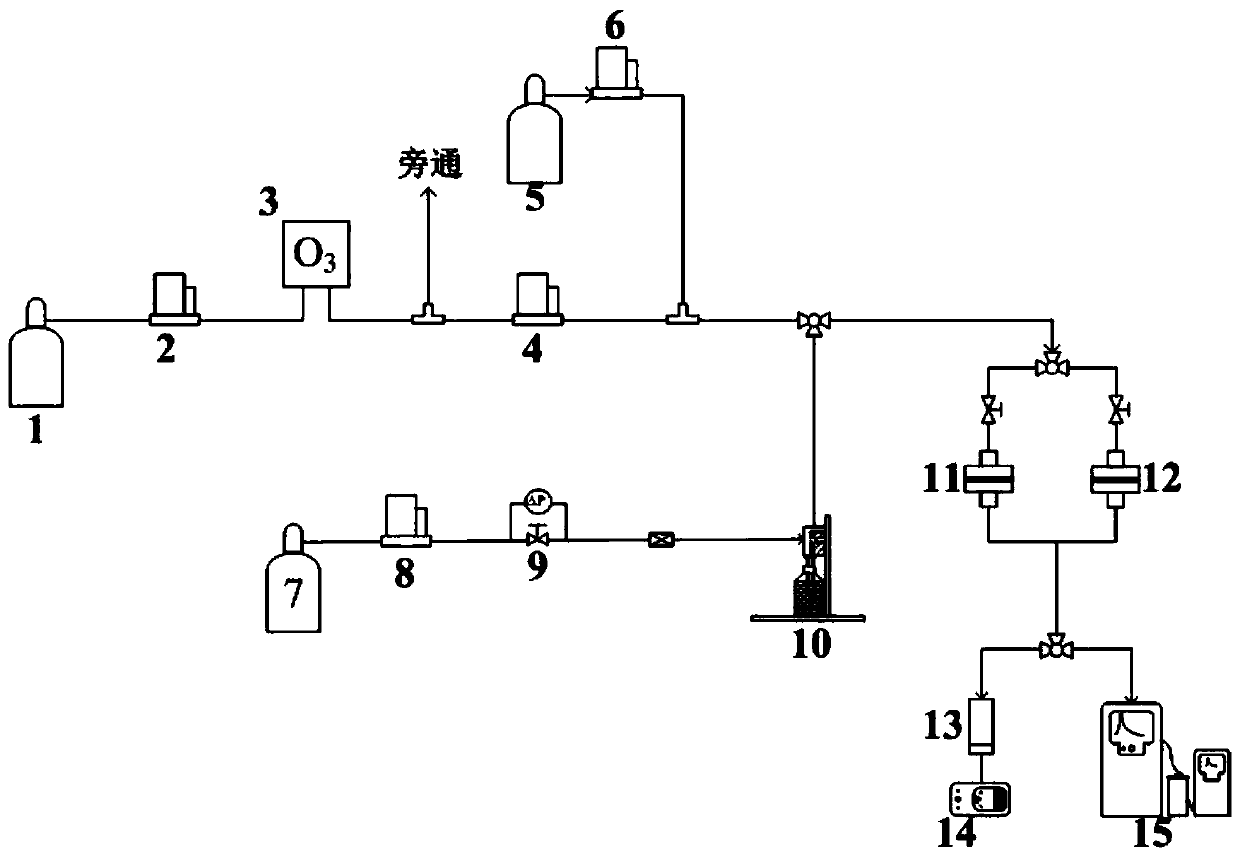

Compound filter material and preparing method and performance testing method thereof

ActiveCN110064248AAdjustable load qualityIncrease spacingDispersed particle filtrationMembrane filtersElectrospinningFilter material

The invention belongs to the field of compound filter materials, and particularly relates to a compound filter material and a preparing method and performance testing method thereof. The preparing method of the compound filter material comprises a series of steps of dispersing an adsorbent through an electrospray method, a small-particle disperser method or a fluidized bed method, spraying a polymer through an electrospinning method to form nanometer fibers, and loading the nanometer fibers on a coarse loaded substrate. The testing method of the compound filter material comprises the steps that ozone and nanometer particulate matter are generated through an ozone generating unit and a particulate matter generating unit respectively, under the push of airflow, the ozone and the nanometer particulate matter flow through a filter paper holder loaded with the compound filter material and a filter paper holder without the compound filter material, the tail ends detect the concentration of the ozone and the particle size and concentration of the particulate matter respectively to obtain an efficiency curve of desorbing of the ozone and the particulate matter by the compound filter material, and then the absorption performance of the compound filter material is improved.

