Three-phase vortex street current sharing method and device

A vortex street, three-phase technology, applied in chemical instruments and methods, fluid flow, mechanical equipment, etc., can solve the problems of increasing system piezoresistance, increasing system operating costs, etc., to reduce system piezoresistance, reduce resistance, reduce The effect of system resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

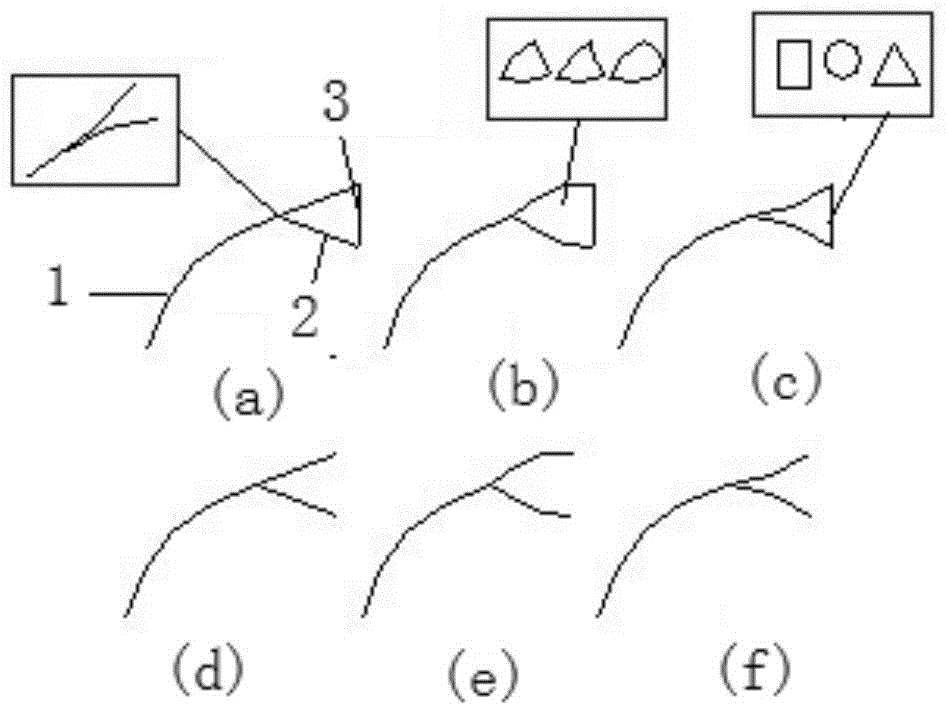

[0032] Such as figure 1 As shown in (a), a three-phase vortex street current sharing device includes a front-end deflector 1 and a three-phase vortex street current sharing baffle, and the windward surface of the three-phase vortex street current sharing baffle is streamlined. Structure 2, the leeward side of the three-phase vortex flow sharing baffle is a bluff body structure 3; the front-end deflector 1 is connected to the streamline structure end of the three-phase vortex flow sharing baffle. It can be directly connected to the conventional baffle or used alone.

[0033] The streamline structure 2 of the three-phase vortex street current sharing baffle is linear (such as figure 1 In (a)), arc (such as figure 1 In (b) shown) or inner hyperbolic (such as figure 1 As shown in middle (c)), the shape of the streamlined body will affect the piezoresistance of the entire system, as well as the form of the rear vortex street.

[0034] The streamline body structure 2 of the three-phase v...