Owner:UNIV OF SCI & TECH BEIJING

EGR adjusting device and internal combustion machine

ActiveCN108150317APrevent backflowSmall pressure resistanceExhaust gas recirculationMachines/enginesCombustion chamberDifferential pressure

The invention provides an EGR adjusting device. The device comprises an EGR mixing pipe communicating with an air inlet pipe and a combustion chamber, an EGR mixing cavity is formed in the inlet segment of the air inlet pipe of the EGR mixing pipe, a waste air inlet communicating with the EGR mixing cavity is formed in the side wall of the EGR mixing pipe, a guide pipe arranged in the air inlet direction of the waste air inlet is arranged in the EGR mixing cavity, the guide end of the guide pipe is provided with a guide rod extending out in the air inlet direction of the waste air inlet, the extending-out end of the guide rod is provided with a lifting valve plate for blocking the waste air inlet, the lifting valve plate comprises a first closing side pushed by input air in the air inlet pipe to move upwards and a second opening side pushed by input air of the waste air inlet to move downwards. The waste air inlet is blocked or opened through the lifting valve plate, EGR gas input andbackflow avoiding are achieved, the structure is simplified, the pressure difference between the fresh air and the waste air is used for blocking the waste air inlet, the pressure resistance of the EGR pipeline is small, and the EGR rate is improved. The invention further provides an internal combustion machine.

Owner:WEICHAI POWER CO LTD

Gas dust collector

InactiveCN104689917APrevent escapeWill not be recontaminatedExternal electric electrostatic seperatorElectrode constructionsEngineeringPollution

The invention belongs to the field of dedusting equipment and in particular relates to a gas deduster formed by a high-efficiency dust-collecting body and static electricity through combination. The gas deduster is composed of a shell, a discharge electrode plate, a dust collecting box, a soot blower and a dust hopper, wherein the shell is of a rectangular chamber and is divided into an upper independent gas purification chamber and a lower independent dedusting chamber by a partition plate; more than two vent holes are uniformly formed in the partition plate; a gas inlet is formed in the box wall at the front end of the dedusting chamber, and the bottom of the dedusting chamber opens and is provided with a support beam; a gas outlet is formed in the box wall at the rear end of the gas purification chamber; the discharge electrode plate and the dust collecting box are fixedly arranged in the dedusting chamber and are uniformly arranged at intervals; the soot blower is fixedly arranged on the top plate of the dedusting chamber; the dust hopper is fixedly arranged at the bottom of the dedusting chamber. The gas deduster has the beneficial effects of being simple in structure, improving the dedusting efficiency, preventing secondary gas pollution and reducing the maintaining cost.

Owner:任利萍

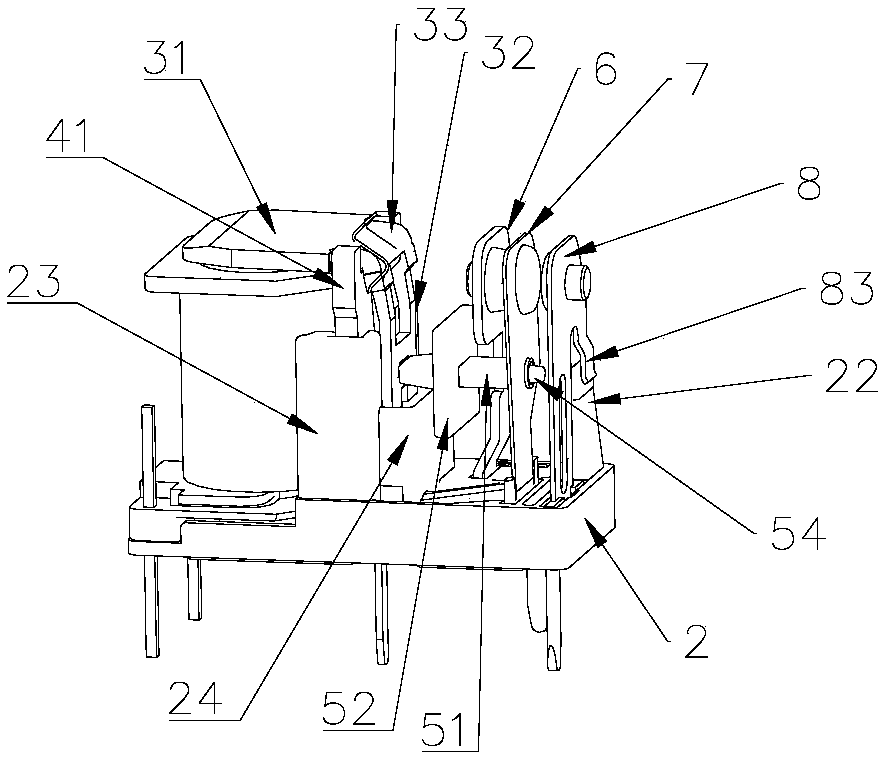

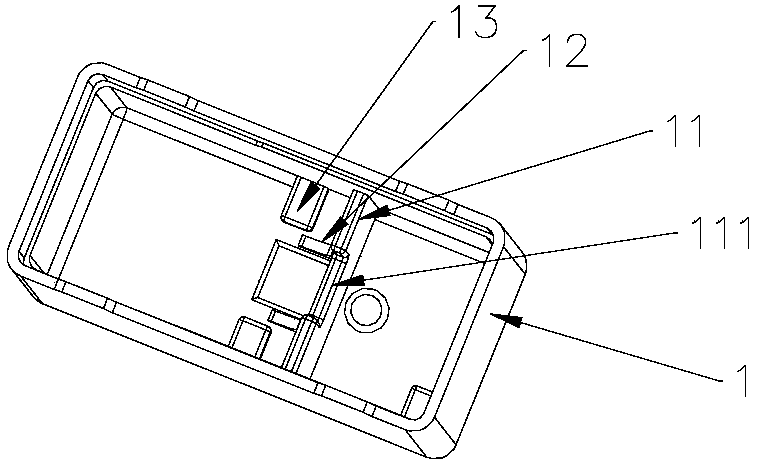

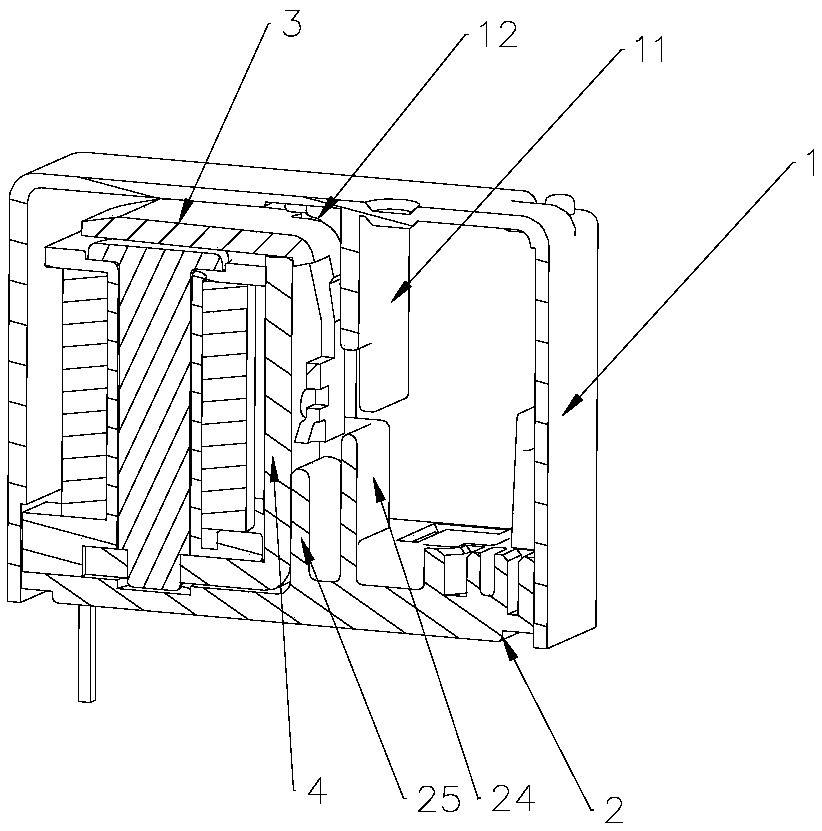

Stable and voltage-resistant power relay

PendingCN110071017ACompact structureSimple structureElectromagnetic relay detailsEngineeringUpward shift

The invention discloses a stable and voltage-resistant power relay. The power relay comprises a casing, a base, an armature, a yoke, a pushrod, a normally-closed static spring, a normally-open staticspring and a dynamic spring, wherein the armature and the yoke are connected together through an elastic sheet, the yoke is installed on the base in an inserted mode, limit blocks at the bottom of thecasing prevents the yoke from shifting upwards, a baffle in the casing avoids lateral shift of the armature, arc-shaped stop blocks avoid upward shift of the armature, the tail of the armature and avoltage-resistant slot of the base are in clearance fit, the tail of the armature is connected with one end of the pushrod through a connecting hole, the other end of the pushrod is connected with a connecting hole of the dynamic spring, an insulation screen is arranged in the middle of the pushrod, the creepage distance between the dynamic spring and the armature is prolonged, the normally-open static spring with a buffer sheet is inserted into the base, a trapezoidal protective plate of the base is in fit with the buffer sheet, and limit protection of the normally-open static spring is realized. The stable and voltage-resistant power relay has the advantages of being compact in structure, small in size, excellent in insulating property, resistant to voltage, high in stability, long in product service life and the like; and moreover, the structure is simple, and it is convenient to perform processing and realize automatic assembling.

Owner:YUEQING MEISHUO ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com