Embodiment 2

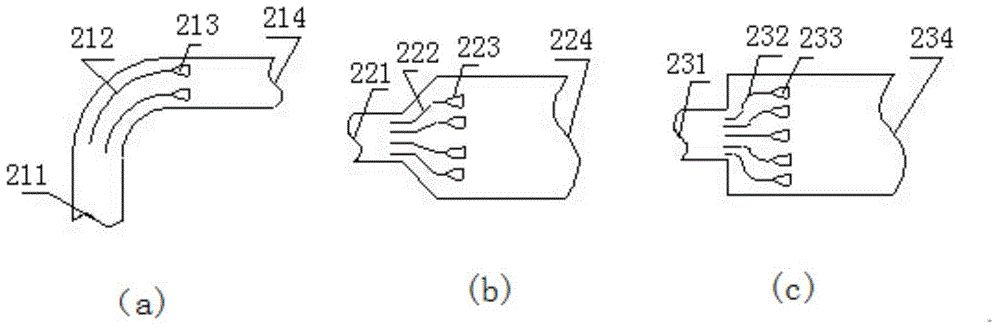

[0039] Example 2: The action process of the three-phase vortex street current equalization device in the turning road, diverging pipeline and sudden expansion pipeline

[0040] by figure 2 As shown, the three-phase vortex street current sharing device is in the turning road ( figure 2 (A)), gradually expanding pipeline ( figure 2 (B)) and sudden expansion pipeline ( figure 2 The arrangement form in (c)); taking the turning pipe as an example, when the airflow enters the turning from the inlet 211, the multiphase flow passes through the front baffle 212 (different forms of baffle are set according to different pipe forms) , To realize the primary gas phase flow equalization, and then, on the basis of the primary gas phase flow equalization, the fluid flows on the windward side streamline body and the leeward side bluff body structure of the three-phase vortex street flow sharing baffle 213 (designed according to the speed difference of each part of the inlet section Three-phase...

Embodiment 3

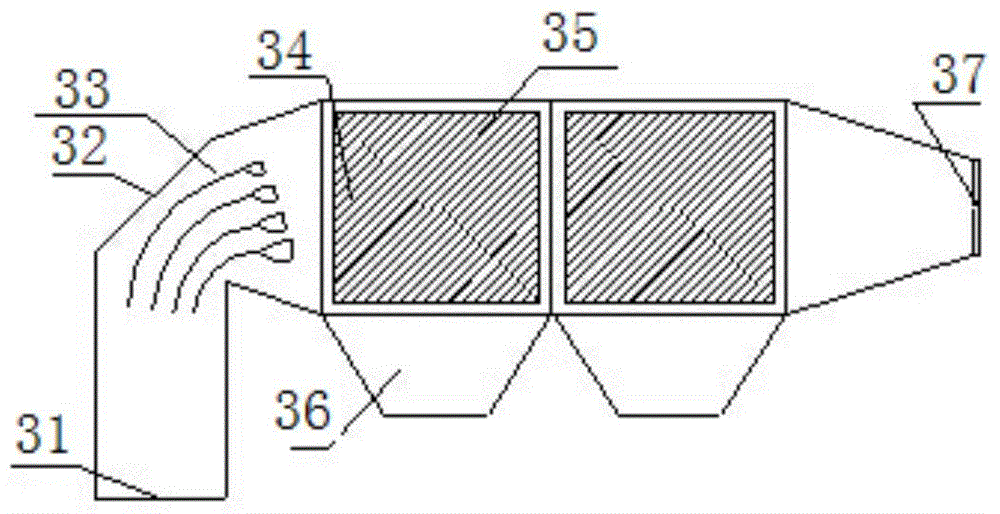

[0042] Example 3: Application of three-phase vortex current sharing device in electrostatic precipitator

[0043] image 3 In order to set up the three-phase vortex flow equalizing plate of the electrostatic precipitator of the present invention, the coal-fired flue gas enters from the inlet 31 and flows through the right-angled bend 32, and the gas-solid two-phase flow is in the three-phase vortex flow equalization device 33. According to the speed difference of each part of the inlet section of the dust collector, a three-phase vortex flow sharing baffle with different sizes and densities is designed to achieve high efficiency three-phase flow sharing. The number of three-phase vortex flow sharing devices 33 and the pipeline The pipe diameter ratio is: 5 / 3600mm, and the separation distance between the three-phase vortex current sharing devices 33 is 300-600mm. Under the action of the three-phase vortex flow equalization device 33, the two phases are uniformly mixed, and the ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com